Patents

Literature

33 results about "Impact depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The physicist Sir Isaac Newton first developed this idea to get rough approximations for the impact depth for projectiles traveling at high velocities.

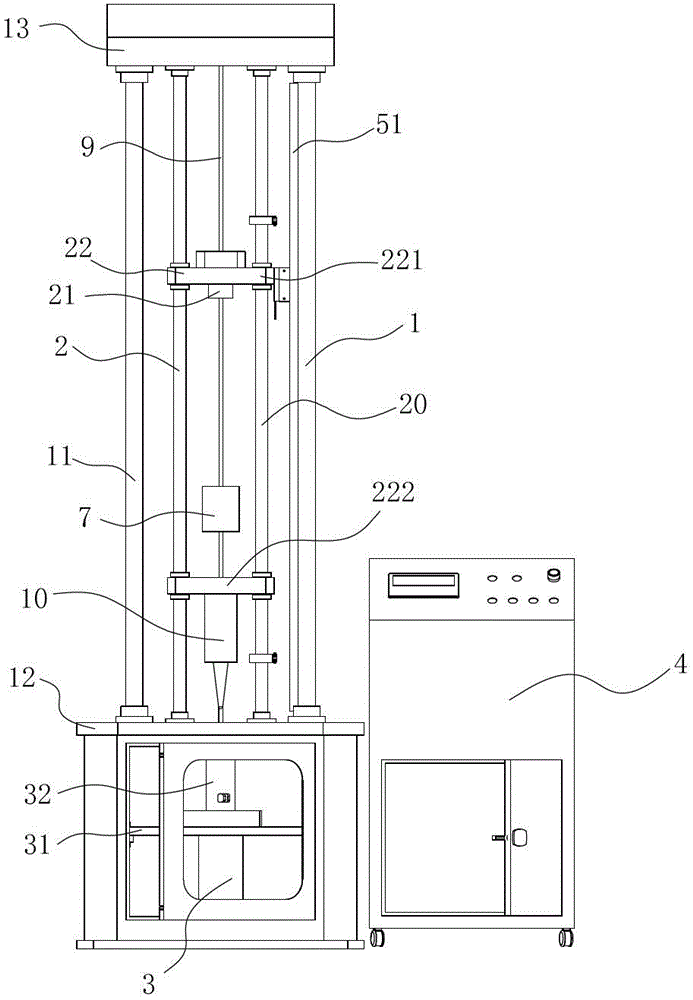

