Original rattan peeling and branch knot removing device for rattan woven product

A technology for weaving products and rattan, which is applied in the field of devices for peeling and removing side branches from the original rattan for rattan weaving products, which can solve the problems of low work efficiency, time-consuming and labor-consuming, etc. The effect of moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

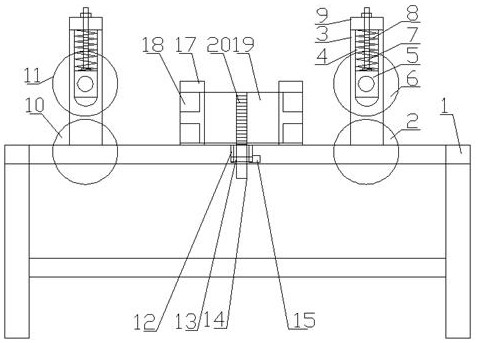

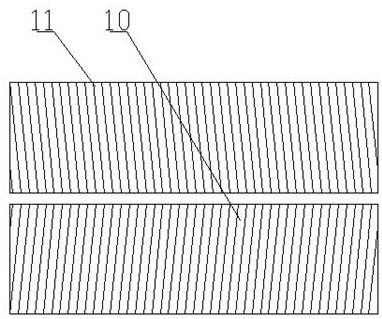

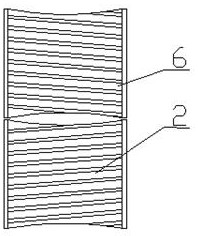

[0022] like Figure 1-5 As shown in , a device for peeling and removing side branches of raw rattan for rattan weaving products, including a frame 1, on which a strip feeding mechanism and a slitting mechanism are arranged at intervals, and a ring cutting mechanism is arranged in the middle of the two mechanisms The circular cutting machine includes symmetrically arranged middle brackets 17, ring cylinders 19 are arranged between the middle brackets 17, and the ring cylinders 19 are supported and connected by rollers 18 symmetrically arranged on the middle brackets 17, and the middle outer surface of the ring cylinders 19 is set The ring gear 20, the ring gear 20 meshes with the main gear 14, the main gear 14 is suspended on the hanger 12, the hanger 12 is fixed in the frame 1, the main gear 14 is connected to the servo motor 15 through the rotating shaft 13, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com