Patents

Literature

55results about "Osier rod peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for increasing wicker product hardness

InactiveCN106182297AImprove insect and mildew resistanceHigh strengthPressure wood treatmentWood treatment detailsHigh humidityHardness

The invention discloses a method for improving the hardness of wicker products, which comprises the following steps: (1) wicker peeling, (2) softening treatment, (3) wicker weaving, and (4) hardness treatment. The matching of each step of the method of the present invention is scientific and reasonable, and the obtained wickerwork has good insect-proof and mildew-proof effects and high surface hardness. Compared with the prior art, the surface hardness can be increased by about 25%, and the service life under normal use conditions It can be extended by about 30%, and the service life under high humidity conditions can be extended by more than 50%. It has good stability in use, strong anti-deformation ability, good corrosion resistance, and high use value.

Owner:阜南县猛发工艺品有限公司

Method for improving corrosion resistance of wicker products

ActiveCN106182248AImprove organizational structureImprove insect and mildew resistanceRadiation/waves wood treatmentWood treatment detailsHigh humidityHardness

The invention discloses a method for improving corrosion resistance of wicker products. The method comprises the following steps: (1) skin removal of wickers, (2) softening treatment, (3) wicker weaving, and (4) anti-corrosion treatment. Various steps of the method are matched scientifically and reasonably, and the manufactured wicker products are good in insect prevention, mildew prevention and corrosion resisting effects and are high in surface hardness. Compared with the prior art, the method has the characteristics that the surface hardness of the wicker products can be improved by about 25%, the wicker products are used under the condition of high acid and alkali, the anti-corrosion time of the wicker products can be 4-5 times longer than the original anti-corrosion time, the service life can be prolonged by about 30% under the conventional using conditions, and can be prolonged by 40% or above under the condition of high humidity, use stability is good, anti-deformation ability is high, corrosion resistance is good, and use value is high.

Owner:阜南县猛发工艺品有限公司

Processing method for green-bark salix integra woven artware

InactiveCN106182246AAvoid damageImprove toughnessWood treatment detailsCane mechanical workingCuticleLacquer

The invention discloses a processing method for green-bark salix integra woven artware. The processing method comprises the steps of material selecting, preliminary sterilizing and softening, bark peeling, secondary softening, setting, mould preventing and softening treatment, weaving and paint brushing. Compared with the prior art, the processing method for the green-bark salix integra woven artware has the following advantages that green-bark salix integra meeting specification requirements is selected and treated with treating fluid A, the effects of softening, preliminary sterilizing and surface bulking are achieved, peeling is accelerated, and damage to the salix integra by machines during peeling is reduced; the salix integra is softened again with hot steam, and then the bent salix integra is pressed to be straight, so that uniform weaving is facilitated; the salix integra is treated with treating fluid B, the tenacity of the green-bark salix integra can be improved, and the antisepsis function and the mould preventing function of the green-bark salix integra are enhanced; and after weaving and setting are completed, a product is brushed with finish paint. The finish paint has excellent pollution resistance, a film can be fast formed on the surface of the product, the finish paint is free of aftertack after being dried, sun cracking and warping do not occur after long-term use of the finish paint, and the surface of the product is maintained bright and attractive.

Owner:阜南佳利工艺品股份有限公司

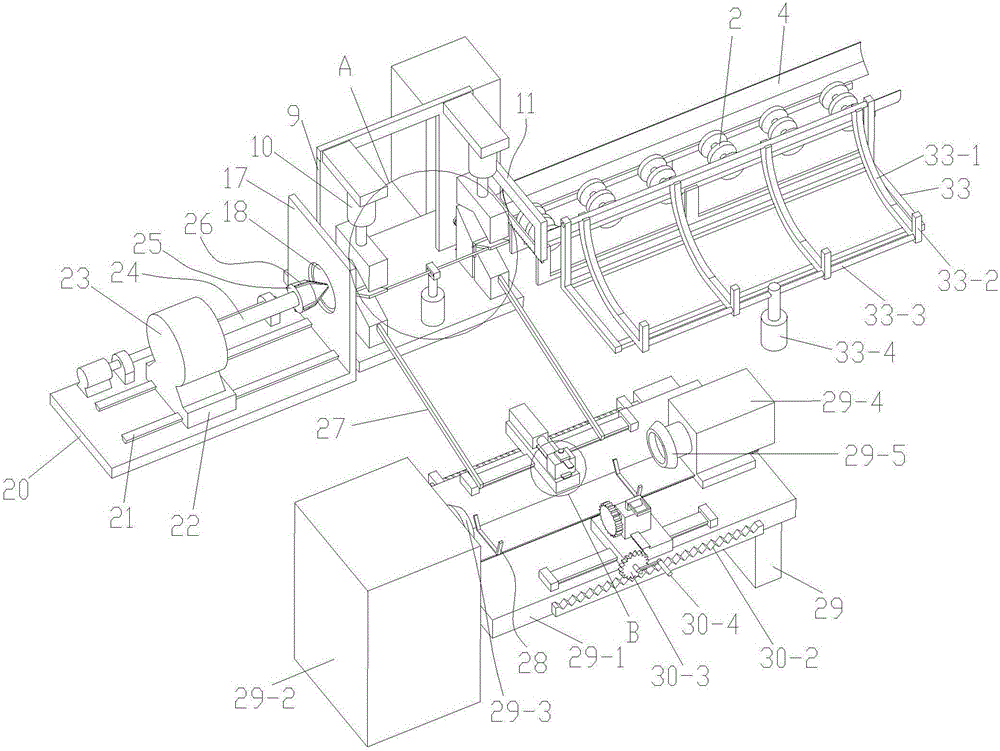

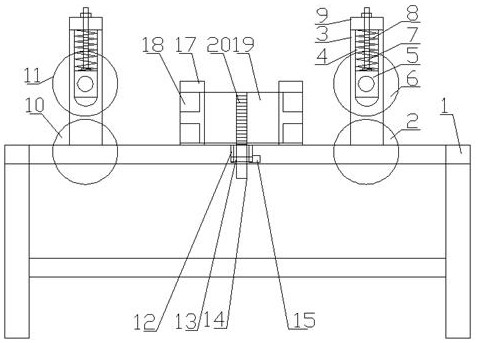

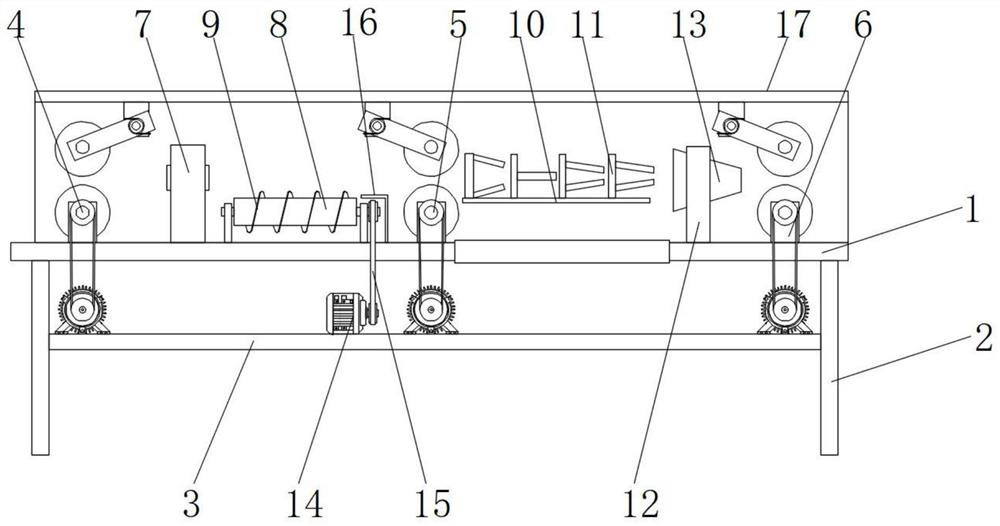

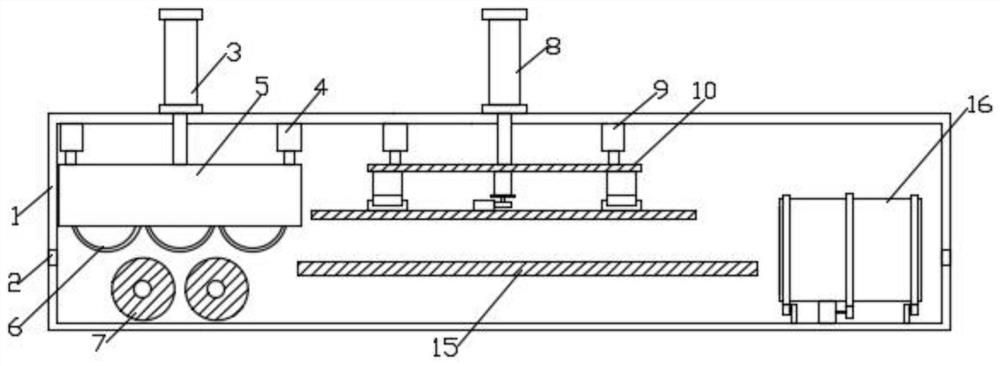

Full-automatic bamboo tube machining production line

ActiveCN106003287AImprove processing qualityReasonable structural designCane mechanical workingOsier rod peelingProduction lineMachining

A full-automatic bamboo tube machining production line comprises a conveying frame. A row of conveying wheels are installed on the conveying frame and connected with a conveying motor. Oblique side baffles are installed on the front side and the rear side of the conveying frame. A storage rack is installed on the front side edge of the conveying frame. A set of containing rods are installed on the storage rack. The rear ends of the containing rods are located above the side baffles and rotationally connected to the storage rack. Stop rods are installed at the front ends of the containing rods. The front ends of the containing rods are connected through a fixing rod. The fixing rod is installed on a supporting air cylinder. A bamboo tube fixing frame is installed on an outlet of the conveying frame and comprises a fixing base. A V-shaped supporting block is installed on the fixing base. A V-shaped compression block is installed above the V-shaped supporting block. A side installation frame is fixed to the rear portion of the fixing base. A compression air cylinder is installed at the top of the side installation frame. The V-shaped compression block is installed on the compression air cylinder. A cutting machine is installed between the conveying frame and the bamboo tube fixing frame.

Owner:LISHUI UNIV

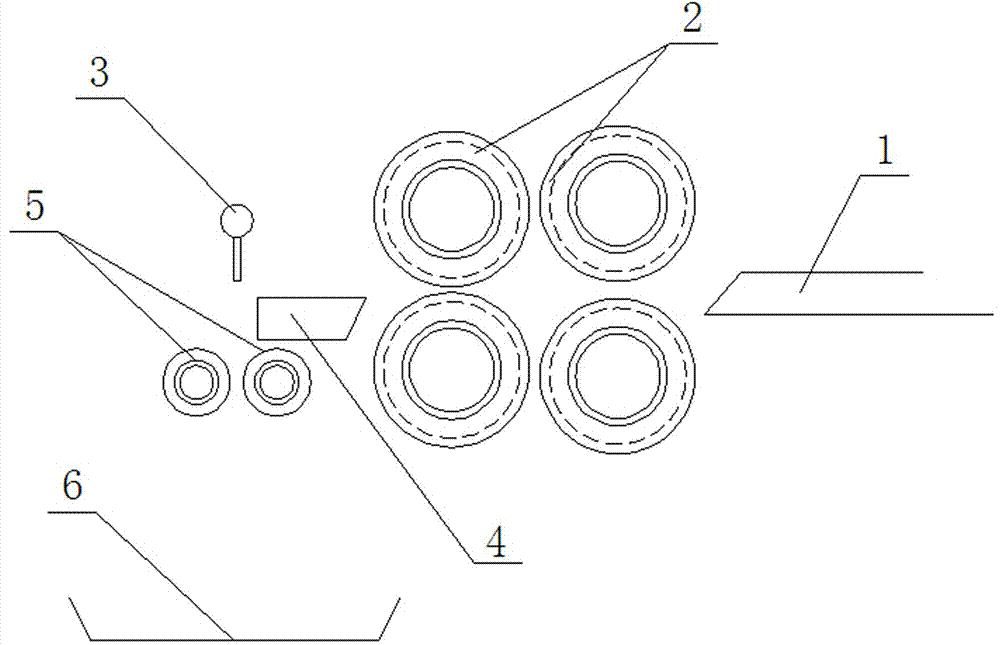

Mulberry twig bark and core stripping machine

The invention discloses a novel mulberry twig bark and core stripping machine. The mulberry twig bark and core stripping machine comprises a bark stripping device and a raw bark bin located under an outlet of the bark stripping device. The bark stripping device comprises two sets of spiral rollers, wherein left-hand threads and right-hand threads with the thread pitch being 8-10 mm and the spiral angle being 20 degrees are arranged on the peripheral surfaces of the upper spiral roller and the lower spiral roller of each set respectively, the normal interval between the upper roller and the lower roller of the first set is 5-8 mm, and the normal interval between the upper roller and the lower roller of the second set is 4-5 mm. The mulberry twig bark and core stripping machine overcomes the defects that a manual bark stripping method is high in labor intensity and low in work efficiency, an existing bark stripping machine easily causes the situation that mulberry twigs are crushed too mush, is poor in mulberry twig completeness and is serious in damage to fibers, and mulberry barks and the mulberry twig chips can not be separated easily. The mulberry twig bark and core stripping machine adopts a simple mechanical structure and a new design principle, the mulberry barks are broken, separated and stripped on the mulberry twigs due to the twisting force and the tearing function of the left-hand and the right-hand threads on the mulberry twigs, the bark stripping effect is good, the bark and core separating rate can reach 90 %, damage to fibers is small, and the economic value of mulberry barks is improved.

Owner:SICHUAN RES INST OF SILK SCI +1

Processing method for mouldproof and dampproof wicker

ActiveCN107471349AImprove toughnessReduce adsorptionRadiation/waves wood treatmentWood treatment detailsMicrobial agentAcetic acid solution

The invention discloses a processing method for mouldproof and dampproof wicker. The processing method is characterized by comprising the following aspects that (1) debarking is conducted, specifically, loess, plant extract and a microbial agent are mixed into mixed mud, and the wicker is steeped and dried and subjected to constant-temperature standing; (2) fibration is conducted, specifically, the wicker is subjected to hydrogen peroxide solution steeping and acetic acid solution steaming treatment, and then a sodium chloride solution is used for washing; (3) boiling is conducted, specifically, the wicker is steeped in plant extract and subjected to low-temperature high-pressure boiling and drying, and the same step is repeatedly conducted for 3-4 times; (4) solidification is conducted, specifically, the boiled wicker is steeped into a kaolin and alumina powder thin glue solution to be boiled; and (5) drying and weaving are conducted, specifically, the solidified wicker is dried till the water content is 7-10%, and then handicraft work is woven.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

Wicker flowerpot manufacturing method

InactiveCN107379163ADamaged will notIncrease moisture contentWood treatment detailsCane mechanical workingSaline waterWarm water

The invention discloses a wicker flowerpot manufacturing method. The wicker flowerpot manufacturing method includes the following steps that (1) wickers which are even in thickness and free of plant diseases and insect pests are harvested, paved and aired until leaves are dried up, and then the dried-up leaves are removed; (2) the wickers obtained after leaf removal are washed with saline water for impurity removal, are placed into warm water at the temperature ranging from 50 DEG C to 60 DEG C to be soaked for 30 minutes, and are taken out after soaking to be subject to wicker skin stripping; (3) the wickers obtained after skin stripping is dried with hot air at the temperature ranging from 30 DEG C to 40 DEG C until the water content of the wickers is lower than 10%; (4) the dried wickers are soaked with a made-to-order soaking solution at 40 DEG C for 4 hours, then wicker surfaces are thoroughly washed with clean water; the wickers treated through the above steps are woven into flowerpots; and (6) the woven flowerpots are placed into a refrigeration house for refrigeration for 5 hours, are taken to be directly placed into a made-to-order soaking solution at 60 DEG C for 2 hours and are taken out after soaking is finished, and the surfaces are thoroughly washed with clean water to obtain finished products.