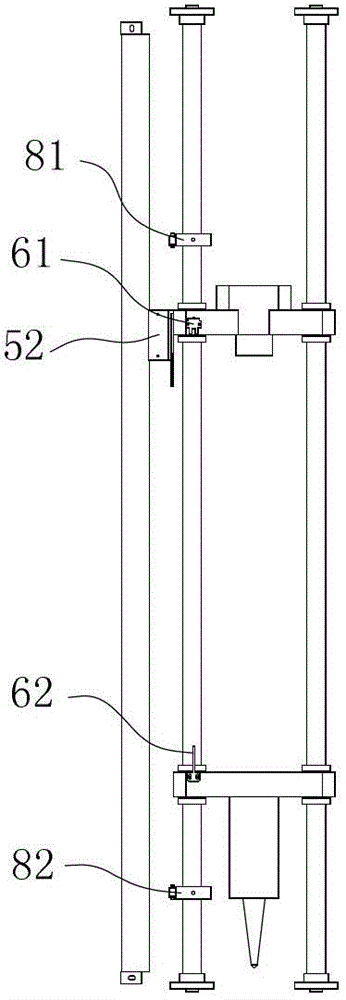

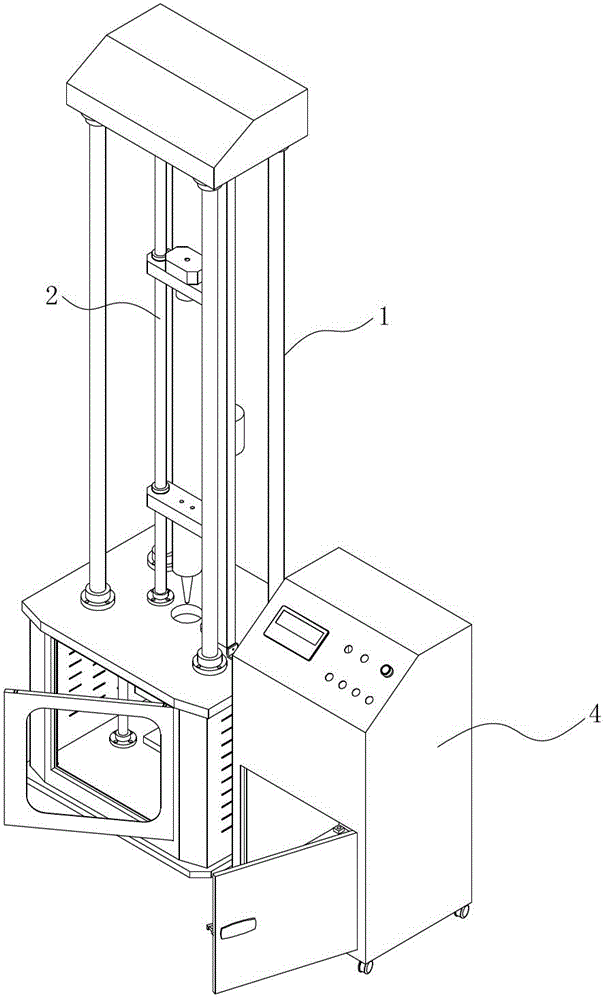

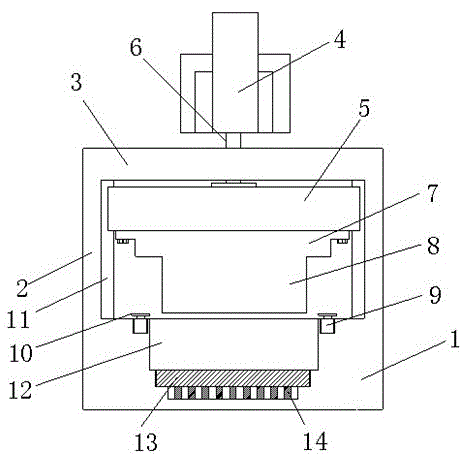

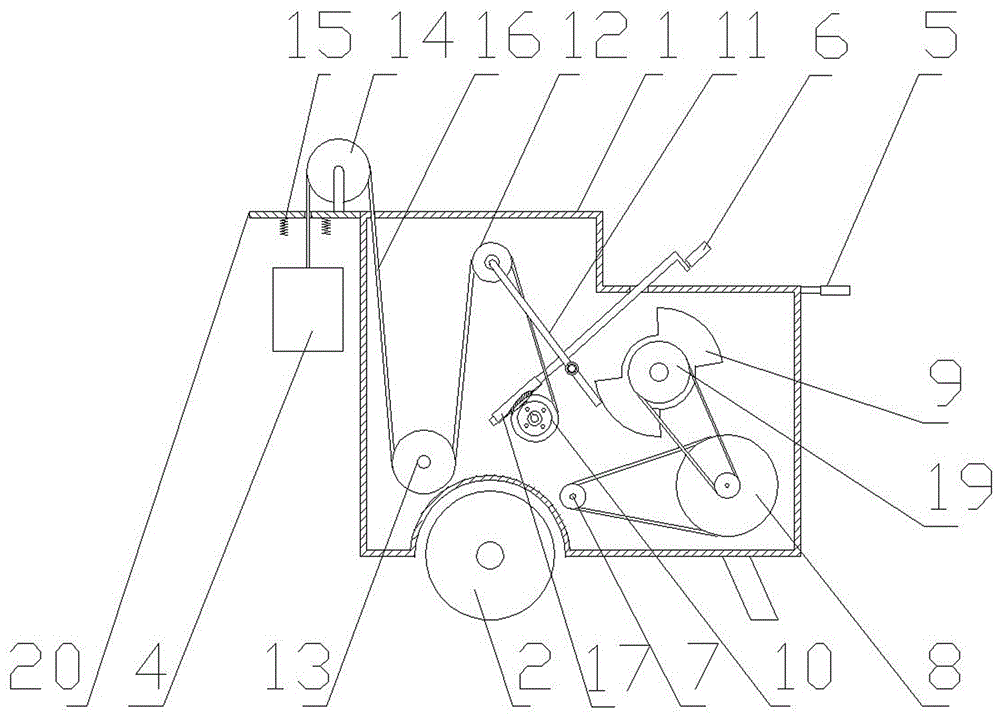

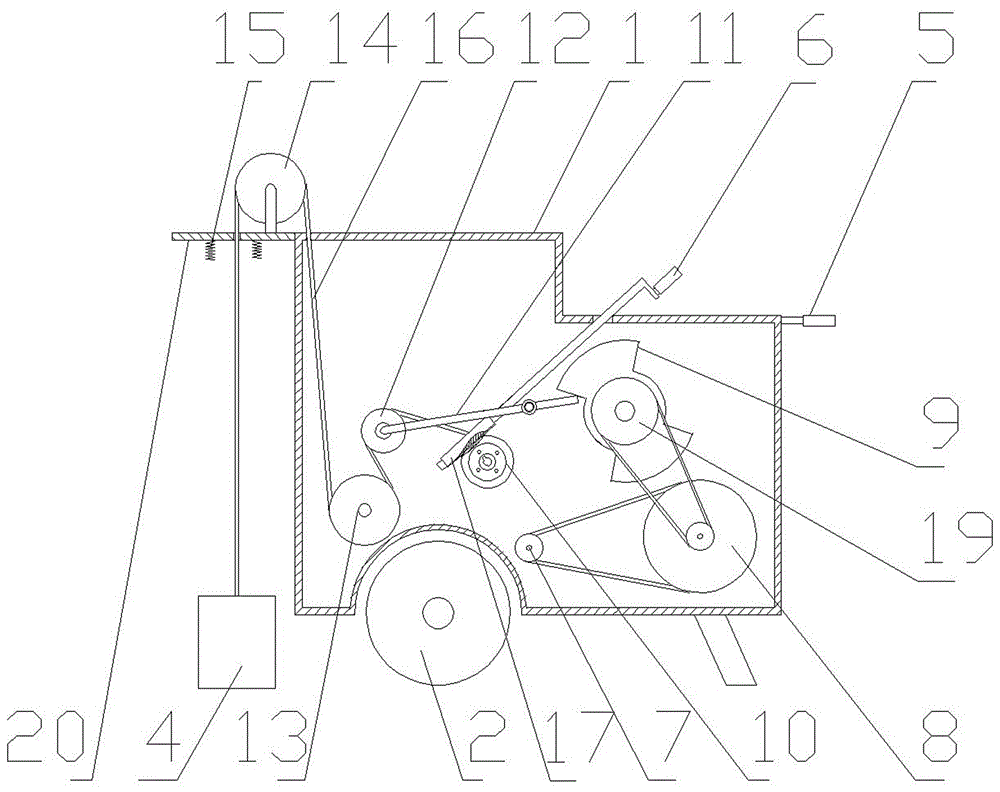

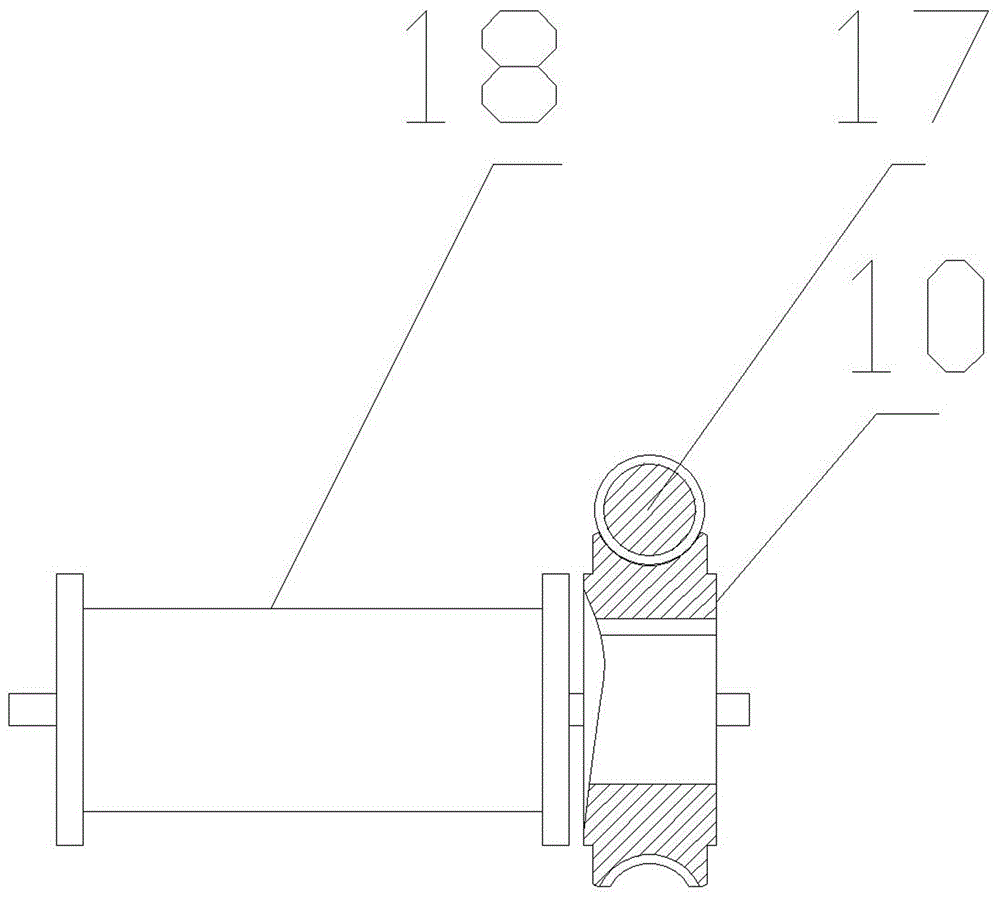

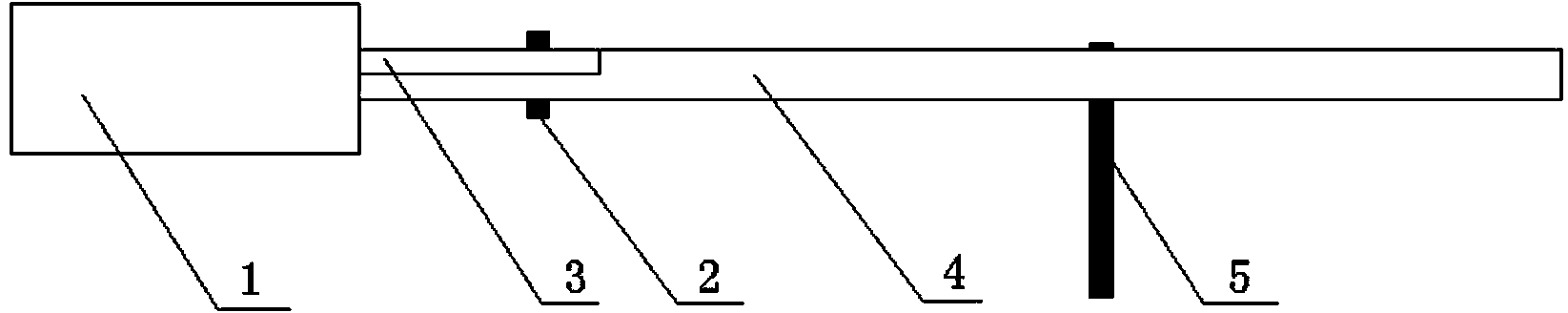

