Patents

Literature

39results about "Wood hardening process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

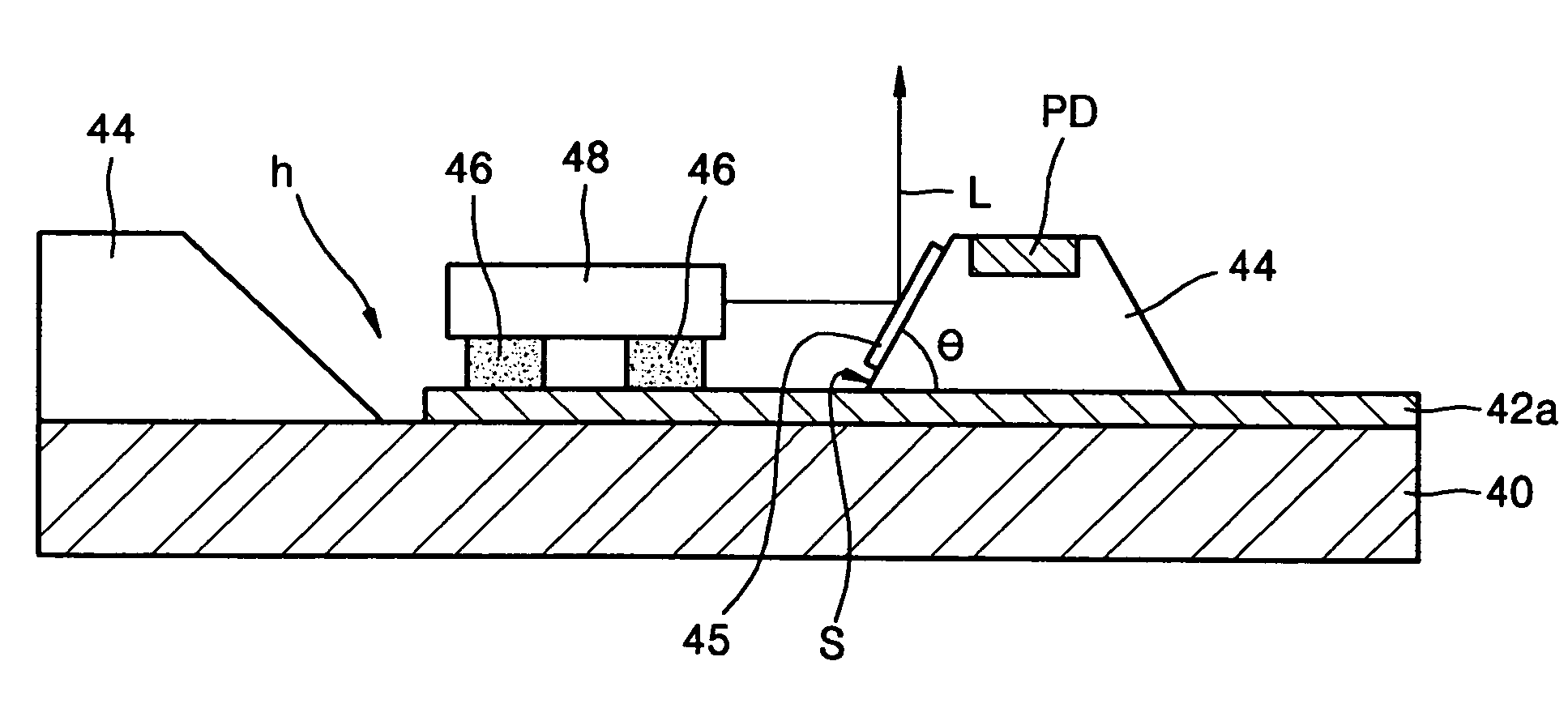

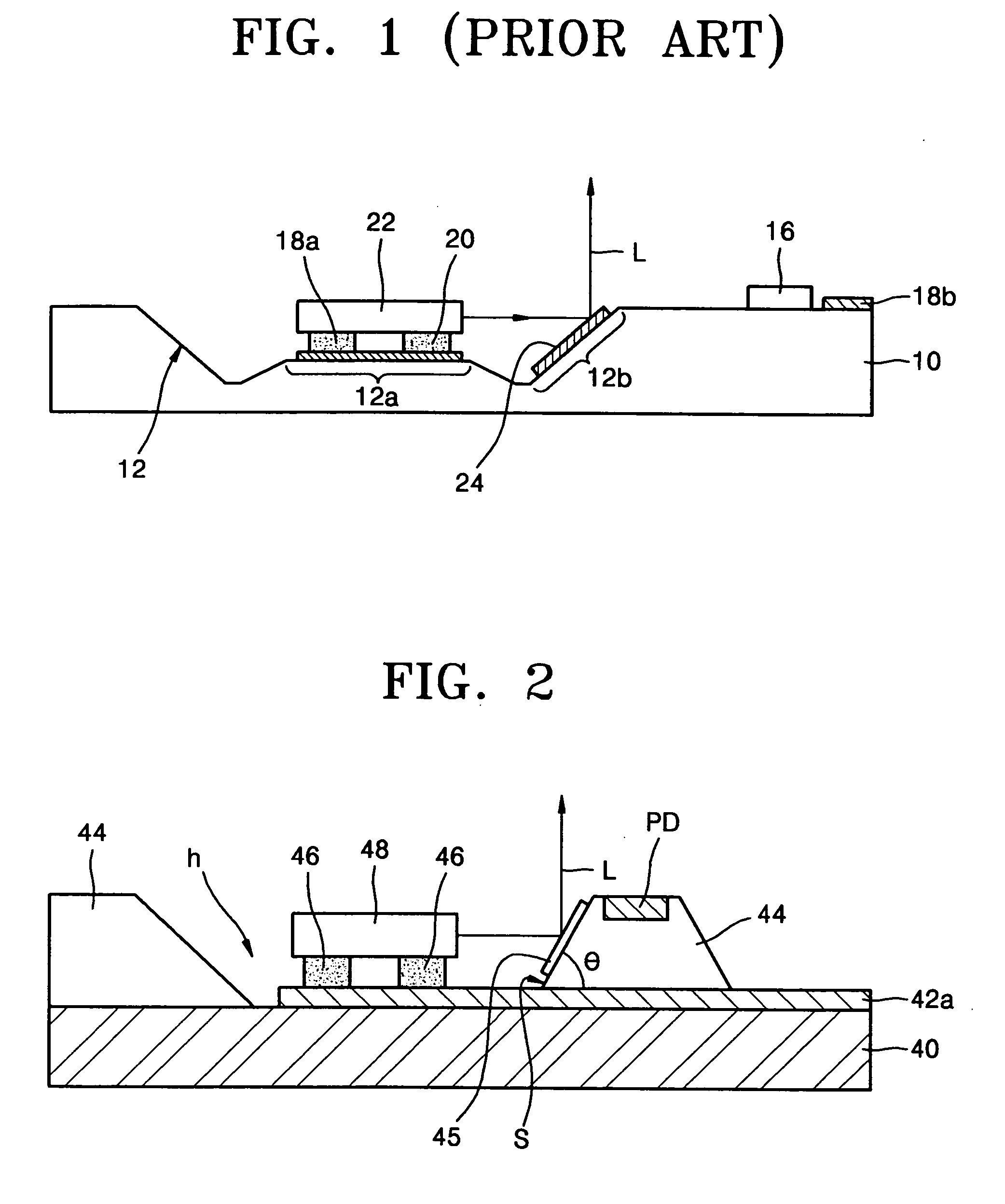

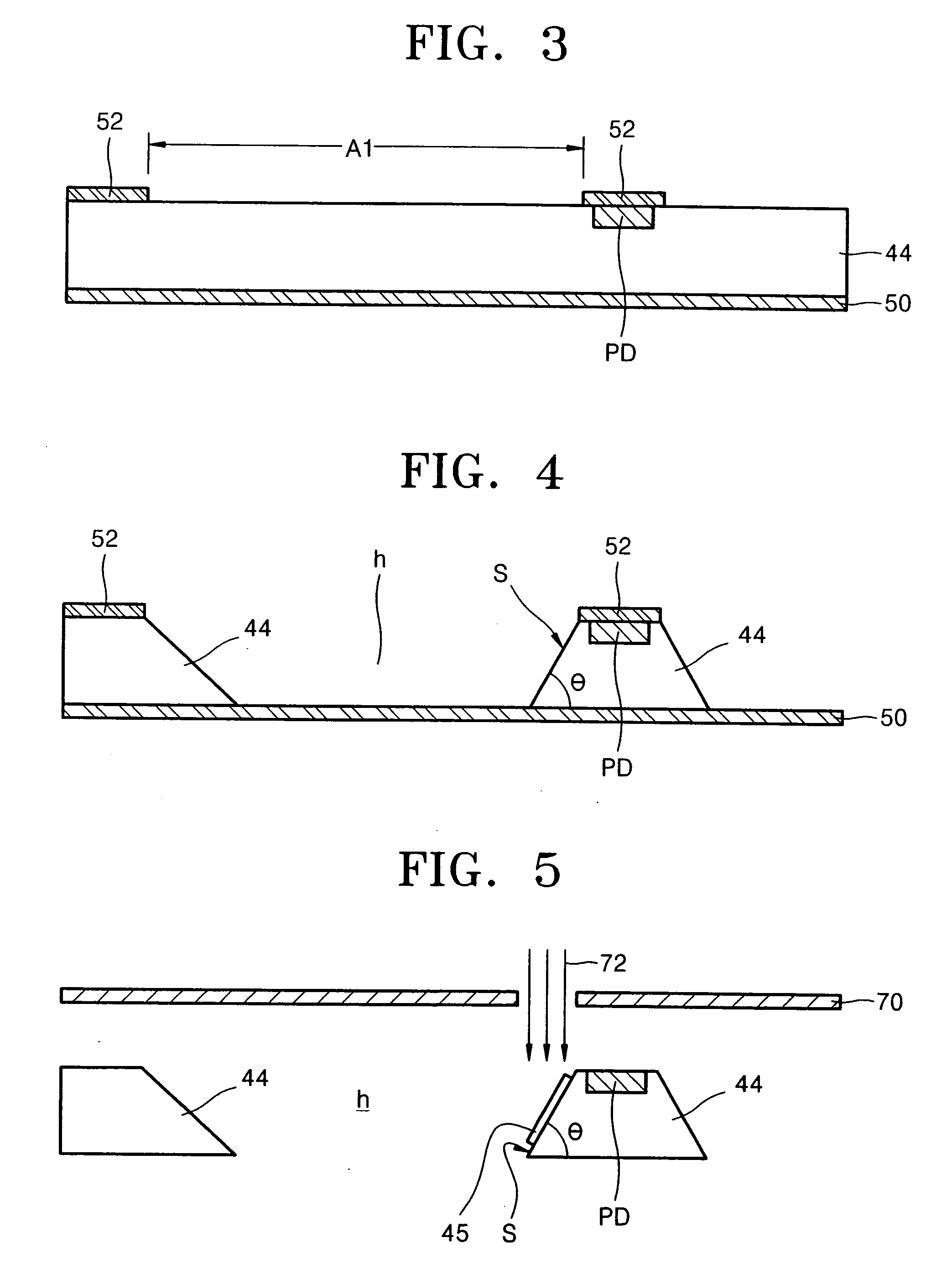

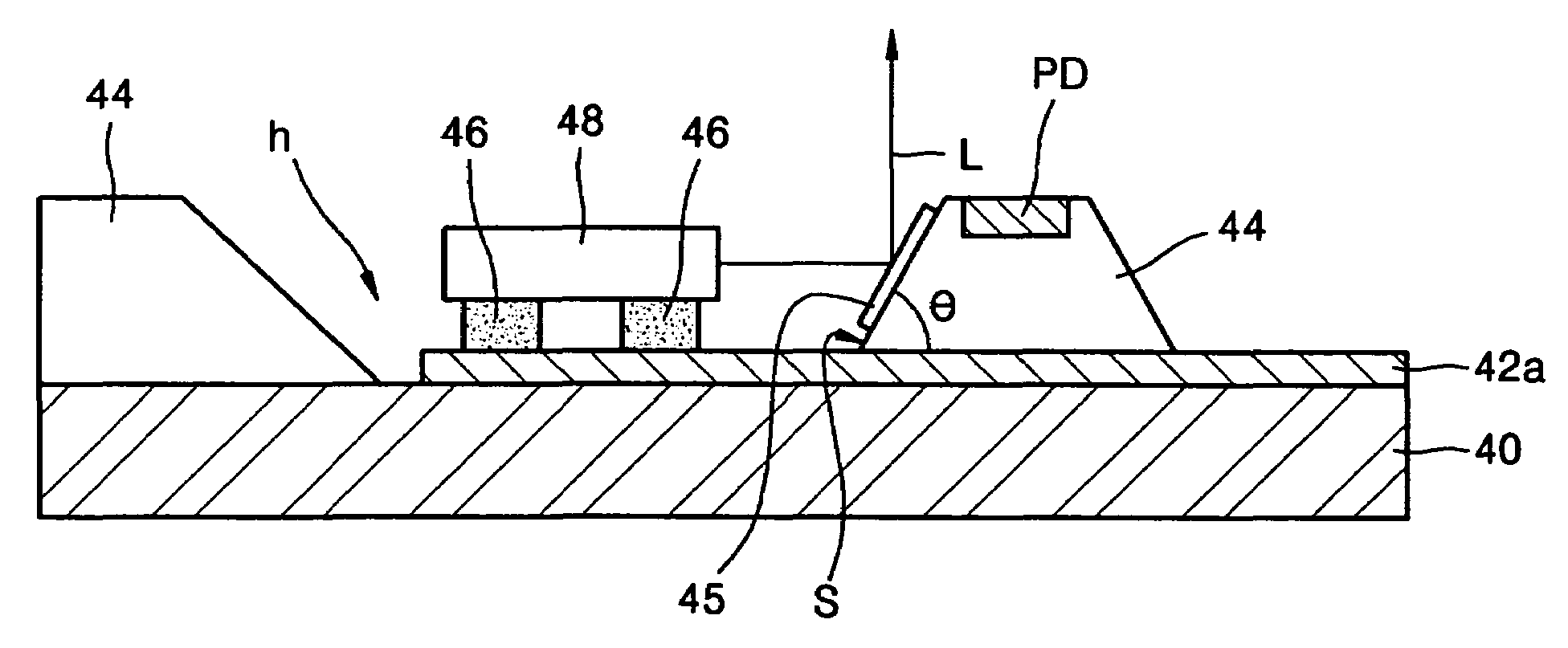

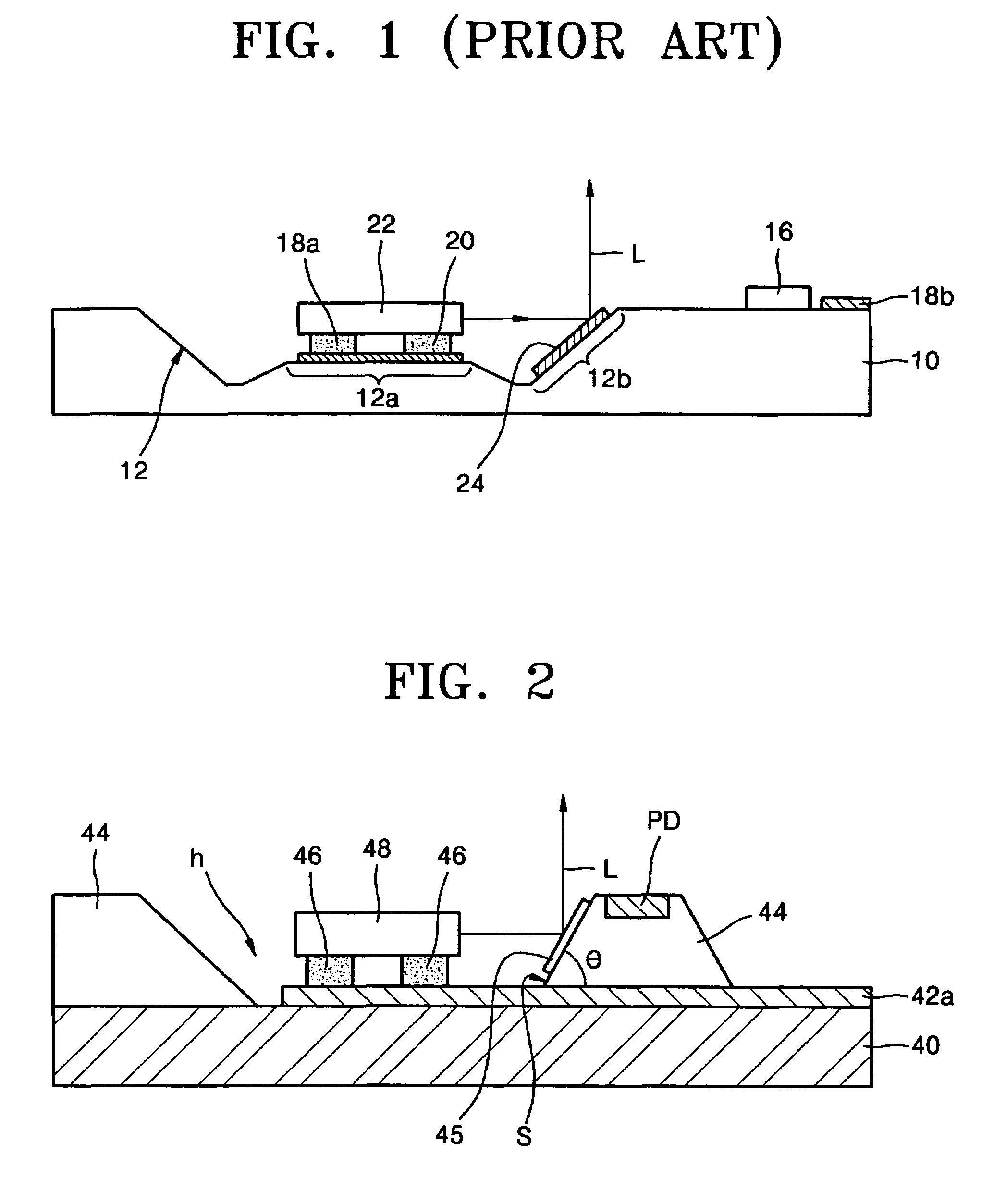

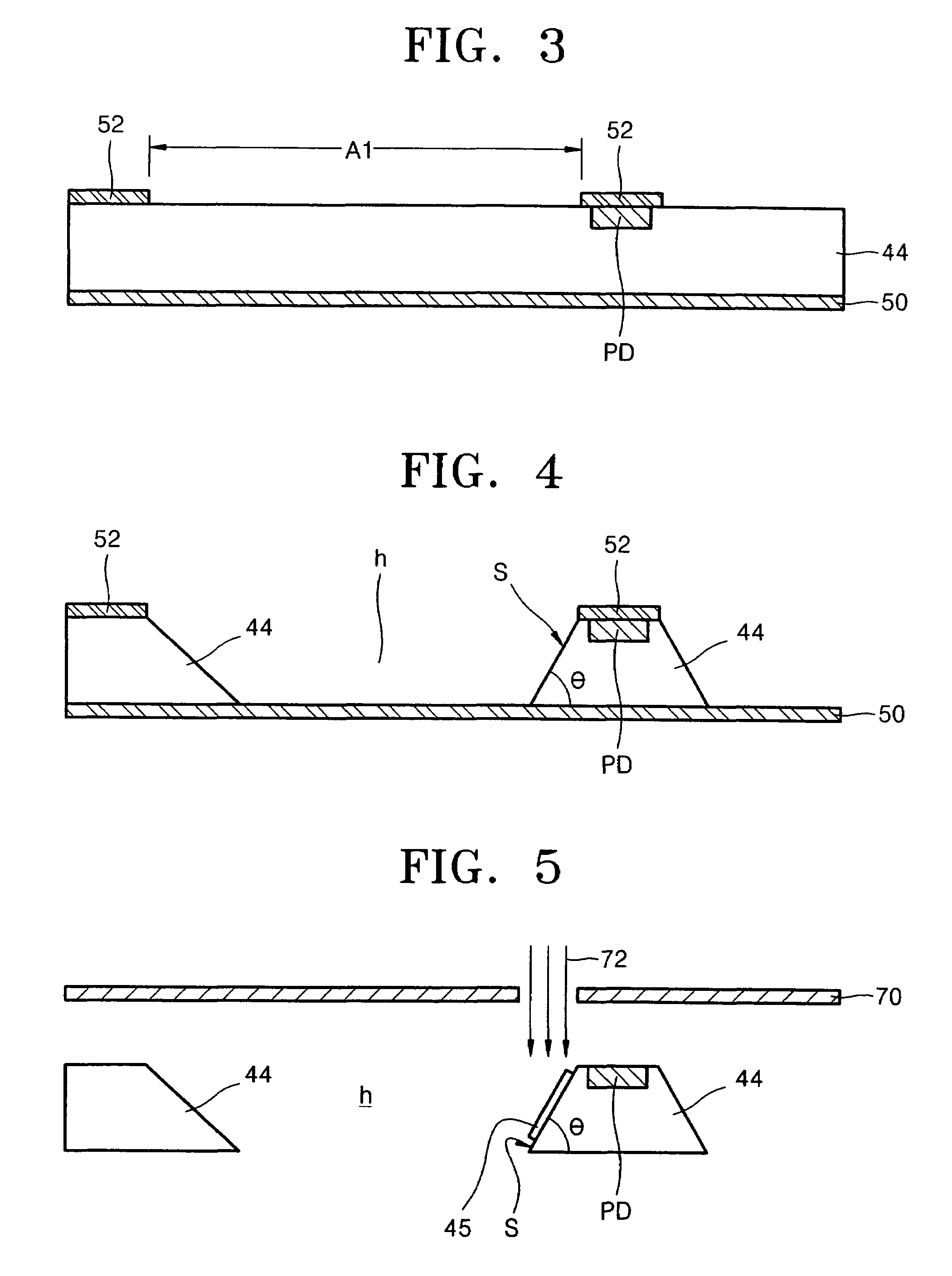

Micro optical bench structure and method of manufacturing the same

InactiveUS20050169570A1Reduce the number of stepsImprove reliabilityLaser detailsDecorative surface effectsEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

