Wood compression-in-situ pressured heat treatment integrated method and compressed wood prepared through method

A compression treatment, wood technology, applied in the direction of wood heat treatment, wood compression, wood treatment, etc., can solve the problems of inapplicability, environmental pollution, etc., and achieve the effect of controlling the loss of mechanical strength, high heat dissipation efficiency, and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

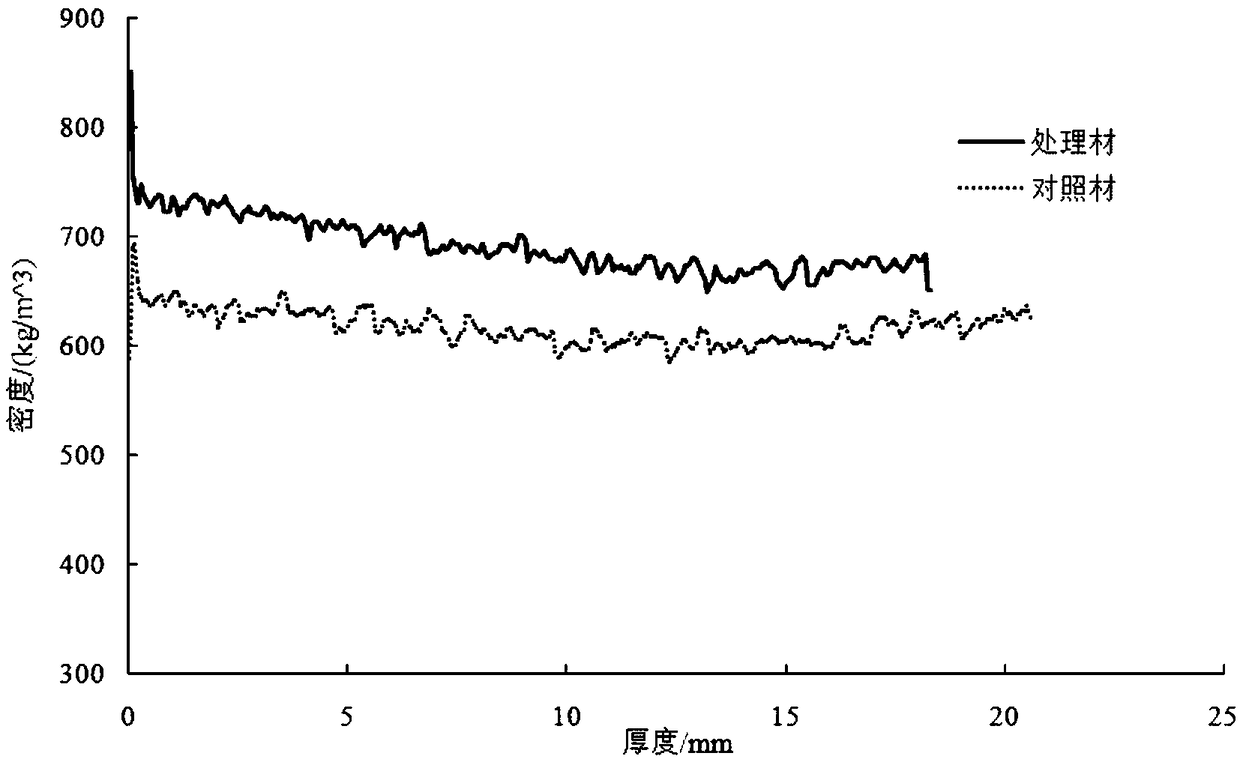

Image

Examples

Embodiment 1

[0033] (1) Dry Thai rubberwood sawn timber with a size of 1000×110×24mm to a moisture content of 12%, and after double-sided planing, the final thickness is 20.5mm;

[0034] (2) Lay 20.5mm thick rubber wood boards neatly in a single row between the platens of the hot press, place 4 pieces at a time, conduct a total of 3 tests, and place 18mm thickness gauges on both sides of the board;

[0035] (3) Turn on the heating system and pressurization system of the hot press, set the pressure to 1.2 MPa, set the temperature to 135°C, heat up at a rate of 100°C / hour, heat for 90 minutes, and the moisture content of the wood is reduced to -1.1%. Online measurement of wood core temperature reaches 135°C;

[0036] (4) After the heating stage ends, the pressure of the press is increased to 10 MPa, the wood is compressed to the target thickness within 60 seconds, the pressure is kept for 300 seconds, and then the pressure is completely released within 60 seconds; The pressure of the press ...

Embodiment 2

[0042] (1) Dry poplar boards with a size of 930×120×26mm until the moisture content is 10%, and the final thickness is 24mm;

[0043] (2) Lay 24mm thick poplar boards neatly in a single row between the pressing plates of the hot press, place 4 pieces each time, and carry out 3 tests in total, and place 20mm thickness gauges on both sides of the board;

[0044] (3) Turn on the heating system and pressurization system of the hot press, set the pressure to 2 MPa, set the temperature to 120°C, heat up at a rate of 100°C / hour, heat for 75 minutes, and the moisture content of the wood is reduced to -0.9%. Online measurement of wood core temperature up to 120°C;

[0045] (4) After the heating stage ends, the pressure of the press is raised to 12 MPa, and the wood is compressed to the target thickness within 45 seconds, held for 300 seconds, and then completely relieved within 45 seconds; The pressure of the press is increased to 6 MPa within 30 seconds, the pressure is kept for 420 ...

Embodiment 3

[0051] (1) Drying the masson pine plate with a size of 980×105×23.5mm to a moisture content of 15%, and a final thickness of 22mm;

[0052] (2) Lay 22mm thick masson pine boards neatly in a single row between the platens of the hot press, place 4 pieces at a time, carry out 3 tests in total, and place 20mm thickness gauges on both sides of the board;

[0053] (3) Turn on the heating system and pressurization system of the hot press, set the pressure to 0.6 MPa, set the temperature to 150°C, heat up at a rate of 100°C / hour, heat for 100 minutes, and the moisture content of the wood is reduced to -1.6%. Online measurement of the core temperature of the wood reaches 148°C;

[0054] (4) After the heating stage ends, the pressure of the press is increased to 8 MPa, and the wood is compressed to the target thickness within 45 seconds, kept under pressure for 300 seconds, and then completely relieved within 45 seconds; The pressure of the press is increased to 4 MPa within 30 second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com