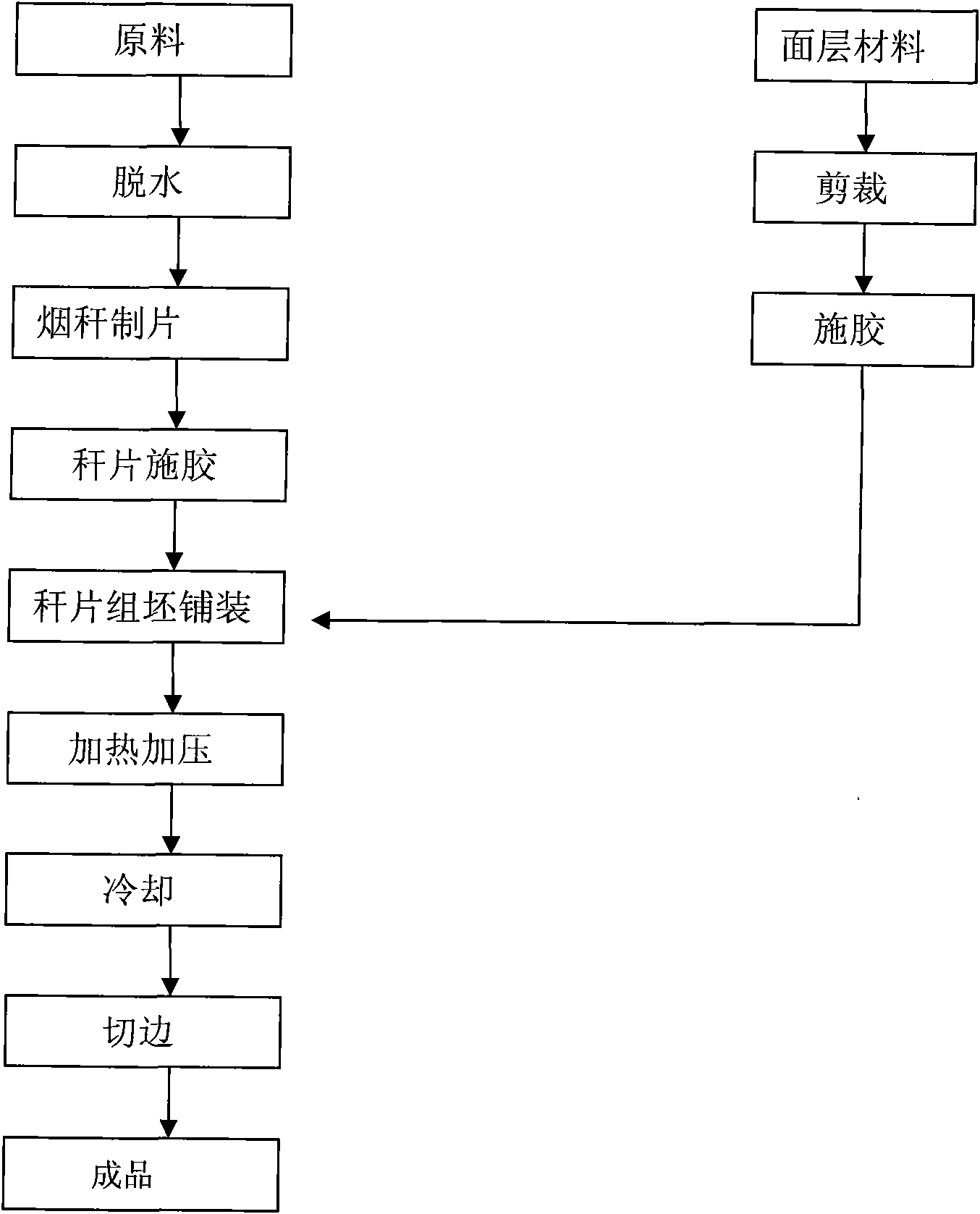

Filmmaking and assembly method and pressing process of tobacco stalk laminated plate

A technology for laminates and tobacco stalks, which is applied in the manufacture of tools, flat products, wood processing appliances, etc., can solve problems such as limited strength, and achieve the effects of improving strength, reducing technological processes, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Firstly, the raw materials should be dehydrated (natural drying and artificial drying) to make the water content <5%, and then the tobacco stalks should be removed and cut into various lengths of 400mm-1500mm. The stalk sections are rolled into sheets with a width of 35mm-65mm, and then the outer skin and pith are removed on special equipment, and then the glue is applied on the gluing machine. 8%-11% of the net weight, the surface layer material is made of 120 grams of corrugated paper or 0.3mm thick wood veneer as the board veneer, first cut the fabric into 2500mm×1300 length×width, then brush glue or spray glue or roll glue, and then Lay the glued fabric on the template, then lay the formwork, and then lay the glued stalks on the surface layer in the same direction and parallel arrangement end to end longitudinally, and then still in the same direction and parallel arrangement end to end in the horizontal direction Lay the second layer of glue-coated stalks in a cris...

Embodiment 2

[0018] The raw materials are dried or air-dried, and the moisture content is less than 5%, so as to ensure that the board does not foam. First, the tobacco stalks are slightly removed, cut into various lengths of 400mm-1500mm, and then processed into 5mm-15mm on special equipment. A variety of stalks of different widths are removed from the outer skin and pith. The stalks processed by this method do not need to be rolled by a pair of rollers, but are directly glued on a roller rubber machine, or sprayed with a glue sprayer. Then 120 grams of corrugated paper or 0.3mm thick wood veneer is cut and glued and laid on the template, then the mold frame is laid, and then the billet is laid in the mold frame. The first layer is arranged end to end in parallel in the longitudinal direction. The glued stalks with different lengths and widths of 5mm-15mm are laid in the mold frame, and the second layer is laid horizontally, which is also arranged end to end in parallel in the same directi...

Embodiment 3

[0020] The surface veneer is 0.2mm thick wood veneer, and the back layer veneer is 90 grams of gypsum board paper to make two layers of veneer on the surface and back of the board. First, lay the cut and glued 0.2mm thick wood veneer on the template, and then lay the mold frame , and then cut into 400mm-1500mm stalk sections, rolled into 35mm-65mm stalk pieces, and then arranged in parallel in the same direction after being glued, connected end to end, criss-cross, and laid repeatedly Lay 7 layers in the form of blank assembly, and then spread 90 grams of gypsum board paper coated with glue on it, then take out the mold frame and lay the template, transfer it to the press, press 7 sheets each time, and use urea-formaldehyde resin glue as the glue. The press is an ordinary wood-based panel press. The pressure is 900 tons, the temperature is 180 degrees, and the pressing time is 12 minutes. Other process conditions are the same as in Example 1, and a qualified plate of 2440mm×12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com