Production method of compressed compact carbonized wood

InactiveCN106493815AEasy to operateHigh strengthPressure wood treatmentWood compressionCelluloseCarbonization

A production method of compressed compact carbonized wood relates to wood modification methods and mainly solves the problem that existing wood modification methods cannot improve the mechanical strength and the waterproof dimensional stability of wood. The method comprises, I, wood softening pretreatment including immersing and heating wood in a pretreatment solution and then washing the wood to obtain softened wood, II, softened wood compression, and III, high-temperature wood carbonization. The production method of the compressed compact carbonized wood can solidify compressed deformation of wood, avoid resilience and reinforce cellulose framework structures to strengthen wood. Wood modified through the method obtains obvious enhancement in mechanical strength and dimensional stability. The production method of the compressed compact carbonized wood is applied to wood modification.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

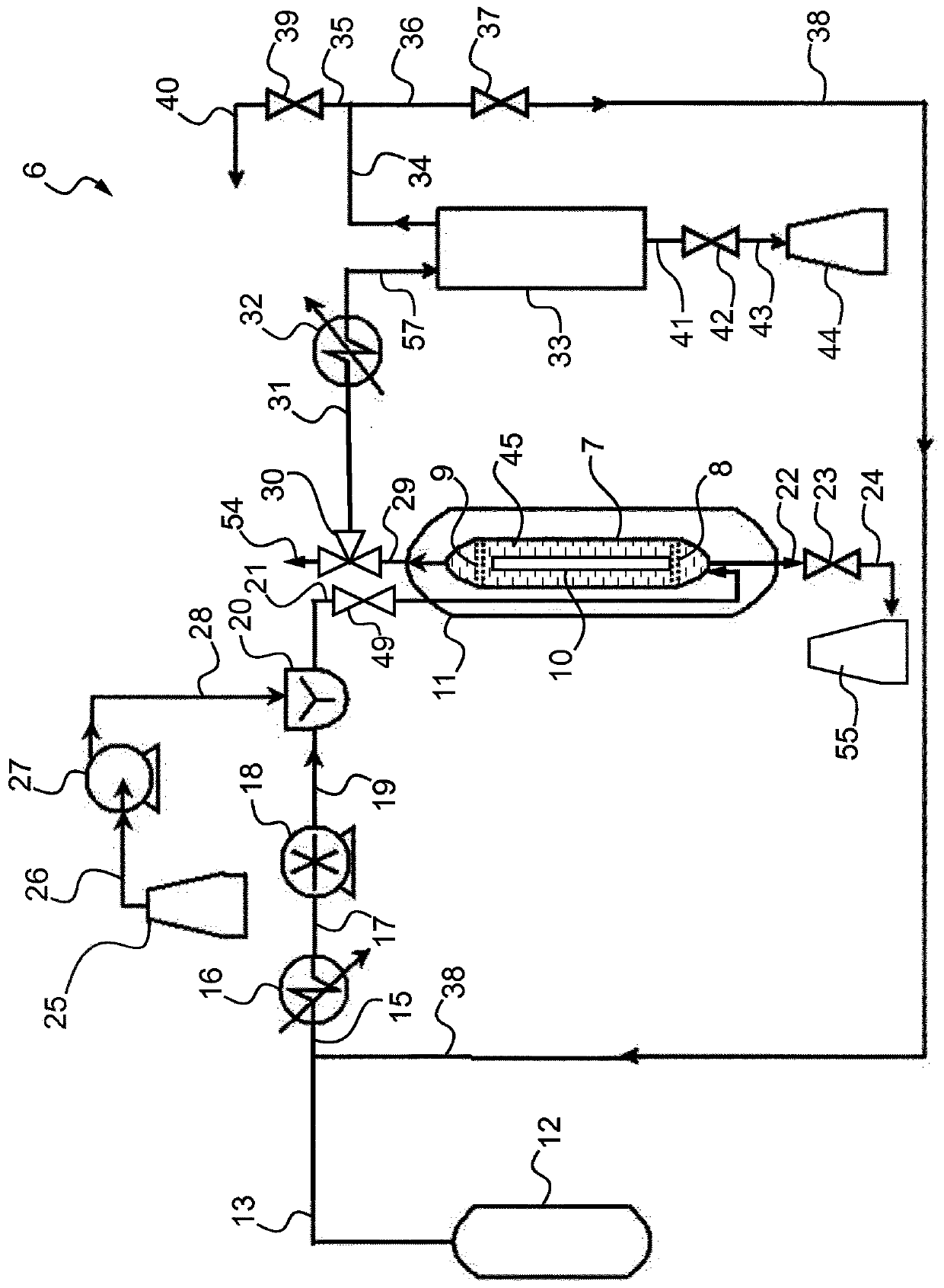

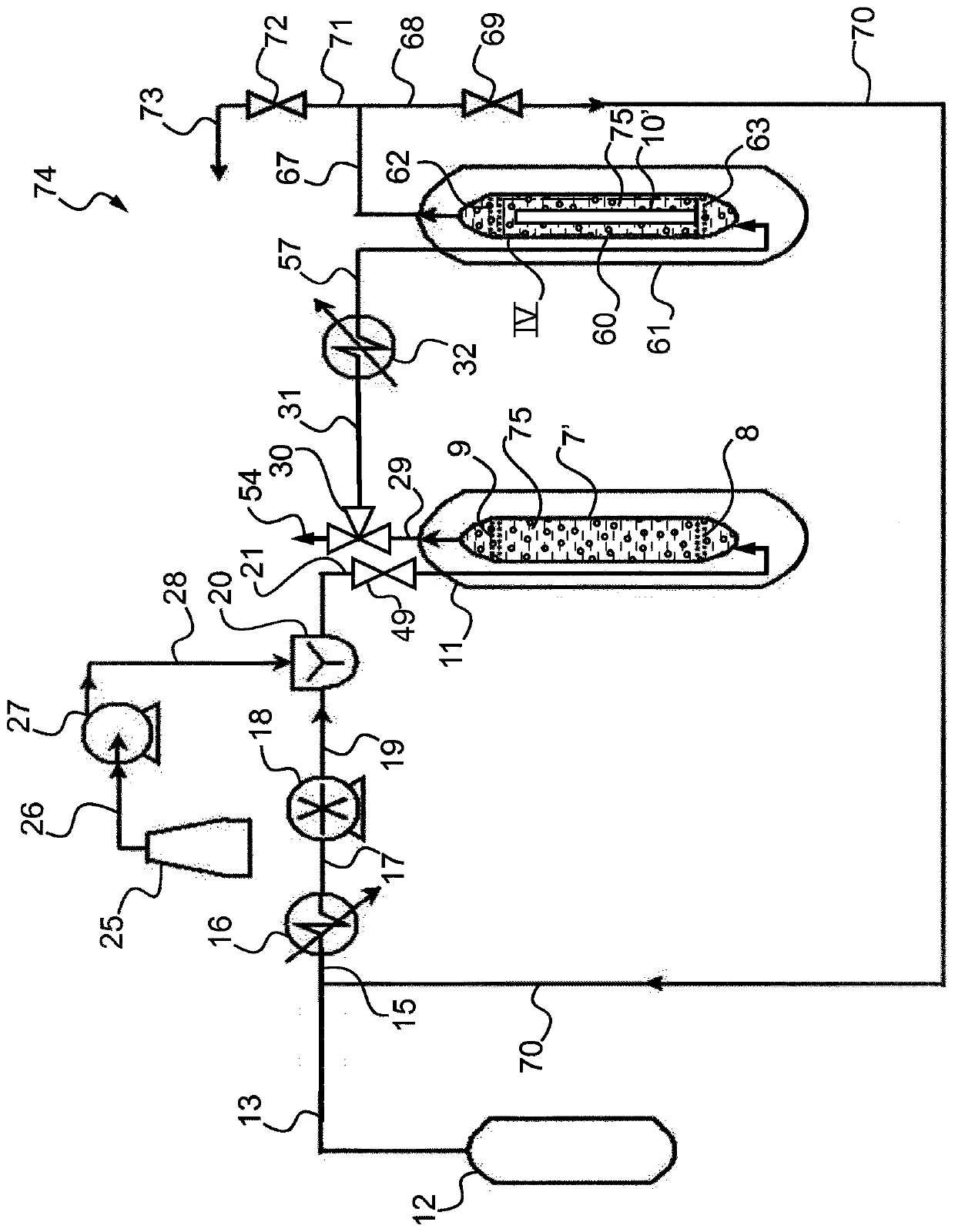

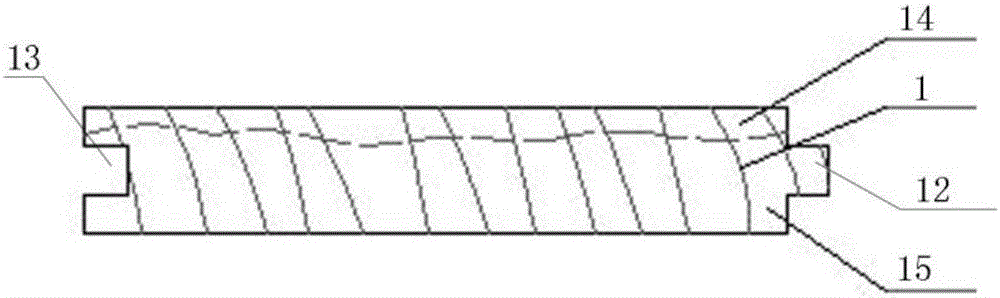

Wood compression-in-situ pressured heat treatment integrated method and compressed wood prepared through method

ActiveCN108582377AAvoid bubblingUniform temperature distributionPressure wood treatmentWood compressionPulp and paper industryDouble stage

The invention discloses a wood compression-in-situ pressured heat treatment integrated method and compressed wood prepared through the method. The method comprises the first step of the drying stage,the second step of pavement, the third step of heating, the fourth step of double-stage pressure compression treatment, the fifth step of heat treatment, the sixth step of stress relief and the seventh step of unloading. By means of the wood compression-in-situ pressured heat treatment integrated method and the compressed wood prepared through the method, the integral compression quality of the wood can be greatly improved, compression rebound of the wood can be controlled, the treated wood flatness is improved, no chemical pollution exists in the treatment process, the production cost is low,operation is simple and convenient, and the beneficial effects of high efficiency, environment friendliness and the like are achieved. Integral compression and deformation perpetual fixing of wood are achieved. By means of the method, the mechanical performance and size stability of the wood can be improved, and meanwhile the defects that anti-bending strength and screw holding force of wood subjected to heat treatment are poor are overcome.

Owner:GUANGXI NANNING QIAOSHENG WOOD

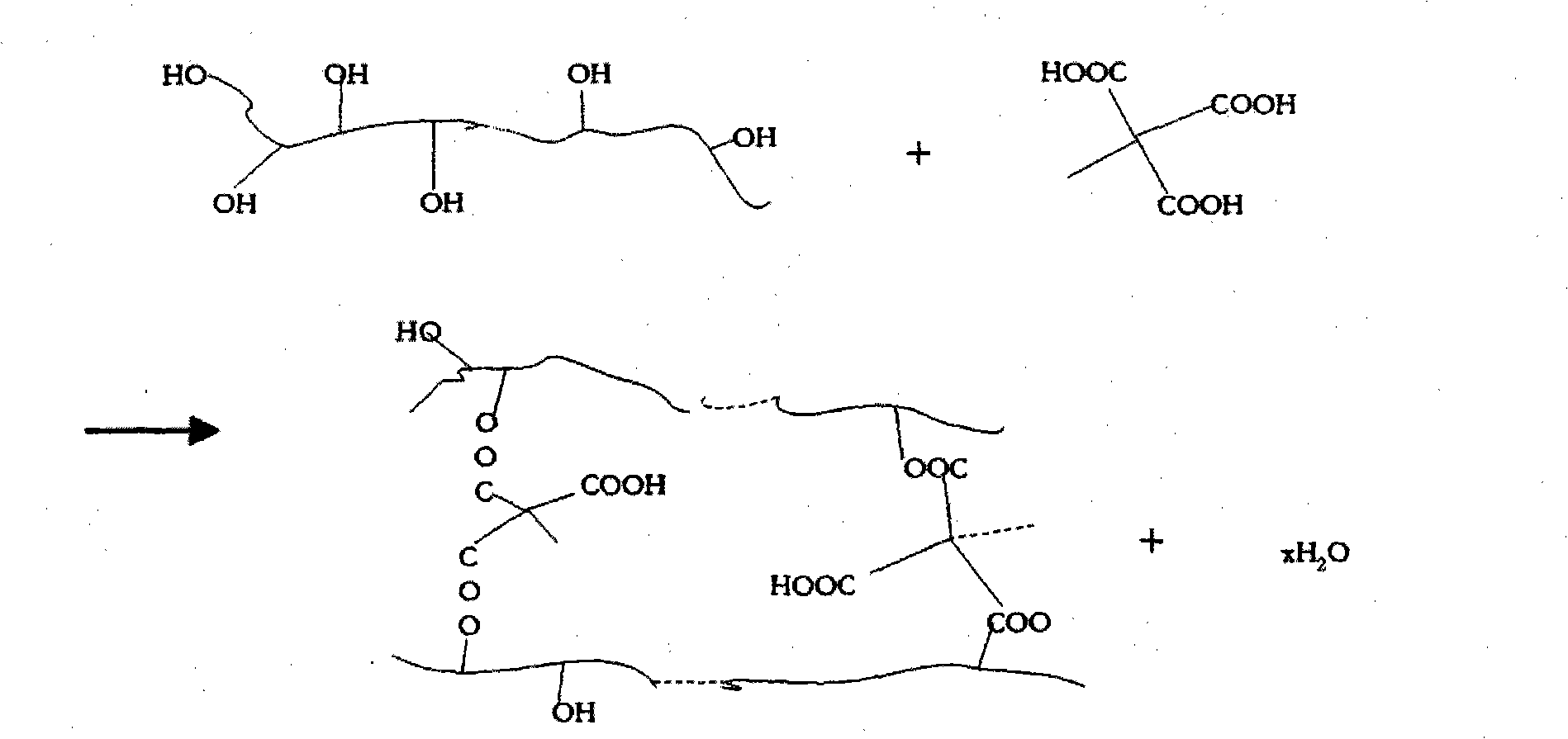

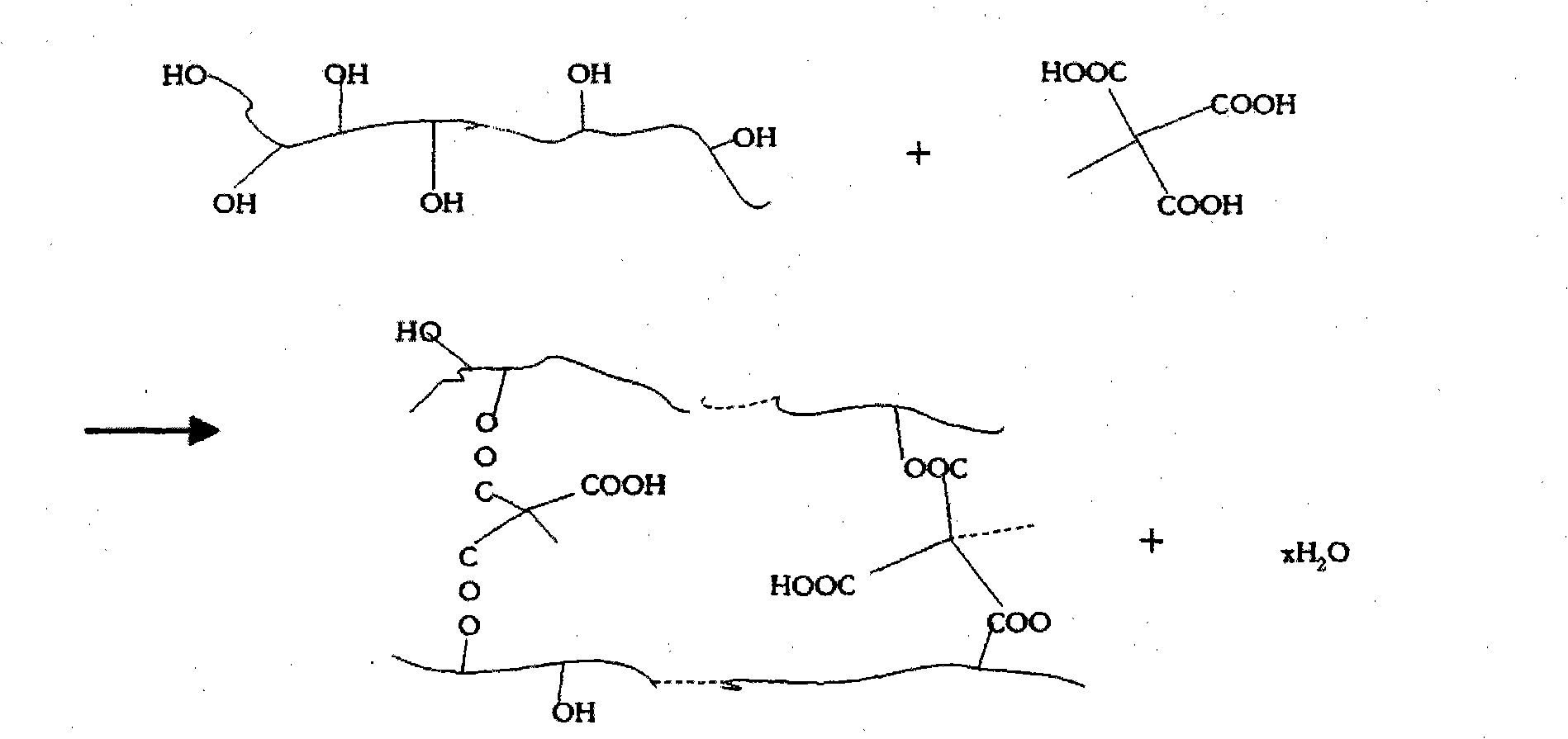

Polymeric composition for cellulosic materials binding and modification

A polymer composition suitable for wood treatment or binding comprises a reaction product of at least a polyol and at least a crosslinking agent. The crosslinking agent has at least 2 carboxylic acid groups per molecule. A wood product comprising a wood substrate and a polymer composition as well as a wood treatment process are also disclosed.