Owner:ANHUI MEIJING ARTS & CRAFTS CO LTD

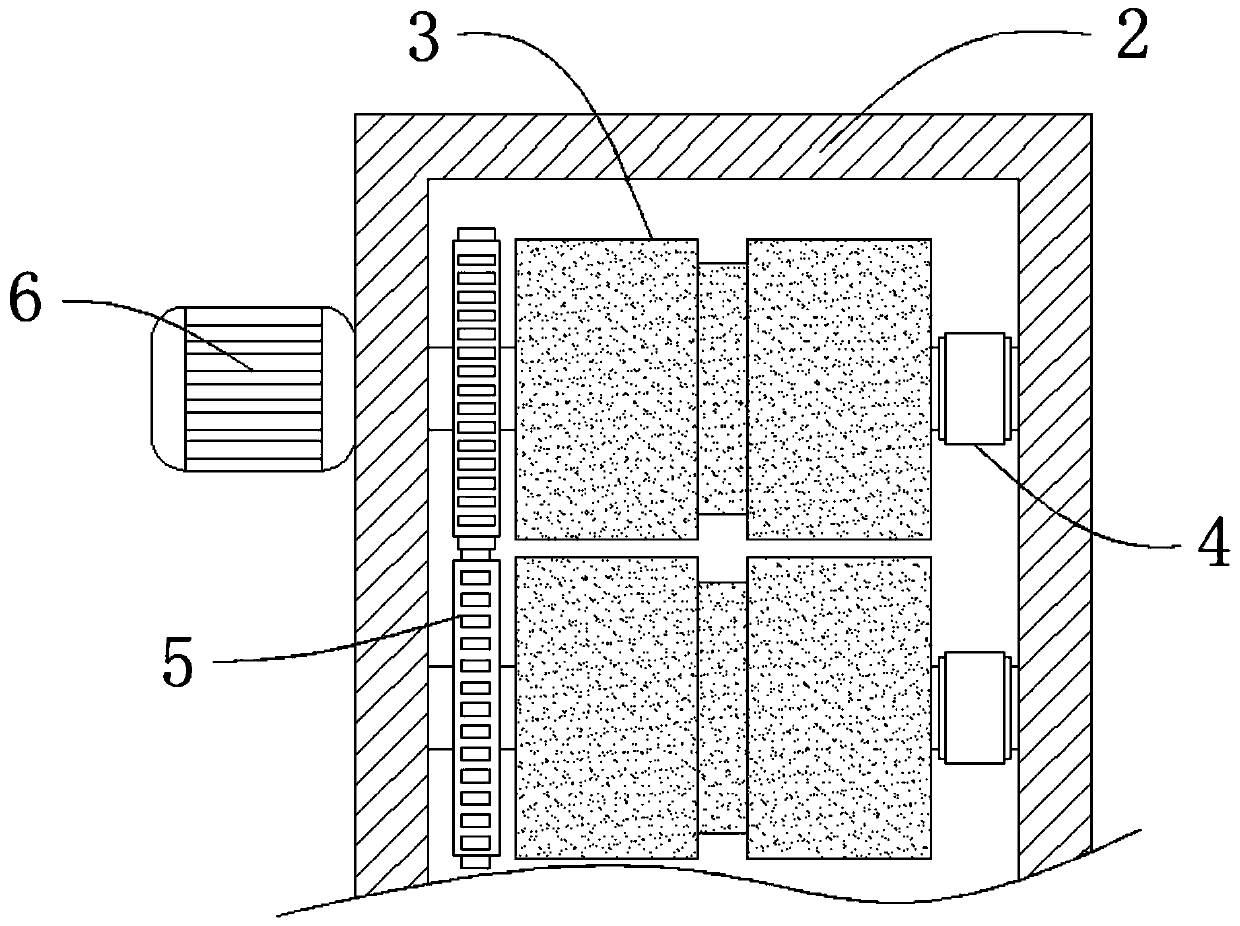

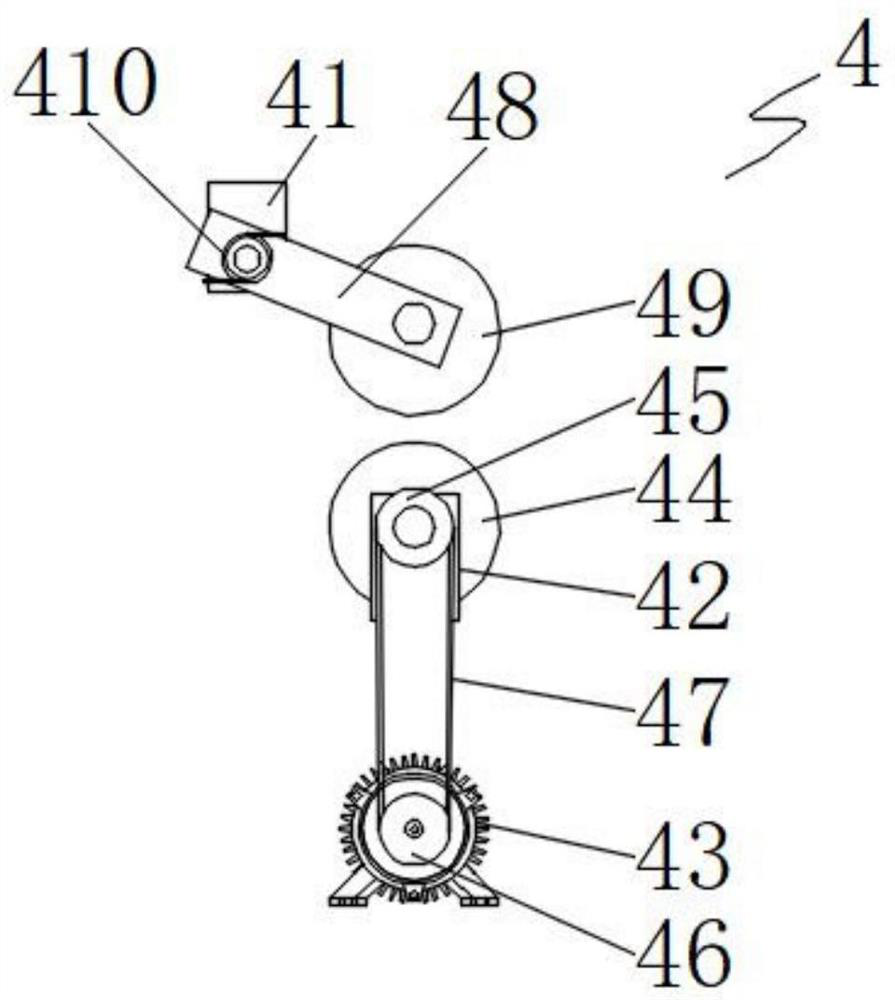

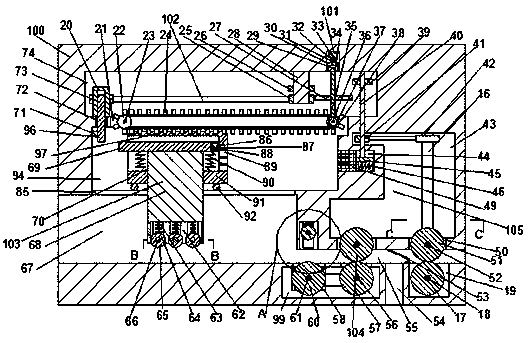

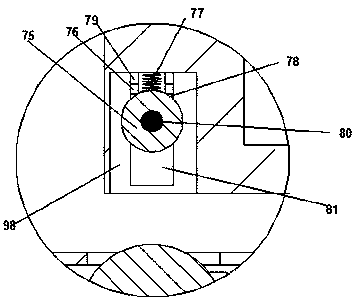

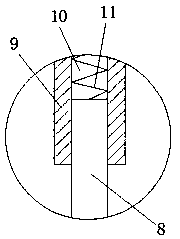

Wicker pole peeling device

InactiveCN109291180AOvercoming the inability to automatically loadOvercoming productivityOsier rod peelingElectric machineryEnergy consumption

The invention discloses a wicker pole peeling device which comprises a peeling machine. A motor sliding chute is formed in the peeling machine, and a power device is arranged in the motor sliding chute, an adjusting space is formed in the lower end wall of the motor sliding chute, and an adjusting device is arranged in the adjusting space. The device can complete the full-automatic peeling of thewillow strips, so that the problems that the traditional manual leather pulling efficiency is low, the pulling skin is not clean are overcome, meanwhile, the defects that a traditional machine cannotcarry out automatic feeding and one-time multi-root production are overcome, the device is in mechanical transmission fit, the working efficiency of the device is improved, the device can be applied to all wicker, the possibility of mistakes is reduced, the double motors are used for achieving multiple functions, the cost of the device is reduced, and the energy consumption is saved.

Owner:周识儒

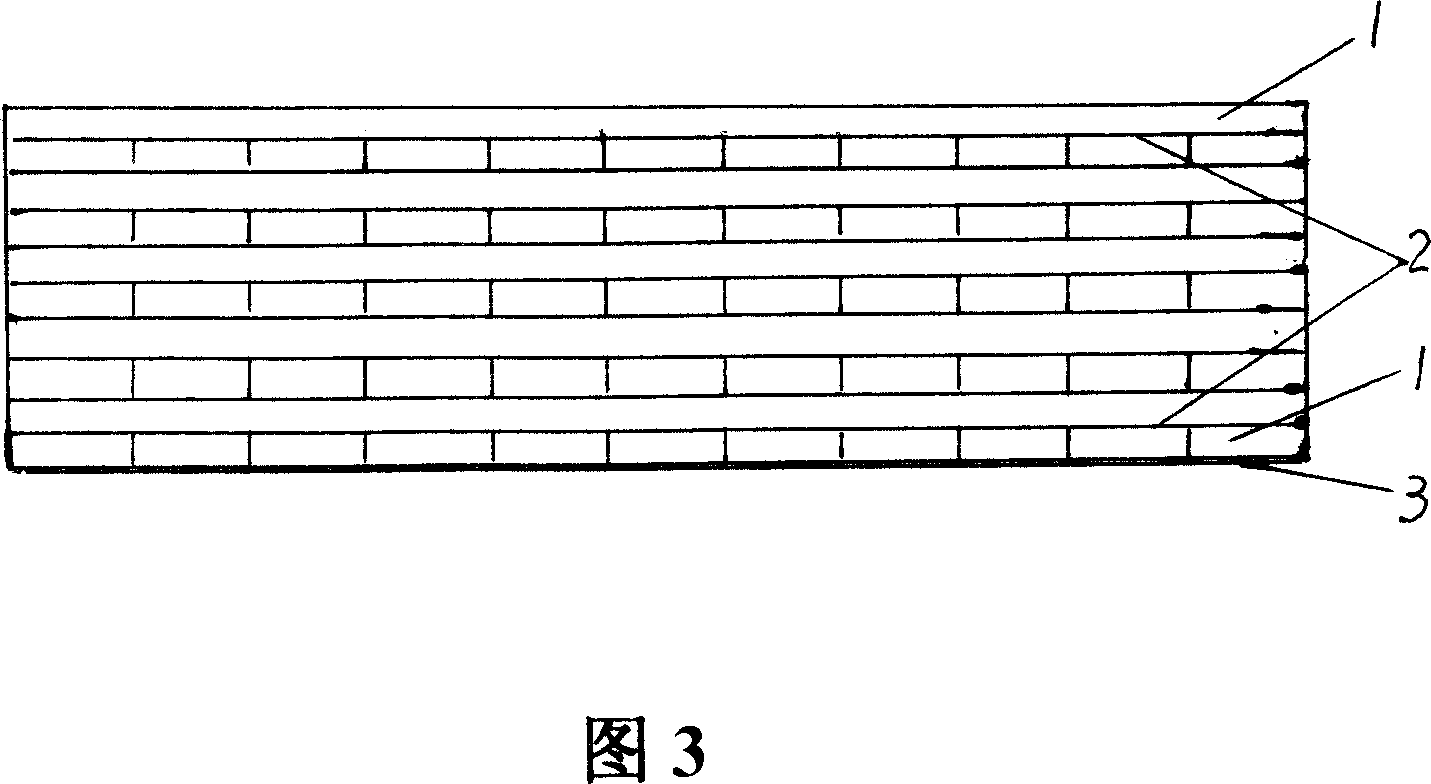

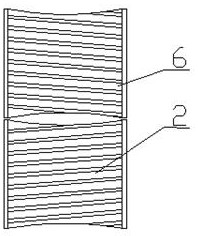

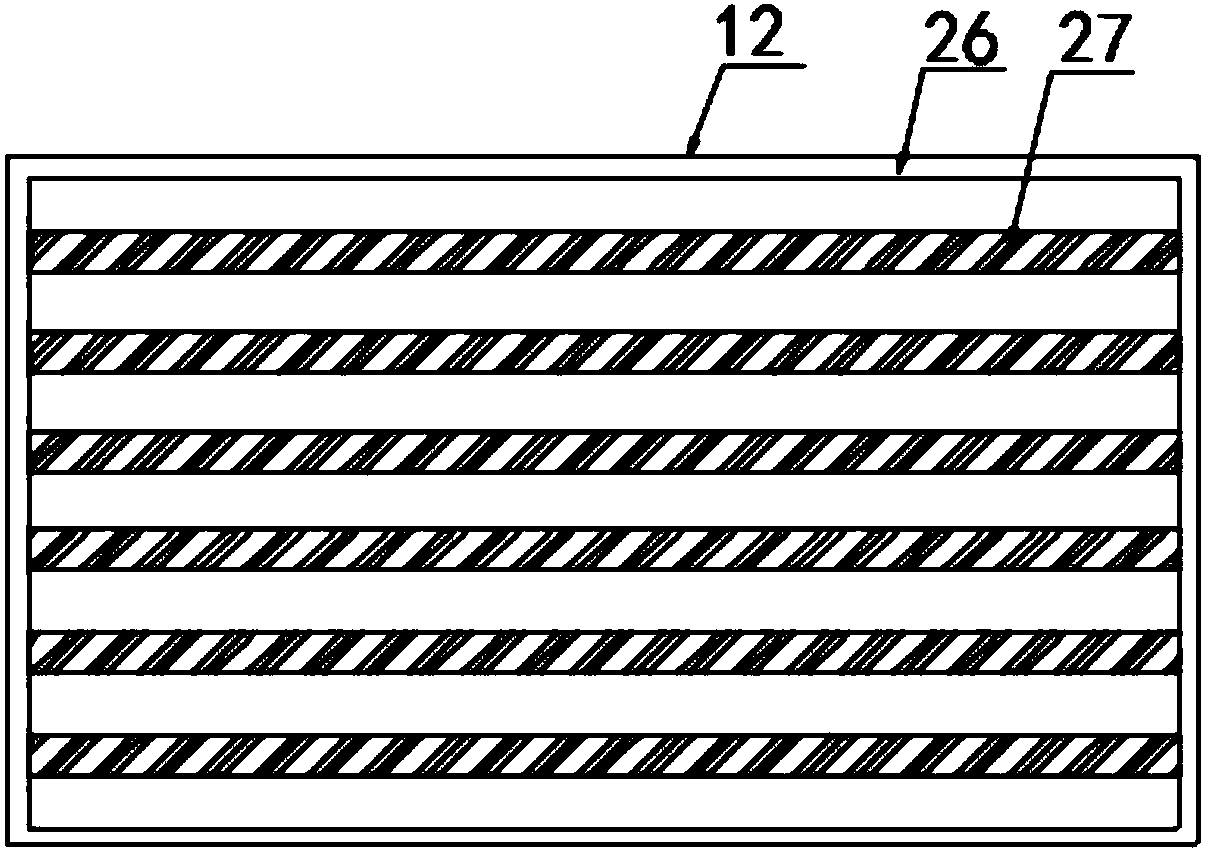

Filmmaking and assembly method and pressing process of tobacco stalk laminated plate

