Full-automatic continuous feeding system of integral stacks of aluminum plates

An automatic feeding and fully automatic technology, which is applied in the direction of object stacking, object destacking, conveyor objects, etc., can solve the problems of low production efficiency and achieve high board loading efficiency, stable feeding, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

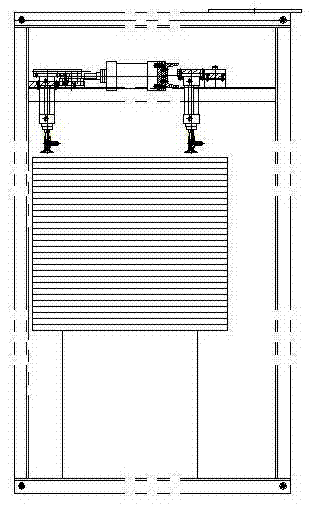

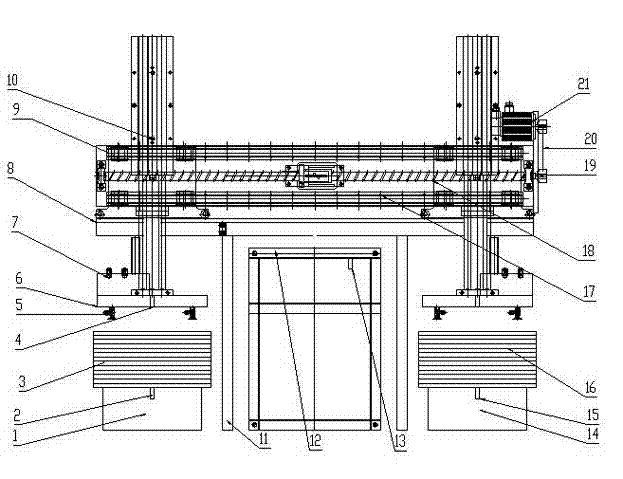

[0009] In order to better understand and implement, the following is combined with the attached figure 2 Further description of the present invention: a fully automatic continuous automatic feeding system for the entire stack of aluminum plates, including a column 11 and a work table 12, the work table 12 is an opening for grabbing a single aluminum plate from the left and right aluminum stacks, and the work table 12 is provided with a proximity switch B13, there is a connecting plate 8 on the column 11, the left aluminum stack pallet 1 and the right aluminum stack pallet 14 are respectively set on both sides of the column 11, the left aluminum stack 3 is placed on the left aluminum stack pallet 1, and the right aluminum stack 13 is placed On the right aluminum stack pallet 12, the left aluminum stack pallet 1 and the right aluminum stack pallet 14 are equipped with proximity switches A2 and proximity switches C15 respectively, and the left aluminum stack pallet 1 and the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com