Modified polyolefins paper without plant fibre

A technology of plant fiber and olefin paper, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of wasting forest and water resources, endangering personal safety, limiting the scope of use, etc., and achieve ink saving , clear printing performance, good tear strength in longitudinal and transverse directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

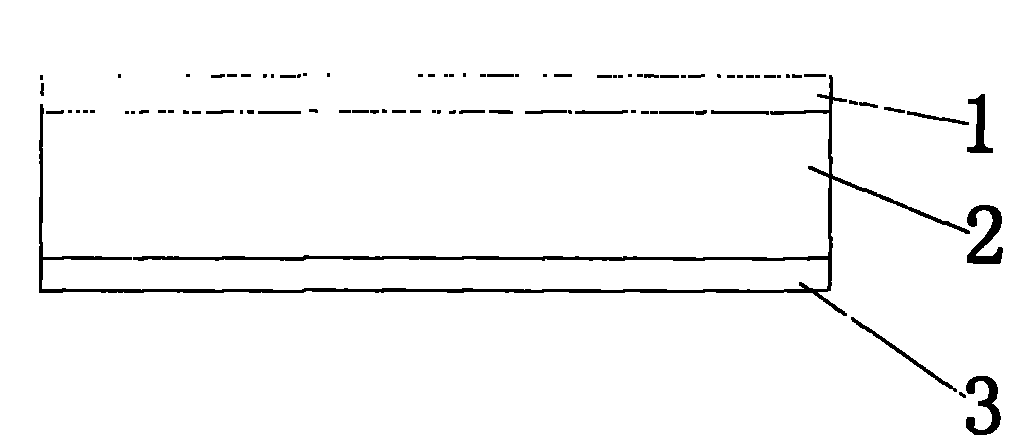

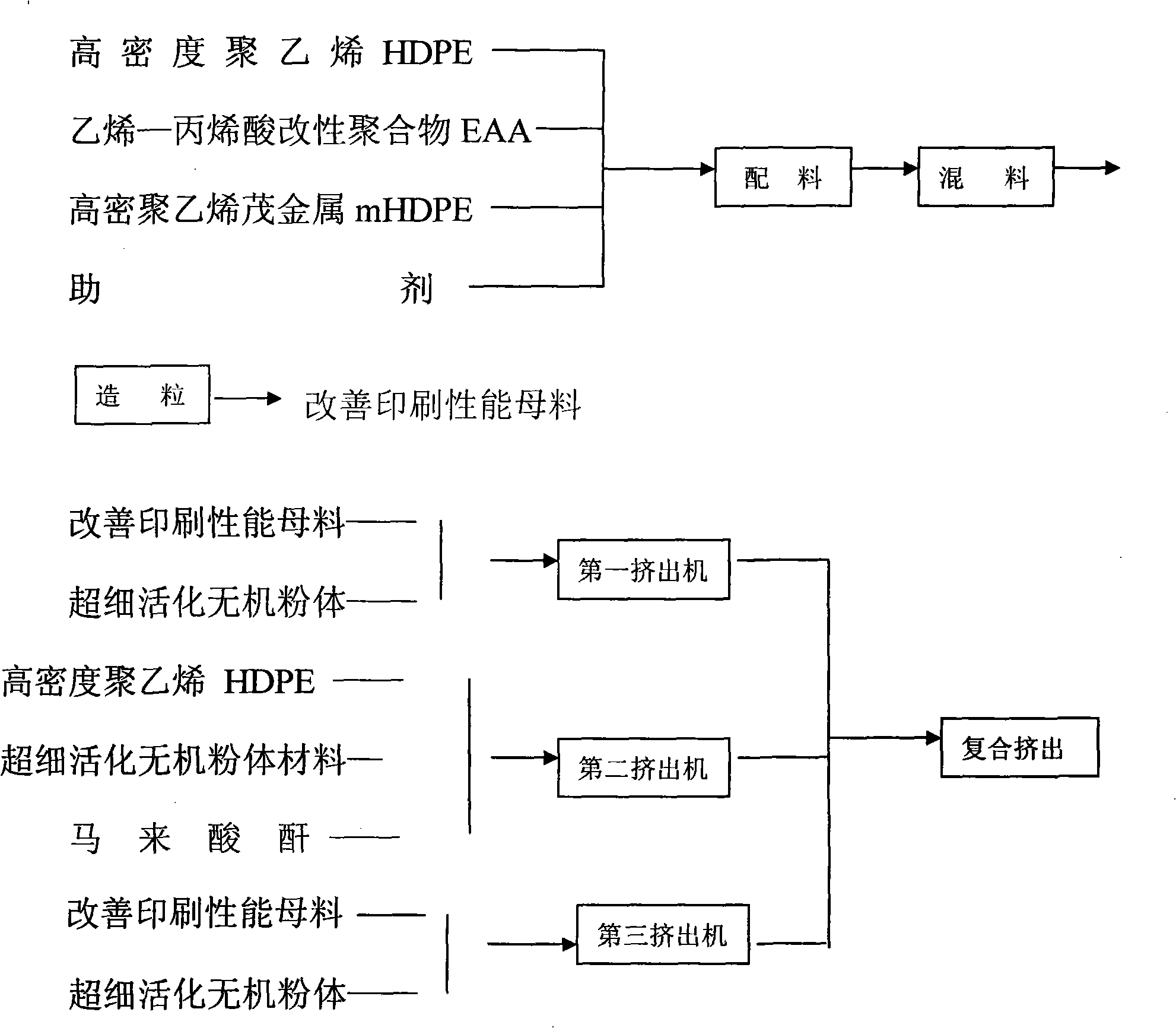

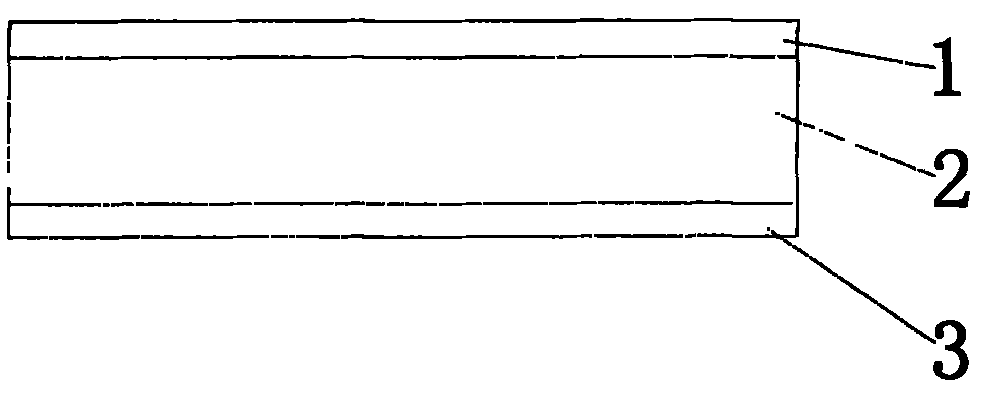

[0037] A modified polyolefin paper without plant fibers is composed of a first matrix layer 1 without plant fibers, a second matrix layer 2 without plant fibers and a third matrix layer 3 without plant fibers.

[0038] The first non-plant fiber matrix layer 1 and the third plant fiber-free matrix layer 3 are respectively made of ethylene-acrylic acid modified copolymer EAA30%, metallocene high-density polyethylene 48%, and aluminum acid with a particle size of 5000 meshes. It is prepared by activating 20% of superfine inorganic powder with ester F-2 type coupling agent and 2% of antistatic agent dodecyl dimethyl betaine.

[0039] The second non-plant fiber matrix layer 2 in the middle of the first plant fiber-free matrix layer 1 and the third plant fiber-free matrix layer 3 is 60% of activated ultrafine inorganic powder with a particle size of 3500 meshes, maleic anhydride 5 %, high-density polyethylene 33 is prepared, and the first non-plant fiber matrix layer 1, the second...

Embodiment 2

[0041] A modified polyolefin paper without plant fiber is composed of a first base layer 1 without plant fiber, a second base layer 2 without plant fiber and a third base layer 3 without plant fiber into a whole.

