Functional film as well as preparation method and application thereof

A technology of functional film and light transmittance, applied in the field of functional film, can solve the problems of less environmental pollution, unstable color, increased production cost, etc., and achieve the effect of avoiding environmental pollution, better visual effect and accurate color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

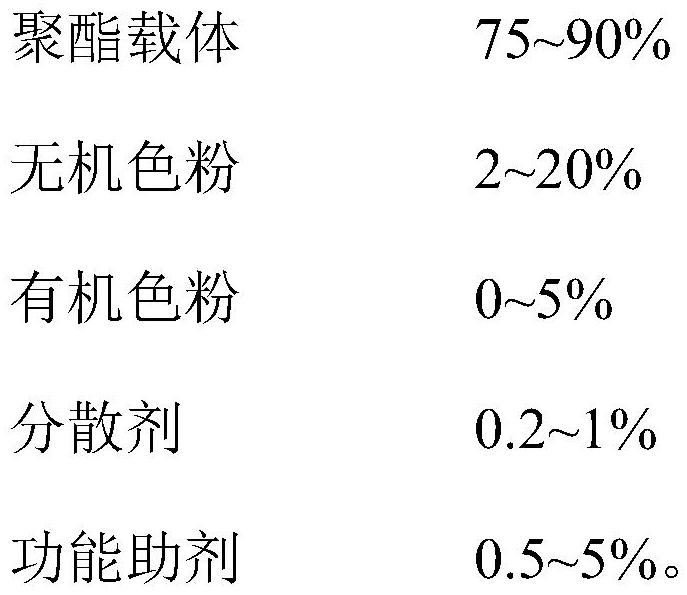

[0041] The functional film of this embodiment comprises the following components by weight percentage:

[0042]

[0043] Wherein, the polyester carrier is S-1000 of Mitsubishi Chemical, the inorganic toner is titanium dioxide, the organic toner is azo yellow, and the dispersant is 0.3% stearic acid amide (manufacturer is Jiangxi Dongyuan Technology Co., Ltd. The brand is a mixture of DY2016) and 0.7% palmitamide (the manufacturer is Jiangxi Dongyuan Science and Technology, and the brand is DY1698), and the functional additives are 3% nano titanium dioxide and 1% nano titanium dioxide by mass percentage. A mixture of zinc oxides.

[0044] The preparation method of the color masterbatch in this embodiment is as follows: Stir and mix the polyester carrier with inorganic toner, organic toner, dispersant and functional additives according to the above ratio, first extrude and granulate, and then extrude and calender the particles to obtain As for the functional film, the thickn...

Embodiment 2

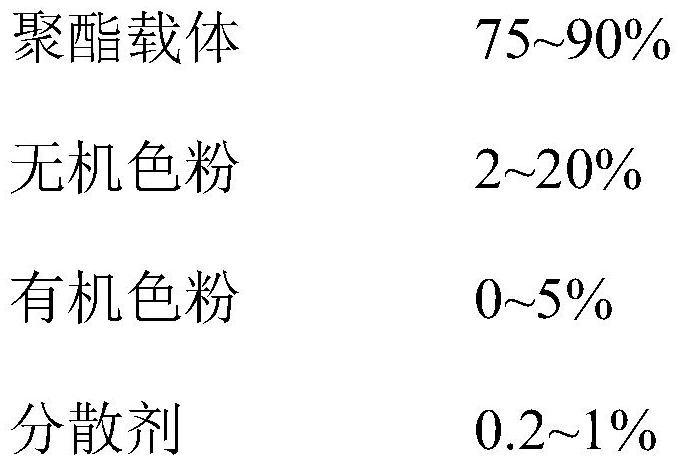

[0047] The functional film of this embodiment comprises the following components by weight percentage:

[0048]

[0049] Wherein, the polyester carrier is S-1000 of Mitsubishi Chemical, the inorganic toner is titanium dioxide, the organic toner is azo yellow, and the dispersant is 0.3% stearic acid amide (manufacturer is Jiangxi Dongyuan Technology Co., Ltd. The brand is a mixture of DY2016) and 0.7% palmitamide (the manufacturer is Jiangxi Dongyuan Science and Technology, and the brand is DY1698), and the functional additives are 3% nano titanium dioxide and 1% nano titanium dioxide by mass percentage. A mixture of zinc oxides.

[0050] The preparation method of the color masterbatch in this embodiment is as follows: Stir and mix the polyester carrier with inorganic toner, organic toner, dispersant and functional additives according to the above ratio, first extrude and granulate, and then extrude and calender the particles to obtain As for the functional film, the thickn...

Embodiment 3

[0053] The functional film of this embodiment comprises the following components by weight percentage:

[0054]

[0055]

[0056] Wherein, the polyester carrier is S-1000 of Mitsubishi Chemical, the inorganic toner is titanium dioxide, the organic toner is azo yellow, and the dispersant is 0.3% stearic acid amide (manufacturer is Jiangxi Dongyuan Technology Co., Ltd. The brand is a mixture of DY2016) and 0.7% palmitamide (the manufacturer is Jiangxi Dongyuan Science and Technology, and the brand is DY1698), and the functional additives are 3% nano titanium dioxide and 1% nano titanium dioxide by mass percentage. A mixture of zinc oxides.

[0057] The preparation method of the color masterbatch in this embodiment is as follows: Stir and mix the polyester carrier with inorganic toner, organic toner, dispersant and functional additives according to the above ratio, first extrude and granulate, and then extrude and calender the particles to obtain As for the functional film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com