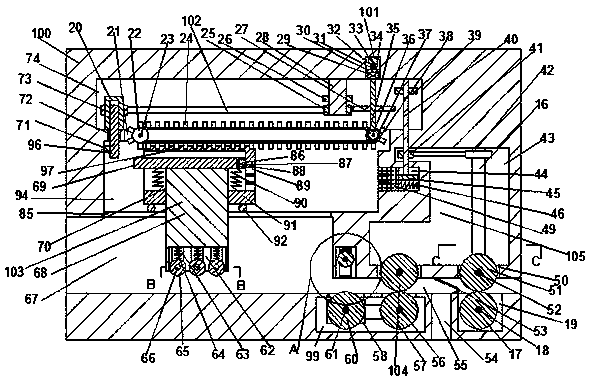

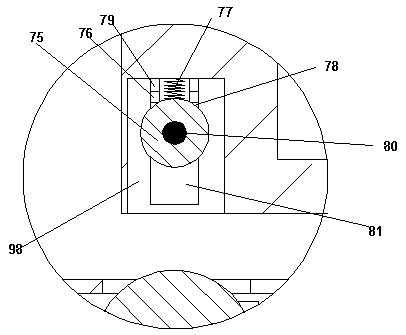

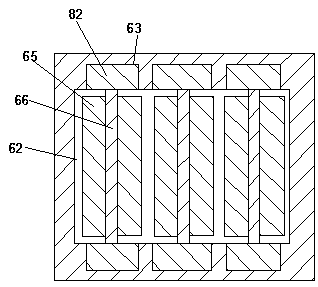

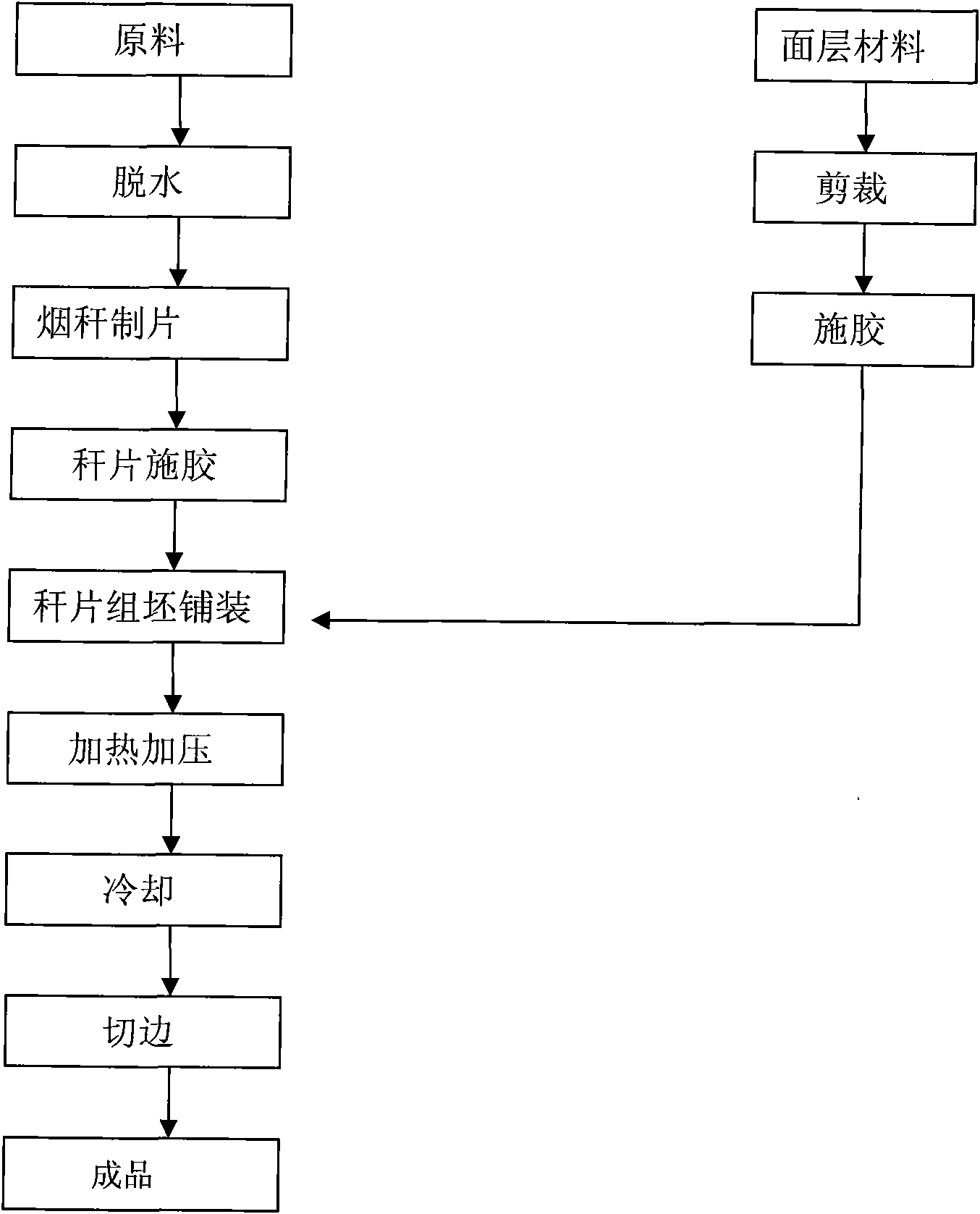

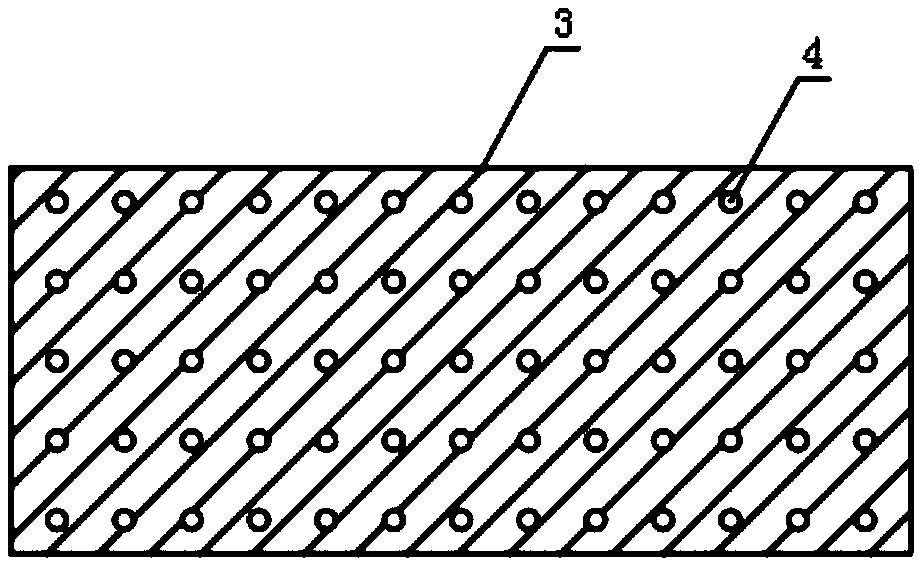

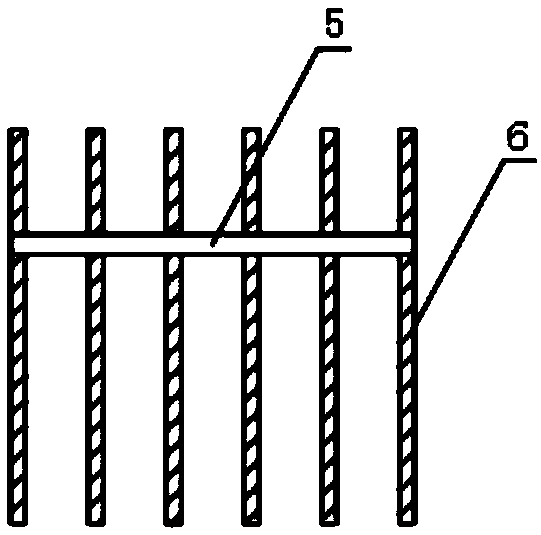

InactiveCN101607409AHigh strengthEasy to apply glueCane mechanical workingOsier rod peelingManufacturing cost reductionPlant stalk

The invention relates to a filmmaking and assembly method and a pressing process of a tobacco stalk laminated plate, which belong to the production industry of non-wood plant stalk plates, in particular to a filmmaking and assembly method and a pressing process of the tobacco stalk laminated plate, which are used for producing a man-made plate by using tobacco stalks as raw materials to replace wood. Aiming at various defects existing in the production process and the technical formulation of the non-wood plant stalk man-made plates, the invention designs a tobacco stalk filmmaking method and an assembly paving method as well as a pressing process. The invention can effectively improve the plate strength, simplifies the production procedure, and lowers the manufacture cost; and the specific procedure can be detailed in the description.

