a filtered water m 3+ Nanofiber membrane material and preparation method thereof

A nanofiber membrane and sewage treatment technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as refractory degradation, difficult treatment, ecological damage, etc., achieve excellent adsorption performance, reduce Concentration, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Fe in filtered water 3+ The preparation method of the nanofibrous membrane material, it comprises the steps:

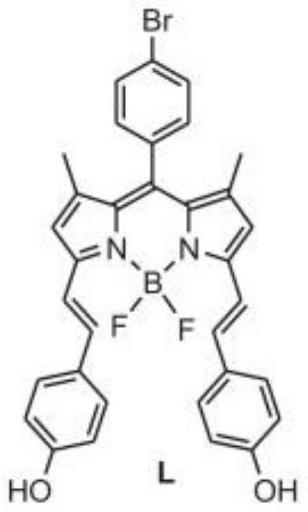

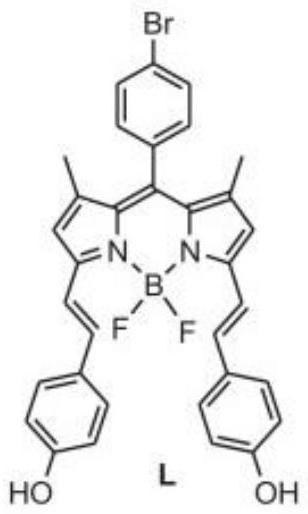

[0022] (1) Weigh polyvinylpyrrolidone PVP and polyvinyl alcohol PVA according to the ratio of parts by weight PVP:PVA=25:4, and carry out vacuum drying, add polyvinylpyrrolidone PVP and polyvinyl alcohol PVA in the ethyl acetate organic solvent , ultrasonically stirred at 45°C until uniformly mixed, then added 6wt% of graphene oxide, ultrasonically stirred, then added 7wt% of p-phenolic fluoroborate dipyrrole L, ultrasonically stirred to mix evenly, and it was a polymer solution;

[0023] (2) The polymer solution obtained in step (1) is metered through a metering pump and enters the spinneret. As the polymer spinning solution is extruded from the spinneret hole and forms a thin stream, a spray device is used to control the fine stream at the same time. Perform high-speed airflow blowing and stretching to obtain PVP / PVA nanofibers deposited on the substrate, an...

Embodiment 2

[0025] Al in filtered water 3+ The preparation method of the nanofibrous membrane material, it comprises the steps:

[0026] (1) Weigh polyvinylpyrrolidone PVP and polyvinyl alcohol PVA according to the ratio of parts by weight PVP:PVA=25:3, and carry out vacuum drying, add polyvinylpyrrolidone PVP and polyvinyl alcohol PVA to N,N-dimethyl In the amide organic solvent, stir ultrasonically at 45°C until the mixture is uniform, then add 8wt% graphene oxide, stir ultrasonically, then add 8wt% p-phenolic fluoroborate dipyrrole L, and stir ultrasonically to make the mixture uniform, that is polymer solution;

[0027] (2) The polymer solution obtained in step (1) is metered through a metering pump and enters the spinneret. As the polymer spinning solution is extruded from the spinneret hole and forms a thin stream, a spray device is used to control the fine stream at the same time. Perform high-speed airflow blowing and stretching to obtain PVP / PVA nanofibers deposited on the subs...

Embodiment 3

[0029] A kind of Cr in filtered water 3+ The preparation method of the nanofibrous membrane material, it comprises the steps:

[0030](1) Weigh polyvinylpyrrolidone PVP and polyvinyl alcohol PVA according to the ratio of parts by weight PVP:PVA=25:2, and carry out vacuum drying, add polyvinylpyrrolidone PVP and polyvinyl alcohol PVA to N, N-dimethyl In the amide organic solvent, ultrasonically stir at 45°C until the mixture is uniform, then add 7.5wt% graphene oxide, ultrasonically stir, then add 7.1wt% p-phenolic fluoroborate dipyrrole L, ultrasonically stir to make the mixture uniform, is the polymer solution;

[0031] (2) The polymer solution obtained in step (1) is metered through a metering pump and enters the spinneret. As the polymer spinning solution is extruded from the spinneret hole and forms a thin stream, a spray device is used to control the fine stream at the same time. Perform high-speed airflow blowing and stretching to obtain PVP / PVA nanofibers deposited on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com