Owner:格林百奥生态材料科技(上海)有限公司

Method for increasing wicker product hardness

InactiveCN106182297AImprove insect and mildew resistanceHigh strengthPressure wood treatmentWood treatment detailsHigh humidityHardness

The invention discloses a method for improving the hardness of wicker products, which comprises the following steps: (1) wicker peeling, (2) softening treatment, (3) wicker weaving, and (4) hardness treatment. The matching of each step of the method of the present invention is scientific and reasonable, and the obtained wickerwork has good insect-proof and mildew-proof effects and high surface hardness. Compared with the prior art, the surface hardness can be increased by about 25%, and the service life under normal use conditions It can be extended by about 30%, and the service life under high humidity conditions can be extended by more than 50%. It has good stability in use, strong anti-deformation ability, good corrosion resistance, and high use value.

Owner:阜南县猛发工艺品有限公司

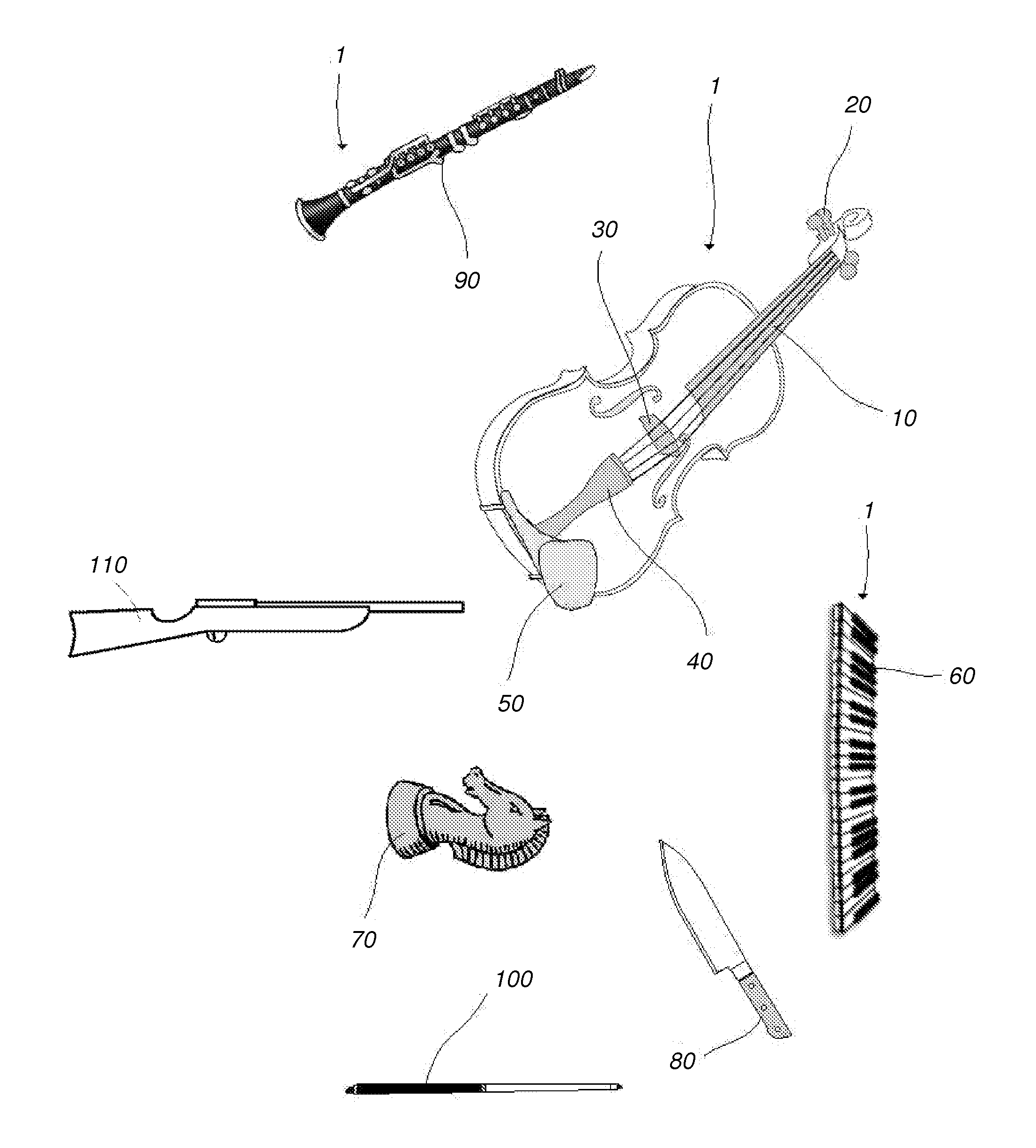

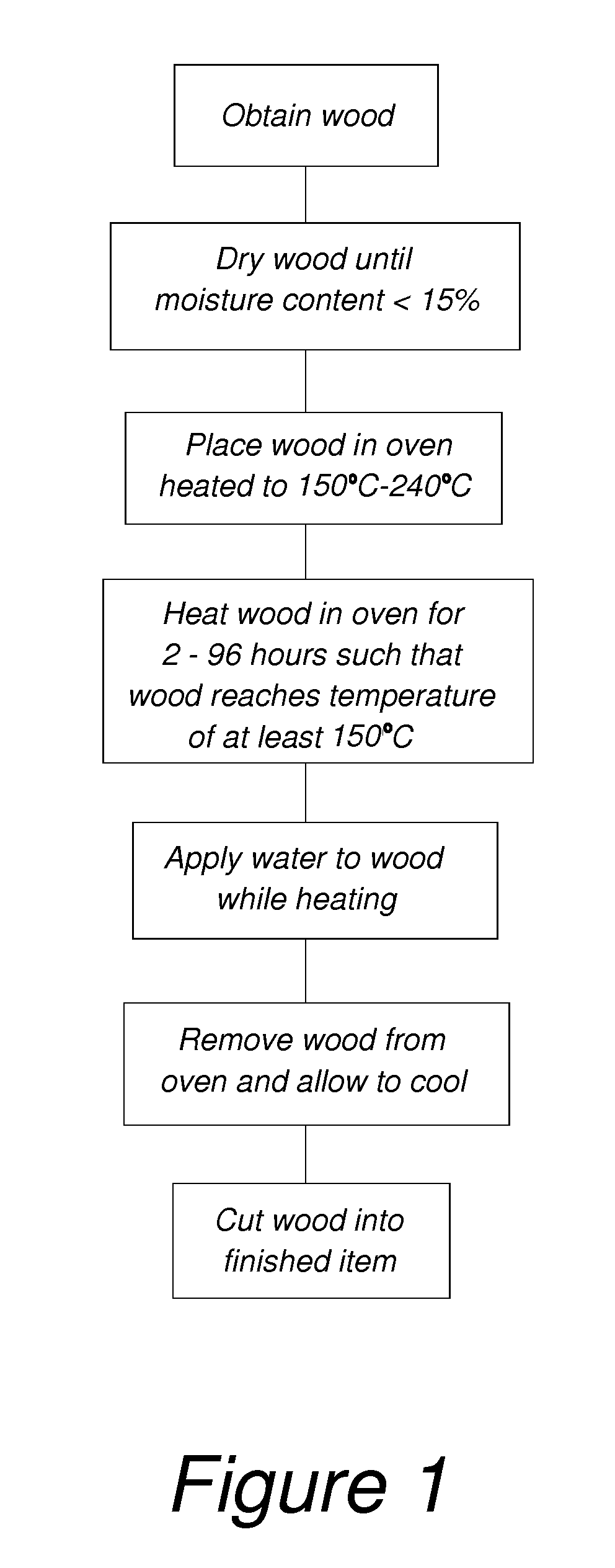

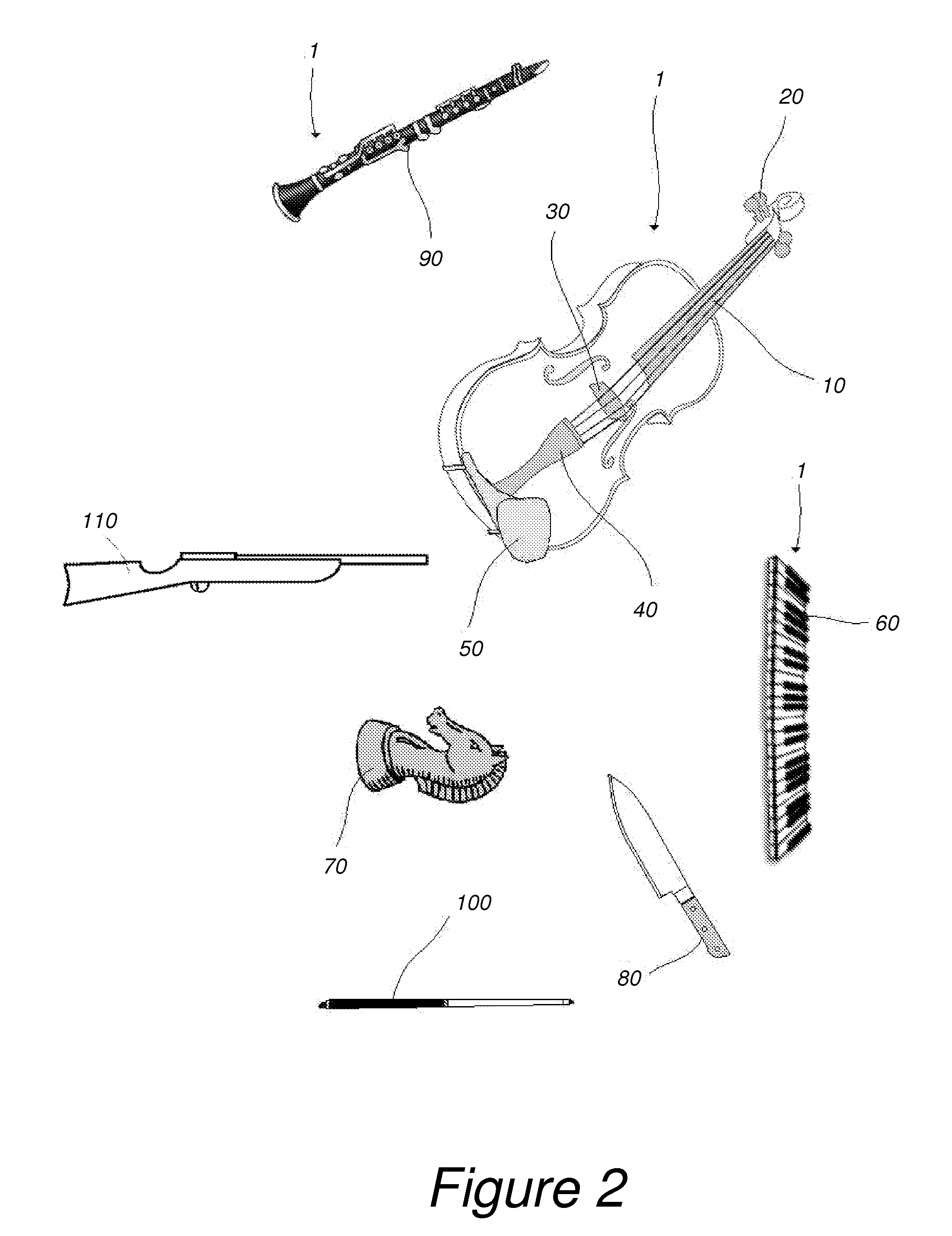

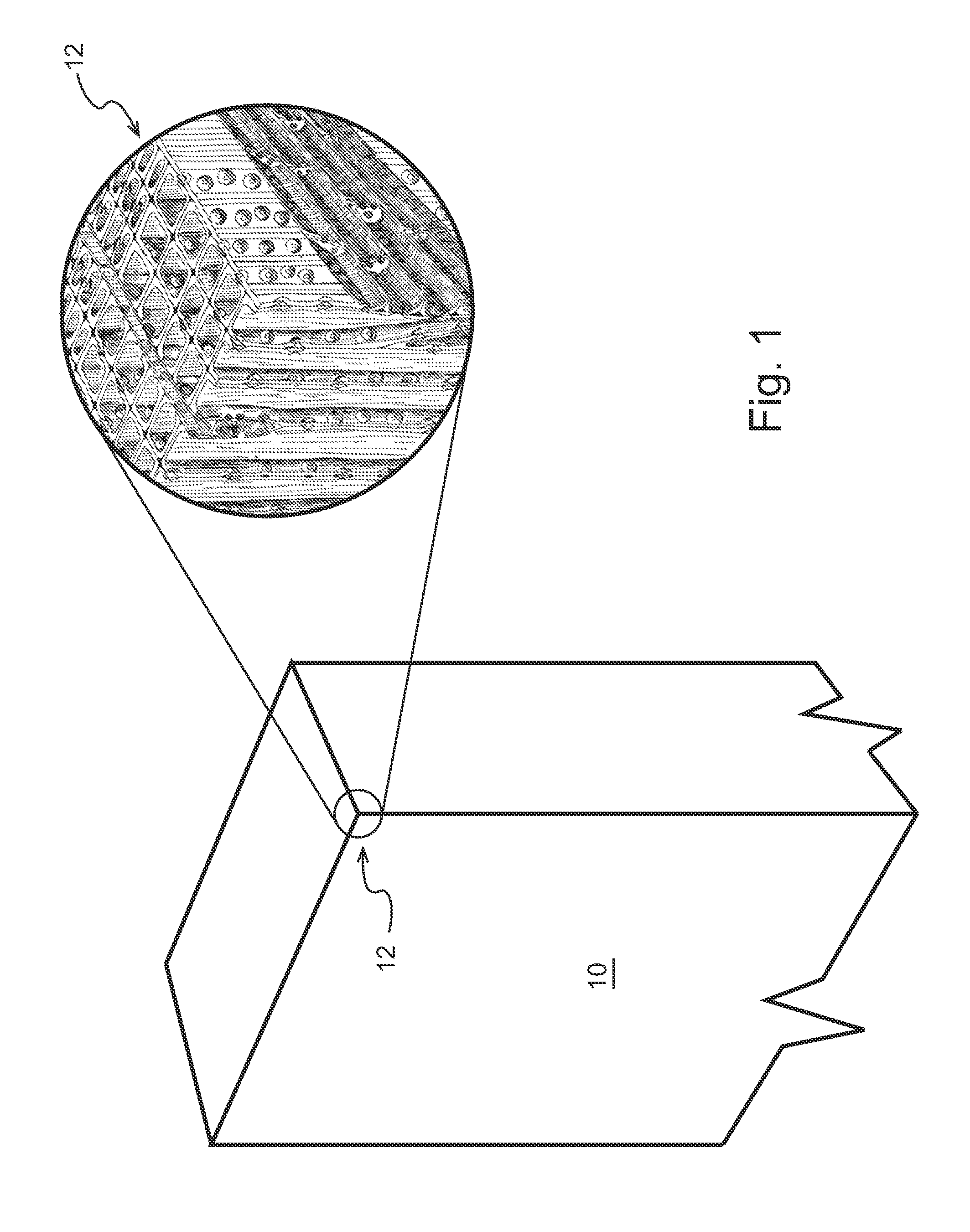

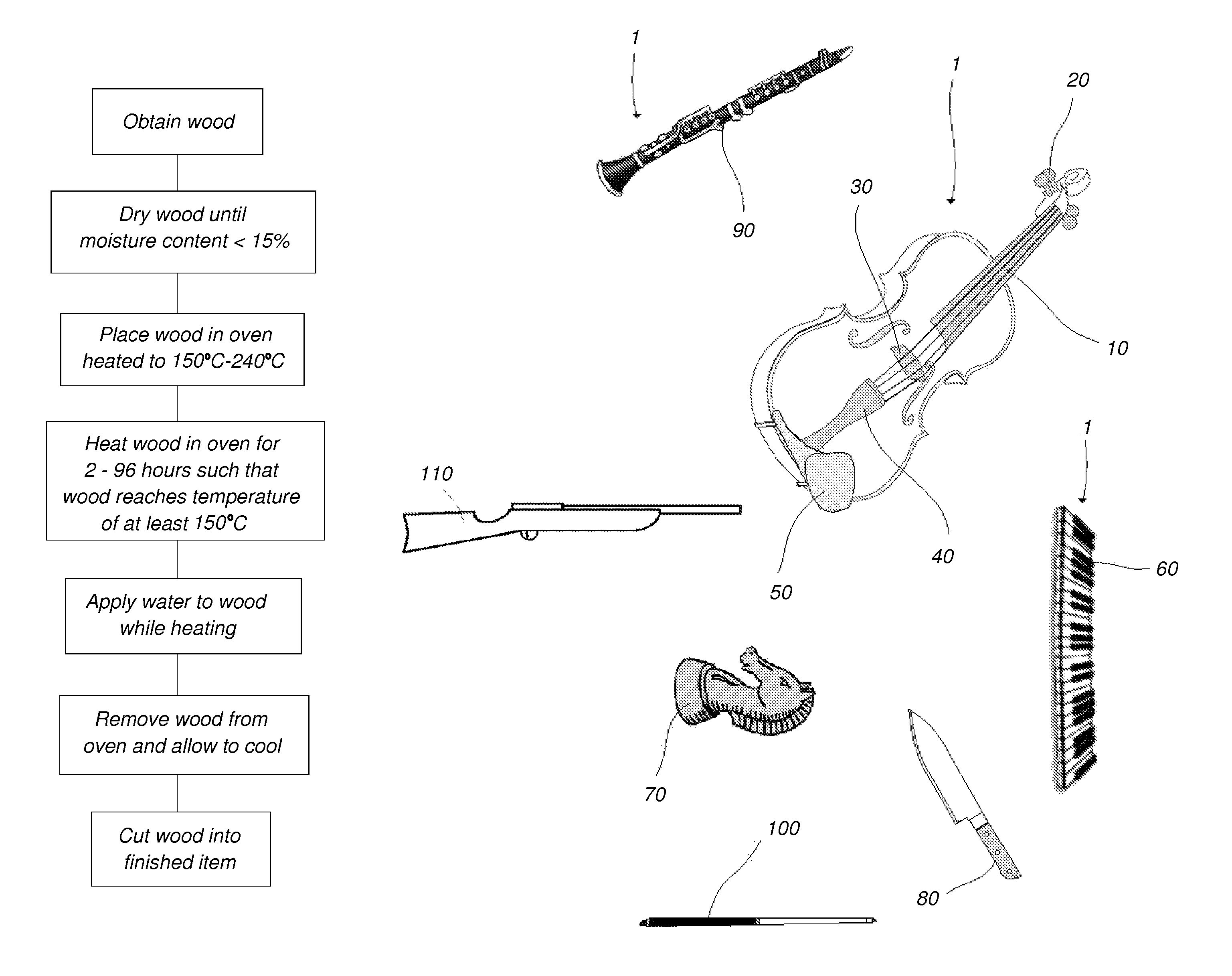

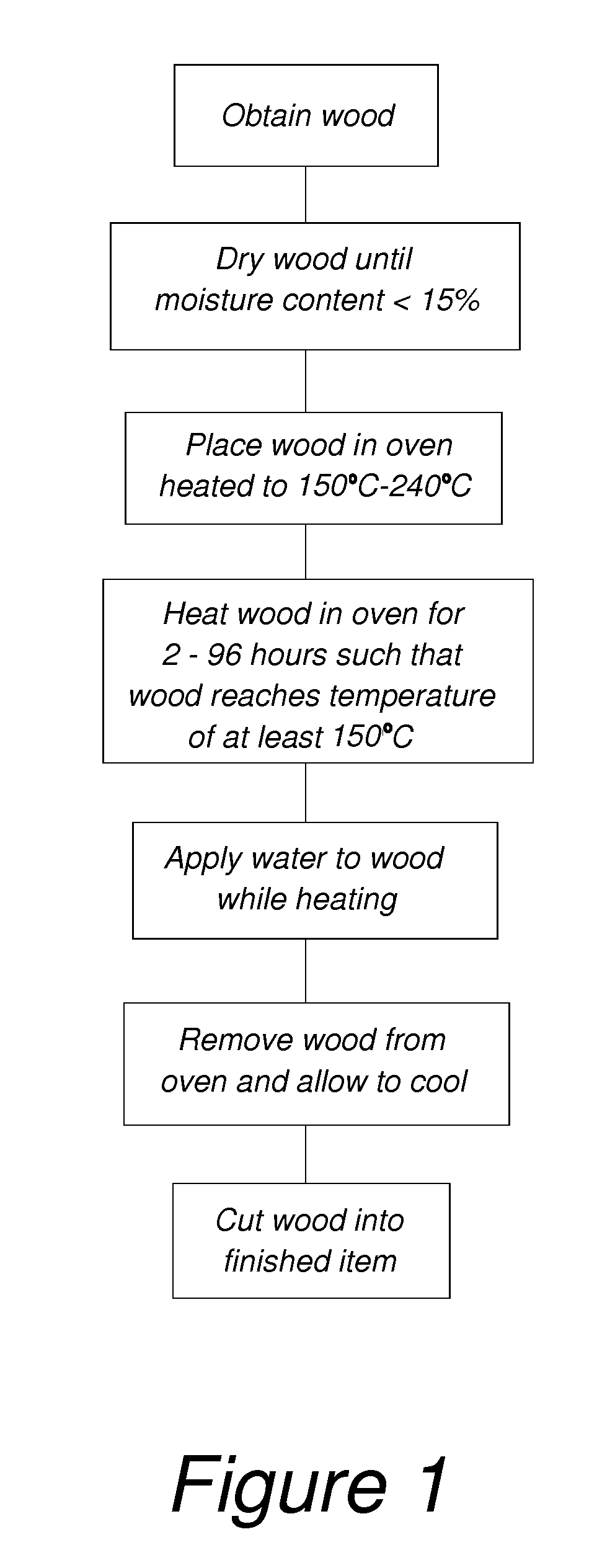

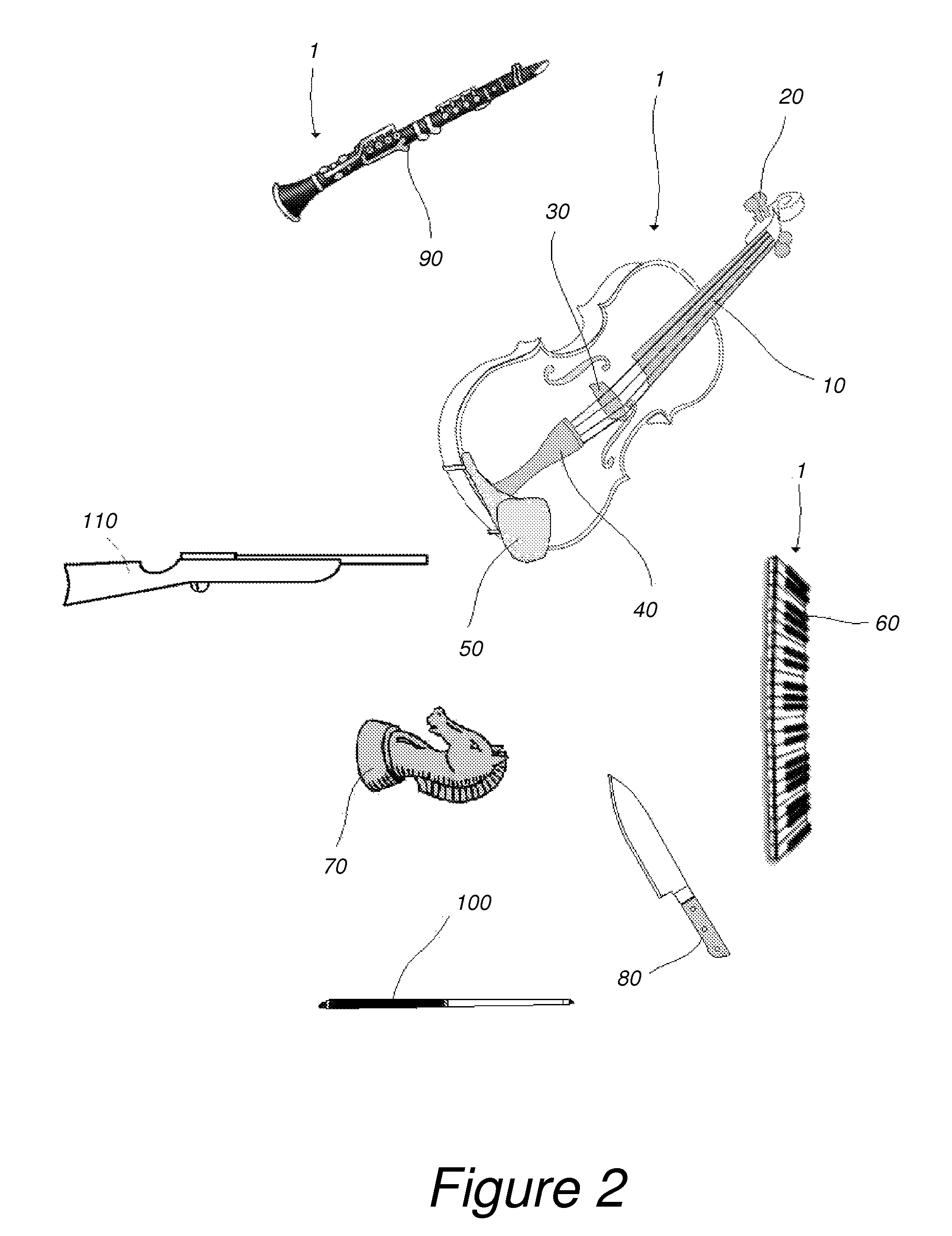

Method of treatment of wooden items

InactiveUS20130153087A1ColorDrying using combination processesWood treatment detailsPulp and paper industryBotany

An improved method for the treatment of wood in preparation for manufacture of wooden items comprising the steps of first heat treating the wood and then fashioning the wood into a finished item, whereby the resulting wooden item is darker, harder, more weather and rot resistant, and more stable than items fashioned from untreated wood.

Owner:HOT WOODS

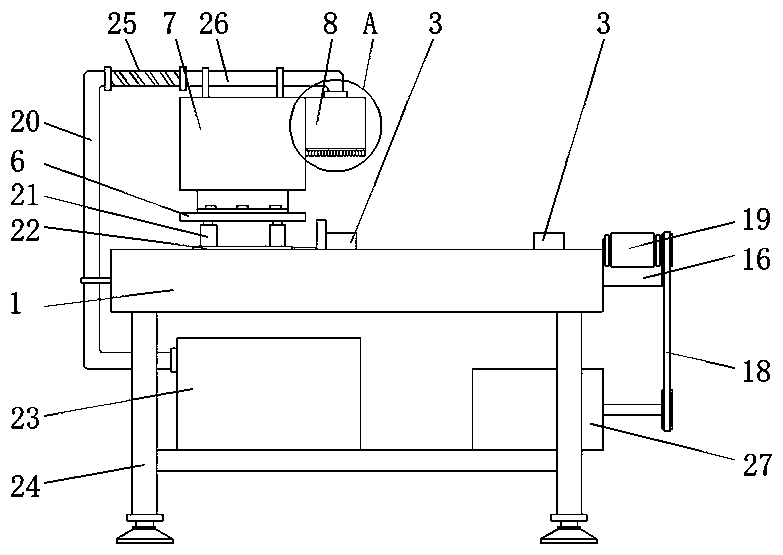

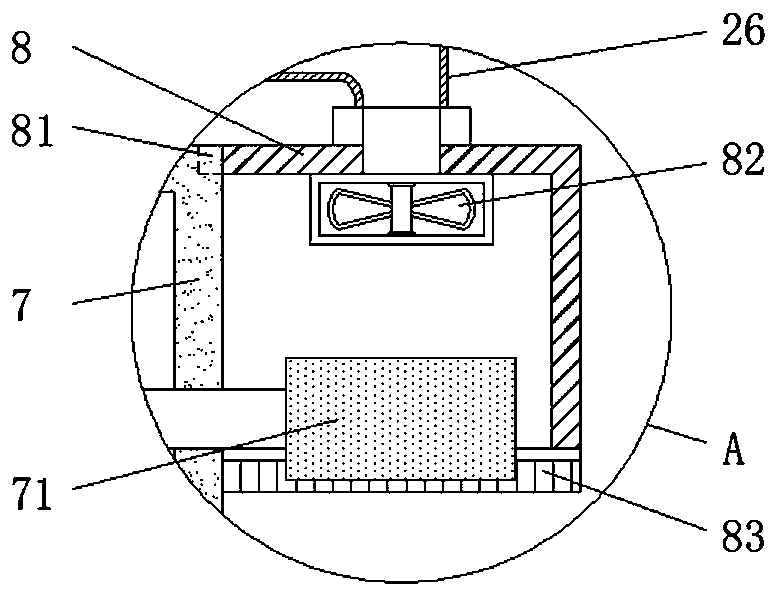

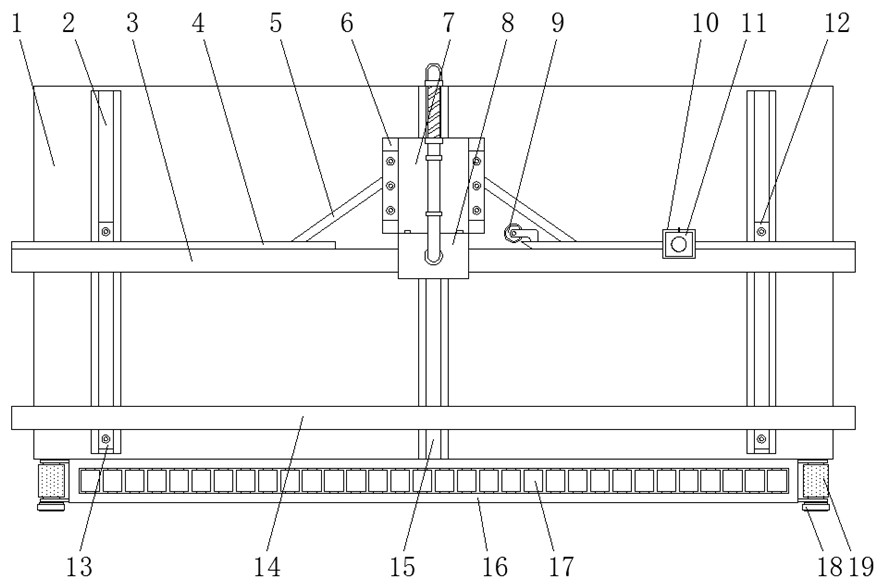

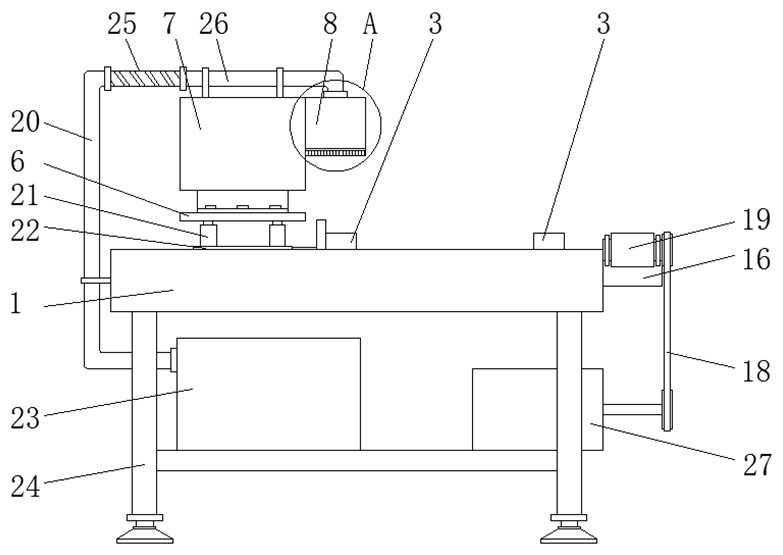

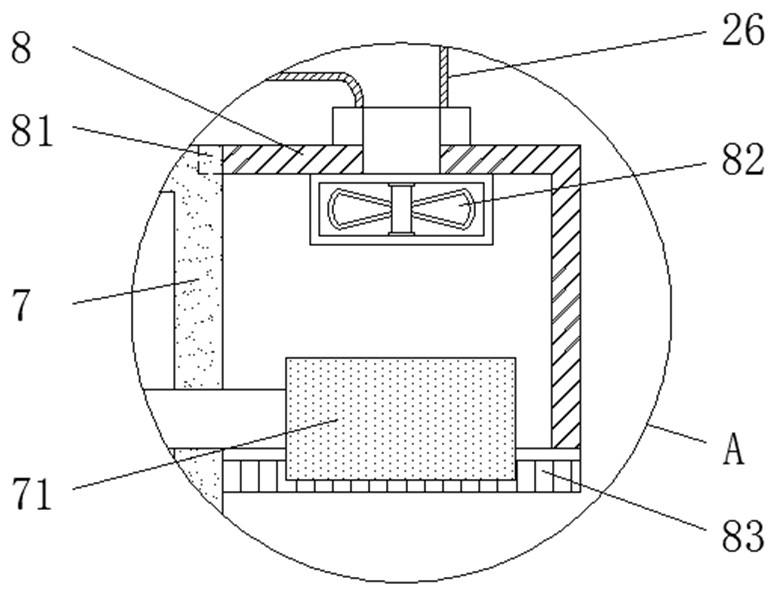

Efficient wood veneer trimming technology and trimming device

ActiveCN109648426AShorten the processing flowShorten the production cycleEdge grinding machinesOther plywood/veneer working apparatusWood veneerLacquer

The invention discloses an efficient wood veneer trimming technology and a trimming device, and belongs to the field of wood trimming. The efficient wood veneer trimming technology comprises the following steps of 1 wood veneer finishing coat spraying, 2 wood veneer cutting, 3 wood veneer edge finishing coat spraying, 4 wood veneer edge sealing and 5 wood veneer trimming. According to the efficient wood veneer trimming technology, UV finishing coat treatment is conducted on wood veneer, UV finishing coat is cured into a film after being subjected to ultraviolet irradiation, the process that ina traditional technology, after the wood veneer is preliminarily ground, primer coat spraying is conducted, and then finishing coat spraying is conducted is effectively reduced, the processing process is effectively reduced, the production period is shortened, therefore, the production cost is reduced, and the production efficiency is improved by 5-10 times; and in addition, the wood veneer is cut, the UV finishing coat wood veneer edge is sealed, therefore, wood veneer edge processing is effectively reduced, the edges and corners of the wood veneer are fully protected through the UV finishing coat wood veneer edge, and damage of the UV finishing coat wood veneer edges and corners is reduced.

Owner:DONGGUAN ZHONGJIN FURNITURE CO LTD

