Wood products impregnated with monomer based compositions

A composition and monomer technology, applied in the direction of impregnating wood, polymer impregnation, wood impregnation, etc., can solve the problem of insufficient hardening of the wood surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Exemplary Process for Preparing Dip Compositions

[0047] The polymerization initiator was weighed and poured into the first container with the acrylate monomer. The specified amount of acrylated plasticizer is then added to the second container. The acrylate monomer was then added to the second container. The acrylate monomer, acrylated plasticizer and polymerization initiator are then mixed until blended. The mixture is then returned to the first container, to which an additional amount of acrylate monomer is added. Mix the contents of the first container until homogeneous.

Embodiment 2

[0048] Example 2: Exemplary Process for Impregnation of Cellulose Substrates

[0049] Load the cellulose substrate to be impregnated into the container and close the door. Close the bleed valve and the main valve. Open the vacuum valve and gauge valve. Start the vacuum pump and turn on the vacuum gauge. Allow the vacuum to drop to a minimum of 50mm. The main valve is opened to allow the infusion composition to pass from the first container to the third container. The main valve was closed and the third vessel was pressurized to about 20 psi with nitrogen. Soak for about 45 minutes at about 20 psi. Open the main valve to blow the dipping composition back into the first container. Close the main valve. Boost to about 40psi and let it drain for about 15min. Open the main valve and allow the remaining dipping composition to drain into the first container. Pressurize and maintain the pressure in the third vessel at 70-80 psi. Steam is introduced into the heated shell of t...

Embodiment 3

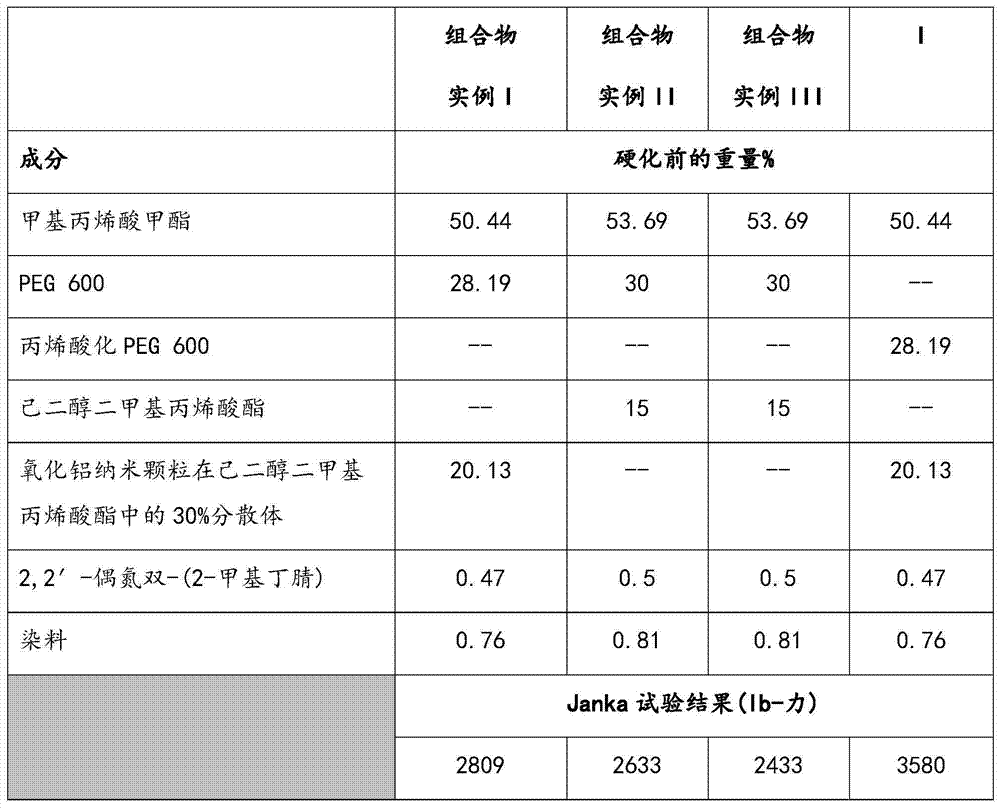

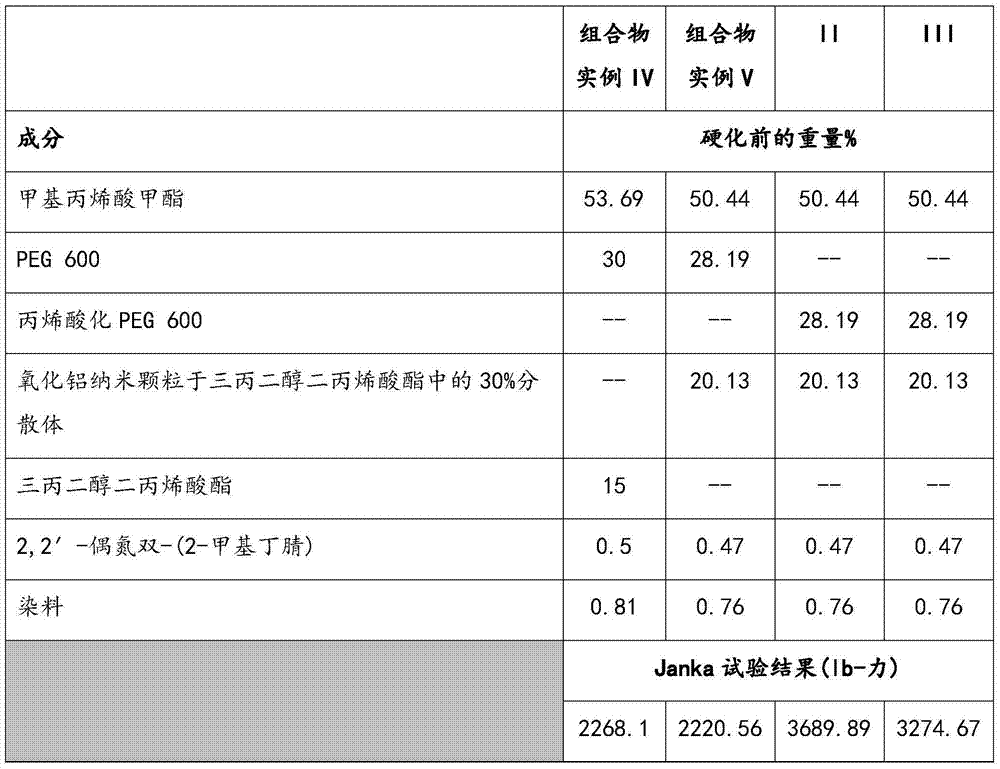

[0051] 1500 g of the acrylate monomer-based composition as described in Table 1 (below) were prepared according to conventional procedures, for example as described in Example 1 (above). A 0.08 inch thick oak veneer was then impregnated with the composition. The impregnated veneers were glued and pressed together with other oak and poplar veneers to make 6-ply samples 1 inch thick for indentation testing.

[0052] Table 1

[0053]

[0054] The data described in Table 1 (above) demonstrate that the inclusion of an acrylated plasticizer in the impregnating composition provides an unexpected increase in the hardness of the cellulosic substrate impregnated therewith. It should be noted that the Janka test results reported in Table 1 are average values taken from multiple tests for each composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com