Bacteriostatic and antibacterial ceramic filter element and preparation method therefor

An antibacterial ceramic and filter element technology, applied in the field of ceramic materials, can solve the problems of single formula and function, and achieve the effects of good sterilization and bacteriostatic effect, stable chemical performance, and good filtration and adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

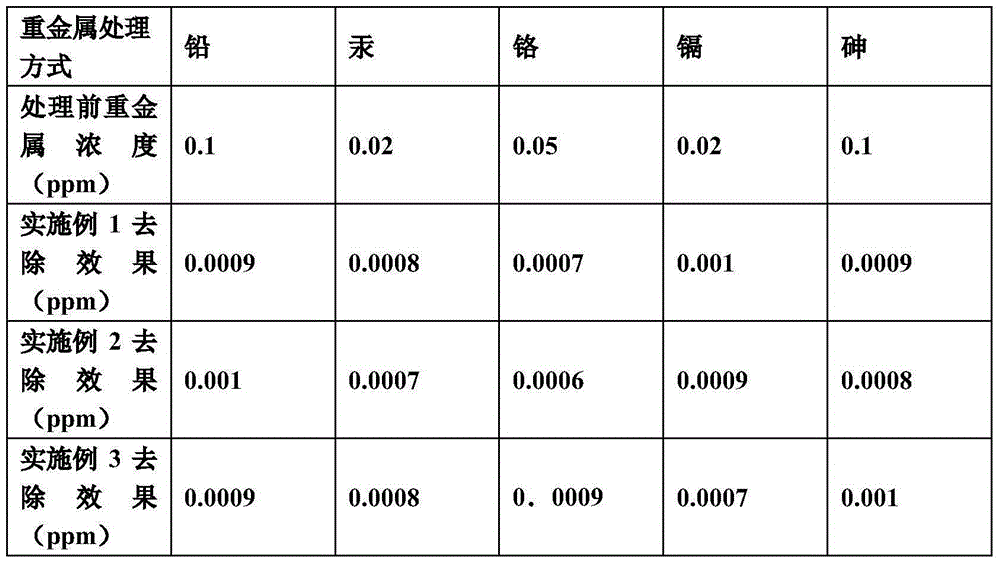

Examples

Embodiment 1

[0015] An antibacterial and antibacterial ceramic filter element, made of the following raw materials in weight (kg): 60 sea green stone, 30 sea pumice, 12 bentonite, 8 nano black gold charcoal, 6 rice husk powder, 3 razor clam shell powder, and 4 wooden fish stone , sodium bicarbonate 3, acrylic emulsion 1, sugar cane molasses 1, palm fiber 2, corn flour 1, phenolic resin 3, epoxy soybean oil 4, beeswax 1, antibacterial additive 6;

[0016] The antibacterial additive is made of the following weight (kg) raw materials: Hokutolite 20, crystal gravel 15, natural manganese sand 8, nano-silver carbon molecular sieve 3, nano-zinc oxide 1, lauryl glucoside 0.5, hydrogen peroxide 35; The preparation method is: calcining hokutolite, crystal gravel, and natural manganese sand at 810°C for 2 hours, crushing and grinding them into powder, then mixing them with nano-silver carbon molecular sieves, and nano-zinc oxide, and then adding dodecyl glucose Glycosides and hydrogen peroxide were s...

Embodiment 2

[0021] Embodiment 2, a kind of bacteriostasis and antibacterial ceramic filter element, is made of the raw material of following weight (kg): glauconite 65, sea pumice 35, bentonite 13, nano black gold charcoal 10, rice husk powder 7, razor clam king shell powder 4 , wood fish stone 5, sodium bicarbonate 4, acrylic emulsion 1, sugarcane molasses 1, palm fiber 3, corn flour 2, phenolic resin 4, epoxy soybean oil 5, beeswax 1, antibacterial additive 6;

[0022] The antibacterial additive is made of the following weight (kg) raw materials: Hokutolite 25, crystal gravel 16, natural manganese sand 10, nano silver carbon molecular sieve 4, nano zinc oxide 2, lauryl glucoside 0.7, hydrogen peroxide 40; The preparation method is: calcining hokutolite, crystal gravel, and natural manganese sand at 850°C for 1.5 hours, crushing and grinding them into powder, then mixing them with nano-silver carbon molecular sieves and nano-zinc oxide, and then adding dodecyl glucose Glycosides and hydr...

Embodiment 3

[0028] An antibacterial and antibacterial ceramic filter element, made of the following raw materials in weight (kg): 70 sea green stones, 40 sea pumice stones, 15 bentonite clays, 12 nano black gold charcoal, 8 rice husk powders, 5 razor clam shell powders, and 6 wooden fish stones , sodium bicarbonate 5, acrylic emulsion 2, sugarcane molasses 2, palm fiber 4, corn flour 3, phenolic resin 5, epoxy soybean oil 6, beeswax 2, antibacterial additive 7;

[0029] The antibacterial additive is made of the following weight (kg) raw materials: Hokutolite 30, crystal gravel 18, natural manganese sand 12, nano-silver carbon molecular sieve 5, nano-zinc oxide 3, dodecyl glucoside 0.5-1 , hydrogen peroxide 45; the preparation method is: calcining hokutolite, crystal gravel, and natural manganese sand at 870°C for 1 hour, crushing and grinding them into powder, then mixing them with nano-silver carbon molecular sieves, nano-zinc oxide, and then adding dodecane Glucoside and hydrogen peroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com