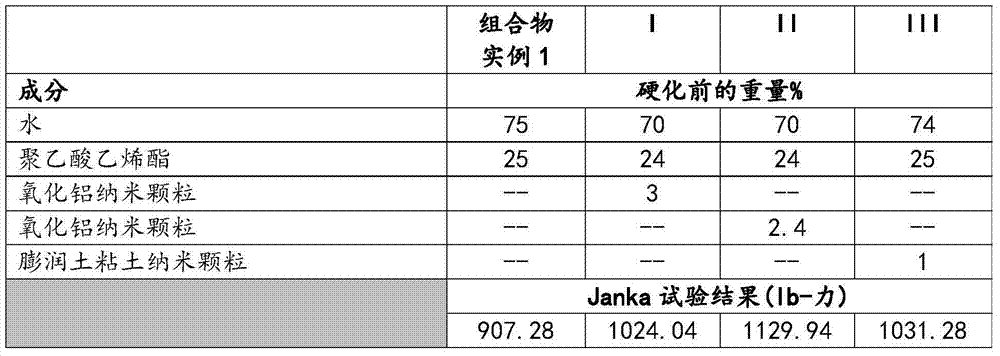

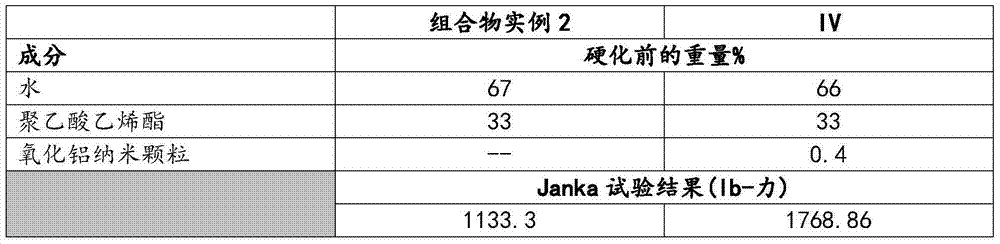

Wood products impregnated with water based compositions

Described herein are impregnated products comprising: a cellulosic substrate having internal voids; and a reaction product of a composition comprising: water; a hygroscopic polymer; and a solid component; wherein the cellulosic substrate is impregnated with said composition. Methods of making and using the products are also described.

Owner:ARMSTRONG WORLD INDUSTRIES

Composition and Method of Manufacture of Hardened Wood

There is a hardened wood composition, comprising an acetylated whole wood portion that may have substantially all of its accessible interior volume impregnated with a hardened thermosetting plastic. A method of manufacturing a hardened wood comprising the steps of: acetylating a whole wood portion and impregnating the whole wood portion with a liquid-phase thermosetting polymer then curing such thermosetting polymer impregnated porous body by the steps of: enclosing the body in a fluid impermeable bag and subjecting the enclosed body to enhanced fluid pressure substantially, contemporaneously, with subjecting the enclosed body to a temperature sufficient to cure the thermosetting plastic impregnated therein by submerging the same in water near its boiling point.

Owner:SANDERSON BRIAN MATTHEW

Method of treatment of wooden items

InactiveUS8555521B2Drying using combination processesDrying solid materials with heatImproved methodMaterials science

An improved method for the treatment of wood in preparation for manufacture of wooden items comprising the steps of first heat treating the wood and then fashioning the wood into a finished item, whereby the resulting wooden item is darker, harder, more weather and rot resistant, and more stable than items fashioned from untreated wood.

Owner:HOT WOODS

Micro optical bench structure

InactiveUS7456434B2Simple processImprove reliabilityLaser detailsDecorative surface effectsEngineeringOptical table

Owner:SAMSUNG ELECTRONICS CO LTD

Four-in-one method for corrosion-preventing, inflaming-retarding, hardening and air purification of wood

ActiveCN104400855AAnti-corrosionAchieve flame retardancyWood compressionWood treatment detailsDisodium octaborate tetrahydrateSediment

The invention discloses a four-in-one method for corrosion-preventing, inflaming-retarding, hardening and air purification of wood. The four-in-one method comprises the following steps: sufficiently mixing water, disodium octaborate tetrahydrate, aluminum dihydrogen tripolyphosphate, boric acid and magnesium sulfate, dissolving for preparing a combined solution, and preparing wood to be treated, wherein the weight percentages of the chemicals in the combined solution are as follows in sequence: 12.5%-15%, 5-6%, 5-6%, and 2.5-3%; placing the wood to be treated into an airtight container, adding the combined solution, and heating to 120-132 DEG C, wherein the pressure is kept at 0.2-0.3Mpa for 16-28 hours. By virtue of the four-in-one method provided by the technical scheme of the invention, the special combined solution is used for dissolving for removing most grease and sediments in the wood, so that a plurality of tiny pipe holes axially communicated are formed inside the wood, meanwhile, exchange filing is realized in the pipe holes of the wood, so that the purposes of preventing corrosion, retarding inflaming, hardening and air purification treatment of the wood are realized, energy conservation and environment protection are facilitated, and industrial prospect is good.

