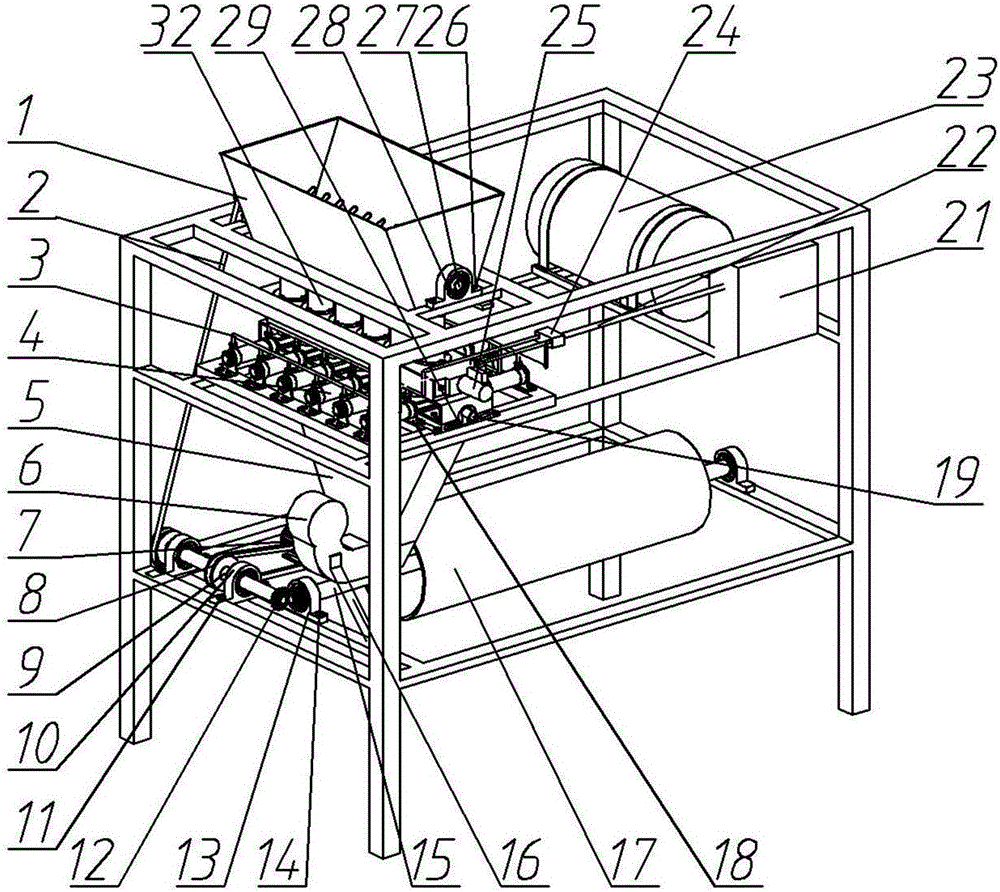

Walnut shell breaking, kernel taking and separating device and application method thereof

A shell breaking device and separation device technology, which is applied in the direction of shelling, application, pod removal, etc., can solve the problems of inefficient control of walnut feeding, shell breaking process, deep processing, inconvenient eating, and low performance indicators. Achieve the effects of reducing labor costs, flexible and adjustable speed, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

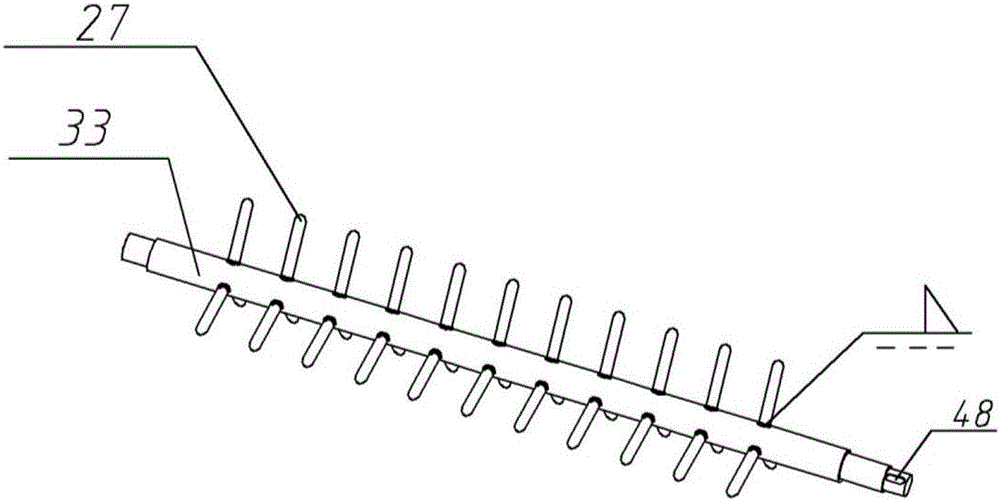

Method used

Image

Examples

Embodiment 2

[0168] The difference between this embodiment and embodiment 1 is:

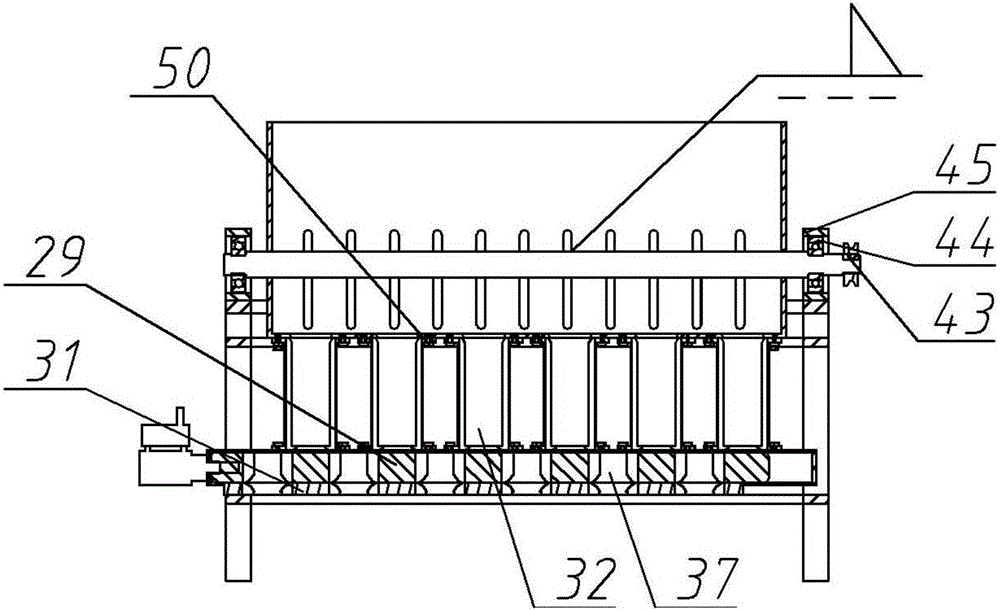

[0169] A baffle plate with holes is set below the walnut positioning mold, such as Figure 16 As shown, in the initial position, the through holes 13 of the baffle are interlaced with the positions of the walnut positioning holes, so as to stop the walnut from falling. Plate reversing cylinder 19 is provided with perforated baffle plate reversing cylinder gas injection hole 62 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com