Ozone treatment system and method for degrading deoxynivalenol in wheat

A deoxynivalenol and ozone treatment technology, applied in the field of microbial treatment, can solve the problems of production cost input, impact on application, general ozone detoxification effect, etc., and achieve the effect of reducing exhaust gas emissions and realizing controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

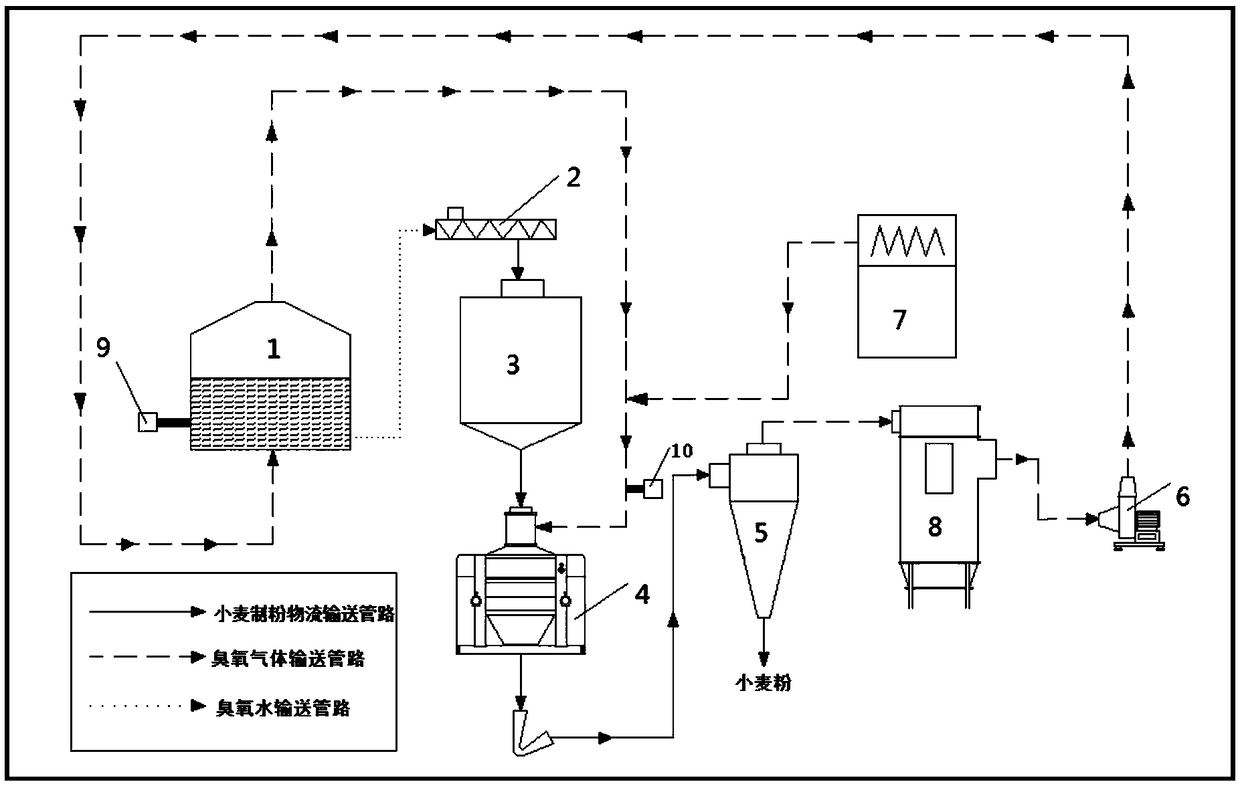

Method used

Image

Examples

Example Embodiment

[0055] Example 1:

[0056] Sample pretreatment: Weigh 2kg of wheat A, and remove impurities and stones in the wheat sample with an experimental grain sieve and destoner.

[0057] Deoxynivalenol in wheat A was treated by the above system and method.

[0058] Conditioning method: According to "NYT 1094.1-2006 Wheat Experimental Milling Part 1: Equipment, Sample Preparation and Conditioning", the moisture content of the wheat sample was adjusted to 16 wt%.

