Polymeric composition for cellulosic materials binding and modification

A composition and polymer technology, applied in the direction of polymer impregnation, thin material treatment, wood treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

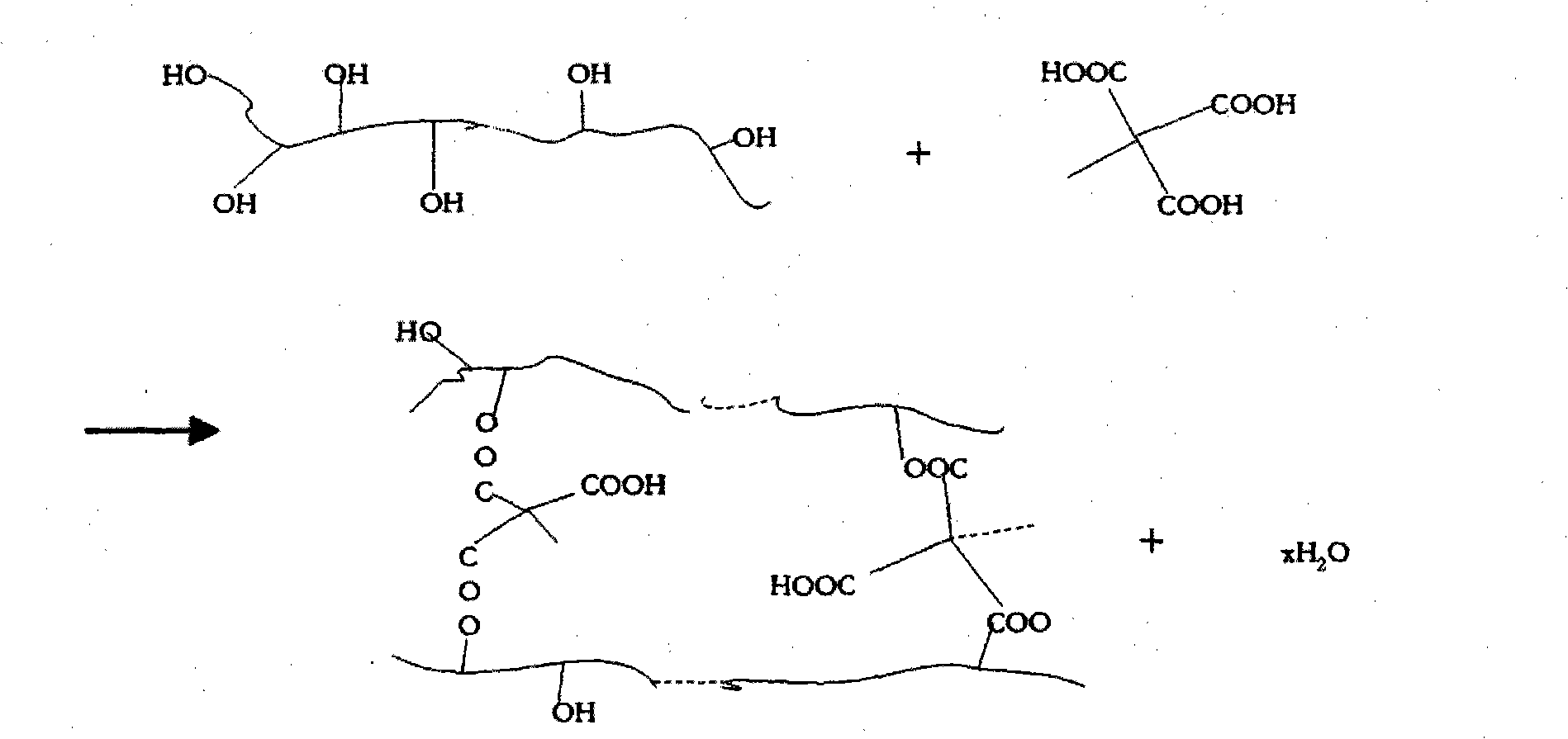

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 5.0 kg of butane tetracarboxylic acid, 20.0 kg of citric acid and 15.6 kg of maltodextrin were mixed with 80.0 kg of water until the solution became clear and a mixed composition was formed. Some poplar solid wood planks were placed in an autoclave, which was then evacuated to about 80% vacuum. The mixed composition was then transferred to an autoclave. When the autoclave was filled with the mixed composition liquid, the system was pressurized and maintained for about 3 hours. The impregnated wood boards were dried in an oven heated to 100°C for about 24 hours to allow the mixed composition to react to form a cross-linked polymer. The resulting treated wood had a specific gravity of about 0.6 g / ml compared to a corresponding untreated wood of about 0.32 g / ml. The treated wood exhibits enhanced mechanical properties.

Embodiment 2

[0032] 5kg of butane tetracarboxylic acid, 20kg of citric acid, 1kg of itaconic acid, 18kg of maltodextrin and 5kg of 20% by weight of polyvinyl alcohol 5000 in water, and 0.5kg of zinc acetate, 0.4kg of Boric acid and 80 kg of water were mixed to form a mixed composition. Some solid radiata pine planks were placed in an autoclave, which was then evacuated to a vacuum of about 80%. The mixed composition was then transferred to an autoclave. When the autoclave was filled with the mixed composition liquid, the system was pressurized and maintained for 3 hours. The impregnated boards were dried in an oven and heated to about 100°C for about 24 hours. The resulting treated wood had a specific gravity of about 0.7 g / ml compared to a corresponding untreated wood of about 0.45 g / ml. The Janka hardness of the treated wood reaches about 1600 pound-force.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com