Mulberry twig bark and core stripping machine

A peeling machine, skin-core technology, applied in mechanical equipment, wicker rod peeling and other directions, to achieve the effect of less fiber damage and breakage, reducing mulberry branch debris, and moderate mode of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

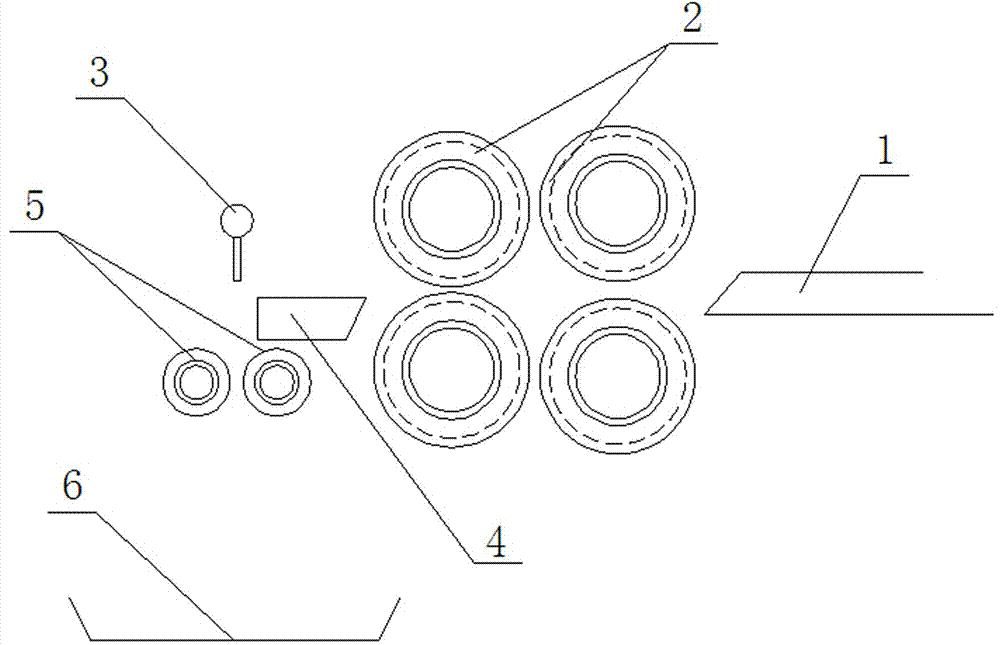

[0019] The invention discloses a peeling machine for mulberry branch skin and core. This machine not only has a major innovation in the design principle, but also optimizes the main structural parameters of the peeling machine, so as to improve the separation rate of the skin and core and peel off the mulberry bark. Integrity, reducing the effect of fiber damage. Its main structure is as figure 1 As shown, several mulberry strips are fed side by side to the feeding trough 1 with the big end in front, and enter the peeling device 2 under the action of the peeling roller. Peeling device 2 is made up of two groups of spiral rollers. Both sets of spiral rollers are pressurized by elastic springs with adjustable pressure. Feeding the mulberry branches, under the moderate pressure of the spiral roller and the reverse twisting force and tearing of the left and right-handed tooth bodies, the mulberry bark will be cracked and peeled off from the branches, and the branches will not be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com