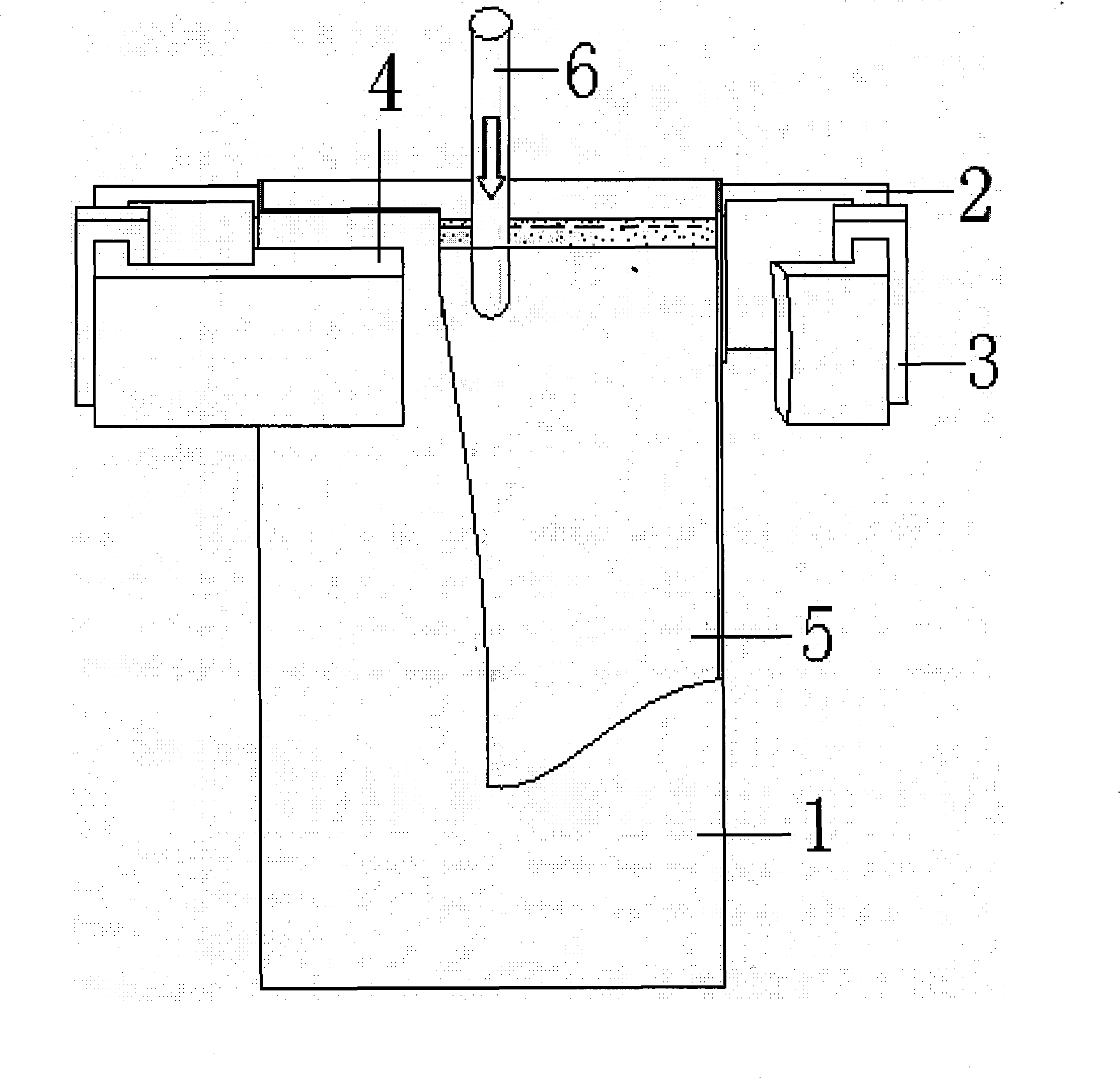

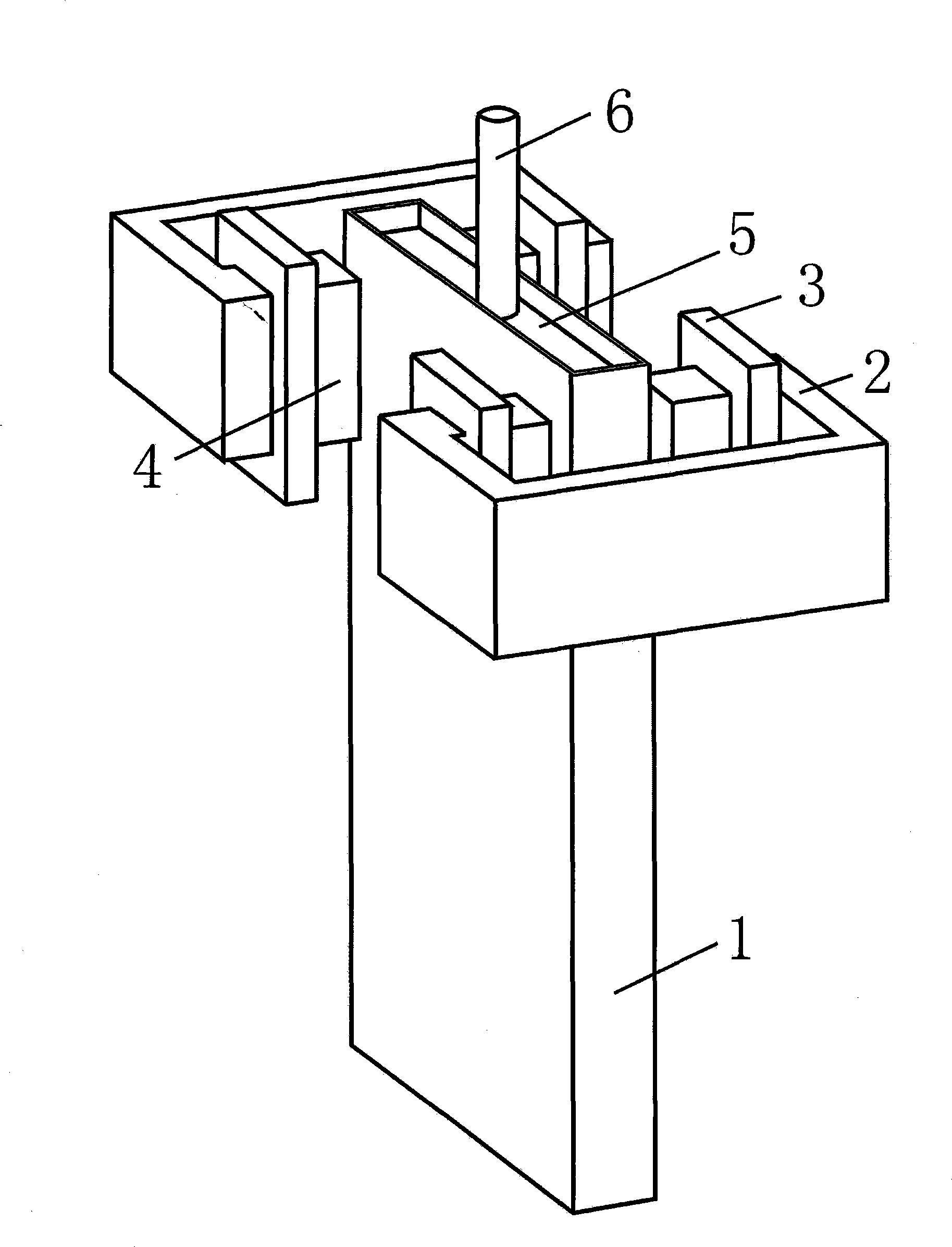

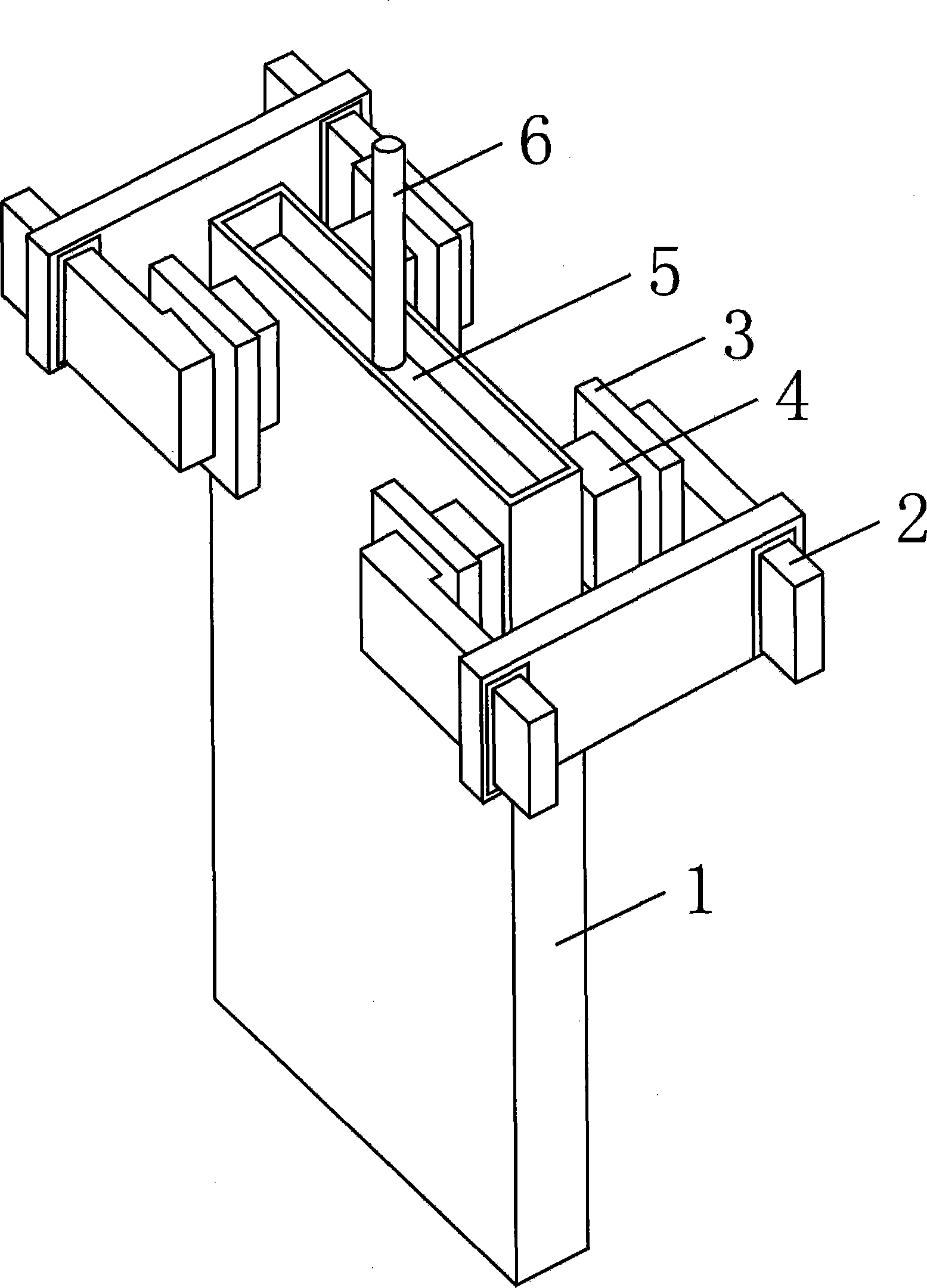

Drop hammer impact testing machine

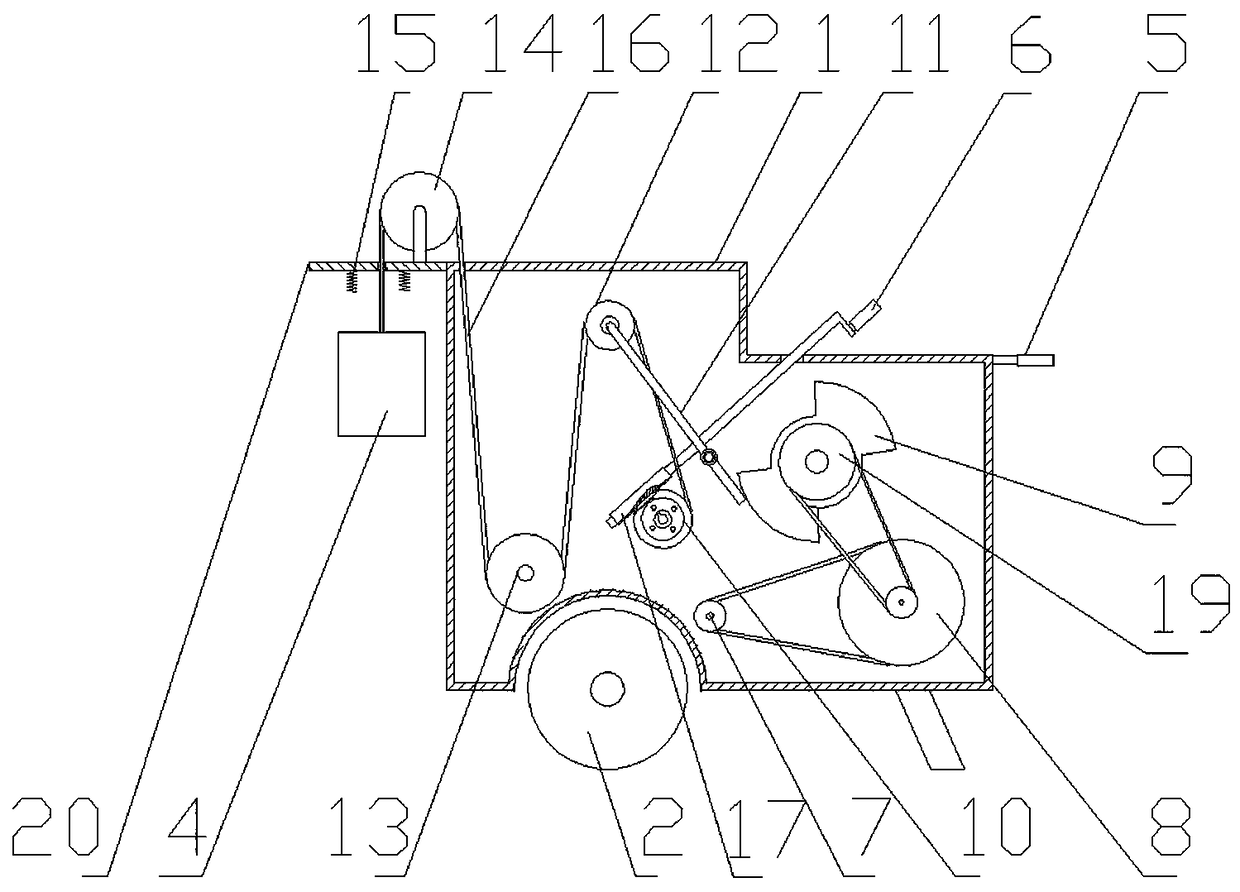

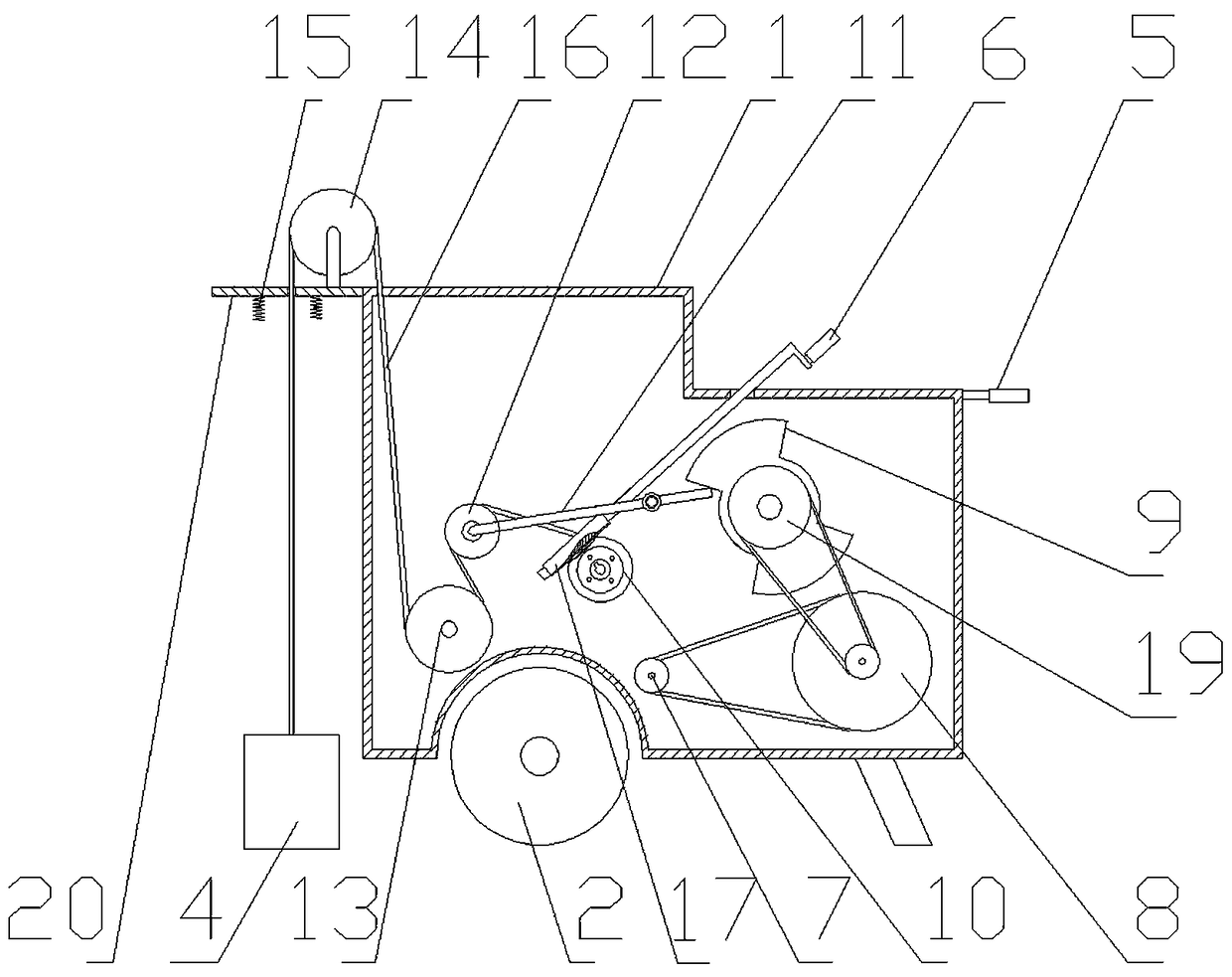

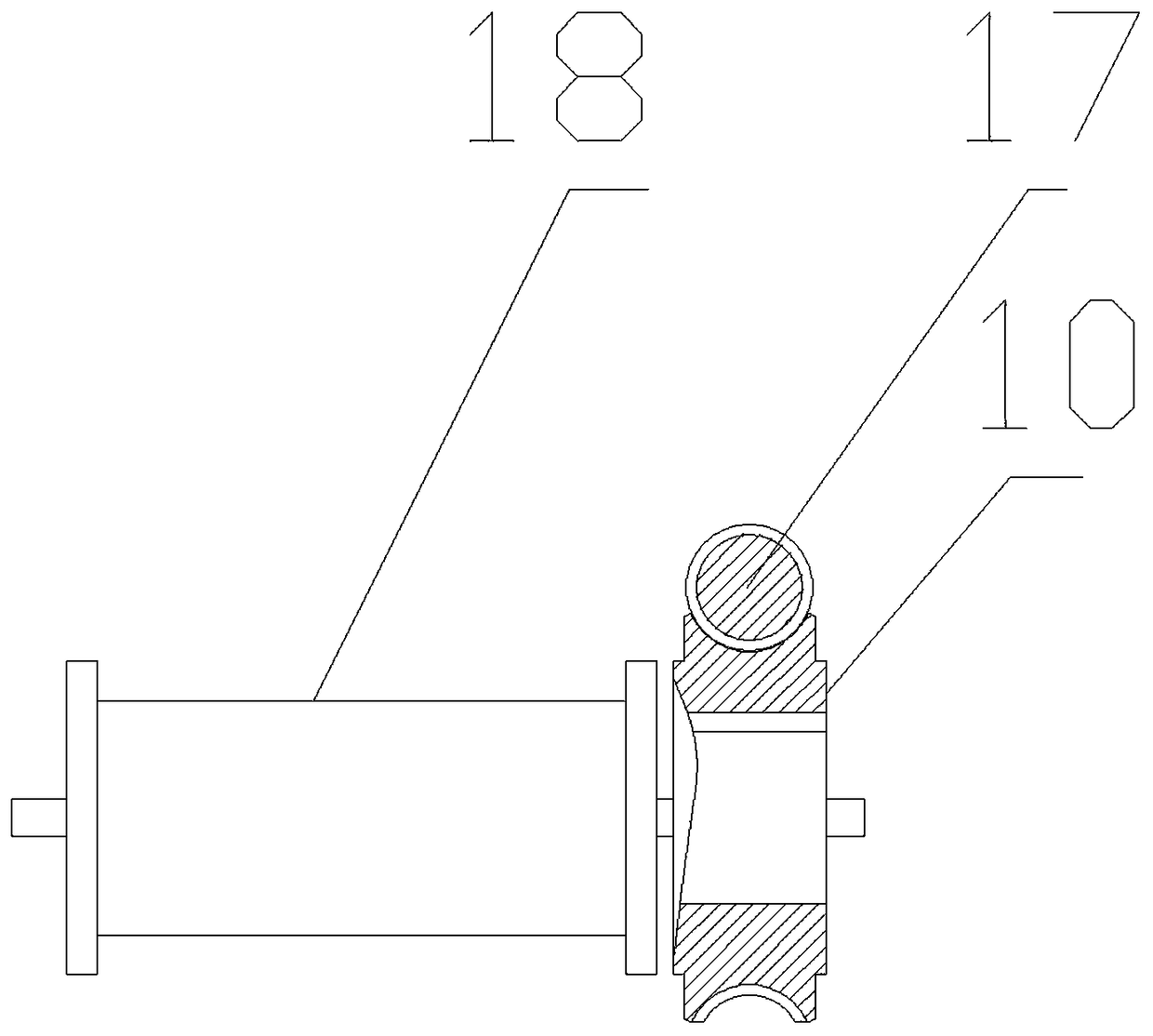