Owner:刘金忠

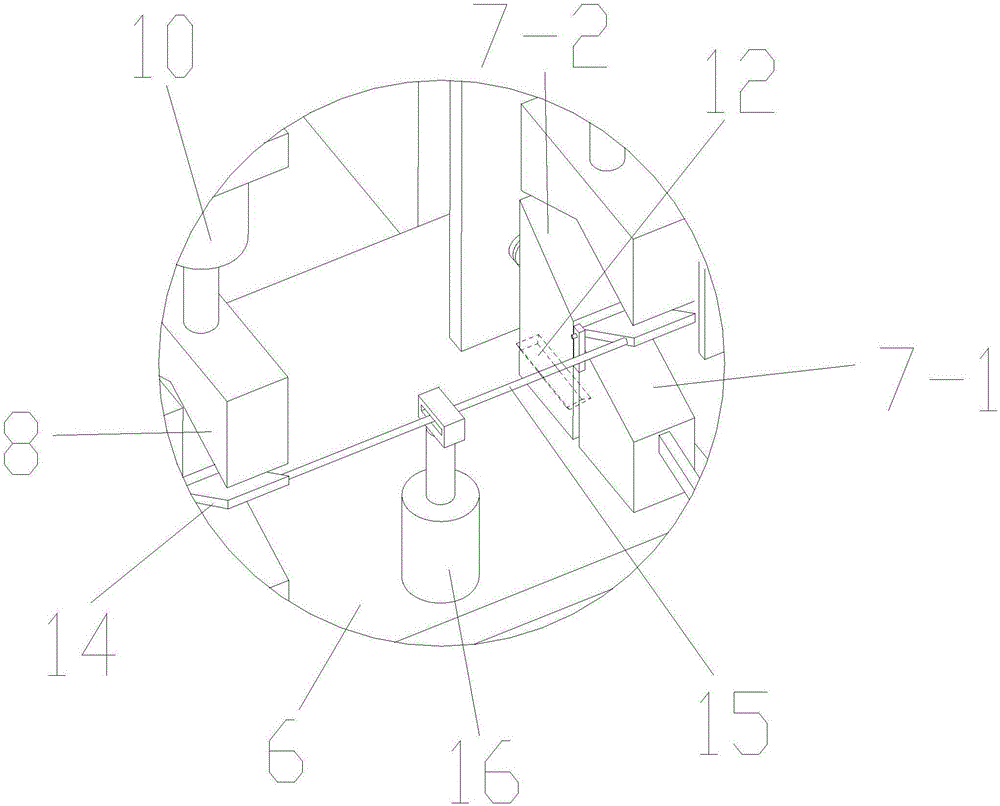

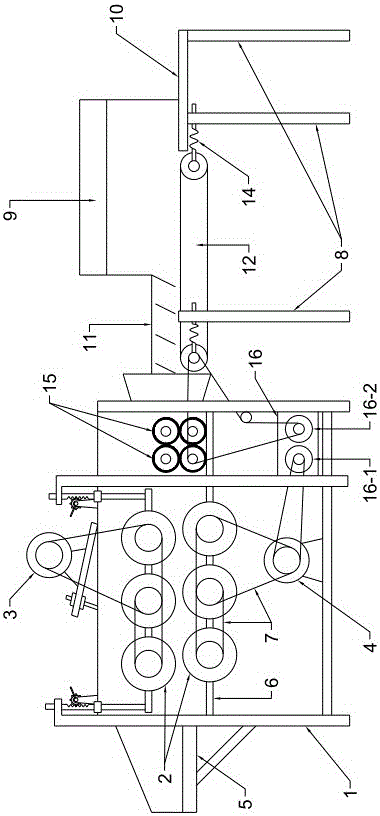

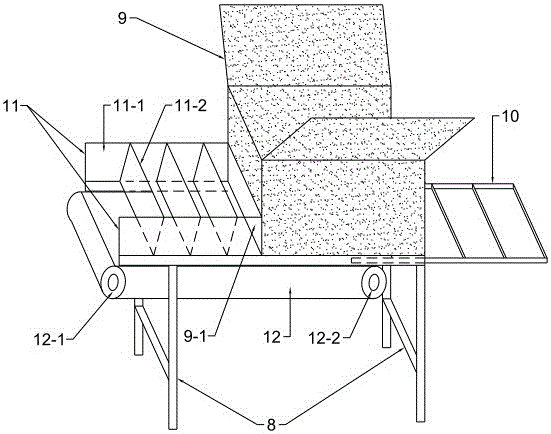

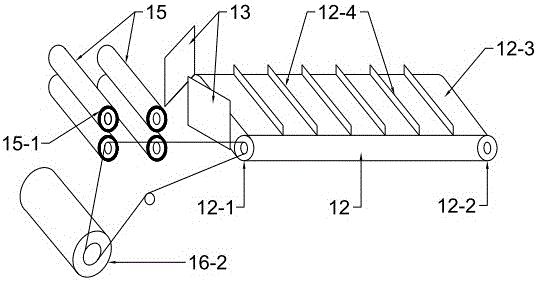

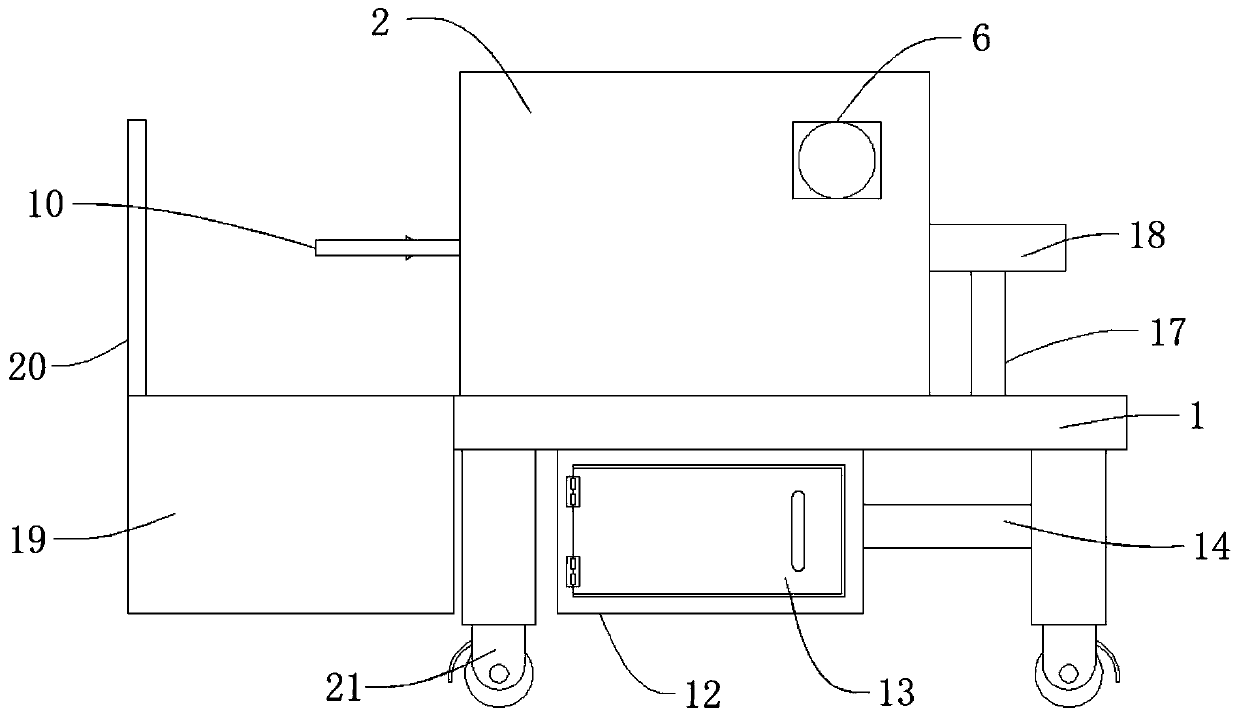

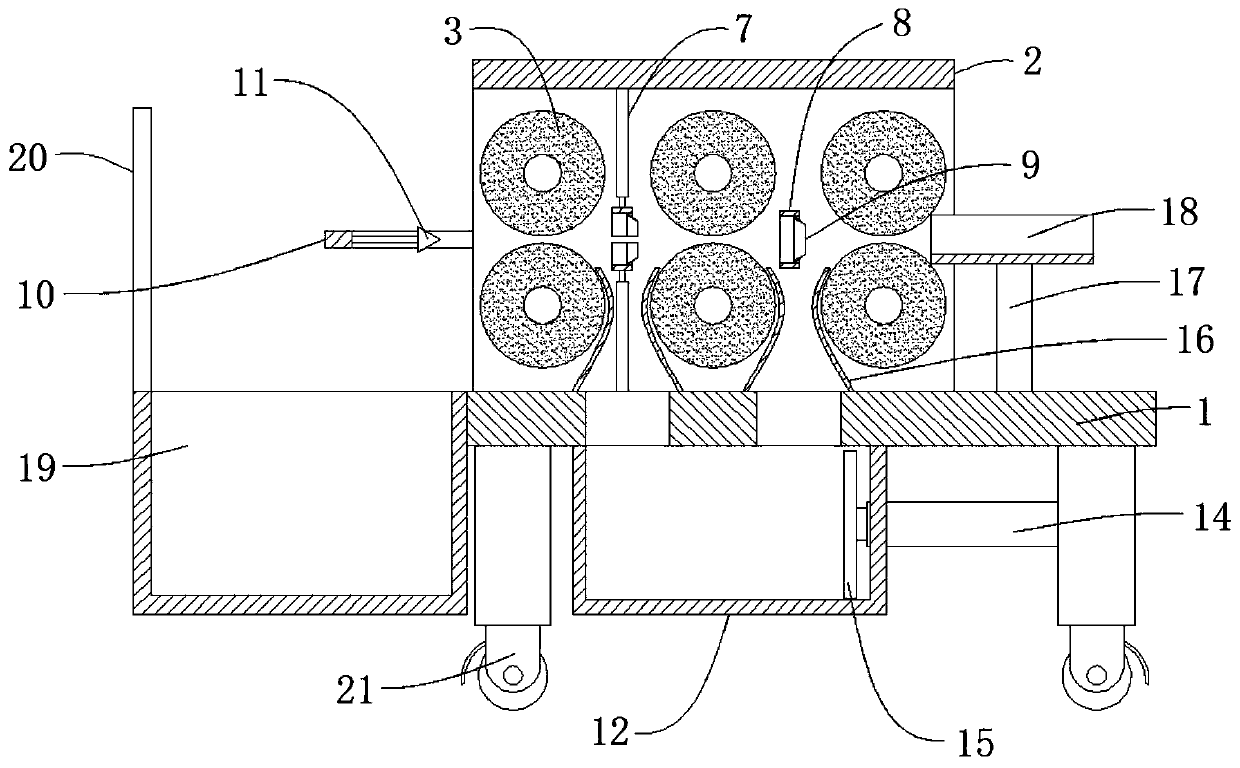

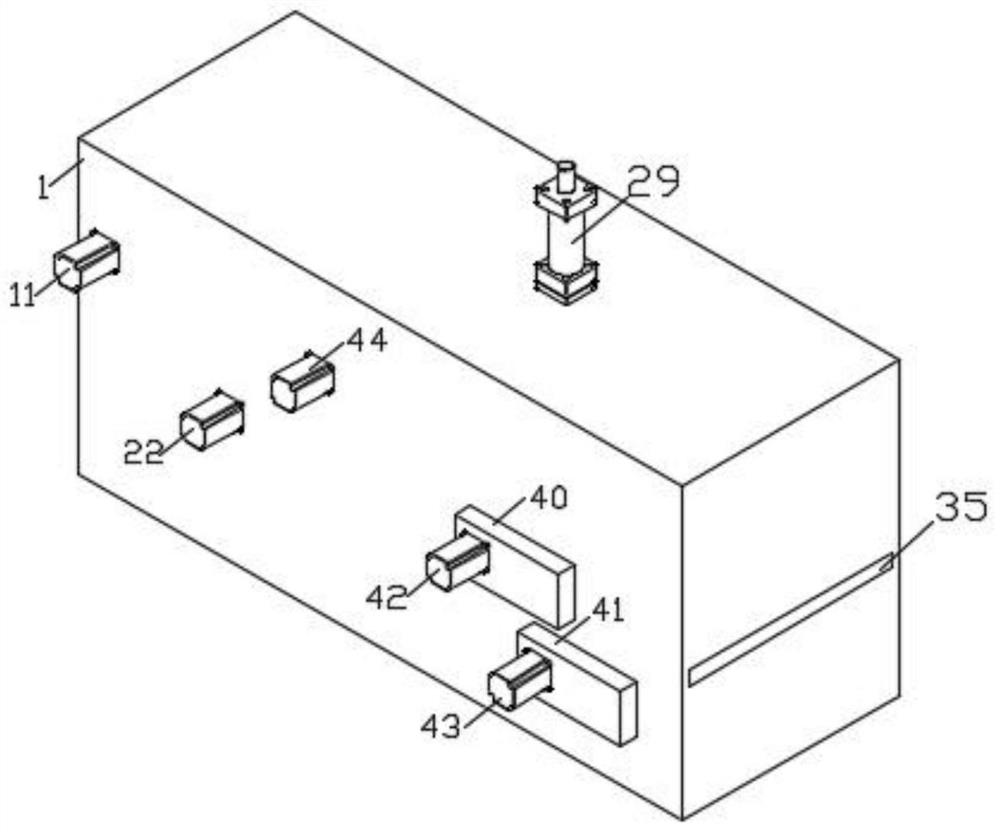

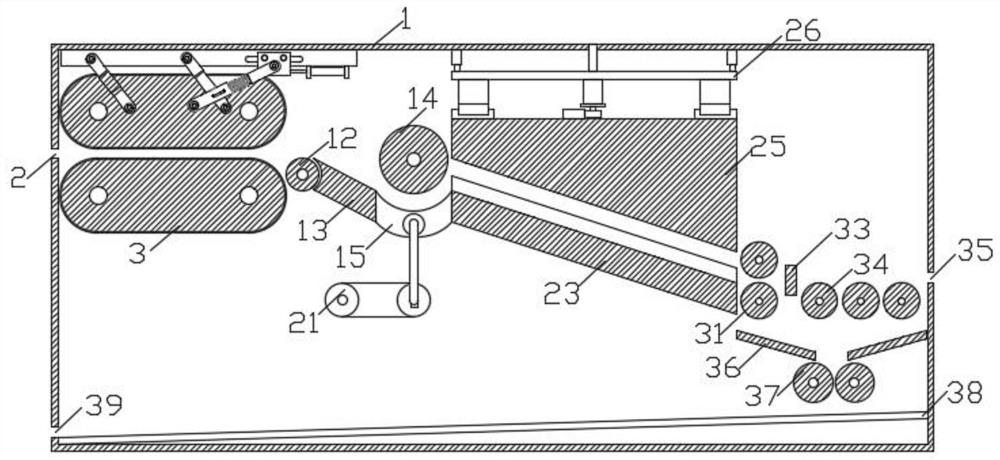

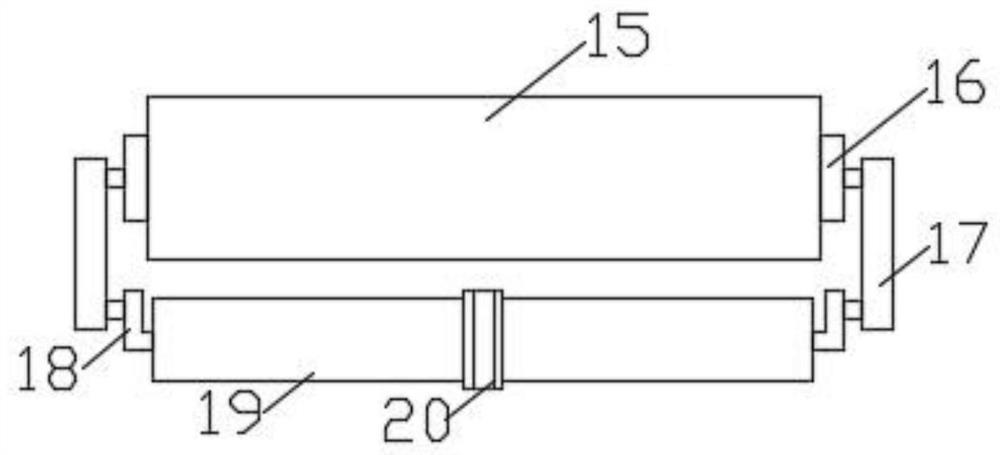

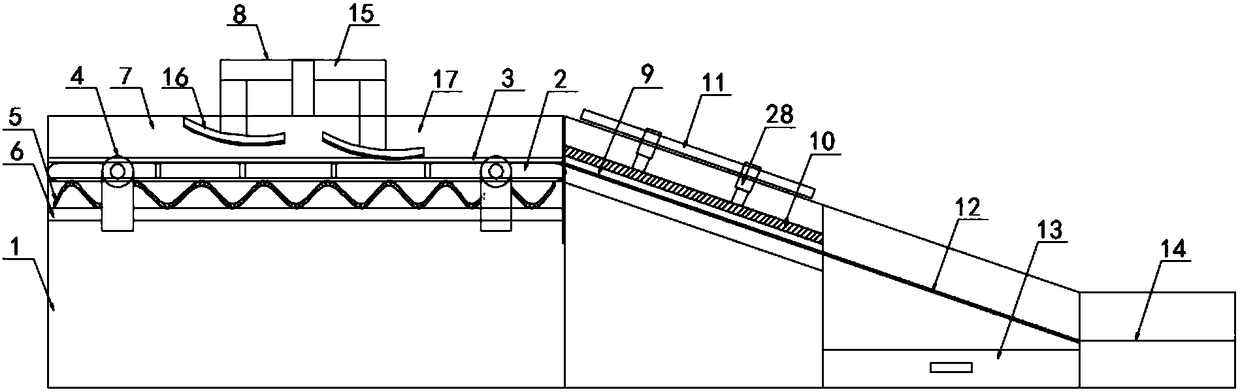

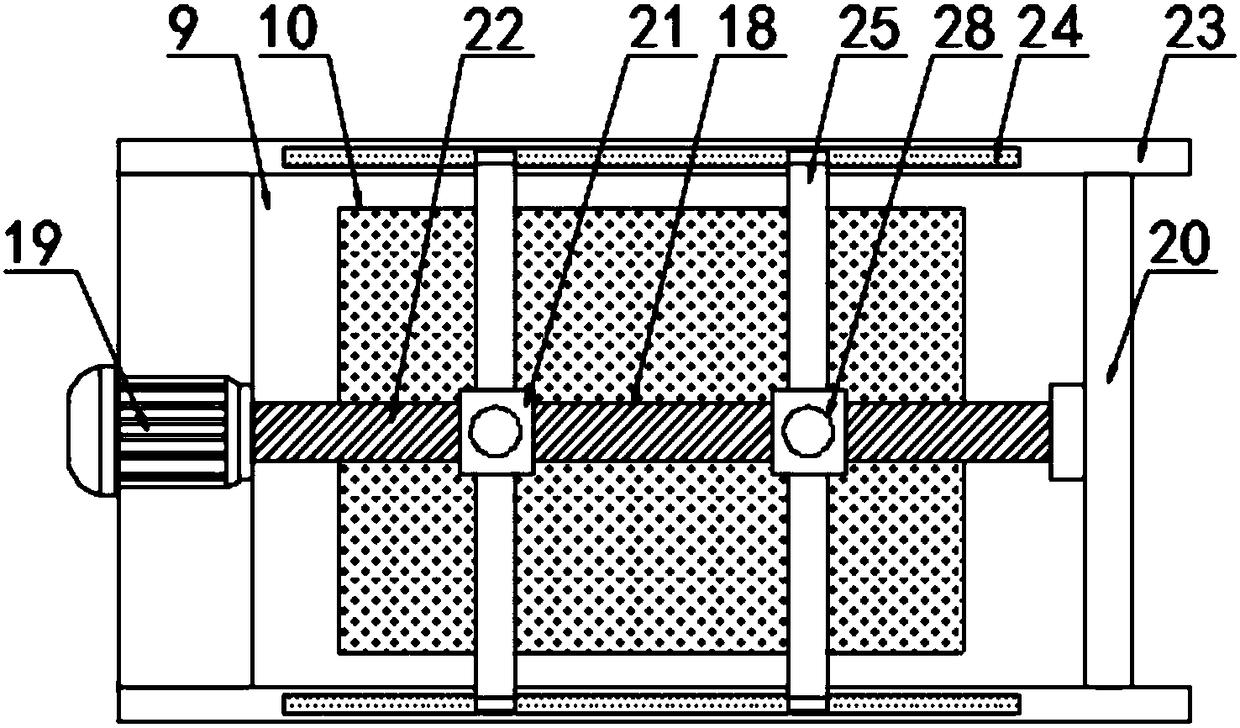

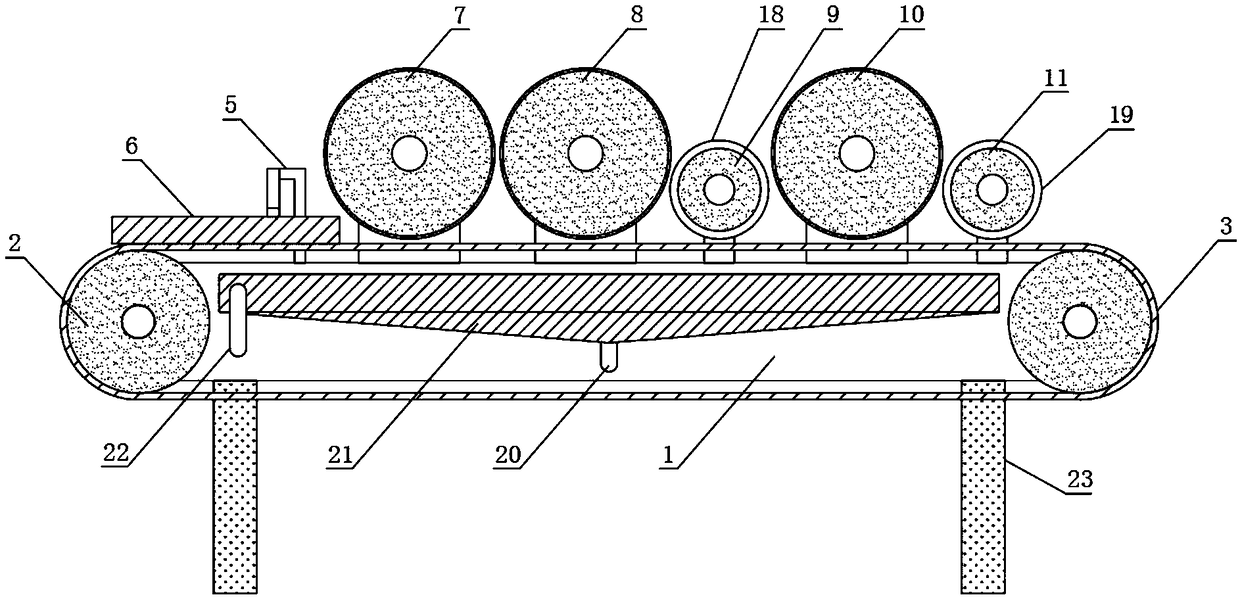

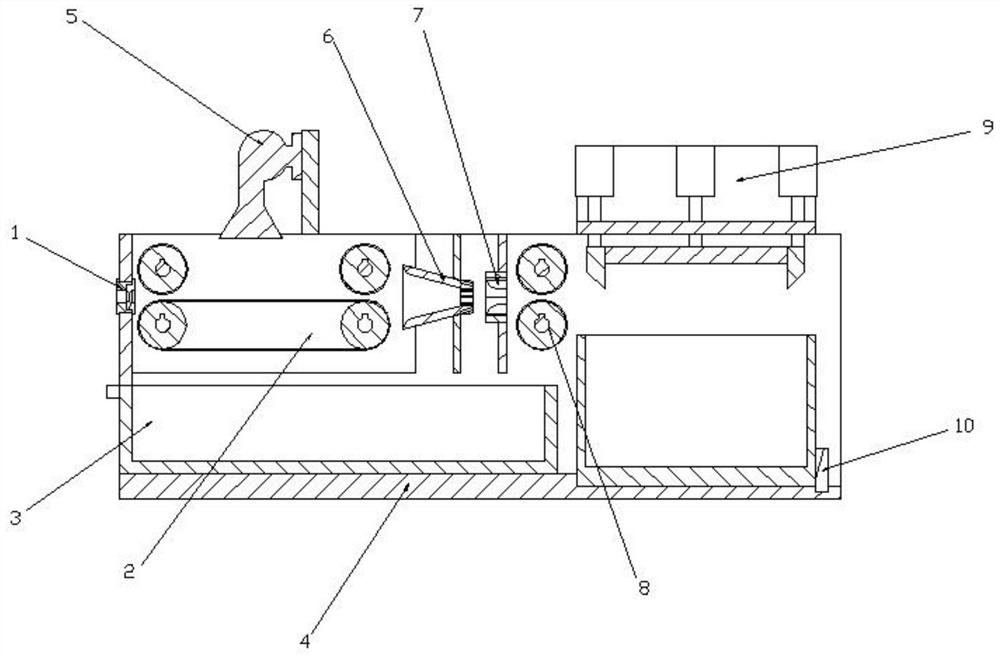

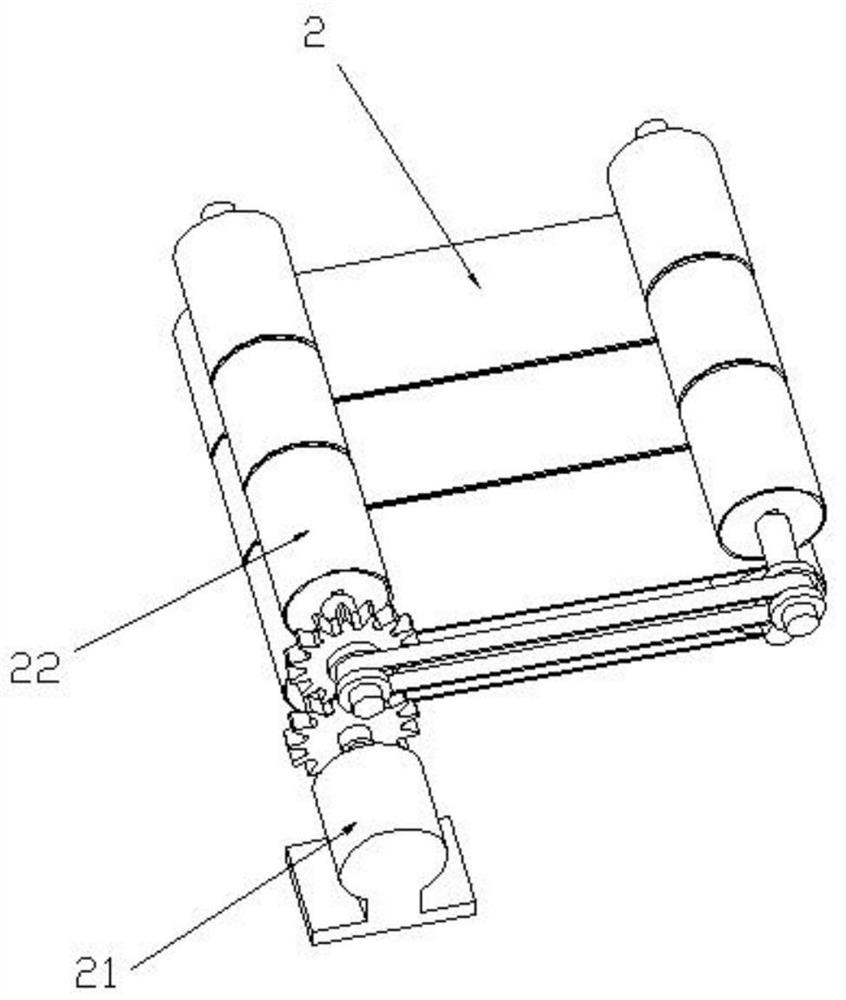

Automatic-feed-type reed peeling machine

ActiveCN107433663AProtect your healthExtended service lifeConveyorsOsier rod peelingReducerEngineering

The invention relates to the technical field of the automatic mechanical equipment and in particular to an automatic-feed-type reed peeling machine. The automatic-feed-type reed peeling machine comprises a peeling mechanism and an automatic feed mechanism. The peeling mechanism is formed by three pairs of upper and lower steel wire rollers, a first motor, a second motor, a reducer, a roller distance regulating device, a discharging port and a peeling machine frame. The automatic feed mechanism is formed by a feed machine frame, an active material bracket, a gliding-type hopper, a feeding machine, a one-way guiding channel, a belt conveyor, and a feeding port. The belt conveyor is formed by a main belt wheel, a driven belt wheel, a conveying belt, a tooth-shaped scraper blade and a conveyor tensioning device. The structure and design of the automatic-feed-type reed peeling machine are rational, a worker does not need to execute the feeding continuously beside the machine, the feeding process is automatically completed by the machine, the labor force is greatly saved, the body health of the worker is protected, the feeding process is rapid, uniform and stable, the working efficiency is greatly improved, the problem of non-uniform wearing of a wire brush can be overcome, and the service life is prolonged.

Owner:崔吉华

Method for fabricating bricks, planks, and strips by using outer skin of straw of corn or kaoliang

InactiveCN101049710AExtensive resourcesEasy to prepareOsier rod peelingDomestic articlesBrickAdhesive

A technology for manufacturing brick, board, or bar with the stalks of corn and sorghum includes such steps as cutting short by needed length, removing leaves and pitch, spreading a paper on the bench, spraying adhesive, spreading the pre-treated stalks and spraying adhesive layer by layer, pressing, solidifying and cutting by required sizes.

Owner:张俊峰

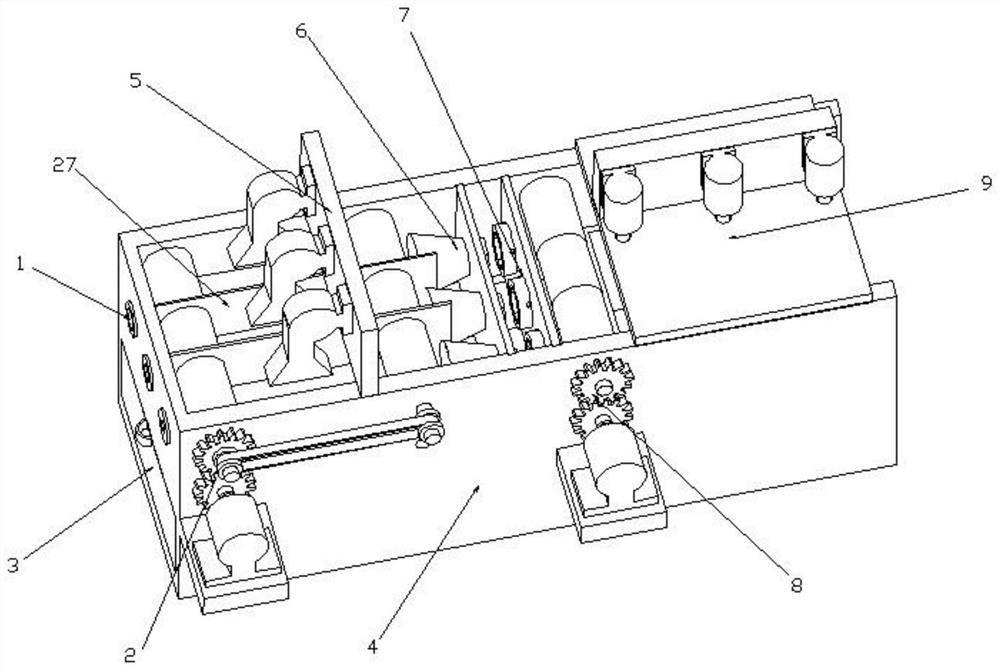

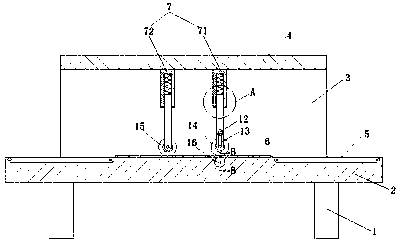

Wicker slicing device for wicker products

InactiveCN111360957AEffective peelingImprove processing efficiencyCane mechanical workingOsier rod peelingRolling-element bearingGear wheel