Owner:SHENZHEN HONGTAO DECORATION

Weather-proof paulownia wood hardening treatment method

InactiveCN107415002AImprove mechanical propertiesReduce forcePlywood pressesMagnetic wood treatmentFiberPaulownia

The invention belongs to the technical field of Paulownia wood treatment, and in particular relates to a weather-resistant Paulownia wood hardening treatment method, which includes treatment with a magnetization device, vacuum impregnation with a treatment liquid and hot pressing. Compared with the prior art, the present invention has the following advantages: the crystalline structure of the fiber is destroyed through the treatment of the magnetization device, and the scope of the amorphous zone is enlarged; It chemically reacts with the hydrophilic hydroxyl group, allowing more water and other substances to immerse in the amorphous area, weakening the force between the crystalline area and the amorphous area, and increasing the mechanical properties of Paulownia wood. After hot pressing, the board has After a certain rebound, the obtained paulownia wood reaches the required thickness, the error range is within ±1mm, the surface forms a dense structure, the overall structure is stable, and it has strong water resistance and weather resistance.

Owner:阜南县中信柳木工艺品有限公司

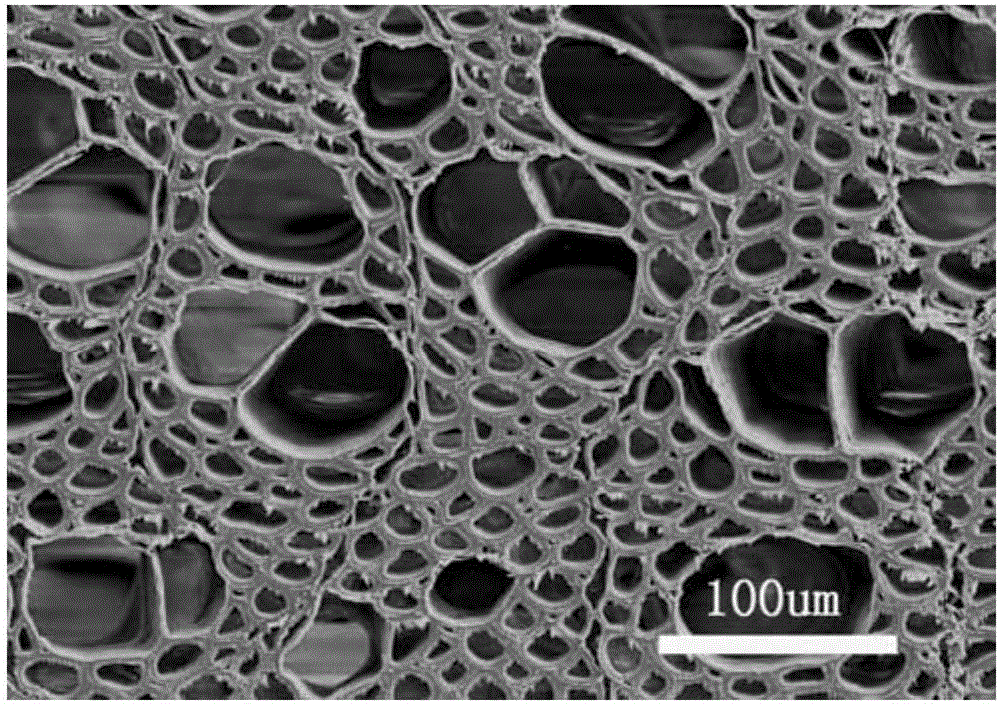

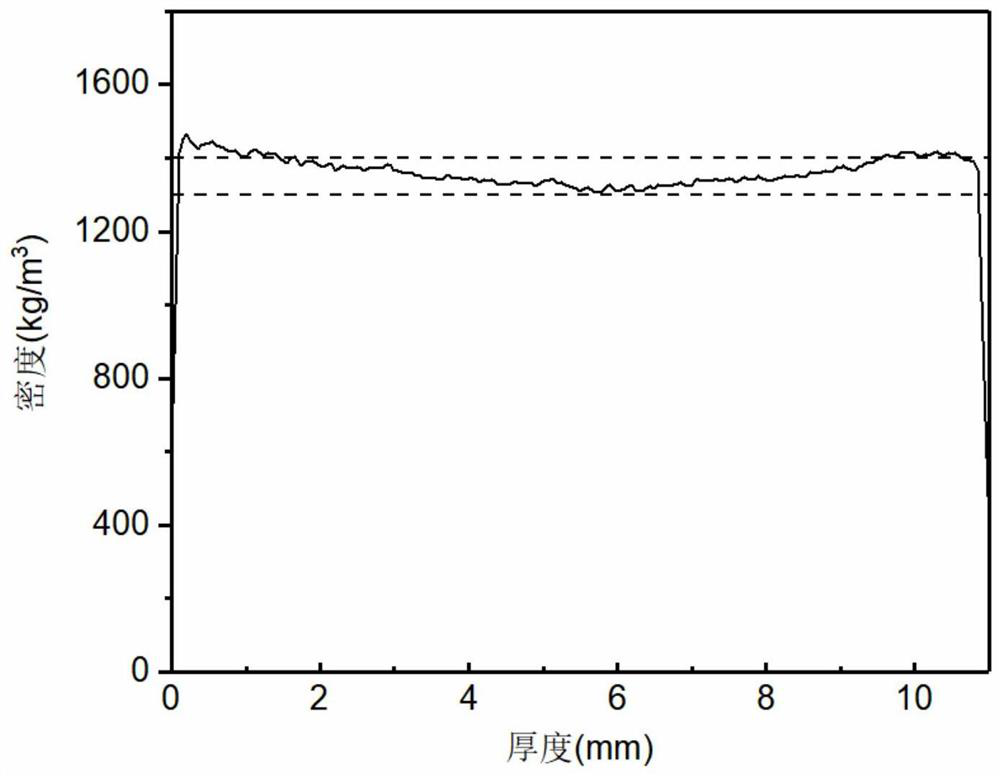

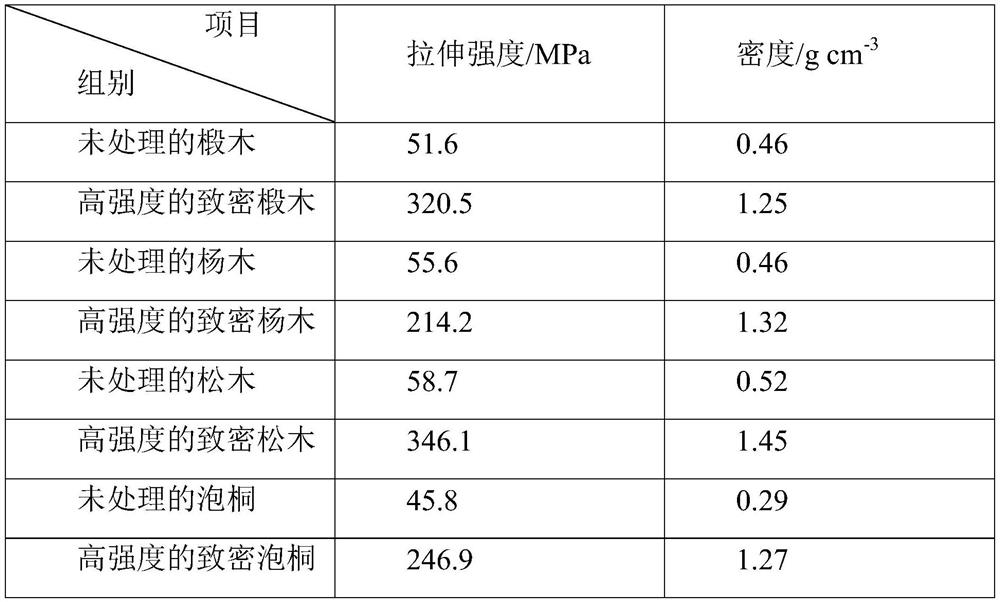

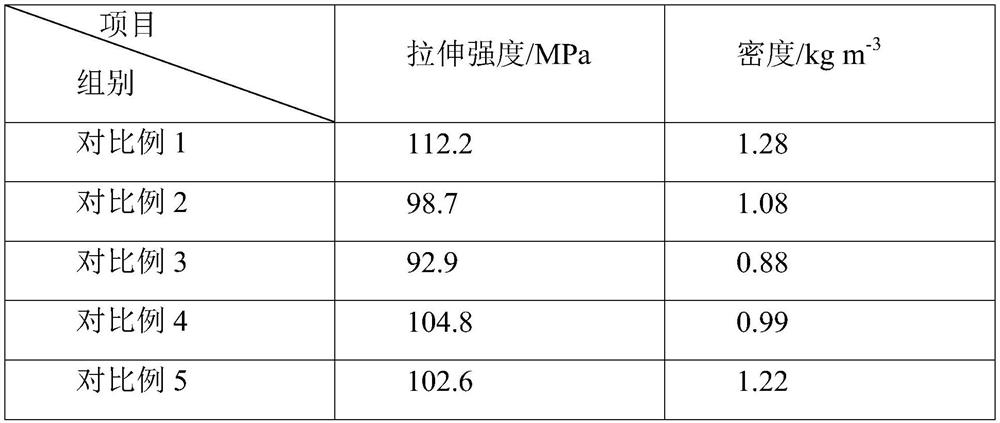

Preparation method of high-strength compact wood

InactiveCN112720747AShorten the timeReduce internal defectsPressure wood treatmentWood compressionPulp and paper industryThermal treatment

The invention provides a preparation method of high-strength compact wood, which comprises the following steps: putting a wood raw material into a vacuum pressurizing tank, and soaking in an alkaline treatment solution under a vacuum condition until the wood raw material is fully soaked; heating the alkaline treatment solution for soaking the wood under normal pressure, and cooling to obtain the alkaline treatment wood; allowing the wood subjected to heating treatment to be subjected to cooking treatment; drying the cooked wood to obtain dried wood; and placing the dried wood in a hot press for hot pressing treatment, heat preservation treatment and cooling treatment to obtain the high-strength compact wood. The high-strength compact wood prepared through the method has high density, the tensile strength of the high-strength compact wood is obviously improved, and the high-strength compact wood further has the advantages of being simple in preparation process, low in energy consumption and low in cost on the whole.

Owner:佛山(华南)新材料研究院

Hybrid wood products

InactiveCN105102738ADimensionally stableWon't fadeWood compressionWood treatment detailsPulp and paper industryFiberboard

Described herein are hybrid wood products comprising: a first layer comprising a first thermally compressed cellulosic substrate; a second layer comprising a fiberboard, a wood- plastic composite, or a vinyl composite; and a locking profile.

Owner:ARMSTRONG WORLD INDUSTRIES

Waterproof flame-retardant wood hardening agent and preparation method thereof

InactiveCN105984006ASafe to useIncreased durabilityWood treatment detailsWood hardening processEnvironmental resistanceGuar gum

The invention discloses a waterproof and flame-retardant wood hardener, which is prepared from the following raw materials in parts by weight: 5-10 parts by weight of water glass, 5-10 parts of borax, 10-15 parts of magnesium sulfate, 2-3 parts of guar gum, and Ammonium sulfate 0.1-0.2, titanate coupling agent 0.1-0.2, styrene 2-4, methyl methacrylate 4-6, sodium lignosulfonate 0.5-1, sodium carboxymethylcellulose 1-2, Modification additive 5-10, water 80-100. The wood hardening agent of the present invention has the characteristics of good permeability, strong binding force with wood, not easy to be lost, good durability, good hardening effect, green and environmental protection, and also has the effect of waterproof and flame retardant, and can improve the use safety and durability of wood , with high practical value.

Owner:FUNAN COUNTY TIANYI CRAFTS

A wood compression-in-situ pressure heat treatment integrated method and the compressed wood prepared therefrom

ActiveCN108582377BAvoid bubblingUniform temperature distributionPressure wood treatmentWood compressionPulp and paper industryStress relief

The invention discloses an integrated method of wood compression-in-situ pressure heat treatment and the compressed wood prepared therefrom. The method comprises the following steps: (1) drying stage; (2) paving; (3) heating; (4) ) two-stage pressure compression treatment; (5) heat treatment; (6) stress relief; (7) unloading. The invention can greatly improve the overall compression quality of wood, and can control the compression rebound of wood, improve the flatness of treated wood, has no chemical pollution in the treatment process, low production cost, relatively simple operation, and has the advantages of high efficiency, environmental protection and the like. Realize the overall compression and deformation permanent fixation of wood. This method can improve the mechanical properties and dimensional stability of wood, and at the same time overcome the shortcomings of heat-treated wood's poor bending strength and screw-holding force.

Owner:GUANGXI NANNING QIAOSHENG WOOD

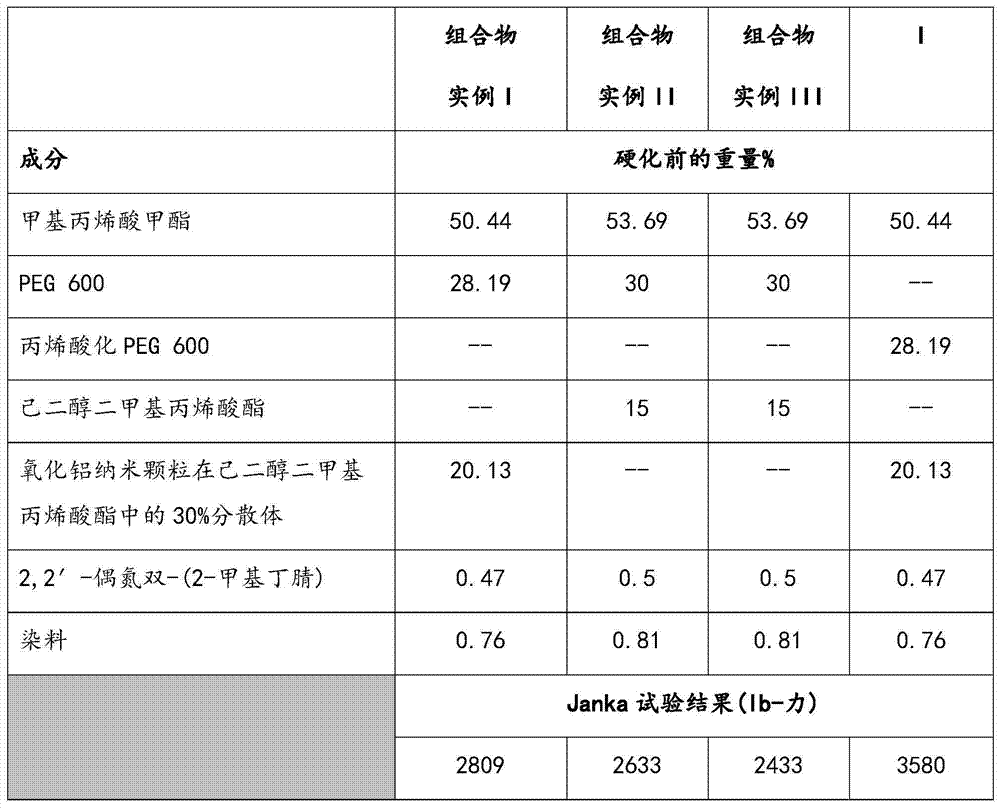

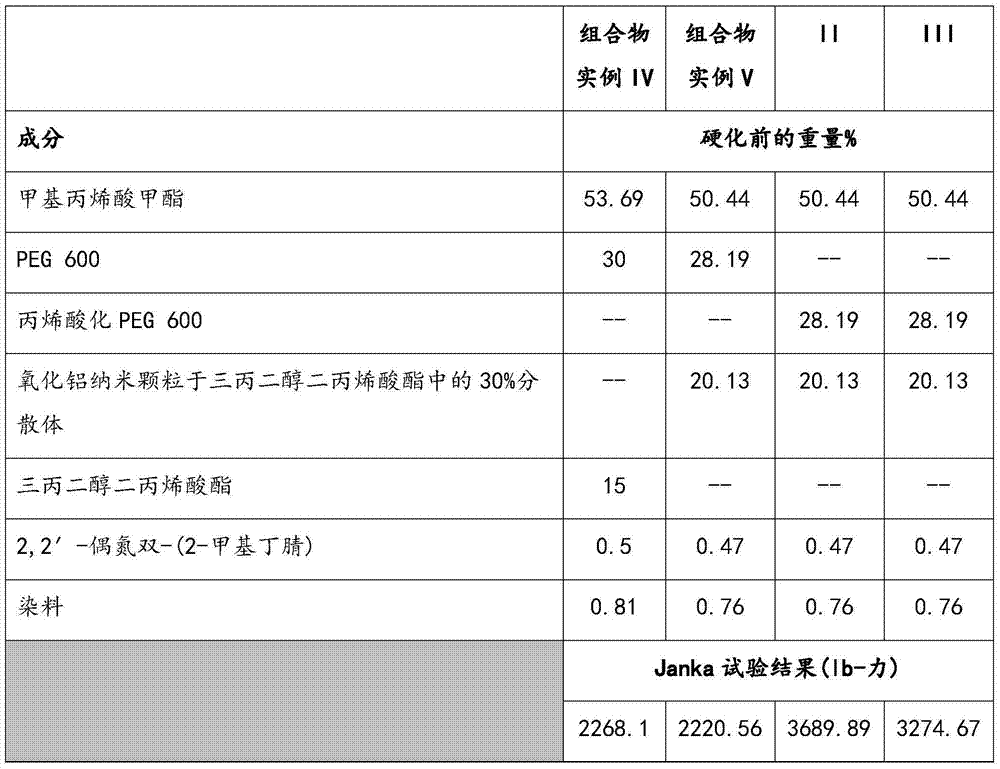

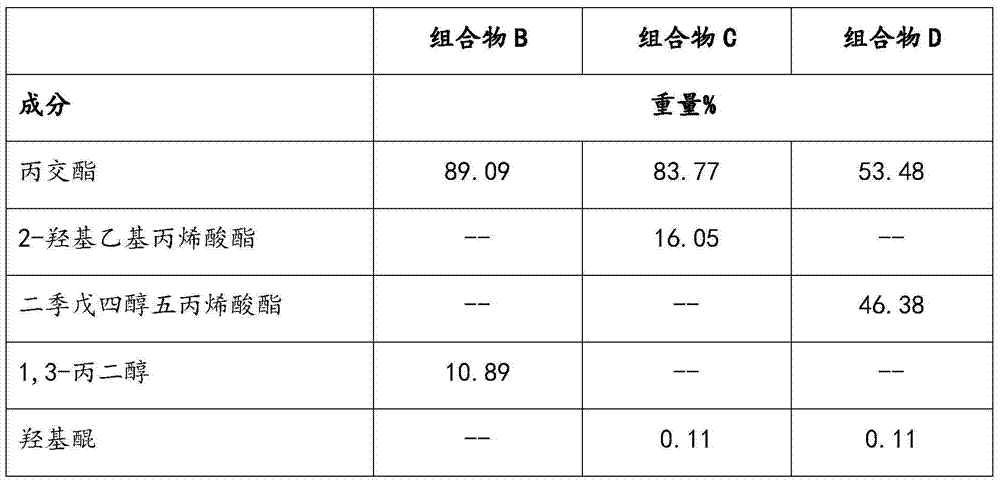

Wood products impregnated with monomer based compositions

InactiveCN104723425AHigh hardnessWood treatment detailsWood hardening processPlasticizerAcrylate ester

Described herein are impregnated products comprising a cellulosic substrate having internal voids; and a reaction product of a composition comprising: an acrylate monomer; and an acrylated plasticizer; wherein the cellulosic substrate is impregnated with said composition. Methods of making and using the products are also described.

Owner:ARMSTRONG WORLD INDUSTRIES

Treating agent to improve the tenacity of rattan

InactiveCN106272822AMildew proofBactericidalWood treatment detailsReed/straw treatmentFiberSulfonate

This invention belongs to the field of processing technology of rattan used for knitting, which involves a kind of treating agent to improve the tenacity of rattan made of eater, special butyl benzoate, acetanilide, piemarker, dimethyl phosphite, sodium sulfonate, hydroxymethyl melamine and adjuvant. Being compared to current technologies, this invention has the following advantages: the adjuvant in this invention has the function of mould proof and sterilization. In the process of soaking, changes of different intensities of pressure are used to accelerate the permeation of agentia, which at the same time makes the lignin within the rattan dissolve out quickly and enables treating agent to act on the center of the rattan through the capillary tubes on the fibers of the rattan surface. Thus, this treating agent can protect carbohydrate, enhance the tenacity of rattan, and improve the knittability of rattan, which is suitable for products with a high requirement for rattan tenacity.

