Gas hot blast stove for heating by burning liquefied gas or natural gas

A gas-fired hot blast stove and natural gas technology, which is applied in the directions of gas fuel burners, burners, combustion types, etc., can solve the problems of insufficient heating of cold air and uneven gas mixing, so as to improve heating effect, improve heat exchange efficiency, and increase The effect of a large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

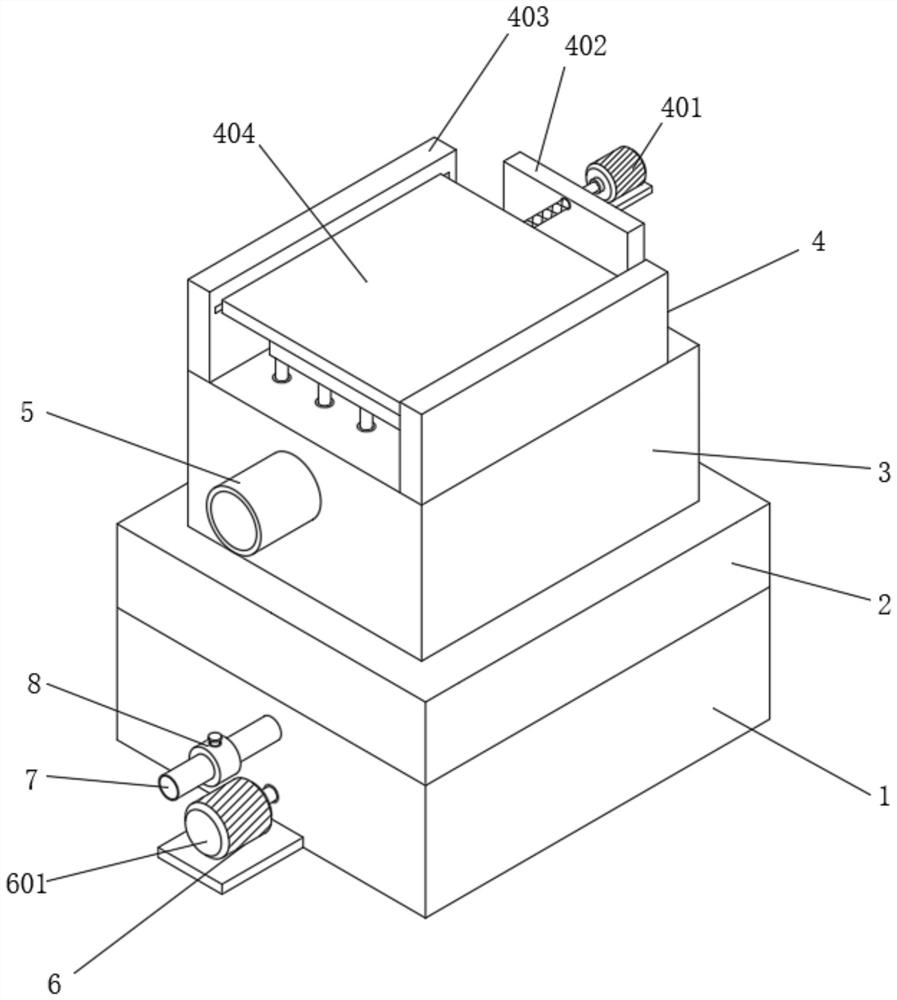

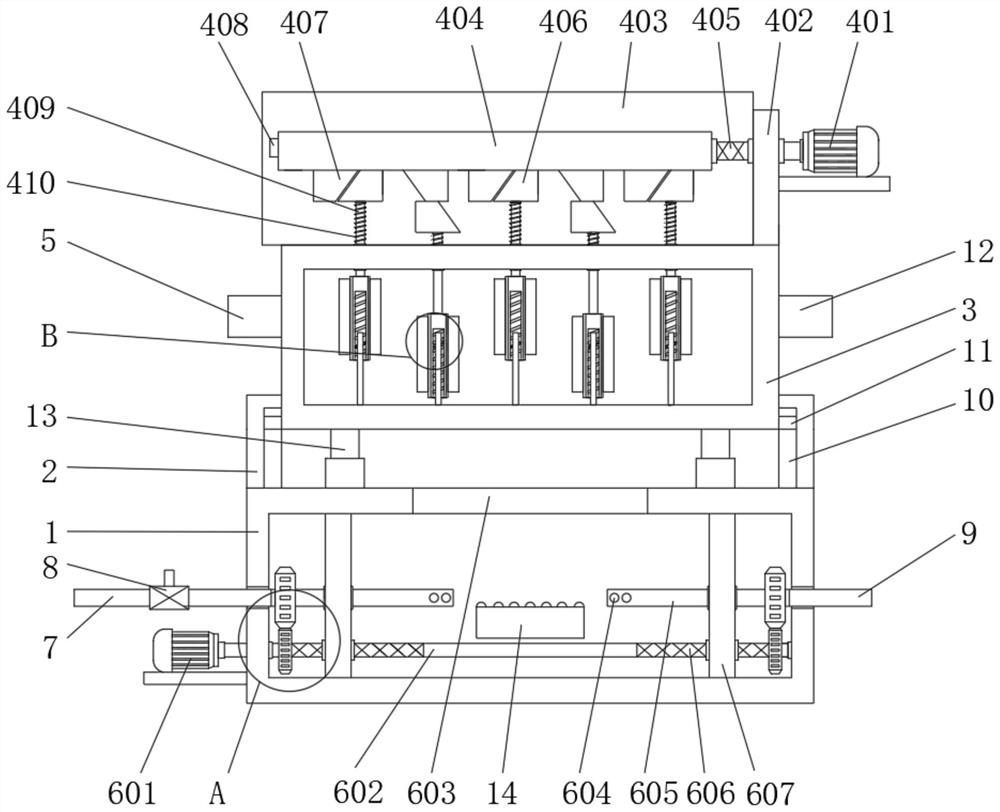

[0039] The specific embodiment is as follows: by arranging the first sliding groove 10 and the first sliding block 11, the first sliding groove 10 and the first sliding block 11 are matched, and the first sliding groove 10 limits the first sliding block 11 to avoid The