The invention relates to the technical field of weaving equipment, and discloses a wicker slicing device for wicker products. The wicker slicing device for wicker products comprises a workbench, wherein a U-shaped plate is fixedly connected to the upper end of the workbench; two group of rotating shafts are rotatably connected to the upper end and the lower end of the inner side wall of the U-shaped plate through rolling bearings separately; the shaft walls of the two groups of rotating shafts are fixedly sleeved with transmission rollers; the shaft walls of the three rotating shafts of each group are fixedly sleeved with belt pulleys; the belt pulleys on the same side are jointly in transmission connection through a belt; the shaft wall of one of the rotating shafts in each group is fixedly sleeved with a gear, and the two gears are in meshed connection; and a motor is fixedly connected to the upper end of the front outer side wall of the U-shaped plate. According to the wicker slicing device for the wicker products, peeling and slicing can be integrated, the processing efficiency of wicker is improved, the production efficiency of the wicker products is improved accordingly, people can produce and use the wicker products conveniently, meanwhile, waste can be stored and collected, and the storage capacity is high.

Owner:霍邱县淮美奇工艺品有限公司

Peeling device for rattan processing and working method thereof

InactiveCN111975900AImprove fracturing effectGood peeling effectCane mechanical workingWood working apparatusEngineeringRattan

The invention discloses a peeling device for rattan processing and a working method thereof. According to the device and the method provided by the invention, a rattan is primarily squeezed by a squeezing plate between two conveyer belts, then, the rattan is subjected to secondary squeezing through an arc-shaped groove and a squeezing roller, an outer skin of the rattan is squeezed to be cracked through squeezing twice, meanwhile, the rattan subjected to primary squeezing is in a straight state, the rattan subjected to secondary squeezing is in a bending state, the outer skin of the rattan issqueezed to be cracked under the two states, and an effect of cracking through squeezing is excellent. In the peeling device, after the outer skin of the rattan is squeezed to be cracked, the rattan is robbed repeatedly through a rubbing block and a second guide plate, some outer skins of a surface of the rattan are rubbed away, by design of a ring-shaped separation plate on a first guiding roller, the rattan is enable to be orderly corresponding to cutting holes on a cutting board so as to be peeled, peeling effect is excellent, and the peeling device can simultaneously satisfy peeling of theouter skins of multiple rattans.

Owner:阜南县欣园柳编工艺品有限公司

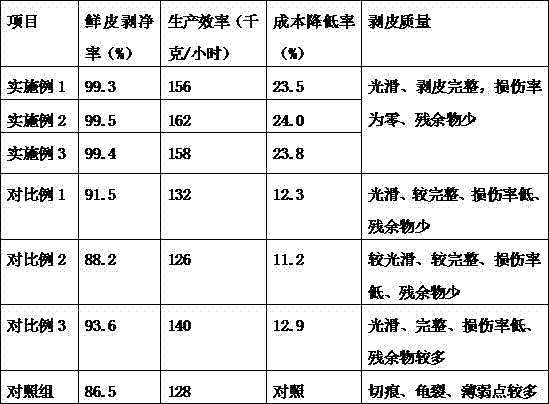

Efficient peeling method for salix integra

InactiveCN108748494AGood effectImprove cleanlinessRadiation/waves wood treatmentElectric wood treatmentSalix integraChemistry

The invention discloses an efficient peeling method for salix integra. The efficient peeling method comprises the following steps of: (1) pre-treating salix integra; (2) soaking the salix integra; (3)loosening peel of the salix integra; and (4) peeling the salix integra. The efficient peeling method is high in peeling efficiency on salix integra, is good in effect, improves processing benefits, and is of a great popularization and application value.