Owner:安徽宏润工艺品有限公司

Tenacity-improving crack-resisting wood hardening agent and preparation method thereof

InactiveCN105984004AExtended service lifeImprove permeabilityWood treatment detailsWood hardening processPolyvinyl alcoholGuar gum

The invention discloses a tenacity-improving crack-resisting wood hardening agent. The tenacity-improving crack-resisting wood hardening agent is made from the following raw material comprising, by weight, 10-15 parts of sodium silicate, 3-5 parts of carbamide, 10-15 parts of magnesium sulfate, 2-3 parts of guar gum, 1-2 parts of sodium carboxymethylcellulose, 0.1-0.2 part of ammonium persulphate, 2-4 parts of styrene, 4-6 parts of maleic anhydride, 3-5 parts of xylitol, 0.5-1 part of polyvinyl alcohol, 0.5-1 part of 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, 5-10 parts of performance additives and 80-100 parts of water. The wood hardening agent has the beneficial effects of being good in permeability, not prone to running off and good in durability and having a strong ability to bond with wood. Besides, the wood hardening agent achieves a good hardening effect, is safe, environmentally friendly and capable of improving tenacity, resisting crack, prolonging the service life of wood, and has high practical value.

Owner:FUNAN COUNTY TIANYI CRAFTS

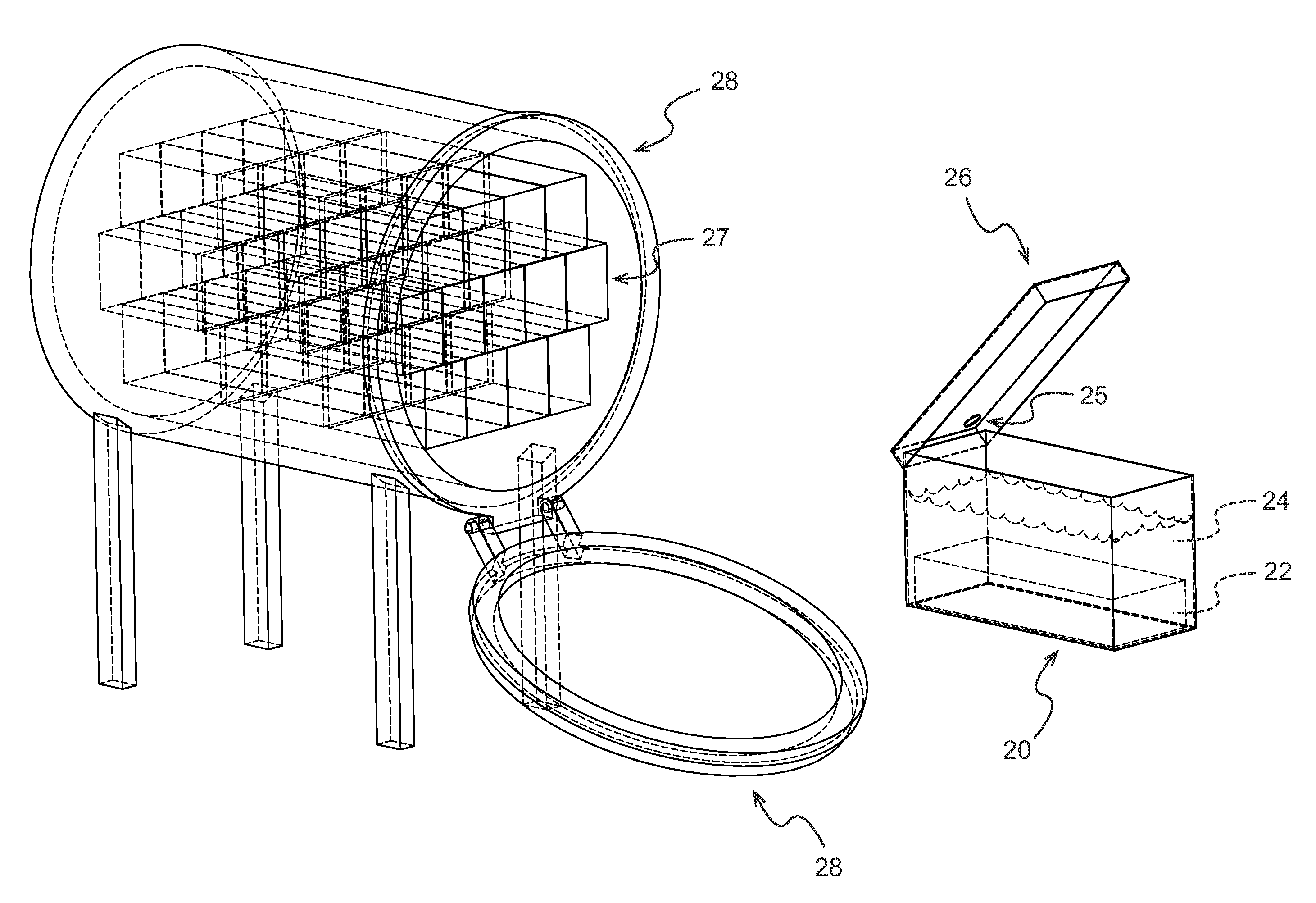

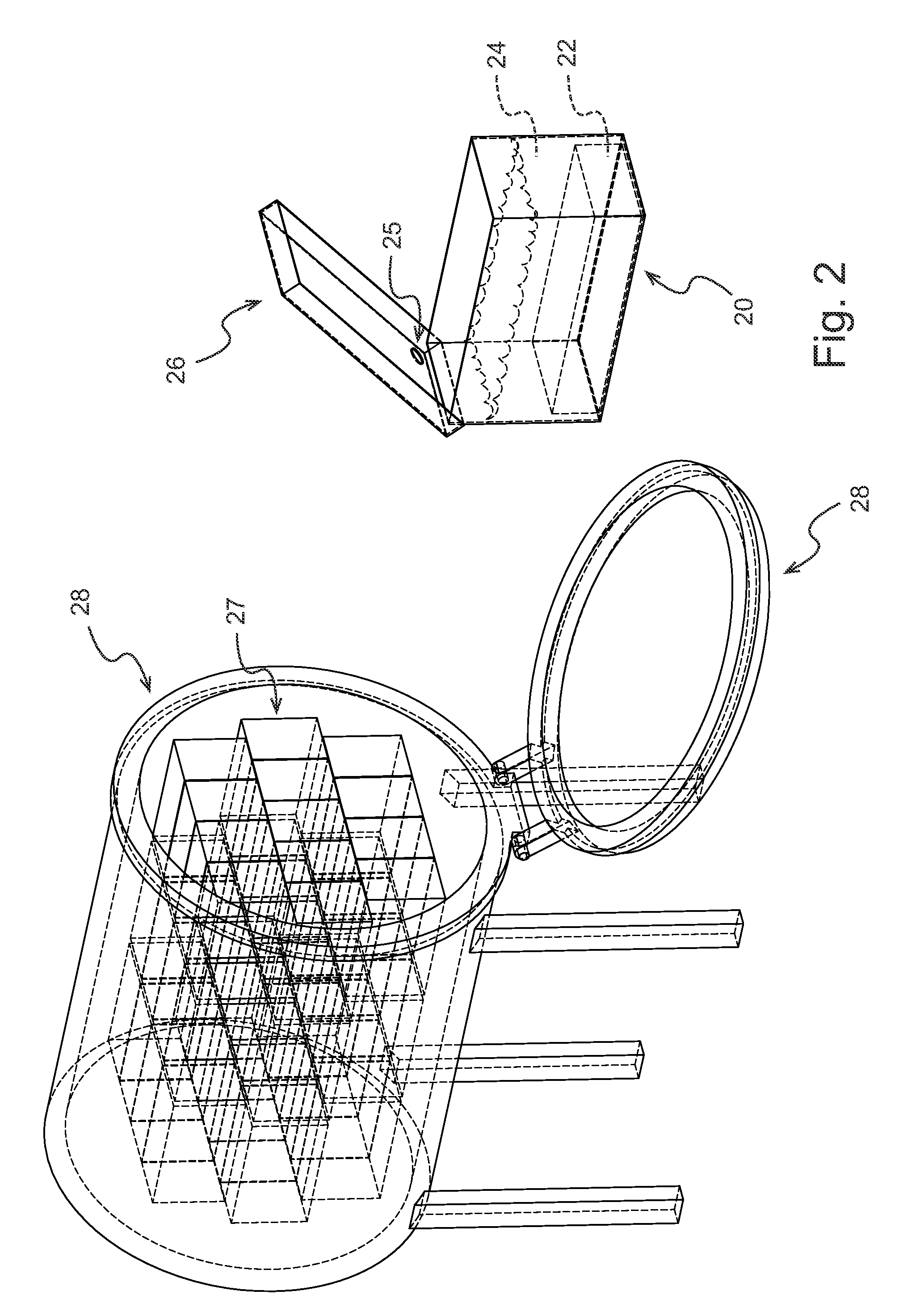

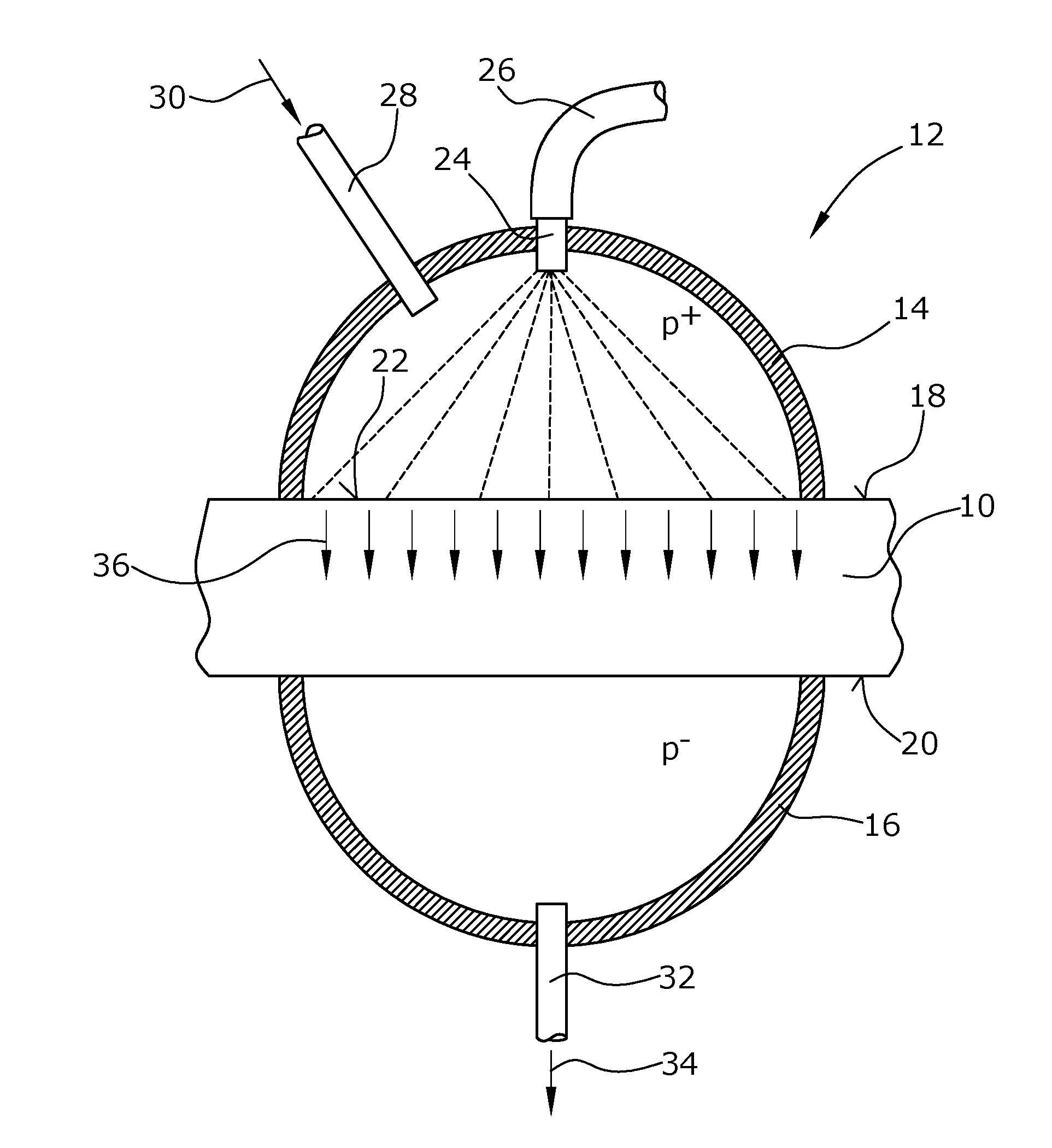

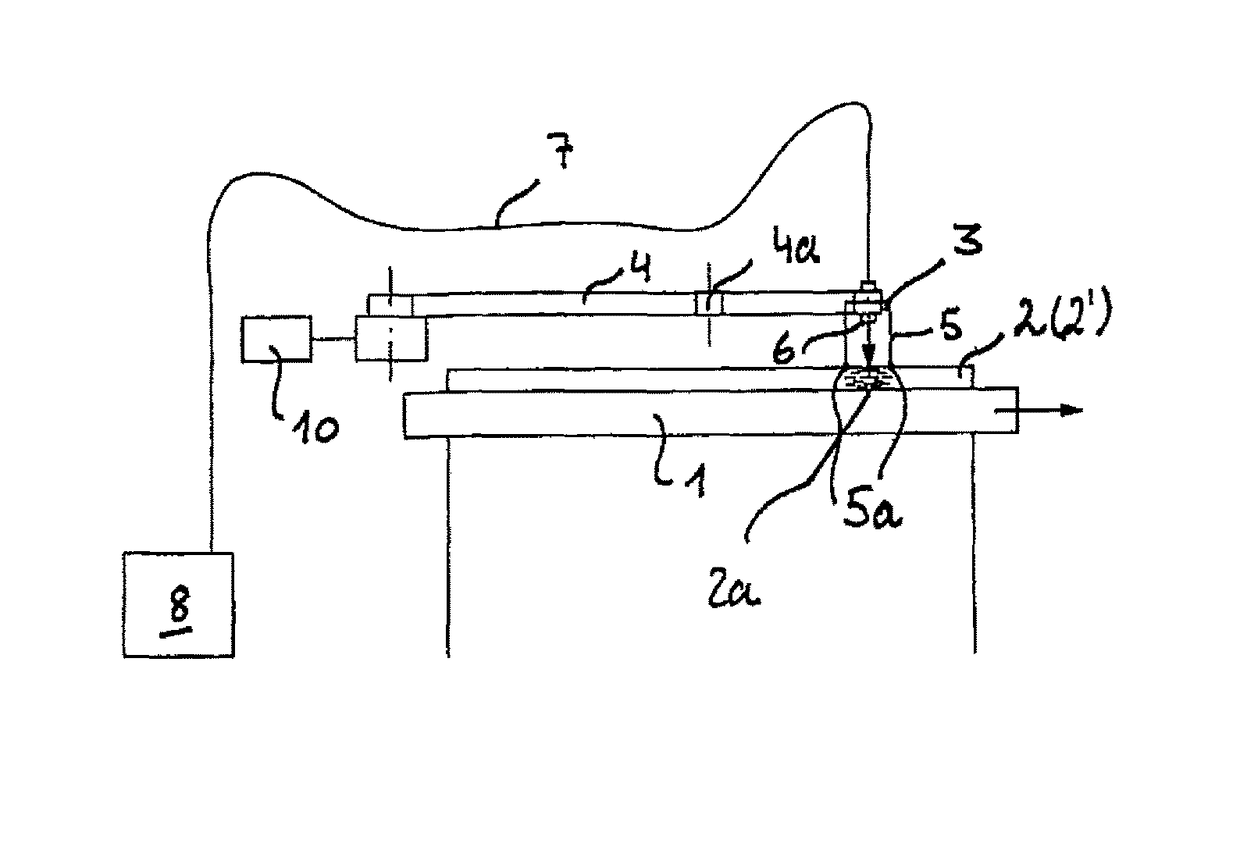

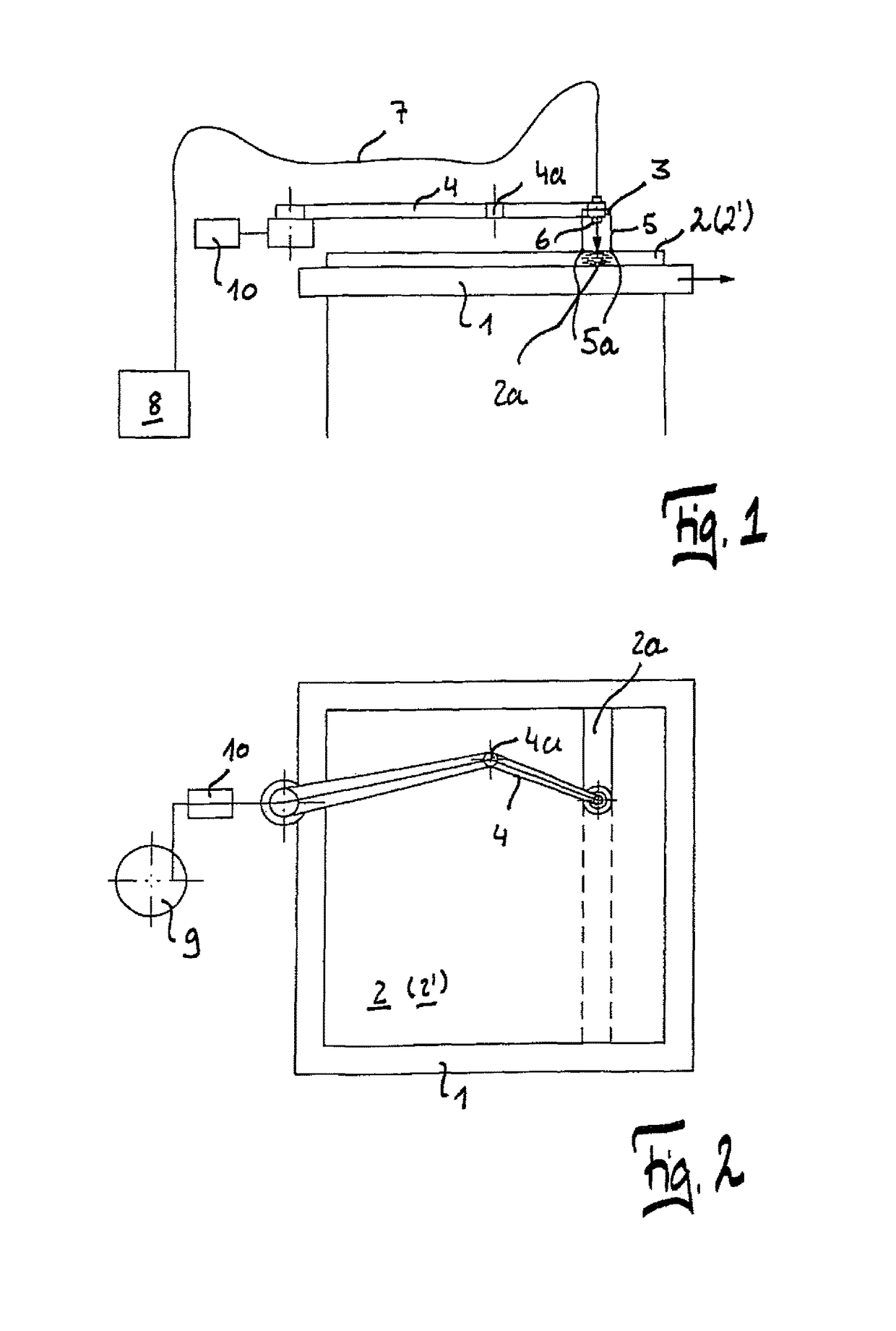

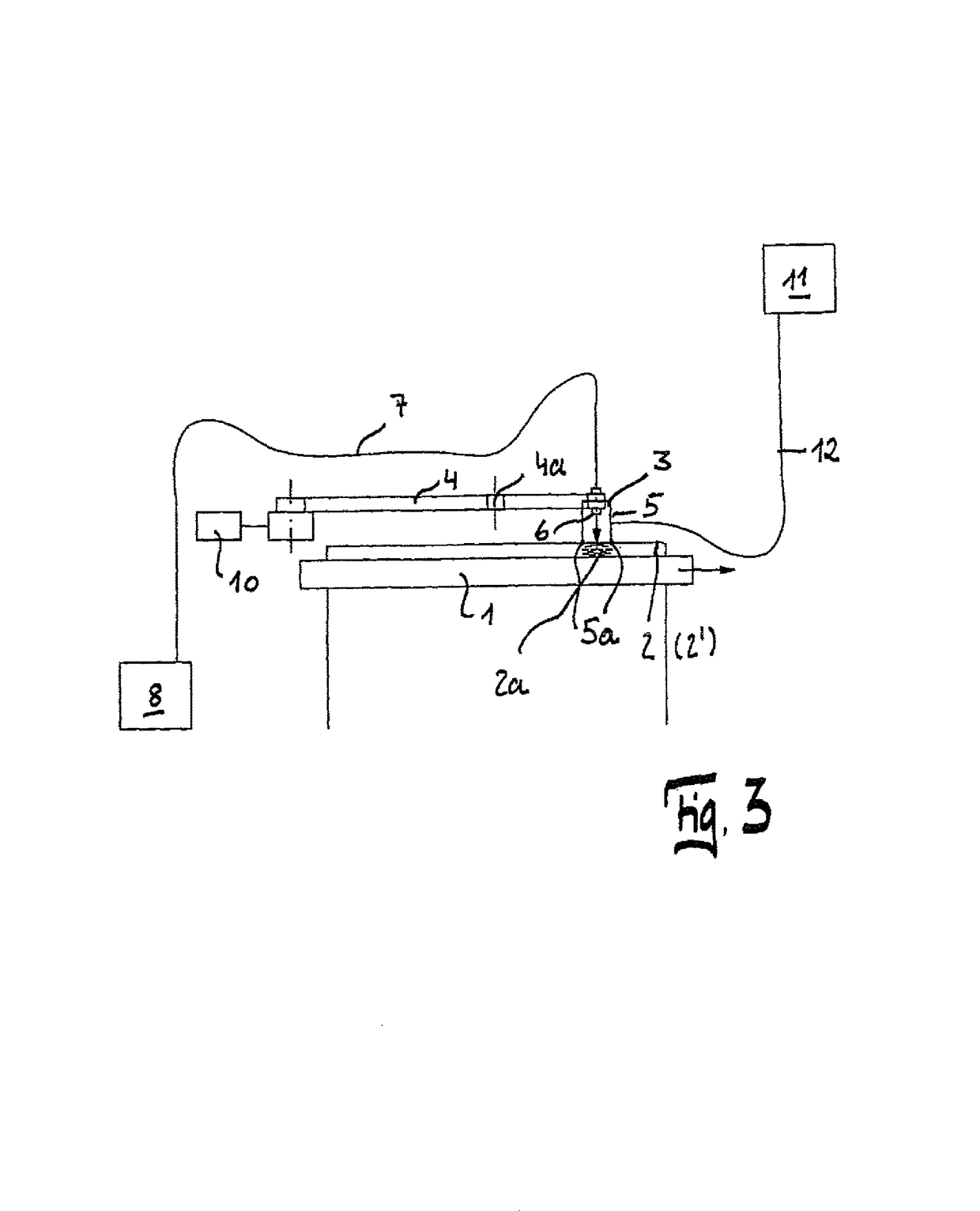

Method for Producing a Partially Solidified Wood Fiber Board, Partially Solidified Wood Fiber Board, and Device for Producing Same

InactiveUS20160303759A1Simple wayThe way is simple and fastConstruction materialImpregnation spraying apparatusFiberEngineering

