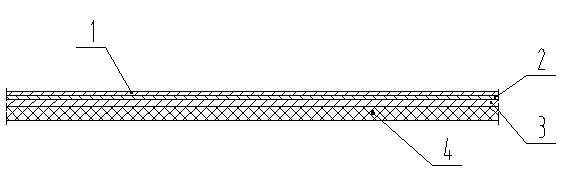

PVC composite shingle

A composite wall and panel technology, applied in the direction of layered products, buildings, building structures, etc., can solve the problem of poor shock absorption, heat insulation, sound insulation, poor wear resistance of the outer surface of the wall panel, poor waterproof and anti-corrosion performance, etc. Problems, to achieve the effect of decreased porosity, not easy to scratch, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Process 1. Make a transparent film with a colorless UV coating on the outer surface according to the conventional process.

[0026] Process 2. Make a color film with imitation stone patterns according to the conventional process.

[0027] Process 3. Make polyvinyl chloride sheets according to the conventional process, with a thickness of 0.5mm.

[0028] Process 4. Make polyvinyl chloride skinned foam board according to the conventional process.

[0029] Step 5. The transparent film, the color film layer, and the polyvinyl chloride sheet are stacked sequentially from top to bottom, and hot-pressed to form an upper composite layer.

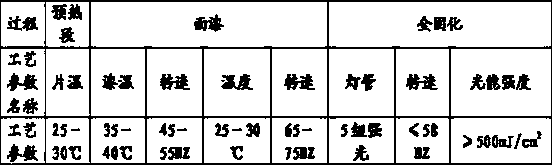

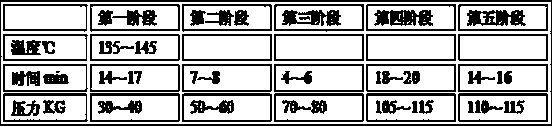

[0030] This hot pressing process is divided into five stages, and the process parameters of each stage are as follows:

[0031]

[0032] Step 6. Spray the upper composite layer once, and the amount of the topcoat is 0.6-0.7g / 12″x12″.

[0033] The drenching process parameters are as follows:

[0034]

[0035] Step 7. Apply PU glue on...

Embodiment 2

[0043] Except for steps 4, 7, and 8, other steps are basically the same as in Embodiment 1.

[0044] Process 4. Make polyvinyl chloride and chlorinated polyvinyl chloride crusted foam boards according to the following components.

[0045] The proportioning components (by weight) are: 65-75 parts of polyvinyl chloride, 25-35 parts of chlorinated polyvinyl chloride, 3.5-4.5 parts of foam regulator, 4-6 parts of stabilizer, 1-3 parts of foaming agent 1.5 parts, foaming nucleating agent 1.5-2.5 parts, external lubricant 0.8-1.2 parts, internal lubricant 0.6-0.9 parts, processing aid 0.8-1.5 parts, antioxidant 0.1-0.4 parts, filler ≤25 parts . The stabilizer is organotin stabilizer, calcium-zinc composite stabilizer or lead salt stabilizer; the foaming regulator is acrylic polymer, and the foaming nucleating agent is superfine calcium carbonate, titanium dioxide or aluminum powder; the foaming agent It is an azo foaming agent or its temperature-adjusting and ultra-fine modified p...

example 1

[0047]Example 1, according to the weight ratio, choose 75 parts of SG-7 polyvinyl chloride, 25 parts of chlorinated polyvinyl chloride with a degree of polymerization of 700 and a chlorine content of 67%, 4 parts of calcium-zinc composite stabilizer, and 3.5 parts of acrylic polymer , 1.5 parts of titanium dioxide, 1 part of azo foaming agent, 0.6 parts of calcium stearate, 0.8 parts of polyethylene wax, 0.8 parts of ACR-401 processing aid, 0.1 part of BHT as antioxidant, and light filler 20 parts of calcium carbonate. Add all the above-mentioned materials into a high-speed mixer to mix and stir evenly, heat to 95-115°C, keep warm for more than 10 minutes, put the mixed materials into the cold mixer to cool to 30-40°C, put them into the silo, and use a conical double Extruded by a screw extruder to form a foam material, the working temperature of the fuselage is 150-180°C, the temperature of the confluence core is 160-175°C, the working temperature of the head is 180-210°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com