Owner:阜南县柳祥工艺品有限公司

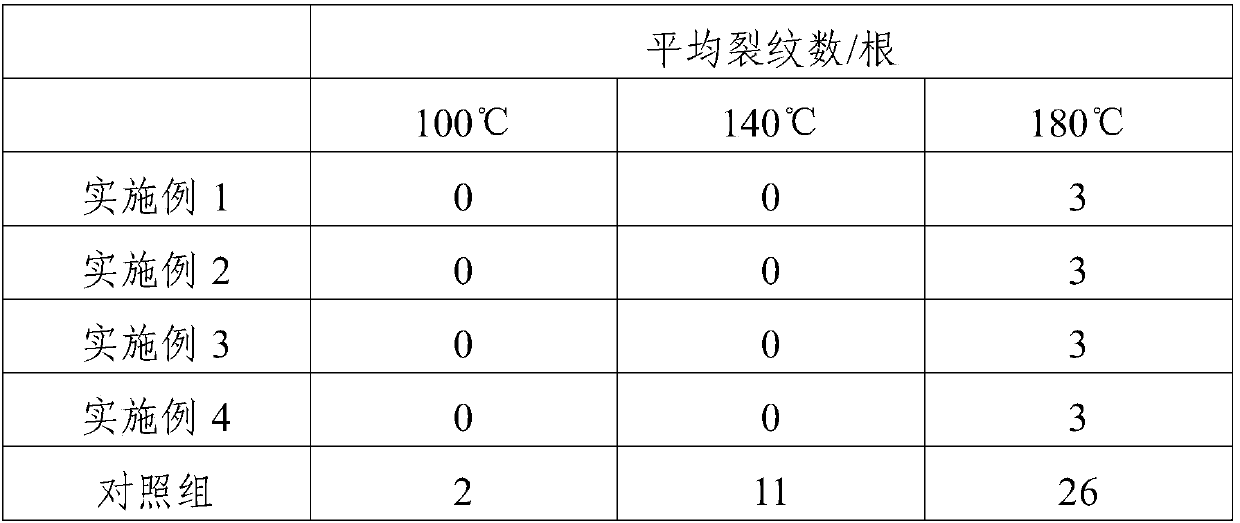

Purple willow anti-cracking treatment method

InactiveCN107599098AGuaranteed StrengthGuaranteed toughnessReed/straw treatmentOsier rod peelingWarm waterWater content

The invention provides a purple willow anti-cracking treatment method and relates to the field of wickers. The purple willow anti-cracking treatment method comprises the following steps that ripe andfresh purple willows are harvested and immediately peeled off, and the wickers are obtained accordingly; the wickers are dried in the sun and stored for 10-15 days; clean water is sprayed on the stored wickers till the water content of the wickers is 20-30%, moisturizing is conducted for 2-3 h, and the wickers are placed in warm water with the temperature of 30-45 DEG C to be steeped for 20-30 min; the steeped wickers are placed in an anti-cracking treatment solution to be steeped for 3-5 h, then taken out and washed with clean water; and the wickers are placed in a stabilizer to be steeped for 1-2 h under the temperature of 55-70 DEG C, taken out, washed with clean water and then dried in the sun, and thus the anti-cracking purple willow wickers are obtained. According to the purple willow anti-cracking treatment method, the simple effect is achieved, operation is easy, the prepared wickers are suitable for being stored for a long time without cracking, meanwhile cracking does not occur in the weaving process, and the very good using value is achieved.

Owner:阜南县润杨家居有限公司

Peeling method for weaving material for wickerwork

ActiveCN107379164AHas a lubricating effectSimple peelingWood treatment detailsReed/straw treatmentEngineeringAlkaloid

The invention relates to the technical field of wickerwork crafts and discloses a peeling method for a weaving material for wickerwork. The peeling method includes the following steps that firstly, the fresh weaving material is put into newly-prepared limewater, a large amount of heat generated through the reaction is used for heating and permeating the peel of the weaving material, a tough peel part can be well peeled to form a layer, alkali liquor has a certain lubricating effect, a joint part cannot be damaged, and the bone and peel separation efficiency is high; secondly, the partly-peeled weaving material is put into self-made bubbling water to be soaked for several hours, a large amount of saponin and alkaloid are contained in the bubbling water, surface tension can be reduced, the surfaces of all bubbles in the solution can be surrounded by the saponin to form a film, the bubbles are durable and do not disappear, an antibacterial action is achieved, and the fresh peel peeling rate is further increased; and thirdly, the treated weaving material is peeled easily and is cleaned and cured after being peeled, few residues are removed, and sterilizing and softening functions are achieved as well.

Owner:FUNAN TENGBO ARTS & CRAFTS CO LTD

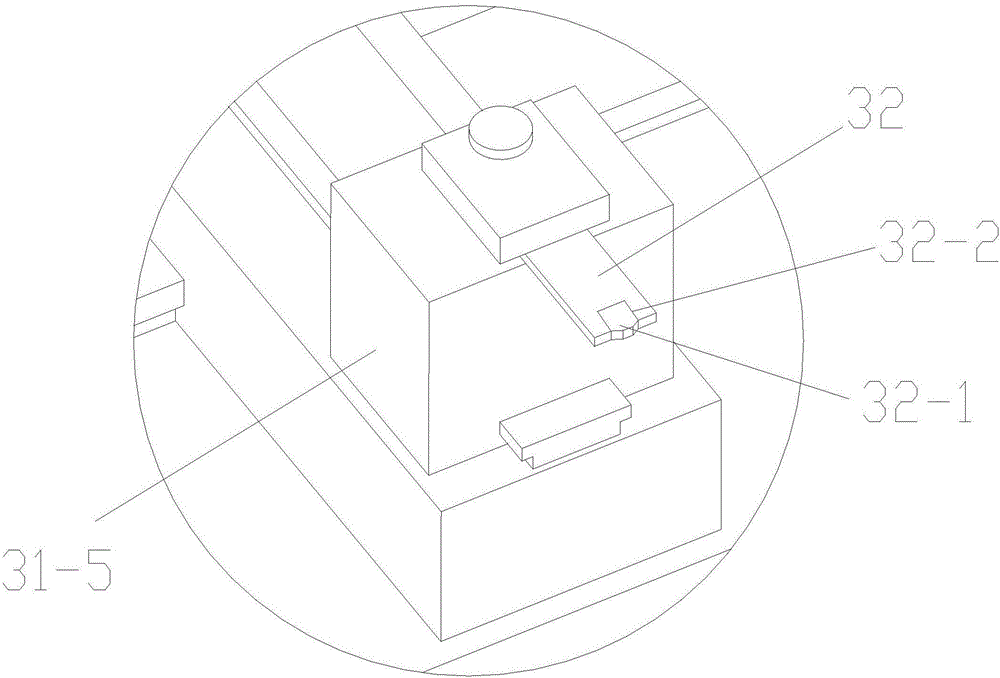

Original rattan peeling and branch knot removing device for rattan woven product

InactiveCN112692943AEasy accessGuaranteed smooth and no bumpsOsier rod peelingIrregularity removal devicesGear wheelRing cutter

The invention discloses an original rattan peeling and branch knot removing device for a rattan woven product. The device comprises a rack, wherein a strip feeding mechanism and a strip tidying mechanism are arranged on the rack at intervals, and a ring cutting mechanism is arranged between the two mechanisms; the ring cutting mechanism comprises symmetrically arranged middle supports, a ring cylinder is arranged between the middle supports, the ring cylinder is supported by rollers symmetrically arranged on the middle supports, a gear ring is arranged on the outer surface of the middle of the ring cylinder, the gear ring is meshed with a main gear, the main gear is connected to a hanging bracket in a hanging mode, the hanging bracket is fixedly connected in the rack, the side wall of the ring cylinder is through and is provided with supporting rods, the inner ends of the supporting rods are connected with a cutter holder, a ring cutter is arranged on the cutter holder, and the supporting rods are further sleeved with springs; and positioning is carried out through a pressing roller and a pressing strip, so that the rattan can enter in a straight line, and left-right movement is avoided; and meanwhile, the pressing roller can move up and down to be suitable for entering of rattans with different thicknesses, then the rattans are cut and peeled through the linkage ring cutter, so that the rattans spirally advance, finally, branch knots on the rattans are ground and removed through the cooperation of an upper peeling wheel and a lower peeling wheel, and the smooth and salient-point-free rattans are guaranteed.

Owner:ANHUI MEIJING ARTS & CRAFTS CO LTD

Wicker peeling device

InactiveCN108527567AConvenient nesting workRealize jitter feedingOsier rod peelingRear quarterFixed frame

The invention discloses a wicker peeling device comprising a working table. The top of the working table is provided with a conveyor belt of which the outer side is provided with a fixed frame, and one side of the fixed frame is provided with a vibrating motor; the bottom of the fixed frame is provided with an elastic plate of which the bottom is provided with a sound-absorbing pad, and the both sides of the top of the working table are provided with side plates; the top of the conveyor belt is provided with a discharging device, and one side of the working table is provided with a sanding sloping desk of which the top is provided with a pressing plate; the top of the pressing plate is provided with a driving device, and one side of the sanding sloping desk is provided with an oblique material leaking plate of which the bottom is provided with a material receiving drawer; and one side of the oblique material leaking plate is provided with a material receiving plate. According to the wicker peeling device, the conveyor belt is vibrated through the vibrating motor for dispersing and conveying materials, and then wickers are spread into a layer through the discharging device; finallythe wickers are compacted and ground through the sanding sloping desk, and the whole device is simple in structure, and the peeling speed of the wickers is high; and the wickers can be machined on a large scale, and the machining cost is low.

Owner:霍邱县淮美奇工艺品有限公司

High-quality peeling method for wickerwork raw materials

Owner:安徽三和工艺品有限公司

Peeling machine used for wicker processing

The invention discloses a peeling machine used for wicker processing. The peeling machine used for wicker processing comprises a workbench, wherein supporting legs are fixedly connected with two sidesof the bottom of the workbench, a connection board is fixedly connected between the supporting legs at the two sides, a protection cover is fixedly connected with the top of the workbench, a first driving device, a second driving device and a third driving device are sequentially arranged on a surface of the workbench from left to right, a transverse cutting device and a longitudinal cutting device are sequentially arranged at the portions, located between the first driving device and the second driving device, at the top of the workbench, the longitudinal cutting device comprises a rotatingroller, a longitudinal cutter is arranged on a surface of the rotating roller, the longitudinal cutter is spirally arranged, a fixing frame is arranged at the portion, located between the second driving device and the third driving device, between two opposite sides of inner walls of the protection cover, and multiple peeling clamps are arranged at the top of the fixing frame. By means of the peeling machine used for wicker processing, the problems that according to traditional wicker peeling machines, wicker is not peeled thoroughly, the peeling efficiency is low, and the wicker is liable tobe damaged are solved.

Owner:GP TOPARTS MFR ANHUI

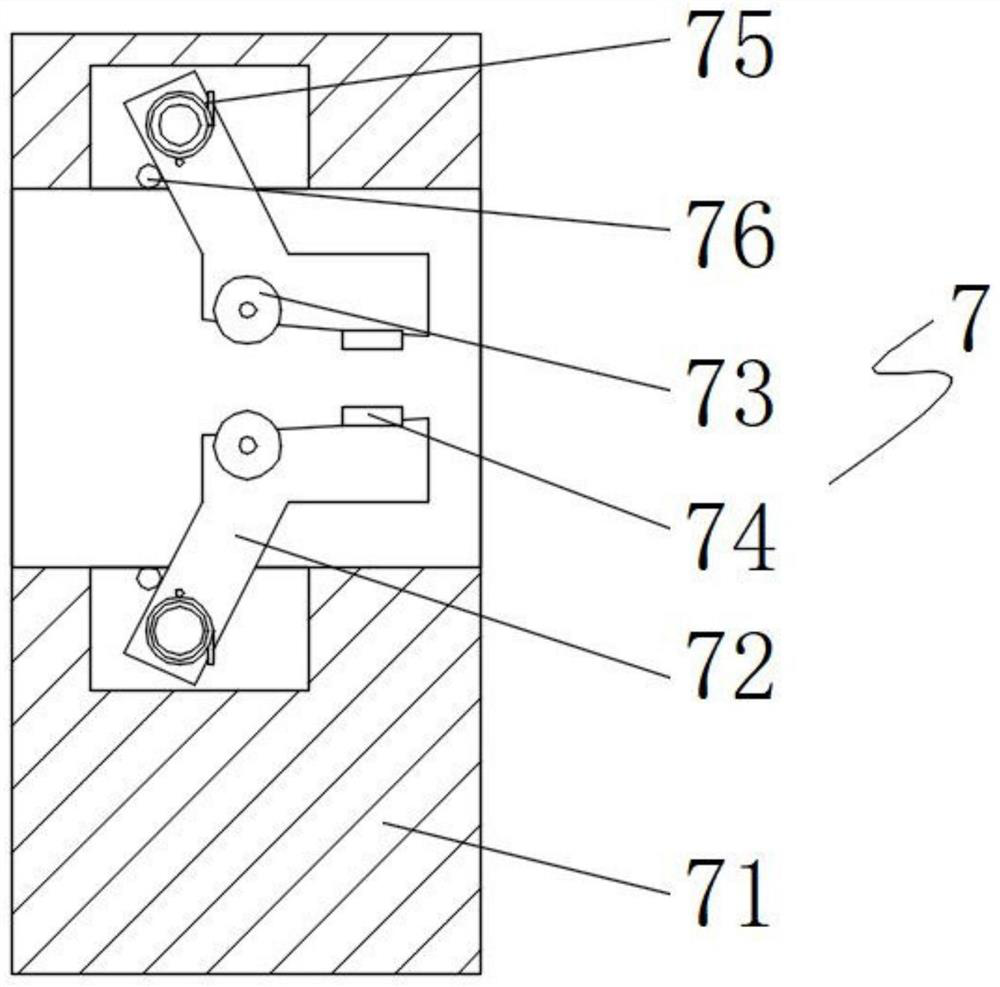

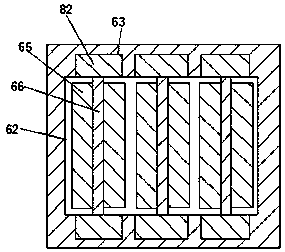

Stripping device of wicker stripping machine

The invention discloses a stripping device of a wicker stripping machine. The stripping device comprises lathe bodies, a conveying roller set is arranged between the lathe bodies, the outer side of the conveying roller set is sleeved with a conveying belt in a connected manner, a slag outlet hole penetrates the conveying belt, an installing support is fixedly arranged on the tops of the lathe bodies, a plurality of separating plates are fixedly arranged on the bottom end of the installing support, a first grinding roller is arranged on one side of the installing support, a second grinding roller is arranged on one side of the first grinding roller, a skin removing roller is arranged on one side of the second grinding roller, a third grinding roller is arranged on one side of the skin removing roller, and a polishing roller is arranged on one side of the third grinding roller. By means of the stripping device, wickers roll back and forth on the conveying belt, and therefore wicker surface layer fiber looseness and cracking are facilitated; and meanwhile, it can be guaranteed that the wicker outer surfaces can be in contact with a steel brush layer, and therefor the good surface layer removing effect is achieved, the polishing effect can be more even, and the quality of the polished wickers is guaranteed.