A method for producing a partially solidified wood fiber board which prior to partial solidification has already been cut to size, includes the defining of a solidification area. Within the solidification area, solidifying agent is applied onto a top side of the wood fiber board. Particularly with the aid of a pressure bell and / or a suction bell, a pressure difference can be generated between the top side and the bottom side of the wood fiber board for suction of the solidifying agent into the wood fiber board.

Owner:CEFLA DEUTLAND

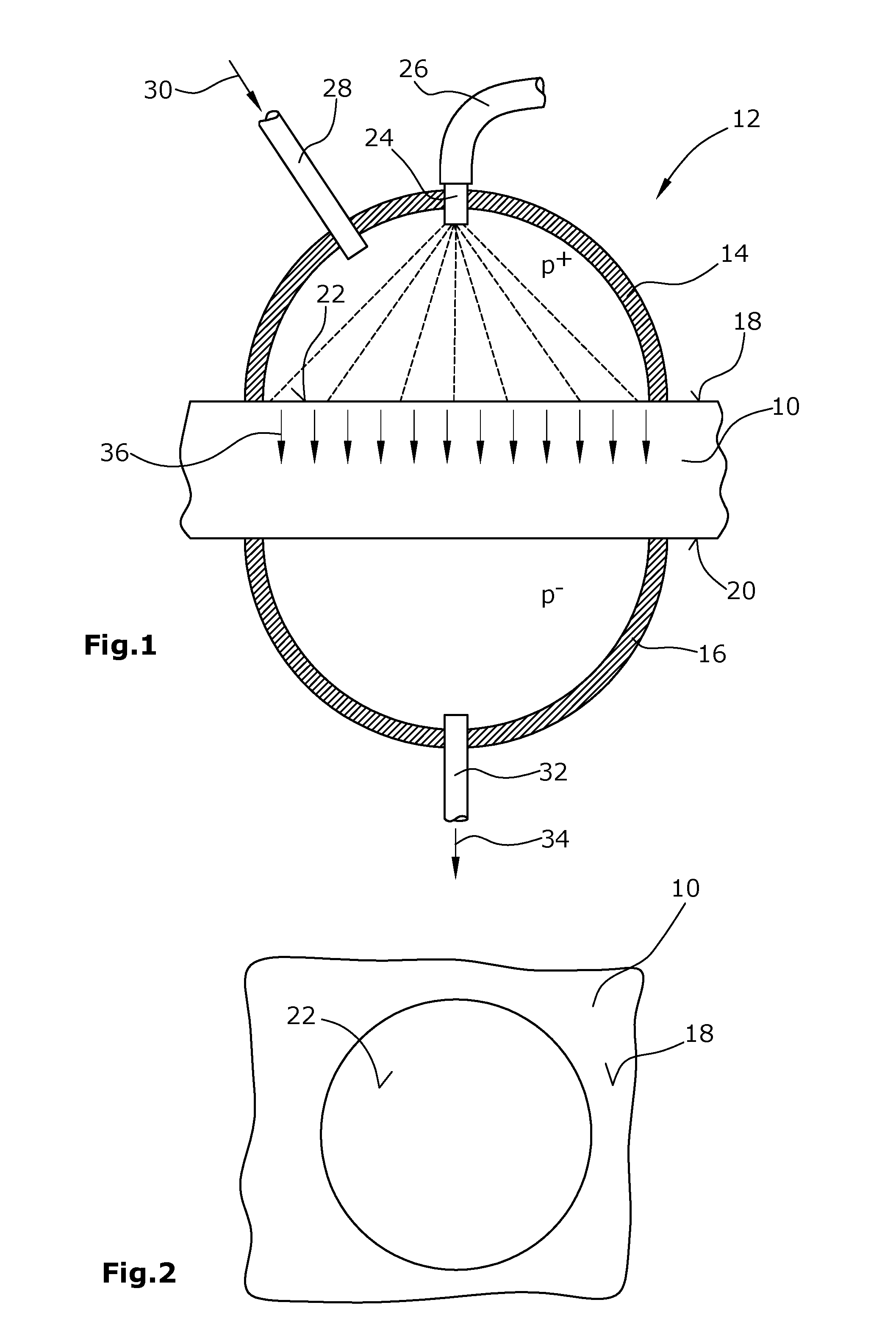

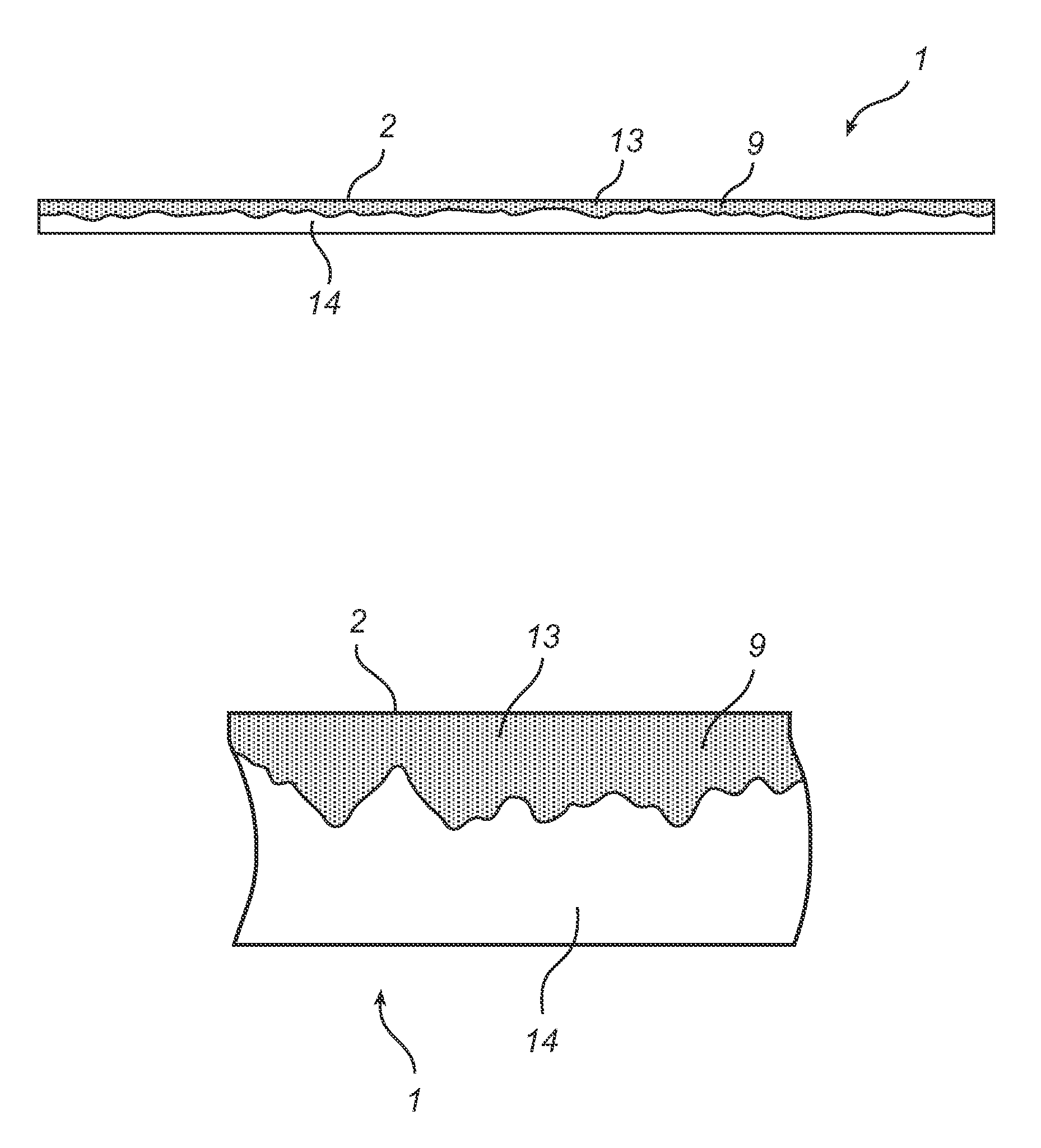

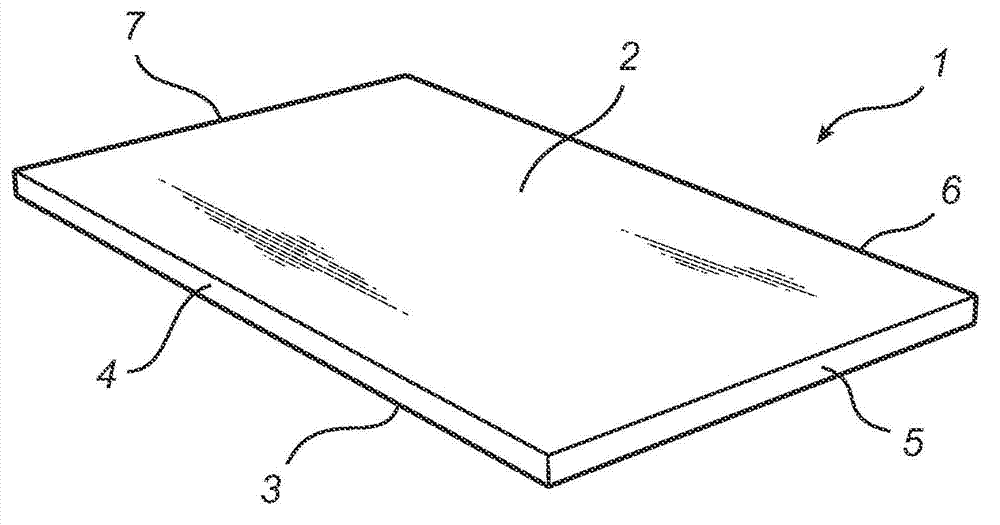

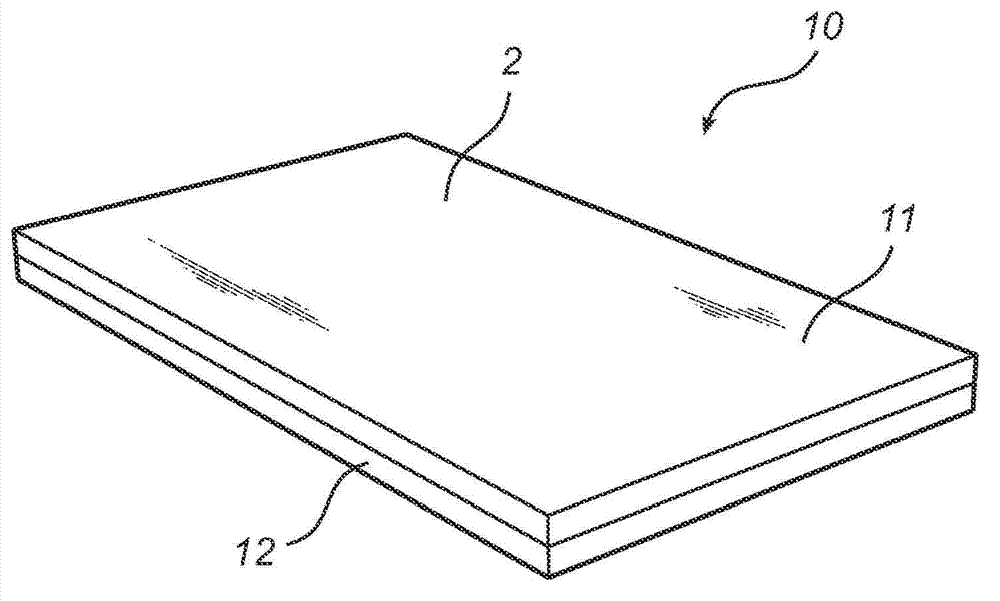

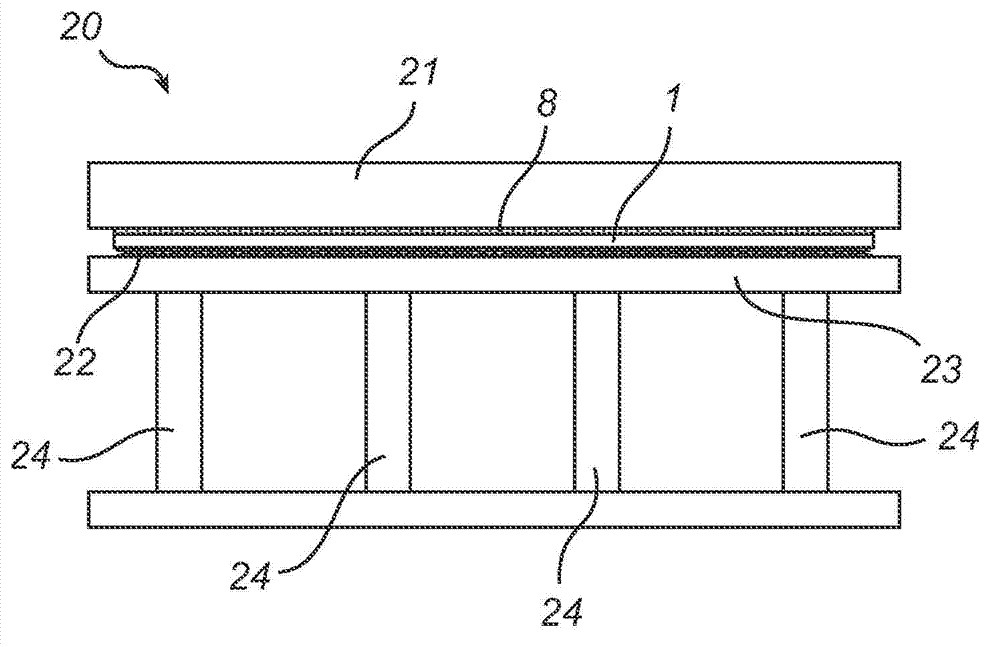

Method for treatment of a board and a board element

InactiveUS20130101786A1Grain-raising problem is reducedReduce decreaseSynthetic resin layered productsWood treatment detailsPolymer scienceEngineering

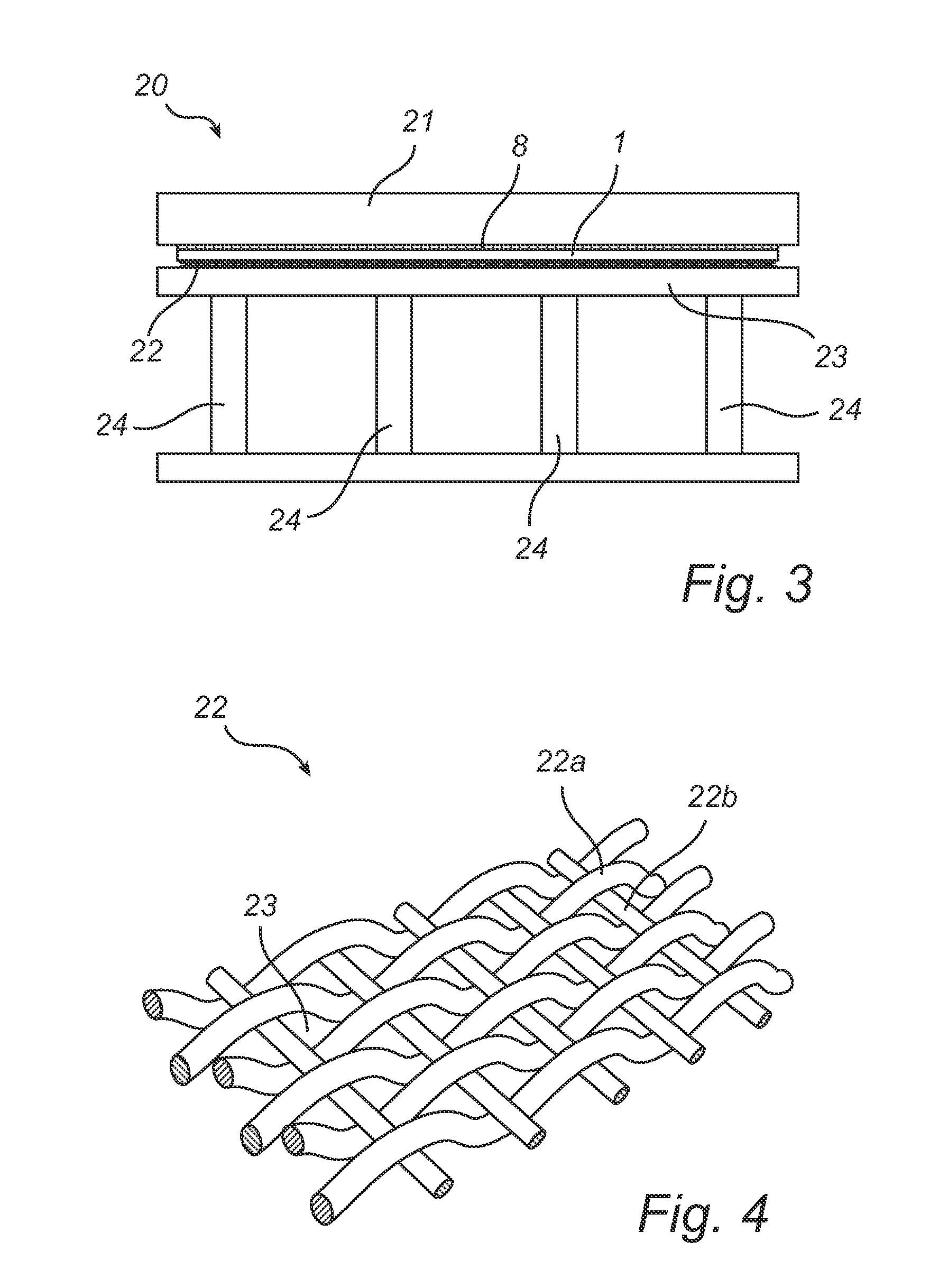

The invention relates to a method for treating a board (1) of wood material, such as an HDF board, an MDF board, a plywood board, planks or boarding, comprising the steps of providing a board (1) of wood material, arranging a composition (8) comprising a binder (9) on a first main face (2) of said board (1), arranging said board (1) on a draining surface (22), heat-treating said board (1) and the composition (8) arranged thereon, and pressing the composition (8) into said board (1). The invention also relates to a board element comprising one or more board layers, which board element comprises binder, the binder being heterogeneously distributed in at least one of said one or more board layers.

