Manufacturing method of refreshing and anti-sleeping wicker desk lamp

A manufacturing method and table lamp technology, applied to lampshades, manufacturing tools, peeling wicker poles, etc., can solve the problems of difficult processing technology, insufficient wicker toughness, lack of refreshment and sleep prevention, etc., so as to achieve easy and labor-saving manufacturing process and scientific and reasonable manufacturing method , Peeling work easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

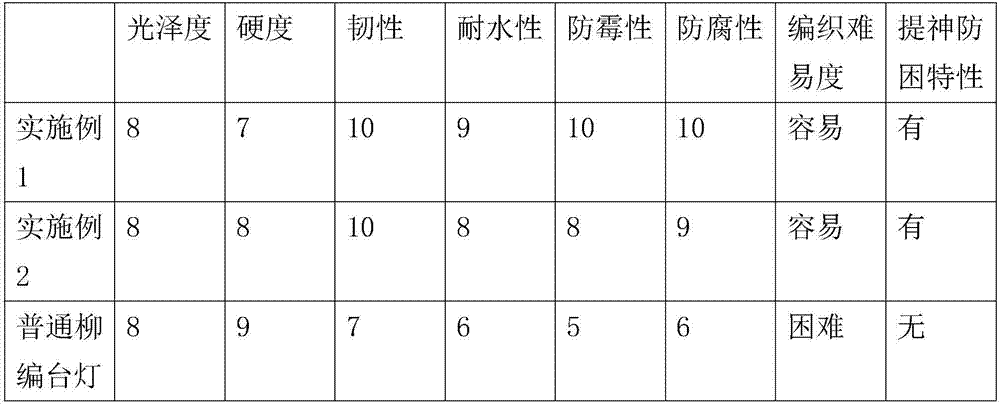

Embodiment 1

[0032] A method for making a wicker table lamp for refreshing and anti-drowsiness, comprising the following steps:

[0033] (1) Select wicker with uniform thickness, good toughness, no damage by diseases and insect pests, and willow wood with hard wood and no moths as raw materials;

[0034] (2) The willow is first soaked in salt water containing 20% salt for 2 hours, and after taking it out, it is placed in the hot sun to dry for 5-7 days. Process it into a desk lamp base and a desk lamp pole, and make grooves on the desk lamp base and desk lamp pole for later arrangement of wires and switches, then put the desk lamp base and desk lamp pole in a cool and ventilated place to dry until the water content is lower than 5 %, then polish the surface, and after removing the burr, install the bottom end of the desk lamp pole to the base of the desk lamp with stainless steel screws, and set aside;

[0035] (3) the wicker is tiled and aired until the leaves are dry, and when the wat...

Embodiment 2

[0048] A method for making a wicker table lamp for refreshing and anti-drowsiness, comprising the following steps:

[0049] (1) Select wicker with uniform thickness, good toughness, no damage by diseases and insect pests, and willow wood with hard wood and no moths as raw materials;

[0050](2) The willow is first soaked in salt water containing 20% salt for 2 hours, and after taking it out, it is placed in the hot sun to dry for 5-7 days. Process it into a desk lamp base and a desk lamp pole, and make grooves on the desk lamp base and desk lamp pole for later arrangement of wires and switches, then put the desk lamp base and desk lamp pole in a cool and ventilated place to dry until the water content is lower than 5 %, then polish the surface, and after removing the burr, install the bottom end of the desk lamp pole to the base of the desk lamp with stainless steel screws, and set aside;

[0051] (3) the wicker is tiled and aired until the leaves are dry, and when the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com