Owner:霍邱县淮美奇工艺品有限公司

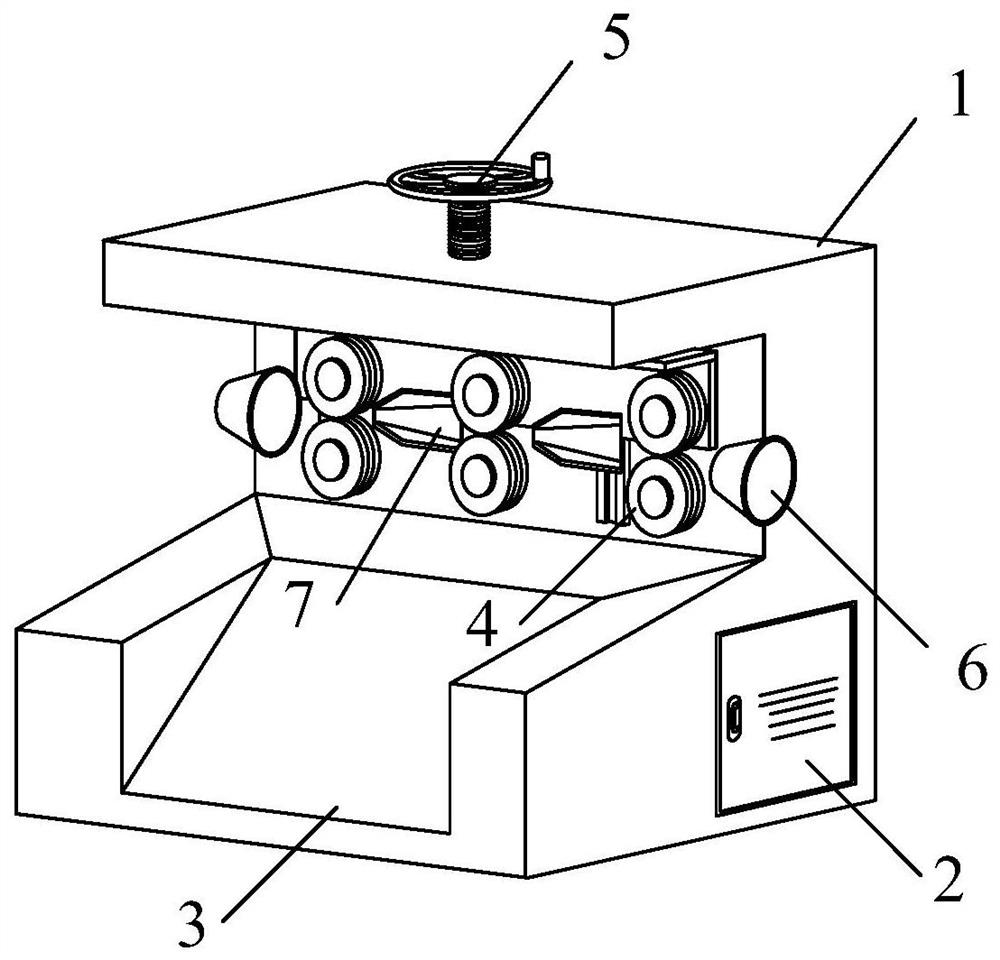

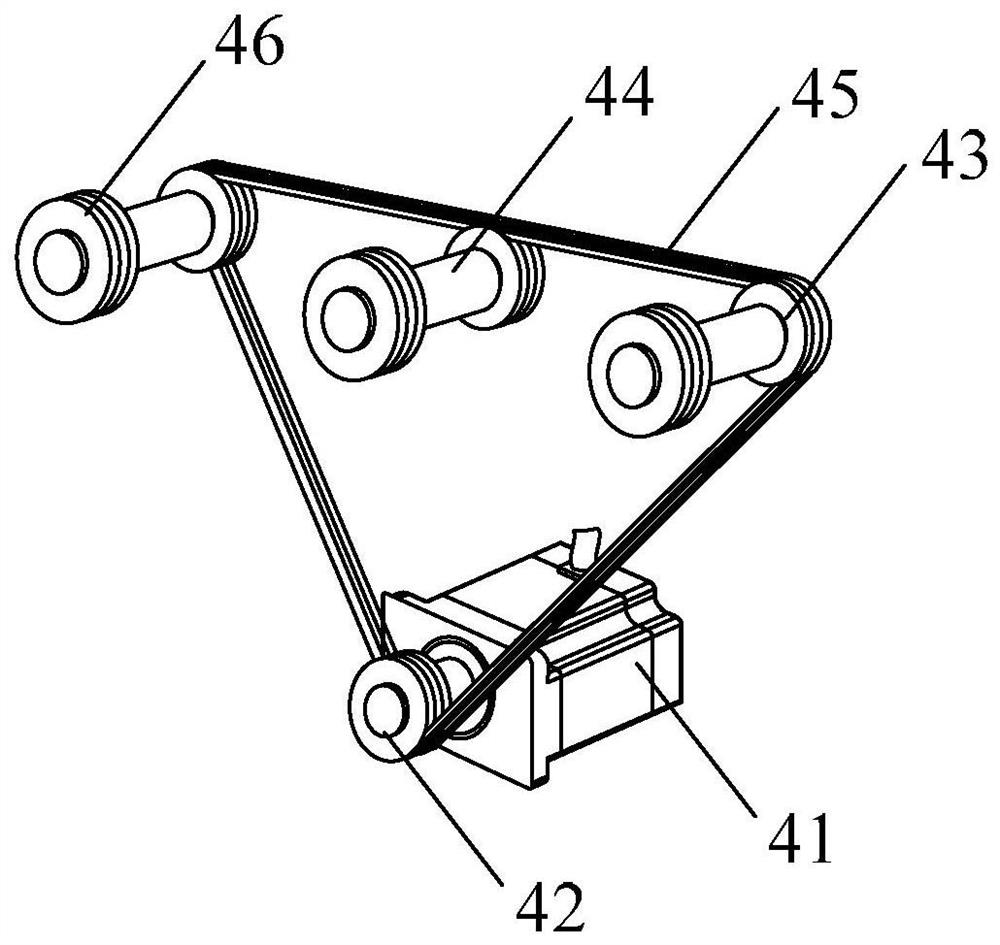

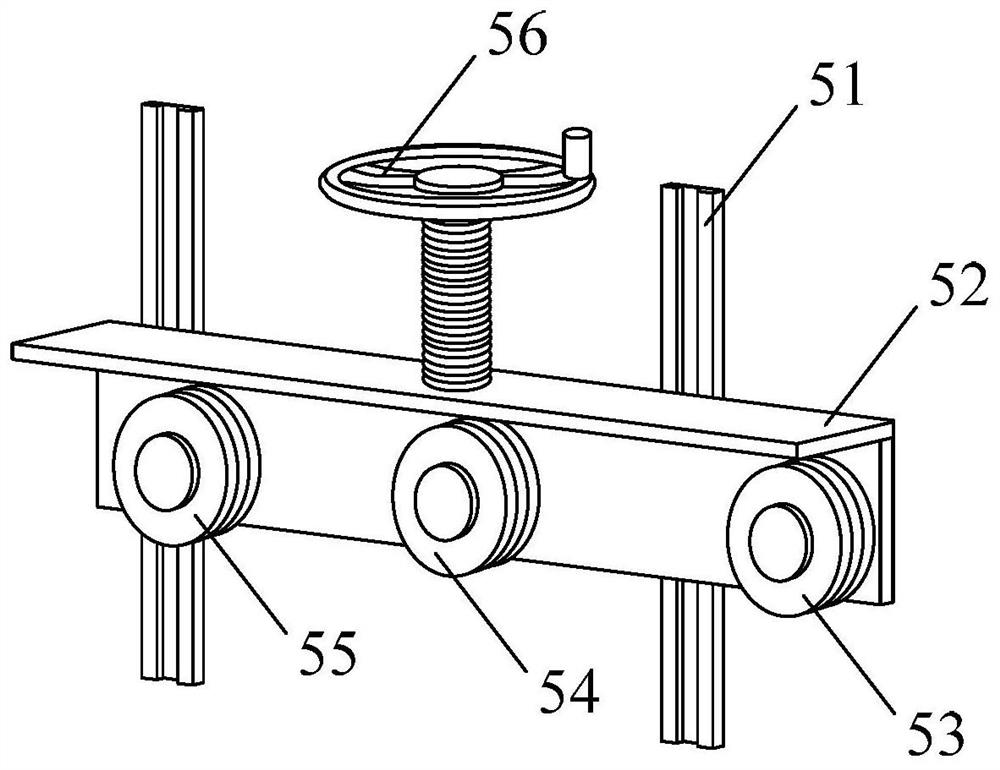

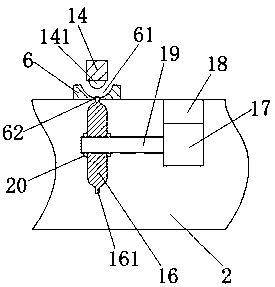

Wicker peeling extrusion wheel adjusting device

The invention discloses a wicker peeling extrusion wheel adjusting device which comprises a machine shell, a transmission mechanism and an extrusion wheel adjusting device. In the wicker peeling extrusion wheel adjusting device, by arranging the transmission mechanism, a transmission motor drives a driving wheel to rotate, driven wheels drive transmission shafts provided with transmission wheels to rotate under the cooperation of a belt, and when wickers are placed on the transmission wheels and a first extrusion wheel, the transmission wheels drive the wickers to be conveyed; through the arrangement of the extrusion wheel adjusting device, when thin wickers are peeled, a hand wheel screw rod is rotated, thus a mounting plate provided with the first extrusion wheel, a second extrusion wheel and a third extrusion wheel moves downwards on sliding rails so that the transmission wheels can make close contact with the first extrusion wheel, it is guaranteed that the thin wickers can be successfully conveyed, and the slipping phenomenon is prevented; and by arranging a horn mouth, wickers can accurately enter the transmission wheels and the first extrusion wheel and prevented from deviating during continuous wicker feeding.

Owner:阜南县金源柳木工艺品有限公司

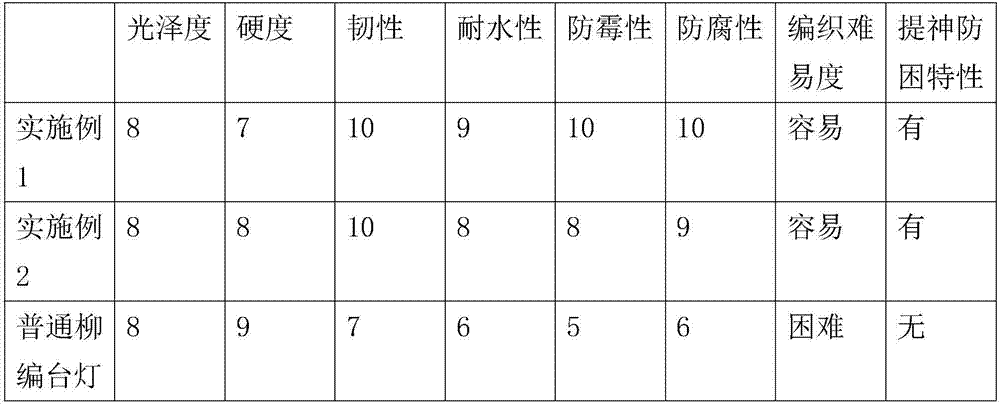

Manufacturing method of refreshing and anti-sleeping wicker desk lamp

InactiveCN107457872AImprove softening effectStrong toughnessWood treatment detailsCane mechanical workingEngineeringReagent

The invention discloses a manufacturing method of a refreshing and anti-sleeping wicker desk lamp. The manufacturing method comprises the following steps that (1) wicker and willows are used as a raw material; (2) the willows are soaked with saline water, then are taken out, air-dried and peeled and are manufactured into a desk lamp base and a desk lamp support rod; (3) the wicker is air-dried until leaves are dried up, and then the leaves are removed; (4) the air-dried wicker is put into pretreatment liquid for soaking, is taken out and peeled and then is cleaned with clean water; (5) the wicker treated in the step (4) is dried; (6) the dried wicker is soaked with a mixed reagent A and then cleaned; (7) the wicker treated in the step (6) is dried; (8) the dried wicker is soaked with a mixed reagent B and then cleaned; (9) the wicker cleaned in the step (8) is woven into a desk lampshade, and the desk lampshade, the desk lamp support rod and the desk lamp base are manufactured into a desk lamp frame; (10) the manufactured desk lamp frame is blow-dried; and (11) a lamp bulb, a wire and a switch are mounted on the desk lamp frame, and then the finished refreshing and anti-sleepy wicker desk lamp is obtained.

Owner:ANHUI MEIJING ARTS & CRAFTS CO LTD

Method for peeling by adopting wicker rod peeling device

InactiveCN109278138AImprove work efficiencyIncrease diversityOsier rod peelingEngineeringEnergy consumption

The invention discloses a method for peeling by adopting a wicker rod peeling device. The wicker rod peeling device comprises a peeling machine, a motor sliding groove is formed in the peeling machine, a power device is arranged in the motor sliding groove, an adjusting space is formed in the lower end wall of the motor sliding groove, and an adjusting device is arranged in the adjusting space. According to the device, full-automatic peeling of wickers can be completed, so that the defects that for traditional manual peeling, the efficiency is low, and peeling is not clean are overcome, meanwhile, the defects that for a traditional machine, automatic feeding can not be achieved, and one-time multi-piece production can not be achieved are overcome, in the case of the device, through mechanical transmission fit, the working efficiency of the device is improved, moreover, the device can be applied to all the wickers, the possibility of mistakes is reduced, meanwhile, multiple functions are achieved by using two motors, the cost of the device is reduced, and the energy consumption is reduced.

Owner:周识儒

Flame retardant treatment method for weaving rattan of craftwork

InactiveCN106363746AAvoid damp and mildewExtended service lifeWood treatment detailsReed/straw treatmentSodium BentoniteAlcohol

The invention discloses a flame retardant treatment method for weaving rattan of craftwork, and relates to the technical field of weaving technologies. The flame retardant treatment method is characterized by comprising the steps of rattan selecting, scar removing, rattan cleaning, peeling, soaking and drying, wherein in the soaking step, the rattan is soaked through adopting a medicinal liquid; and the medicinal liquid comprises the following components in parts by weight: 0.4 to 0.6 part of iodine, 0.8 to 1 part of polyvinylpyrrolidone, 0.4 to 0.6 part of nonylphenol polyoxyethylene ether, 2 to 3 parts of ethyl alcohol, 80 to 120 parts of purified water and 2 to 3 parts of bentonite. According to the flame retardant treatment method, the rattan is prevented from being affected with damp and going mouldy, worms are not liable to breed, the flame retardant effect is good, the strength is high, and the service life of woven products is prolonged.

Owner:ANHUI MEIJING ARTS & CRAFTS CO LTD

Treatment method for amorpha fruticosa of wickerwork raw material

InactiveCN107160513AEasy knittingEasy to separateWood treatment detailsReed/straw treatmentFiberAmorpha fruticosa

The invention relates to the technical field of wicker handicrafts, and discloses a treatment method of amorpha fruticosa, a willow weaving raw material, comprising the following steps: (1) using a simple and quick method to remove the skin of amorpha fruticosa, reacting quicklime and water to generate a calcium hydroxide solution, It has a lubricating effect, and the reaction releases a large amount of continuous heat, which can accelerate the separation of the epidermis; (2) Treat the dried branches of Amorpha fruticosa with oily liquid A. The treatment agent is compounded with an organic solvent and a surfactant, which can Change the softness and physical and mechanical properties of the branches, avoiding the dehydration of the fibers caused by the direct drying of the branches, and the bonding between the fibers, resulting in the problem that the dried product board is hard, not resistant to bending, and lacks flexibility; (3 ) Coating a layer of oily liquid B on the surface of the woven product can improve the water resistance of the product, and it is easier to carry out surface coating and decoration, and it is not easy to deform under rewetting and drying, and it is easy to clean.