Owner:MB ADELTRA

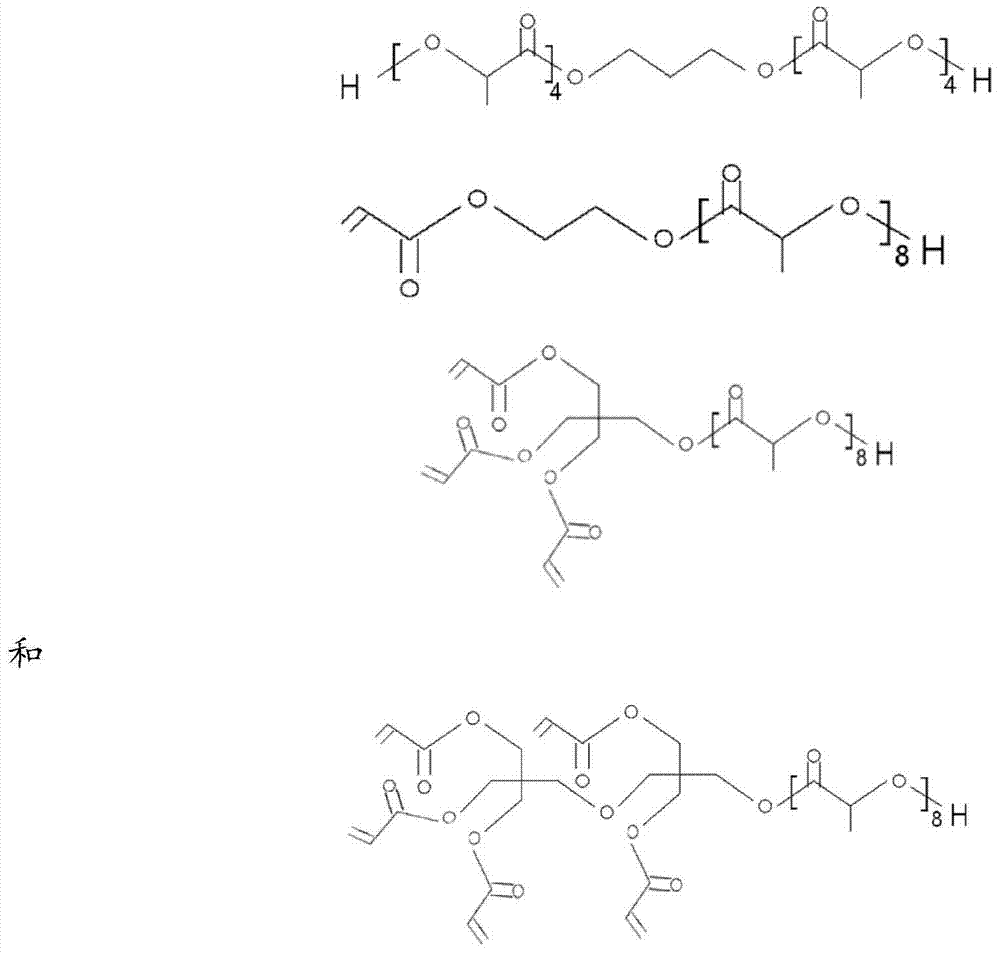

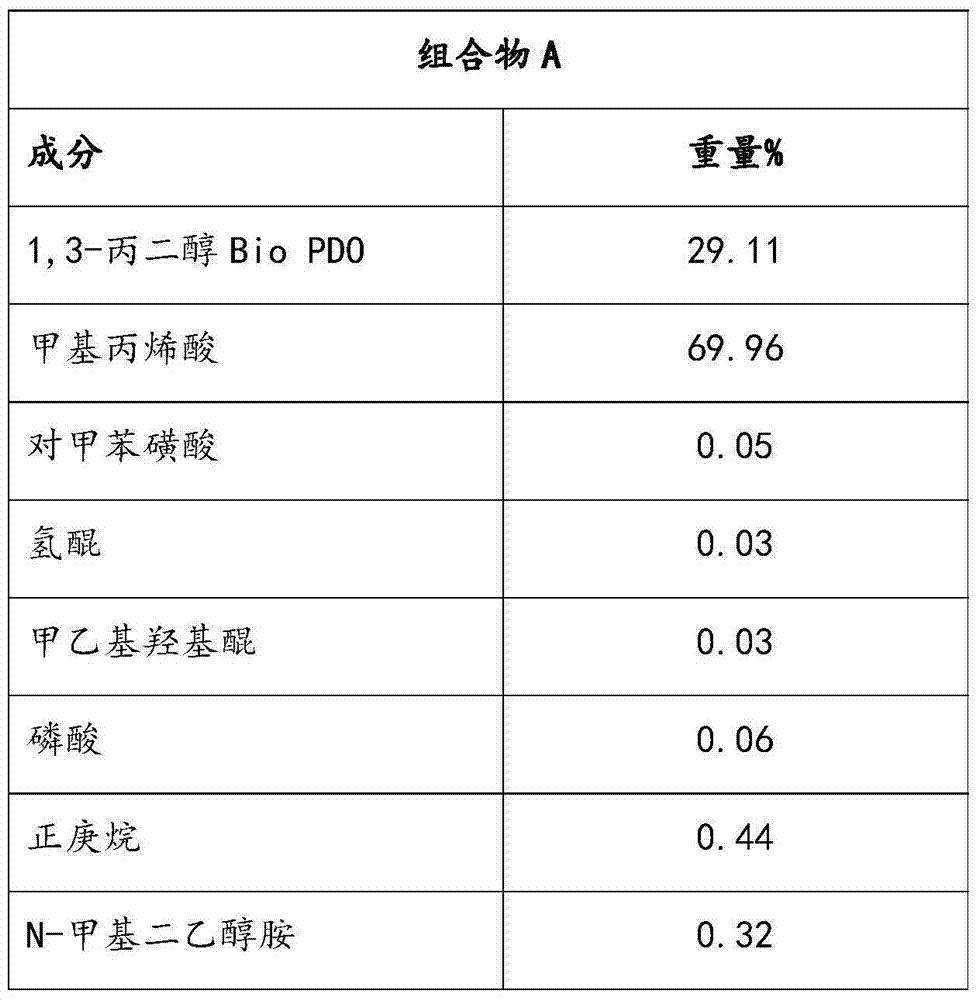

Biobased impregnating composition and products comprising same

InactiveCN104723423AHigh hardnessWood hardening processPressure impregnationReaction productAcrylate

Described herein are impregnated products comprising a cellulosic substrate having internal voids; and a reaction product of a composition comprising: an acrylate monomer; a biobased component; and an acrylate additive; wherein the cellulosic substrate is impregnated with said composition. Methods of making and using the products are also described.

Owner:ARMSTRONG WORLD INDUSTRIES

Polymeric composition for cellulosic materials binding and modification

A polymer composition suitable for wood treatment or bonding comprising the reaction product of at least one polyol and at least one crosslinking agent. Each molecule of the crosslinking agent contains at least 2 carboxylic acid groups. The invention also discloses a wood product comprising a wood substrate and a mixing composition, and a wood treatment step.

Owner:格林百奥生态材料科技(上海)有限公司

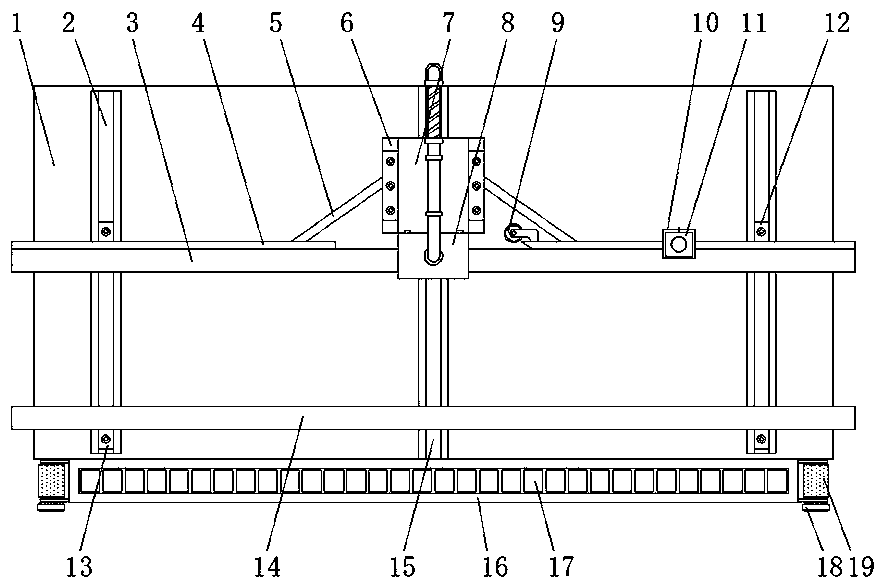

Method and device for specifically influencing the technological properties of individual regions of a sheet-like material, a pre-compacted material nonwoven or a material fibre cake

A device and a method for specifically influencing the technological properties of individual regions of a sheet-like material are provided, including the following steps: a) fixing the sheet-like material or a pre-compacted material nonwoven or a material fiber cake on a workbench, b) placing at least one applicator on the upper side and / or the underside of the sheet-like material, the material nonwoven or the material fiber cake, c) specifically moving the at least one applicator on the upper side and / or the underside and pressing an improving medium into partial regions of the sheet-like material, the material nonwoven or the material fiber cake in a predetermined amount and under a predetermined pressure, d) optionally, subsequently pressing the pre-compacted material nonwoven or the material fiber cake to form a sheet of the desired thickness.

Owner:FLOORING TECH +1

A high-efficiency wood veneer trimming process and trimming device

ActiveCN109648426BShorten the processing flowShorten the production cycleEdge grinding machinesOther plywood/veneer working apparatusWood veneerPulp and paper industry

The invention discloses a high-efficiency wood veneer trimming process and a trimming device, belonging to the field of wood trimming, comprising the following steps: step 1, spraying the top paint of the wood veneer; step 2, cutting the wood veneer; step 3. Spraying veneer edge topcoat; Step 4, Wood veneer panel edge sealing; Step 5, Wood veneer panel trimming. The present invention treats the wood veneer board with UV topcoat, so that the UV topcoat is cured and formed into a film after being irradiated by ultraviolet rays, which effectively reduces the process of spraying the topcoat on the board after preliminary polishing in the traditional process. , effectively reduce the processing flow, reduce the production cycle, thereby reducing the production cost and improving the production efficiency by 5‑10 times, and by cutting the wood veneer board and sealing the edge with UV topcoat veneer, effectively reducing the cost The processing of the veneer edge makes the UV top-coated veneer edge fully protect the corners of the wood veneer, reducing the damage to the corners of the wood veneer.

Owner:DONGGUAN ZHONGJIN FURNITURE CO LTD

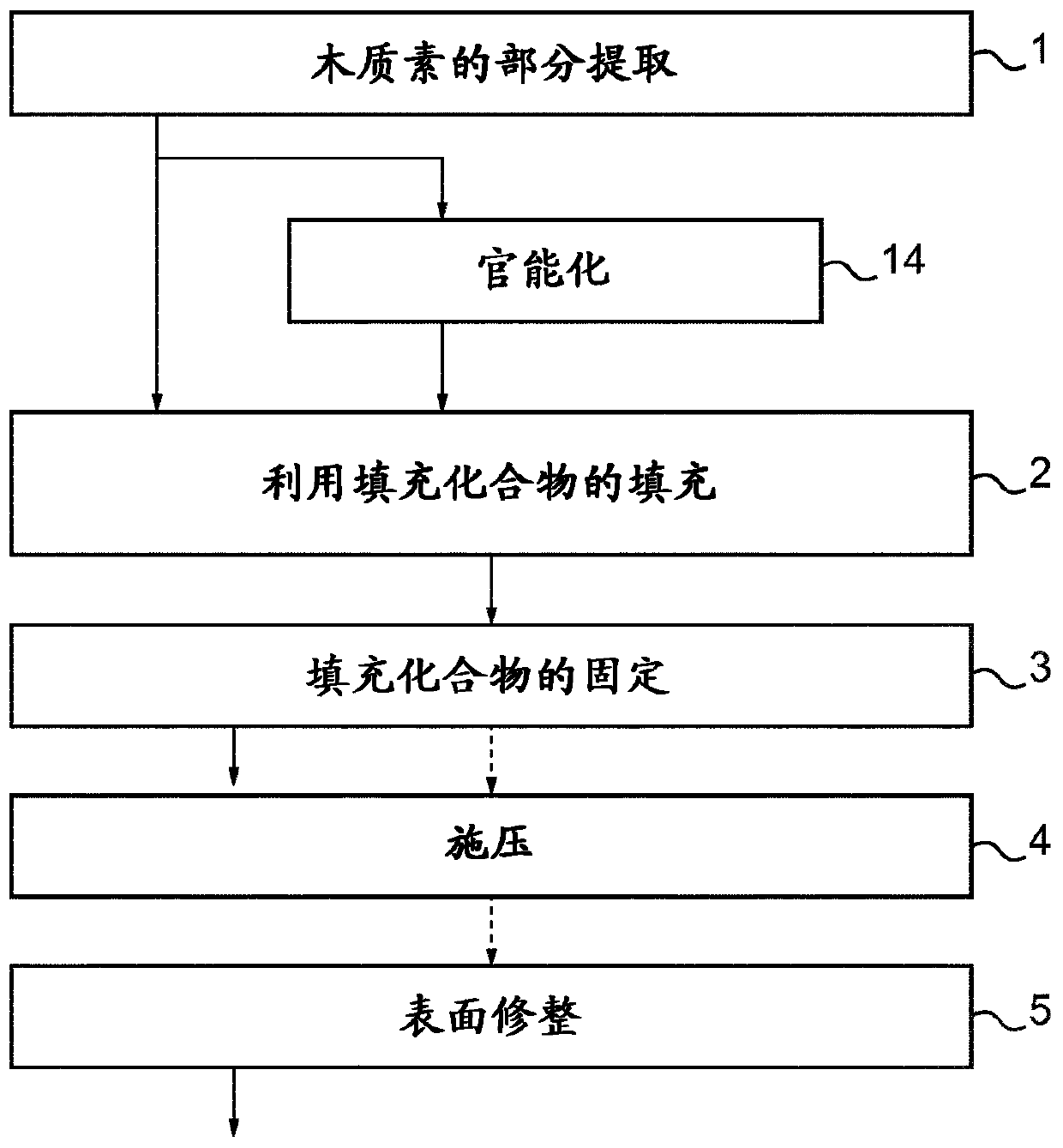

Process for supercritical or subcritical partial delignification and filling of a lignocellulosic material

ActiveCN110831731AOptimize extraction stepsImprove performanceLiquid surface applicatorsPressure wood treatmentCelluloseMaterials science

The invention relates to a process for treating lignocellulosic material, preferably wood, comprising the following successive steps: (1) extraction of lignin by a fluid in supercritical or subcritical phase in order to extract from 40 to 85%, in % by weight, of the lignin from the initial material; (2) filling by a filling compound, preferably in the presence of a fluid in supercritical or subcritical phase.; and (3) finishing, so as to obtain a composite material formed of a three-dimensional network of filling compound converted and incorporated in a network of cellulose and of lignin.

Owner:SAS WOODOO

Hardened stage floor and preparation method thereof

ActiveCN106239682AIncrease elasticityImprove flexibilityOther plywood/veneer working apparatusWood treatment detailsFinger jointEngineering

The invention relates to a hardened stage floor and a preparation method thereof. The hardened stage floor is arranged on the upper surface of a stage and is formed by horizontally connecting multiple quarter-sawed lumbers in a finger joint manner. Each quarter-sawed lumber sequentially comprises a hardened layer and an elastic layer from top to bottom. The hardened layers and the elastic layers are integrally connected. The density of the hardened layers accounts for 125% to 135% of the density of the elastic layers. According to the hardened stage floor, by arranging the hardened layers and the elastic layers on the surfaces of the quarter-sawed lumbers, on the premise that elasticity, flexibility, unsmoothness, toughness, reversibility and impact absorptivity of the quarter-sawed lumbers are ensured, the surface harness of the quarter-sawed lumbers is improved, and the wood properties, such as compressive strength and shear strength, of the surface of the stage wood floor are improved.

Owner:杭州大森体育文化发展有限公司

Environment-friendly type guardrail manufacturing process

InactiveCN108098955AHigh strengthNot easy to corrodeWood treatment detailsWood hardening processUltimate tensile strengthMaterials science

The invention discloses an environment-friendly type guardrail manufacturing process comprising the procedures of soaking, drying, forming, oil smearing, varnishing and the like. Wood is adopted as the main raw materials of an environment-friendly type guardrail made through the environment-friendly type guardrail manufacturing process, and energy saving and environment friendly effects are higher. The overall strength of the soaked wood is promoted substantially, and the wood is firmer and more durable. Meanwhile, the soaked wood is not liable to external corrosion and is not liable to mildewcorrosion even if the wood is exposed in a windy and rainy environment for a long time, and service life is long.

Owner:江苏鑫格调护栏科技有限公司

Method for treatment of a board and a board element

InactiveCN102858506AReduce consumptionParticle lift problem reducedWood treatment detailsPretreated surfacesThick plateEngineering

The invention relates to a method for treating a board (1) of wood material, such as an HDF board, an MDF board, a plywood board, planks or boarding, comprising the steps of providing a board (1) of wood material, arranging a composition (8) comprising a binder (9) on a first main face (2) of said board (1), arranging said board (1) on a draining surface (22), heat- treating said board (1) and the composition (8) arranged thereon, and pressing the composition (8) into said board (1). The invention also relates to a board element comprising one or more board layers, which board element comprises binder, the binder being heterogeneously distributed in at least one of said one or more board layers.

Owner:MB ADELTRA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com