Hybrid wood products

A product, wood-based technology, applied in the field of treated cellulosic materials, which can solve the problems of increased cost, environmental friendly impact, etc., and achieves the effect of dimension stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

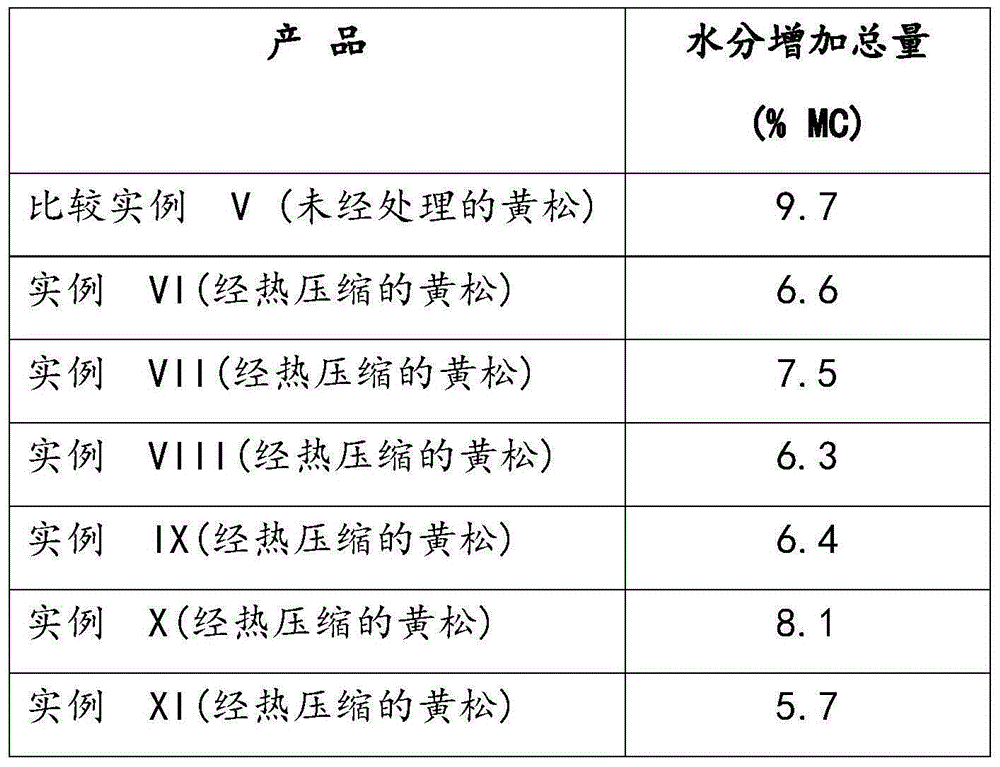

Examples

other Embodiment approach

[0010] Other embodiments provide a densified wood product having a first ply is a densified veneer and a second ply is glued to the first ply.

[0011] Still other embodiments provide a compacted wood product wherein the first layer is compacted wood, the second layer is glued to the first layer, and the product is machined to include locking profiles, such as tongue and groove edge.

[0012] Other characteristics and advantages of the present invention will appear from the following more detailed description of the preferred embodiment.

[0013] Specific instructions

[0014] As used herein, the term "thermocompressed" or "thermocompression" refers to a product or process that uses thermal and mechanical compression (among others) to densify a substrate. Typical thermal compression techniques are described in US Patent No. 7,404,422 to Kamke et al., which is hereby incorporated by reference in its entirety.

[0015] In some embodiments, the compression process includes the...

example 1

[0048] To carry out the impact resistance test, a steel ball with a diameter of 1-1 / 2 inches supported on the frame is dropped from a predetermined height, and if there is an impact, the maximum impact depth on the surface of the wood flooring product is measured. Smaller depths or indentations indicate greater impact resistance. A first ply consisting of a typical hardwood (Hard Maple) and a typical softwood (Ponderosa Pine) was evaluated for the impact of thermal compression on impact resistance. As shown in Table 1, thermal compression had the least effect on hardwoods. In contrast, the effect of thermocompression on cork, shown in Table 2, is considerable. In particular, the data shown in Table 2 illustrate the unexpected improvement in impact resistance of representative products of the present invention.

[0049] Table 1

[0050] product

Dent (inch)

Comparative Example I (Untreated Hard Maple)

0.014

Comparative Example II (Heat-Compress...

example 2

[0054] Thermocompressed and untreated samples were evaluated for color differences based on calculations of delta values as deviations from the measured x,y color coordinates of a black body radiator. For the duration of the test, it was exposed to a xenon arc for 100 hours at a wavelength of 280nm-800nm and filtered to approximate sunlight passing through window glass. At the end of the test, the test results vary from the initial color reading to the final color reading. A small difference is good, as shown in Table 3, the wood product with the thermocompressed first layer has greater resistance to fading than the untreated wood.

[0055] table 3

[0056] product

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com