Method for adjusting and firming components built in free space isolator

A free space, component technology, applied in the coupling of instruments, optical waveguides, optics, etc., can solve the problems of difficult processing, large insertion loss, long optical path deviation, etc., to achieve simple and easy processing and long service life. , good corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

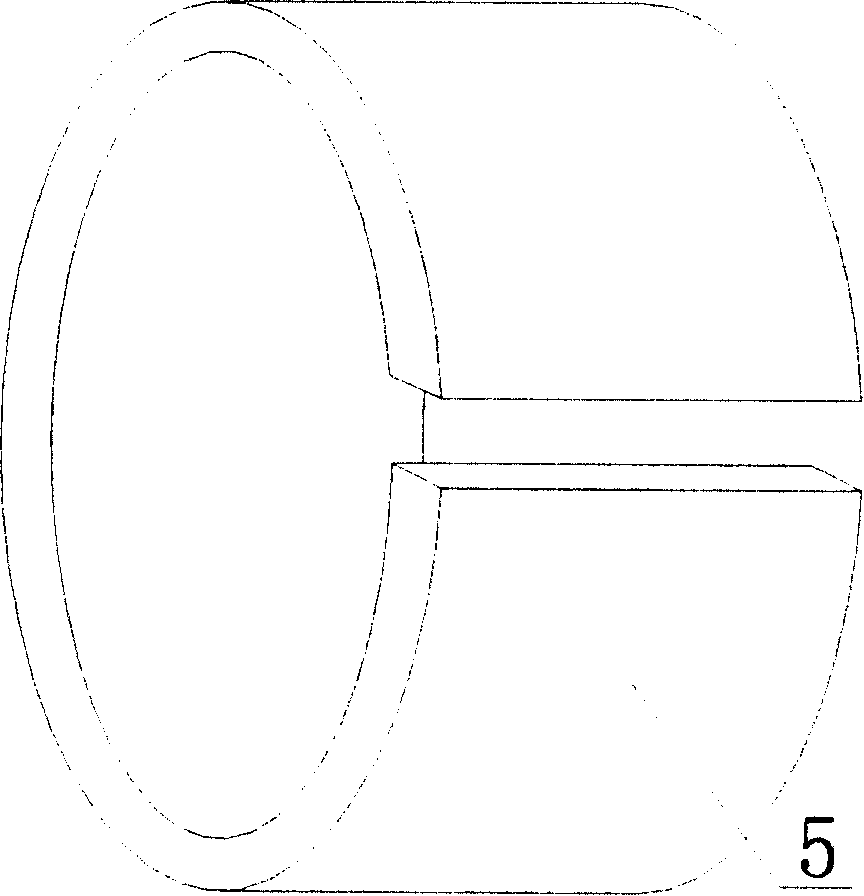

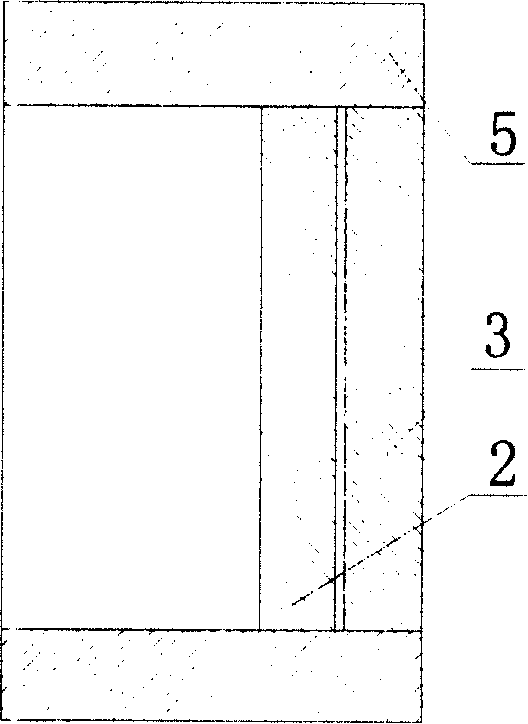

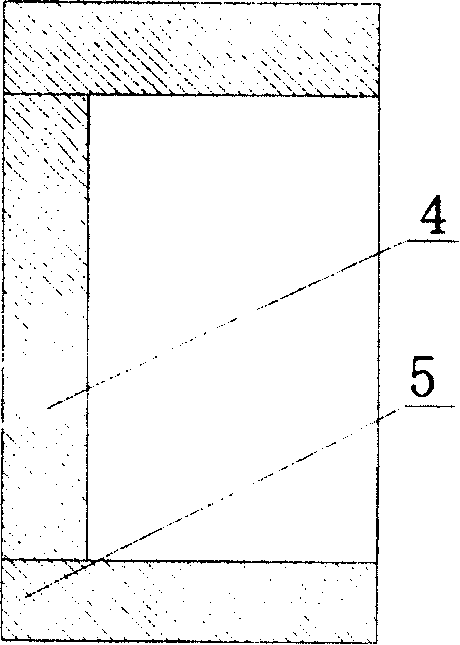

[0017] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments: the method of the present invention uses zirconia ceramics as a material to make the porcelain holder 5 for stabilizing the free-space isolator built-in polarizer and Faraday rotator. First select the material and certify the source of the zirconia ceramic components: composition requirements: 95% ZrO2, 5% Y2O3; density requirements:> 6.05g / cm 3 ; Hardness requirement: >87HRA; Thermal expansion coefficient requirement: 9.6×10-6 ; Elastic modulus: 200~250Gpa; Fracture toughness: 1 / 28Mpam; Flexural strength: >1150Mpa; Grain size requirement: <0.6μm; Thermal conductivity: 2.5W / mK; inner hole surface finish Ra 0.1, outer surface The hollow rod-shaped zirconia ceramic material with a smoothness of Ra 0.2 and a concentricity of Ф0.01mm is qualified and available. Then make the porcelain support, cut the ceramic component into 0.7mm long small ring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com