Heat-resistant single-component moisture-curing polyurethane sealant and preparation method thereof

A polyurethane sealant, one-component technology, applied in the field of sealants, can solve the problems of poor thermal stability, bubbles and cracks, etc., to improve heat resistance, expand the use range, avoid bubbling and mechanical performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

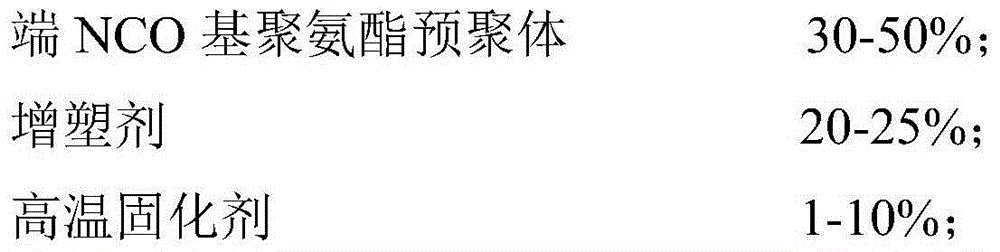

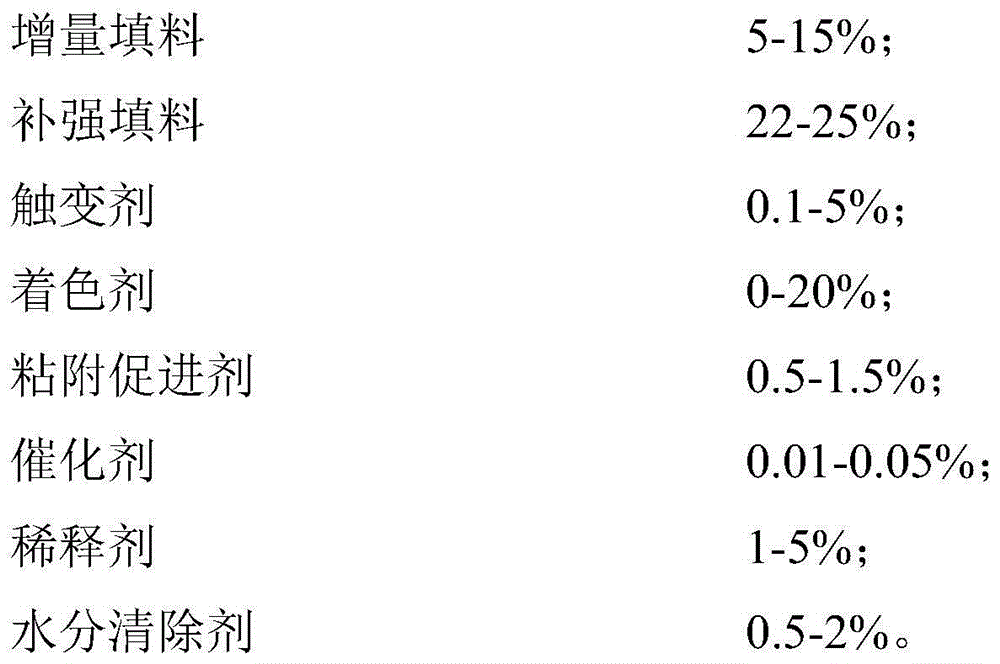

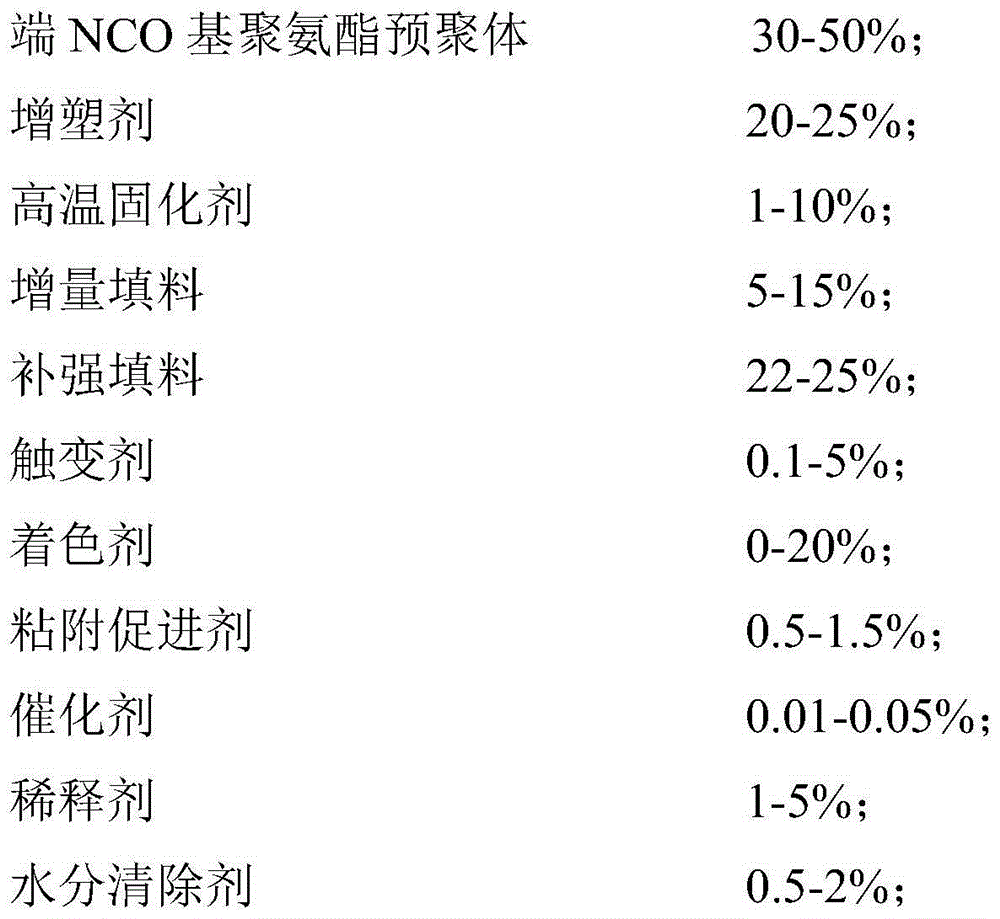

Method used

Image

Examples

preparation example Construction

[0041] For the heat-resistant one-component moisture-curing polyurethane sealant composed of the above-mentioned components according to the corresponding proportion, the present invention also provides a corresponding preparation method, the method comprising the following steps:

[0042] (1) Take the polyol compound, plasticizer and diluent and put them into the vacuum reaction kettle, dehydrate under the vacuum environment of 100°C-130°C for 1-5 hours until the water content of the mixture is lower than 0.01%, and then put the vacuum reaction The temperature of the material in the kettle is lowered to 40-60°C, and the measured isocyanate compound is added, stirred and heated to 75-85°C in a vacuum environment, and reacted for 3-7h until the isocyanate content of the system reaches the theoretical value, and the NCO-terminated polyurethane prepolymerized things.

[0043](2) At room temperature, sequentially add plasticizer, NCO-terminated compound, water scavenger, and exten...

example 1

[0048] Preparation of NCO-terminated polyurethane prepolymer:

[0049] 250kg polyether trihydric alcohol (average molecular weight 4700), 290kg polyether diol (average molecular weight 2000) and 180kg diisooctyl phthalate were vacuum dehydrated at 100°C for 5 hours until the water content of the mixture was less than 0.01%, then reduce the material temperature of the vacuum reactor to 40-60°C, add 63kg of toluene diisocyanate, stir in a vacuum environment and heat up to 85°C, react for 5h until the isocyanate content of the system reaches 1.1%, and obtain terminal NCO groups Polyurethane prepolymers.

[0050] Preparation of heat-resistant one-component moisture-curing polyurethane sealant:

[0051] At room temperature, sequentially add 4.7 parts of plasticizers, 57.7 parts of NCO-terminated compounds, 1.1 parts of p-toluenesulfonyl isocyanate moisture scavenger, and mix and stir for 20-40 minutes, then add 5.6 parts of calcium carbonate, Mix and stir 19.5 parts of carbon bla...

Embodiment 2

[0053] Preparation of NCO-terminated polyurethane prepolymer:

[0054] 250kg polyether trihydric alcohol (average molecular weight 4700), 290kg polyether diol (average molecular weight 2000) and 180kg diisooctyl phthalate were vacuum dehydrated at 100°C for 5 hours until the water content of the mixture was less than 0.01%, then reduce the material temperature of the vacuum reactor to 40-60°C, add 63kg of toluene diisocyanate, stir in a vacuum environment and heat up to 85°C, react for 5h until the isocyanate content of the system reaches 1.1%, and obtain terminal NCO groups Polyurethane prepolymers.

[0055] Preparation of heat-resistant one-component moisture-curing polyurethane sealant:

[0056] At room temperature, sequentially add 9.8 parts of plasticizers, 47.8 parts of NCO-terminated compounds, and 1.2 parts of p-toluenesulfonyl isocyanate into a double planetary kettle, mix and stir for 20-40 minutes, then add 9.3 parts of calcium carbonate, 20.9 parts of carbon Blac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com