Owner:阜南县宏达工艺品厂

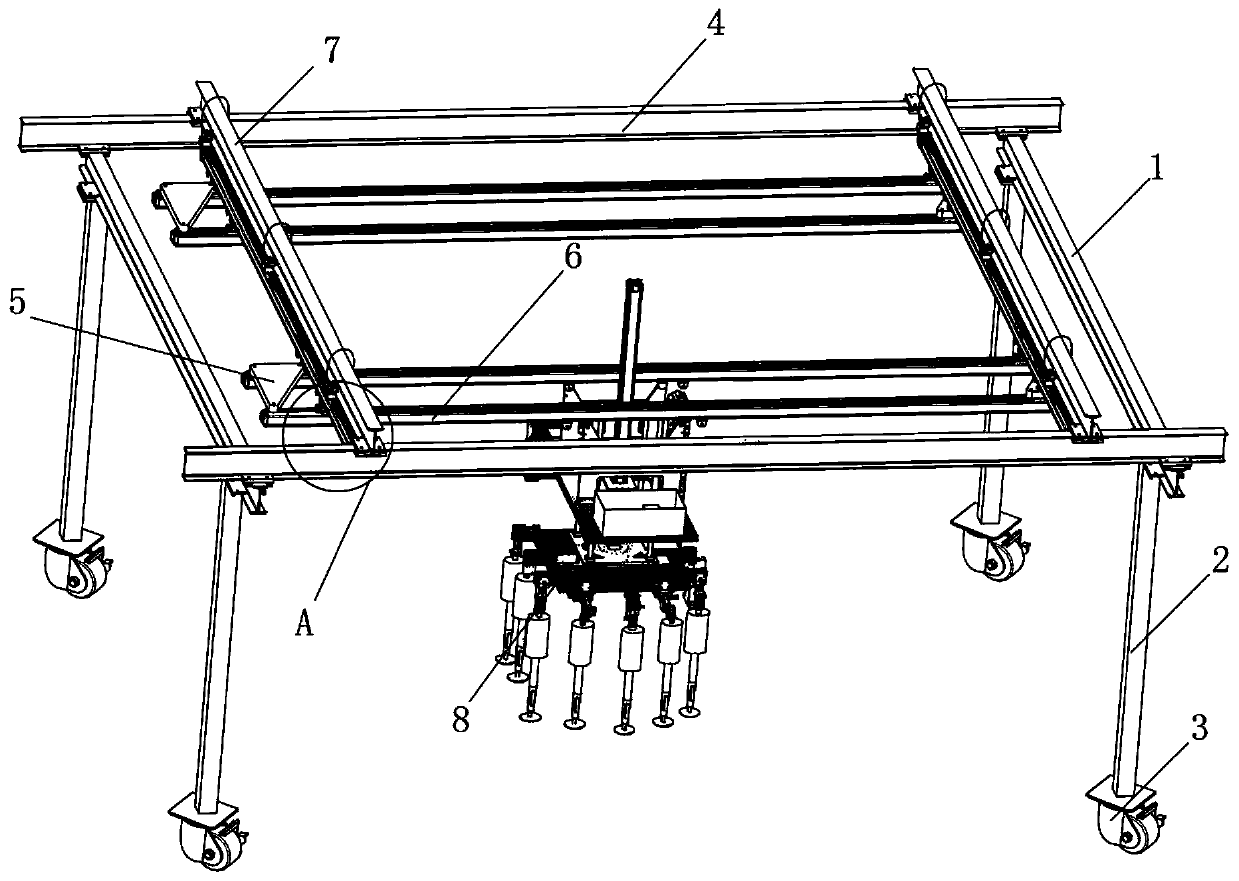

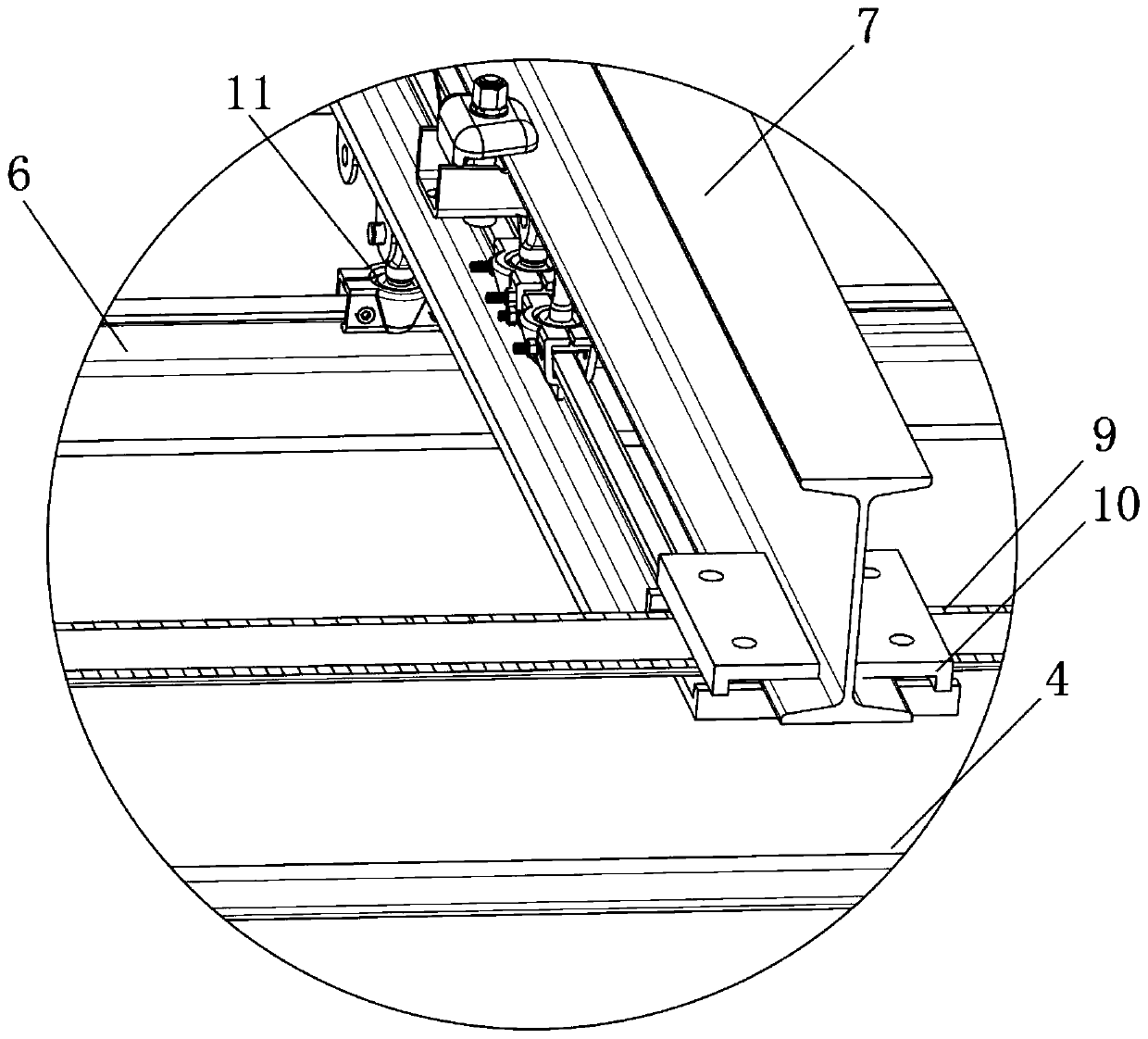

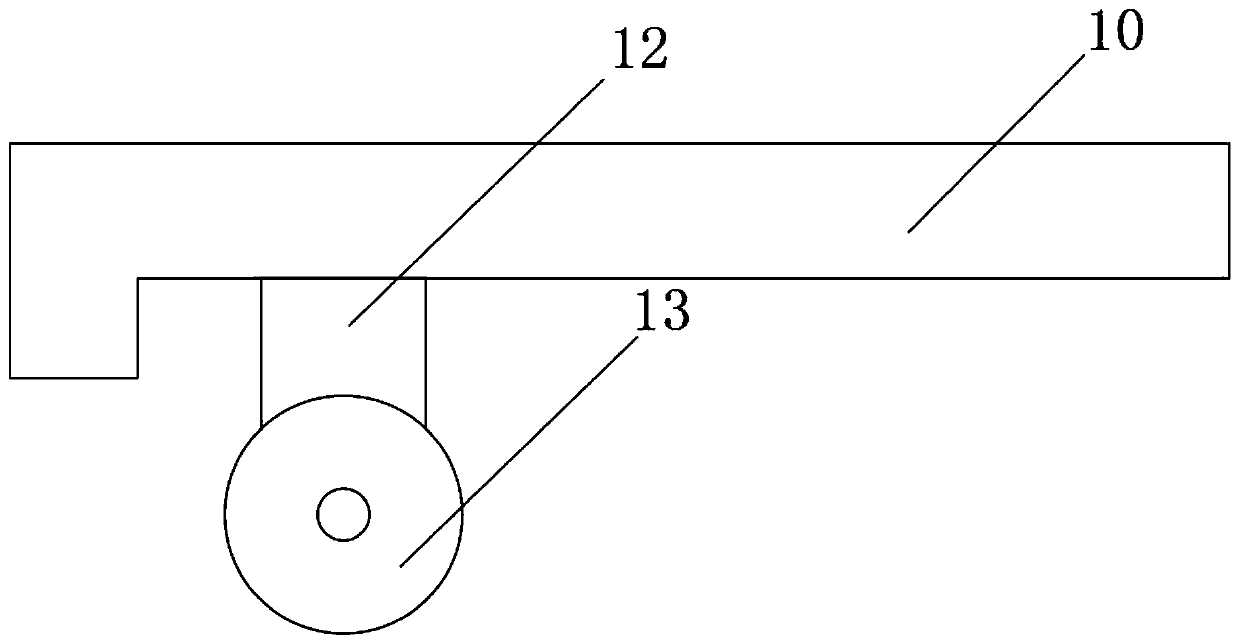

Removing device for wicker external branches

The invention discloses a removing device for wicker external branches. The removing device comprises two first side supporting rods, two second side supporting rods, upper sleeve bases and a carryingmechanism, wherein the first side supporting rods and the second side supporting rods are arranged in parallel, the second side supporting rods are arranged at the two ends of the two first side supporting rods, and the upper sleeve bases are arranged above the two ends of the two second side supporting rods. The removing device has the beneficial effects that a hydraulic oil cylinder drives a rotary cutting plate to move downwards through a telescopic shaft, a sixth motor drives the rotary cutting plate to rotate and cut the branches outside the wicker on the wicker, the working automation degree of the device is high, a fourth motor drives a third roller to roll in a connecting support plate to drive the carrying mechanism to move left and right, the carrying mechanism can be quickly and accurately moved to the upper portion of the bundled wicker to remove branches, the use flexibility and the working precision are guaranteed, a plurality of branch removing mechanisms work synchronously, branches on different branches is removed respectively in a rotating mode, and the work efficiency of the device is greatly improved.

Owner:安徽持家汉家居工艺品有限公司

Wicker peeling device for wickerwork and working method of wicker peeling device

InactiveCN111775248ARemove cleanEfficient removalDrying gas arrangementsProfiling/shaping machinesEngineeringMechanical engineering

The invention discloses a wicker peeling device for wickerwork and a working method of the wicker peeling device. The wicker peeling device is characterized in that a scraping mouth system is fixedlyarranged in the middle of a side plate at the left end of a shell; a first transmission system is fixedly arranged at the left end of the shell; a waste box is slidably arranged inside the bottom endof the left side of the shell; an air drying system is fixedly arranged at the top of the left side of the shell; a first peeling fixture system and a second peeling fixture system are fixedly arranged in the middle of the housing; the second peeling fixture system is arranged on the right side of the first peeling fixture system; the first peeling fixture system is arranged on the right side of the first transmission system; a second transmission system is fixedly arranged in the right side of the shell; a cutting system is fixedly arranged on the right side of the shell; the second transmission system is arranged on the right side of the second peeling fixture system; and the cutting system is arranged on the right side of the second transmission system. According to the wicker peeling device, wickers of different diameter sizes can be processed at the same time, and the wicker peeling effect is good.

Owner:阜南县欣园柳编工艺品有限公司

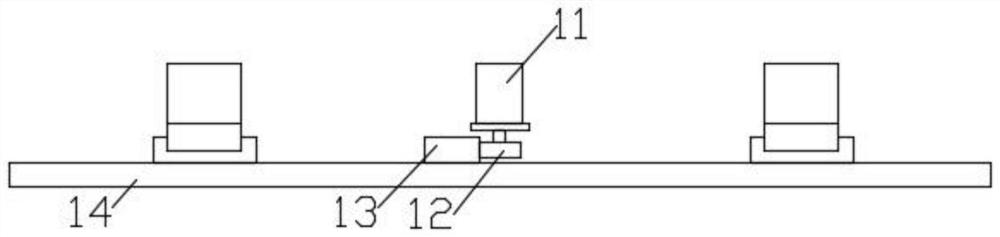

Peeling device of wicker raw material for wickerwork products

InactiveCN111409163AImplement peeling operationsRealize automatic transportationOsier rod peelingDrive wheelElectric machinery

The invention discloses a peeling device of a wicker raw material for wickerwork products, and belongs to the technical field of wickerwork production. The peeling device comprises a base, a working table is arranged on the base, a support is vertically arranged on the working table, a top plate is transversely arranged above the support, and a buffer mechanism is fixed below the top plate; the buffer mechanism specifically comprises a first buffer mechanism and a second buffer mechanism, and each buffer mechanism is composed of a connecting rod, a sleeve and a spring; a driving stepping motorand a driving wheel are further fixed to the bottom of the connecting rod on the first buffer mechanism; a peeling wheel is further fixed at the bottom of the connecting rod on the second buffer mechanism; conveyor belts are further symmetrically arranged on the working table, a guide groove is further formed between the two conveyor belts, and a peeling mechanism is further arranged below the guide groove. By means of the device, high-quality peeling treatment can be conducted on wickers of different specifications, the quality of the treated wickers is high, inner bones cannot be damaged, and the phenomena of peeling jamming, blocking and the like are not likely to happen.

Owner:FUNAN NATURE ARTS & CRAFTS

Wicker bark removal mechanism for wickerwork processing

The invention discloses a wicker bark removal mechanism for wickerwork processing. The wicker bark removal mechanism comprises a processing chamber, two wicker via holes are formed in the two sides ofthe processing chamber, a lifting shell is arranged in the processing chamber, three upper extrusion rollers are arranged in the lifting shell, two lower extrusion rollers are arranged in the processing chamber, and the three upper extrusion rollers and the two lower extrusion rollers are arranged in an up-down staggered manner, a lifting plate is arranged in the processing chamber, an upper pressing plate is slidably mounted at the bottom of the lifting plate, a lower pressing plate is arranged below the upper pressing plate, a rotating cylinder is arranged on one side of the lower pressingplate, two gear rings are mounted on the rotating cylinder, four shaft seats are mounted at the bottom of an inner cavity of the processing chamber, guide wheels are rotatably mounted on the shaft seats, and the four guide wheels are arranged on two sides of the rotating cylinder correspondingly. According to the wicker bark removal mechanism, before wicker bark removal, wicker bark is subjected to fracturing and rubbing treatment, the wicker bark treatment effect is good, the requirement for removing the bark of wicker of different diameters can be met, and the wicker bark can be thoroughly removed through rotation of two blades.

Owner:安徽持家汉家居工艺品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com