A controllable and intelligent magnetorheological piezoelectric vibration isolation bearing

A vibration-isolating bearing and voltage-transforming technology, applied in building types, buildings, building components, etc., can solve the problem of failure to achieve monitoring + control + reset effect, failure to achieve semi-active or active external energy consumption control effect, Unable to realize real-time monitoring and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing.

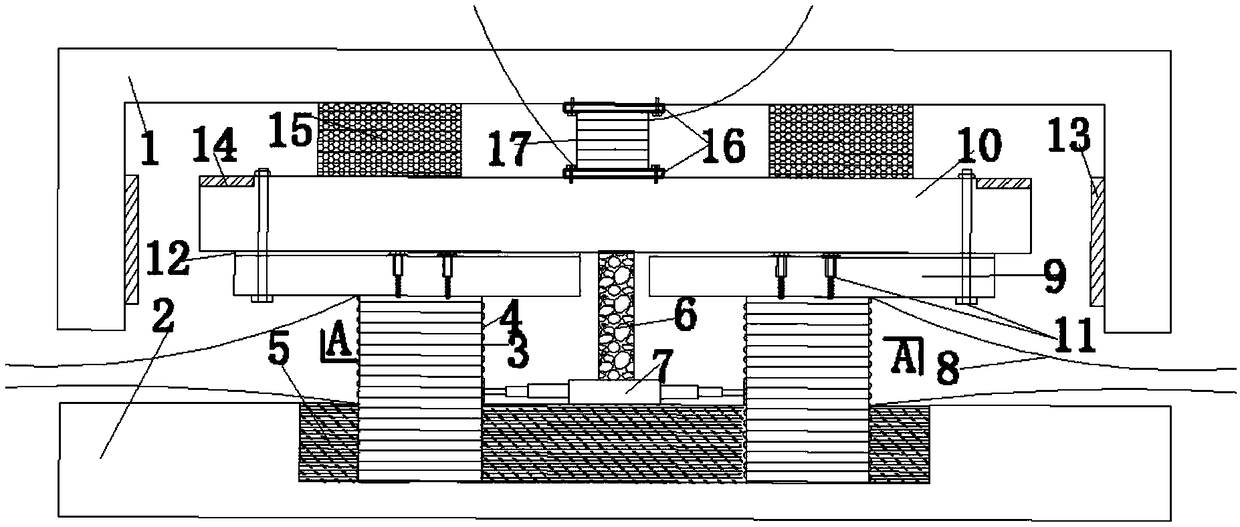

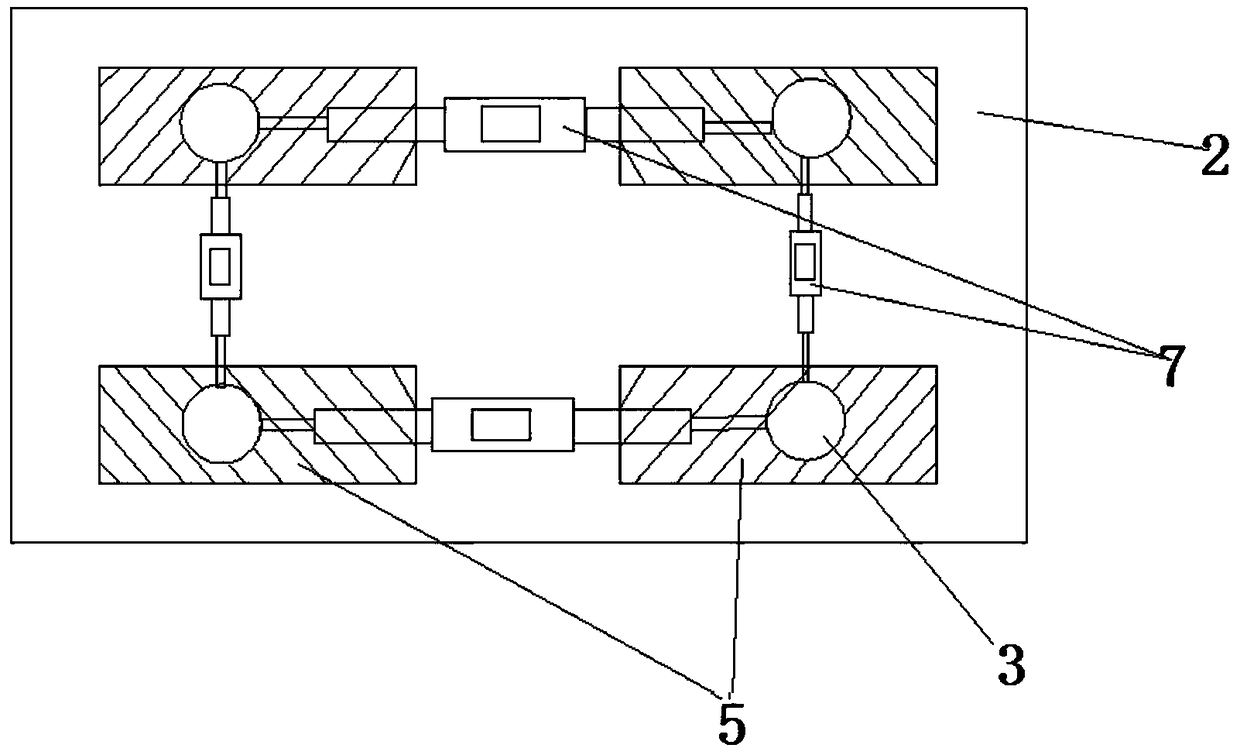

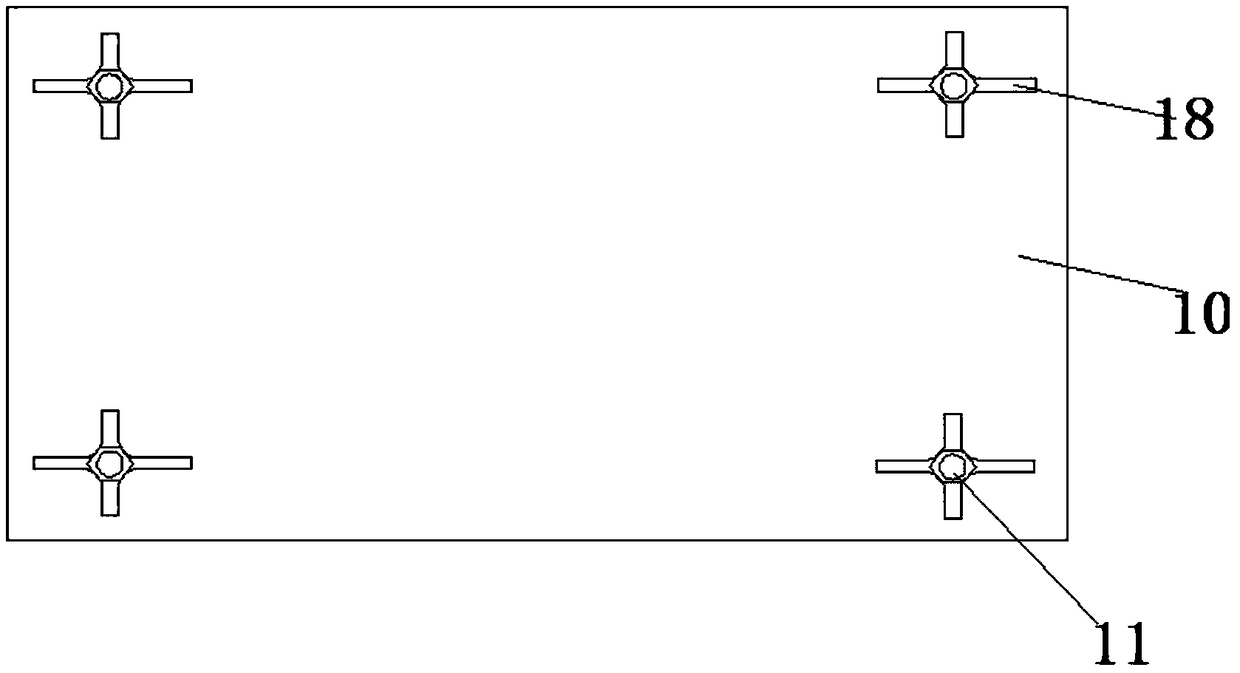

[0021] refer to figure 1 , figure 2 , image 3 with Figure 4 , a controllable and intelligent magnetorheological piezoelectric vibration isolation support, including a concave lower steel plate 2 and an upper cover plate 1, four grooves are opened inside the lower steel plate 2, and magnetorheological Liquid 5, the groove is placed with a high magnetic sliding cylinder 3, so that the high magnetic sliding cylinder 3 can slide inside the groove, and the outside of the high magnetic sliding cylinder 3 is surrounded by an excitation coil 8, and a layer of excitation coil protective film is wrapped on the outside 4 to protect the excitation coil 8 from corrosion, damp and damage; at the same time, a hydraulic telescopic rod 7 is set in the middle of two adjacent high magnetic sliding cylinders 3, and an external current is used to energize the excitation coil 8 of the high ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com