Longitudinal-radial coupled vibration ultrasonic rolling welding device

A technology for coupling vibration and welding devices, applied in the field of ultrasonic rolling welding devices, can solve the problems of wrinkling and poor welding sealing of multi-layer non-woven products, and achieve the effects of convenient installation, large welding pressure, and reducing the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

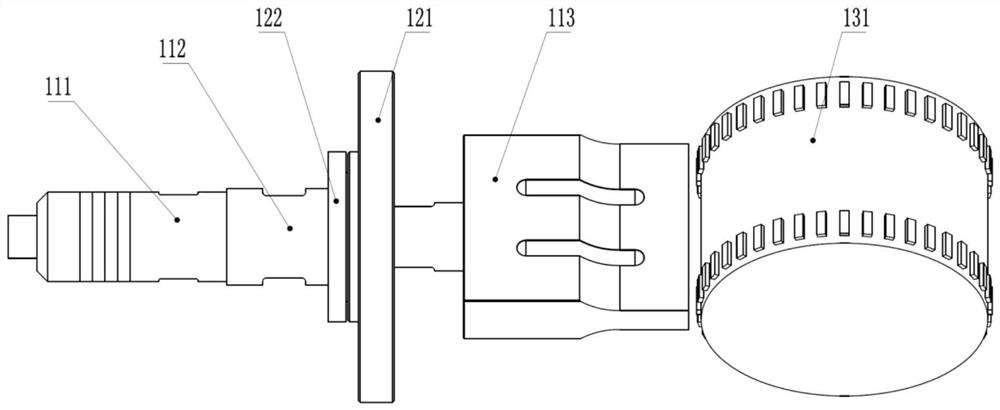

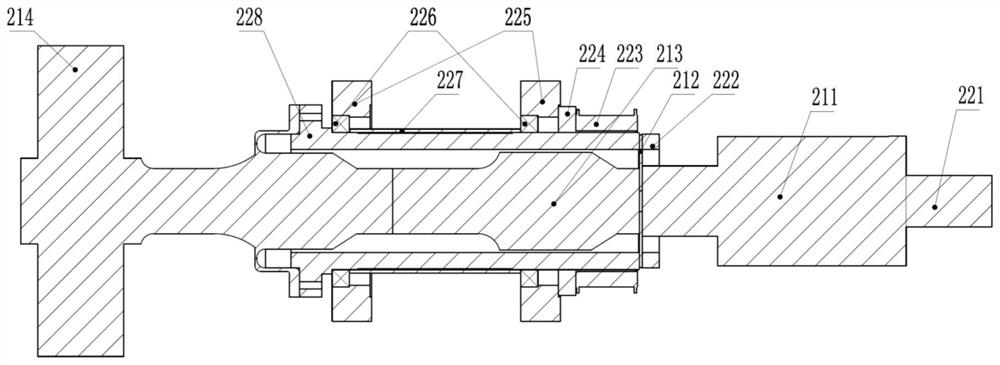

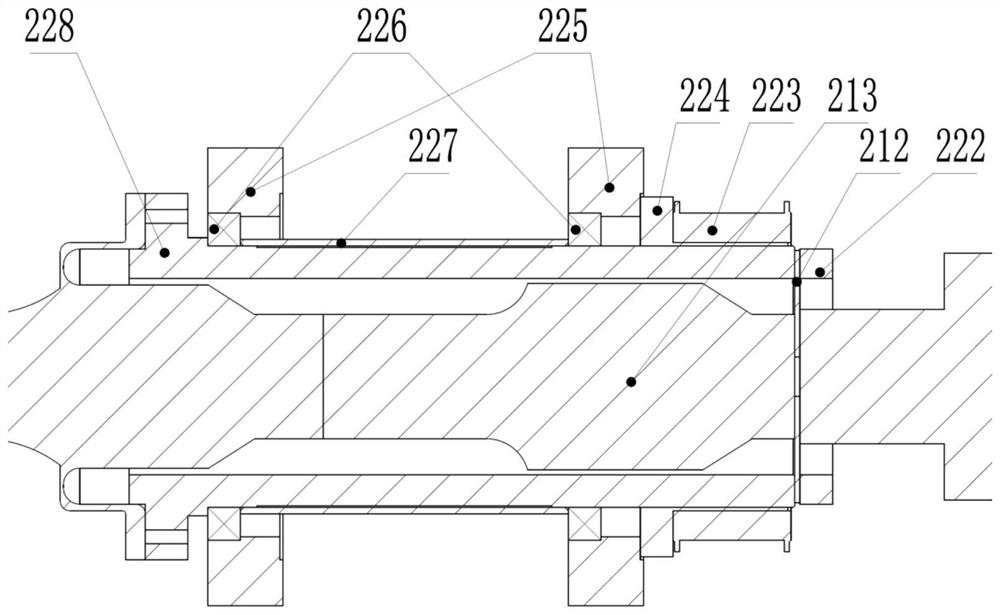

[0029] figure 2 , 3 The ultrasonic rolling welding device provided by the present invention with longitudinal coupling is shown, which includes two parts: an ultrasonic vibration part and a fixed clamping part. Wherein, the ultrasonic vibration part is formed by coaxially connecting the ultrasonic transducer (with the casing) 211 , the horn 213 and the seam welding tool head 214 through bolts.

[0030] The components of the fixed clamping part include: conductive slip ring 221, synchronous pulley 223, support plate 225, bearing 226, bearing positioning sleeve 227 and fixed shell 228; the cylindrical fixed shell 228 is coaxially set on the horn 213, and one end thereof is fixedly connected to the radially protruding flange on the roll welding tool head 214 through a circle of bolts; the first bearing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com