High-performance lithium battery separator dry double-drawing process

A lithium battery diaphragm, high-performance technology, applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of uneven pore size distribution of diaphragm micropores, large porosity changes, lateral shrinkage, etc., and reach the range of product thickness wide, low transverse shrinkage, and small transverse shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

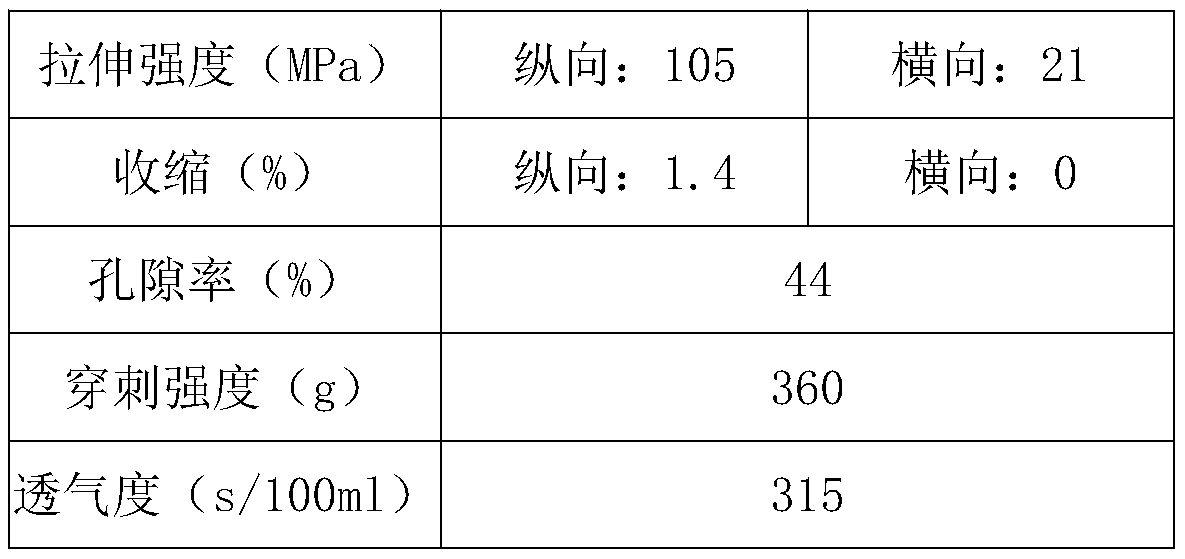

Embodiment 1

[0027] A high-performance lithium battery diaphragm dry double drawing process includes the following steps:

[0028] (1) Dissolve ultra-polypropylene, antioxidant, nucleating agent and silica in a certain proportion in a soluble polymer solvent to form a sol-like composite, and then add it into the mixer to fully stir the raw materials at a speed of 200 rpm ;

[0029] (2) Take out the raw material obtained in step (1) and transfer it to the template, absorb the solvent with molecular sieve, and then transfer it to a vacuum drying oven for drying;

[0030] (3) Put the mixture dried in step (2) into an extruder and heat it at 180°C for continuous extrusion to form a substrate;

[0031] (4) The substrate extruded from the twin-screw extruder is cooled and molded by a cooling molding machine with a temperature range of 5 to 40°C at a speed of 10 m / min;

[0032] (5) The substrate is stretched horizontally and vertically at a speed of 2 m / min through the biaxial stretching equipment to stre...

