Glass fiber filter material with positive Zeta potential and preparation method and application thereof

A technology of filter material and glass fiber, which is applied in the field of glass fiber filter material and preparation, can solve the problems such as the decrease of interlayer binding force and filtration effect, and achieve the effect of excellent industrialization prospect, long service life, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

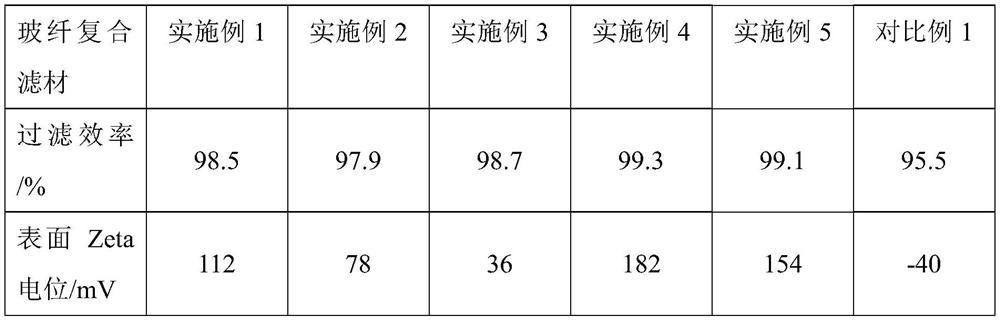

Examples

Embodiment 1

[0046]The present embodiment provides a kind of preparation method of the glass fiber composite filter material with positive Zeta potential, comprises the steps:

[0047] (1) Mix microfiber glass wool with a knock-down degree of 39° and glass fiber chopped strands with a diameter of 10 μm in a mass ratio of 80:20, add water and acetic acid, and stir evenly with a high-frequency decomposer to obtain a mass percent concentration 0.5wt% fiber slurry with a pH of 5;

[0048] (2) Filtering and removing slag from the fiber slurry, and diluting with water to obtain a suspension with a mass percent concentration of 0.1 wt%, and forming and dehydrating it by a Fourdrinier machine to obtain a glass fiber wet paper sheet;

[0049] (3) Place the same kind of PET non-woven fabric (30g / m2) on the upper and lower surfaces of the glass fiber wet paper sheet 2 ), using tank sizing to immerse the glass fiber wet paper sheets with PET non-woven fabrics placed on the upper and lower surfaces re...

Embodiment 2

[0051] The present embodiment provides a kind of preparation method of the glass fiber composite filter material with positive Zeta potential, comprises the steps:

[0052] (1) adding water and acetic acid to the microfiber glass wool with a degree of percussion of 34°, stirring evenly through a high-frequency disintegrating machine to obtain a fiber slurry with a mass percentage concentration of 2wt% and a pH of 3;

[0053] (2) Filtering and removing slag from the above-mentioned fiber slurry and diluting with water to obtain a suspension with a mass percentage concentration of 0.5 wt%, which is formed and dehydrated by a Fourdrinier machine to obtain a glass fiber wet paper sheet;

[0054] (3) Adopt the mode of spray sizing, uniformly coat the cationic melamine formaldehyde emulsion that solid content is 5% on the surface of above-mentioned glass fiber wet paper sheet, dry 30min at 100 ℃, obtain glass fiber filter material, this glass fiber filter The material includes a gla...

Embodiment 3

[0057] The present embodiment provides a kind of preparation method of the glass fiber composite filter material with positive Zeta potential, comprises the steps:

[0058] (1) Mix microfiber glass wool with a knock-down degree of 39° and carbon fiber chopped strands with a diameter of 12 μm in a mass ratio of 95:5, then add water and polyacrylamide emulsion accounting for 0.05% of the fiber slurry mass, after high-temperature Stir with a frequency decontamination machine to obtain a fiber slurry with a mass percentage concentration of 5wt%;

[0059] (2) Filtering and removing slag from the above-mentioned fiber slurry and diluting with water to obtain a suspension with a mass percentage concentration of 1 wt%. After forming and dehydrating by a fourdrinier machine, a glass fiber wet paper sheet is obtained;

[0060] (3) The horizontal roller sizing method adopted is uniformly coated with a cationic epoxy emulsion with a solid content of 1% on the surface of the above-mentione...

PUM

| Property | Measurement | Unit |

|---|---|---|

| beating degree | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com