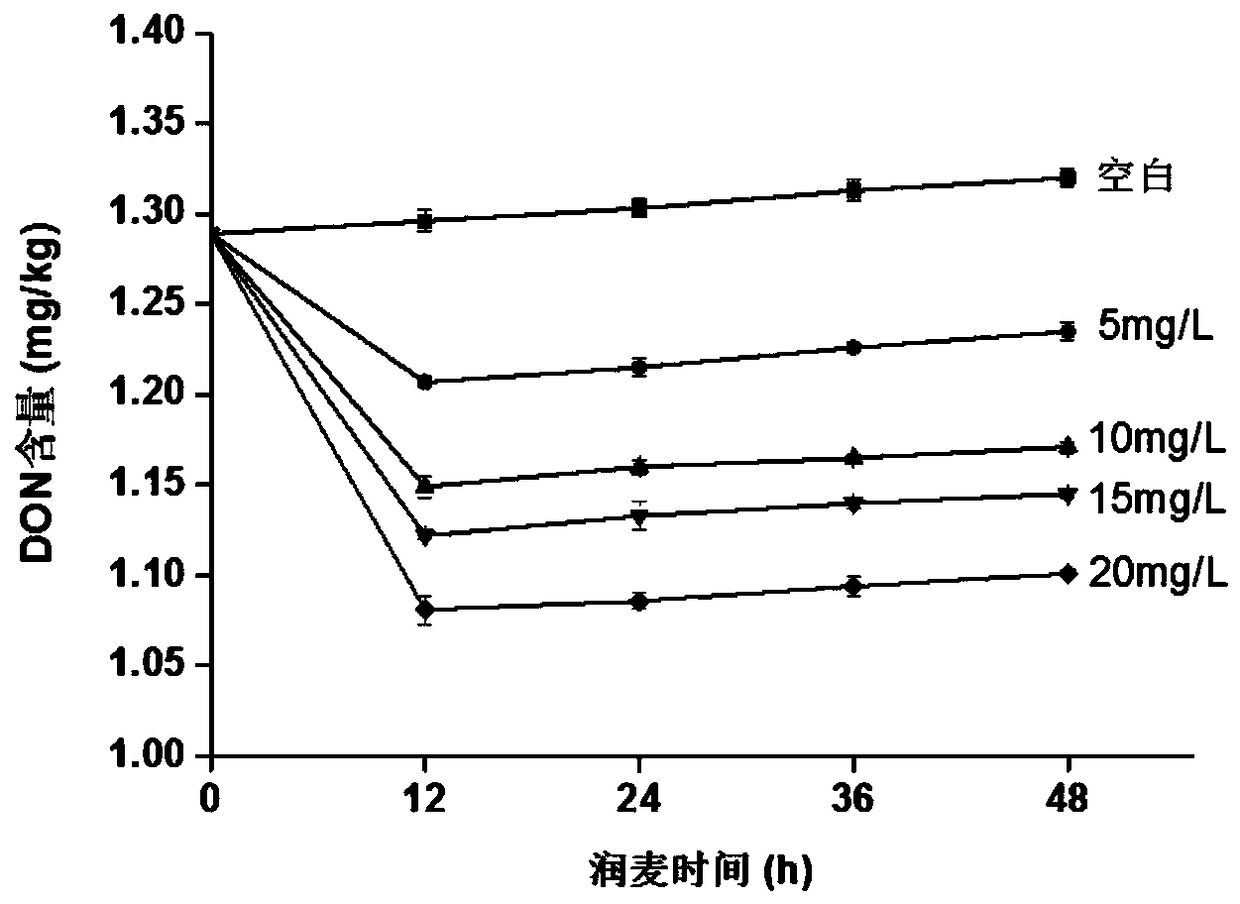

[0059] Wherein, after scab polluted wheat A is cleaned up with a vibrating sieve and a stone remover, the concentration of ozone water produced by the ozone water generating tank is 20mg / L, and the moisture of the wheat A is sprayed with water to moisten the wheat for 24 hours to reach 16wt% moisture. The feed inlet of pulverizer 4 feeds the ozone gas of 60mg / L.

Example Embodiment

[0060] Example 2:

[0061] Sample pretreatment: Weigh 2kg of wheat B, and remove impurities and stones in the wheat sample with an experimental grain sieve and stone remover.

[0062] Deoxynivalenol in wheat B was treated with the system and method described above.

[0063] Conditioning method: According to "NYT 1094.1-2006 Wheat Experimental Milling Part 1: Equipment, Sample Preparation and Conditioning", the moisture content of the wheat sample was adjusted to 16 wt%.

[0064] Among them, after the scab-polluted wheat B was cleaned with a vibrating screen and a stone remover, the concentration of 5mg / L ozone water was produced by the ozone water generation pool, and the moisture of the wheat B was sprayed with water to moisten the wheat for 24 hours to reach 16wt% moisture. 20mg / L of ozone gas is fed into the feed port of the leather mill system of the Le Mill.

[0065] The content of deoxynivalenol in Example 1 and Example 2 is detected, and the results are shown in Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com