heating box 3 slides out of the connecting groove 2, and at the same time, the first chute 10 is used in conjunction with the first sliding block 11, which can reduce the shaking of the heating box 3 when sliding and improve the stability of the heating box 3. By setting the hydraulic lifting rod 13, it can be The distance between the combustion box 1 and the heating box 3 is controlled, thereby controlling the heating effect of the combustion box 1 on the heating box 3, which is convenient for the staff to adjust according to actual needs, and improves the applicability of the hot blast stove.

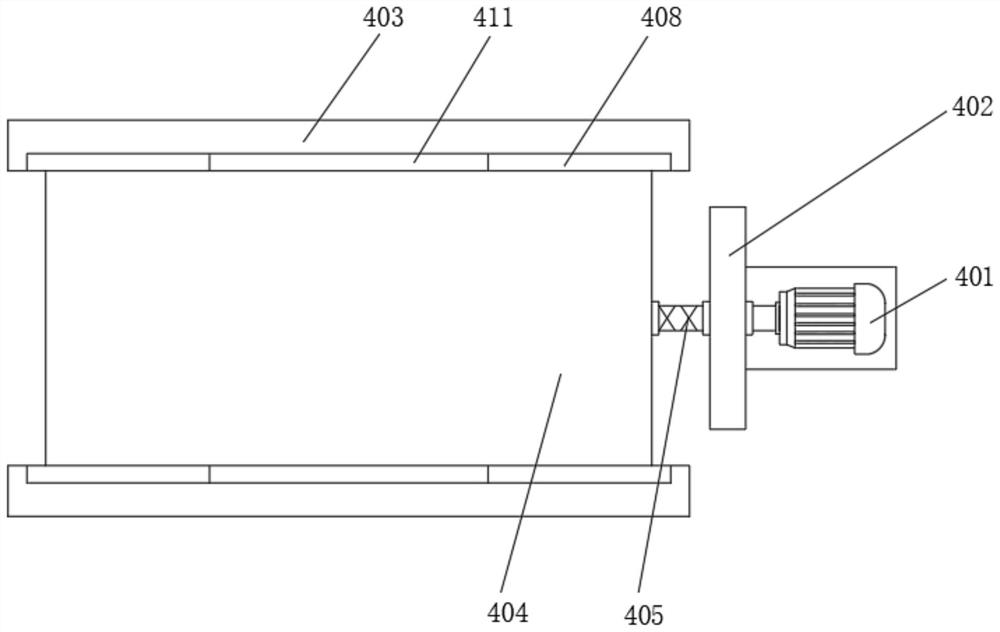

[0040] The gas mixing assembly 6 includes a gas delivery pipe 605, which is rotatably connected to one end of the natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com