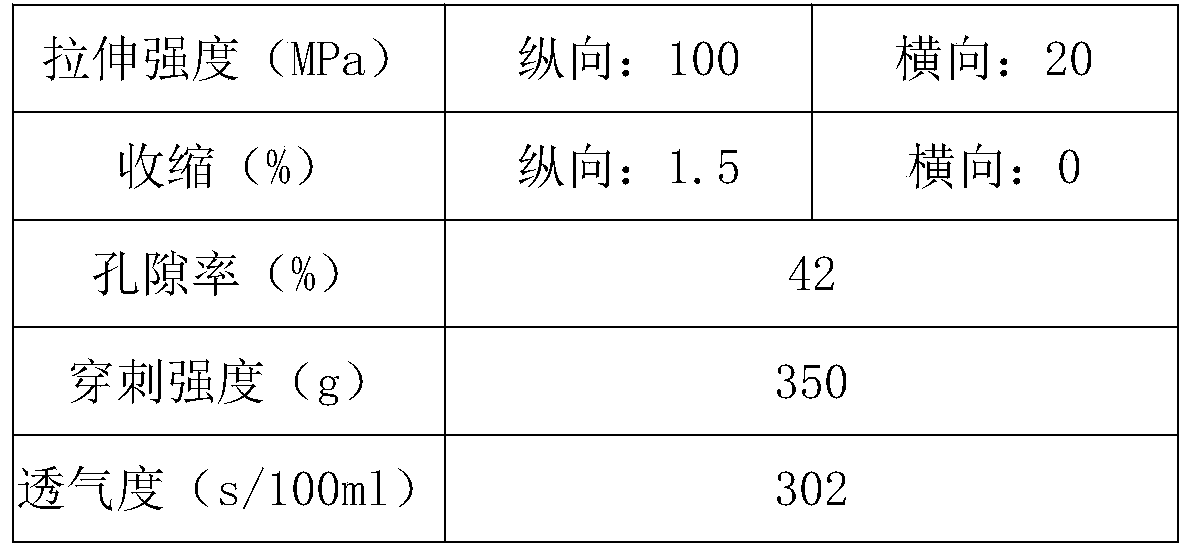

Embodiment 2

[0044] A high-performance lithium battery diaphragm dry double drawing process includes the following steps:

[0045] (1) Dissolve ultra-polypropylene, antioxidant, nucleating agent and silica in a certain proportion in a soluble polymer solvent to form a sol-like composite, and then add it into the mixer to fully stir the raw materials at a speed of 250rpm ;

[0046] (2) Take out the raw material obtained in step (1) and transfer it to the template, absorb the solvent with molecular sieve, and then transfer it to a vacuum drying oven for drying;

[0047] (3) Put the mixture dried in step (2) into an extruder and heat it at 220°C for continuous extrusion to form a substrate;

[0048] (4) The substrate extruded from the twin-screw extruder is cooled and molded by a cooling molding machine with a temperature range of 25°C at a speed of 15 m / min;

[0049] (5) The substrate is stretched horizontally and vertically at a speed of 3 m / min through the biaxial stretching equipment to stretch th...

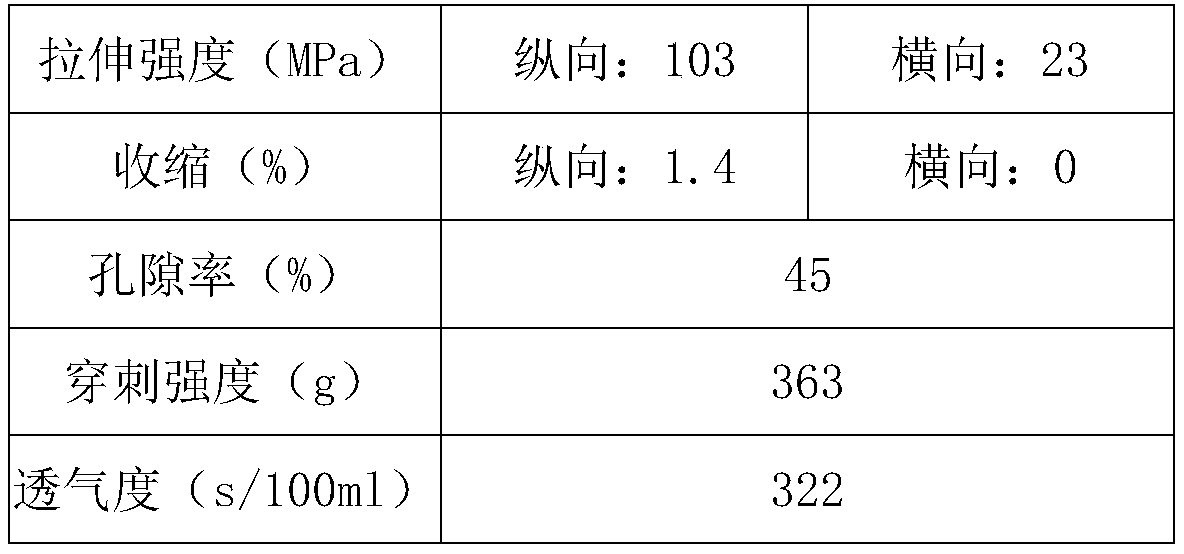

Embodiment 3

[0061] A high-performance lithium battery diaphragm dry double drawing process includes the following steps:

[0062] (1) Dissolve the super polypropylene, antioxidant, nucleating agent and silica in a certain proportion in a soluble polymer solvent to form a sol-like compound, and then add it into the mixer to fully stir the raw materials at a speed of 300 rpm ;

[0063] (2) Take out the raw material obtained in step (1) and transfer it to the template, absorb the solvent with molecular sieve, and then transfer it to a vacuum drying oven for drying;

[0064] (3) Put the mixture dried in step (2) into an extruder and heat it at 250°C for continuous extrusion to form a substrate;

[0065] (4) The substrate extruded from the twin-screw extruder is cooled and molded by a cooling molding machine with a temperature range of 40°C at a speed of 20 m / min;

[0066] (5) The substrate is stretched horizontally and vertically at a speed of 5m / min through the biaxial stretching equipment to stretch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com