[0042] The first non-plant fiber matrix layer 1 and the third plant fiber-free matrix layer 3 are respectively made of ethylene-acrylic acid modified copolymer EAA20%, metallocene high-density polyethylene 59%, and aluminate F for 3000-5000 mesh It is prepared by activating 20% of superfine inorganic powder with type 2 coupling agent and 1% of antistatic agent dodecyl dimethyl betaine as auxiliary agent.

[0043] The second non-vegetable fiber matrix layer 2 is an ultrafine inorganic powder activated by an aluminate F-2 type coupling agent with a particle size of 1000-1500, that is, 70% talcum powder, 5% maleic anhydride and high-density polymer Ethylene 25% is prepared. The above percentages are percentages by weight. The first plant fiber-free and the third pl...

Embodiment 3

[0045] A modified polyolefin paper without plant fiber is composed of a first base layer 1 without plant fiber, a second base layer 2 without plant fiber and a third base layer 3 without plant fiber into a whole.

[0046] The first base layer 1 without plant fiber and the third base layer 3 without plant fiber are respectively composed of ethylene-acrylic acid modified copolymer EAA 25%, metallocene high-density polyethylene mHDPE 49.5%, particle size is 3000-5000 mesh super 23% of fine inorganic body talcum powder and 2.5% of aluminate are prepared as additives.

[0047] The second non-plant fiber matrix layer 2 is prepared from 70% ultrafine inorganic talcum powder with a particle size of 1000-1500 mesh, 4% maleic acid, 24% high-density polyethylene and 2% low-molecular polyethylene as an auxiliary agent .

[0048] The above percentages are percentages by weight. The first base layer 1 without plant fiber and the third base layer 3 without plant fiber account for 9% of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com