The invention provides a drop hammer impact testing machine which is simple and practical in structure and can be used for conveniently measuring the depth of a hammer head which impacts into a sample. The drop hammer impact testing machine comprises a frame, a hammer lifting mechanism, a sample lifting mechanism, an electric appliance cabinet and a grating ruler, wherein the hammer lifting mechanism is arranged in the center on the upper part of the frame and comprises a pair of guide rods, an electromagnet sucker and a hammer body component; the hammer body component is movably connected with and positioned between the pair of guide rods; the sample lifting mechanism is arranged in the center of the lower part of the frame; the electric appliance cabinet is in transmission connection with the hammer component through a chain; the grating ruler is connected with the hammer component; the hammer component comprises a lifting block and a hammer lifting block; the lifting block is arranged above the hammer lifting block and is connected with the top surface of the electromagnet sucker; a proximity switch is arranged on the lifting block; a contact for triggering the proximity switch is arranged on the hammer lifting block. The impact depth of the sample is conveniently measured by the machine, and the operation is simple.

Owner:JIANGSU TIANYUAN TEST EQUIP

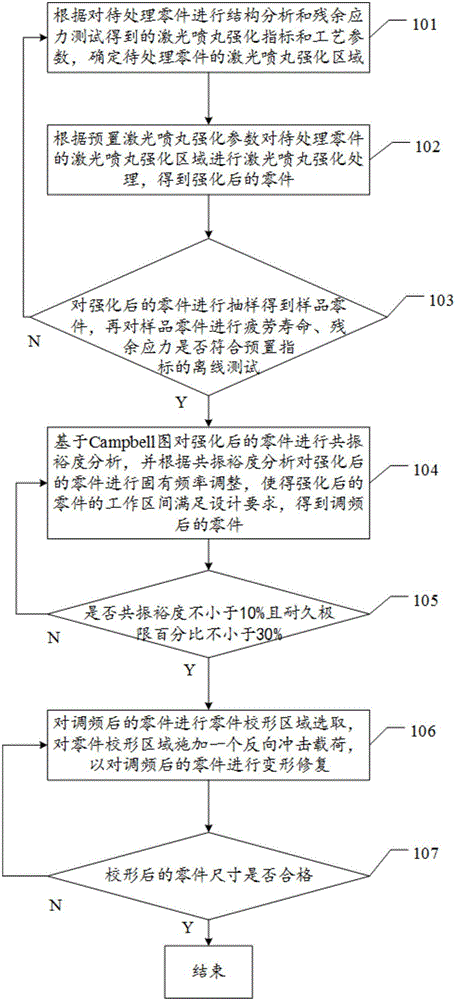

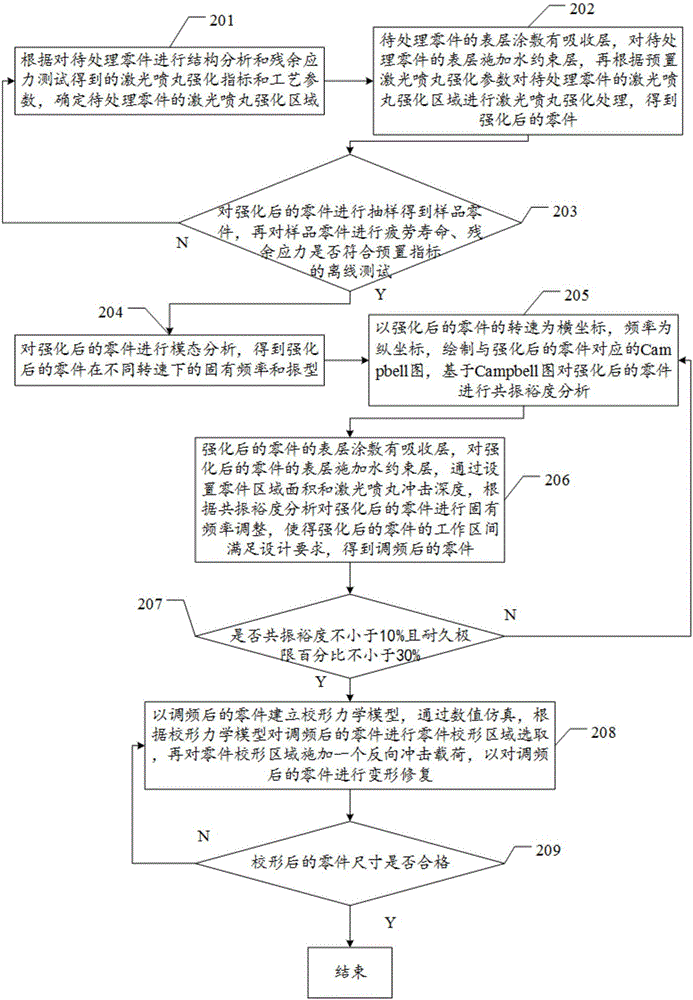

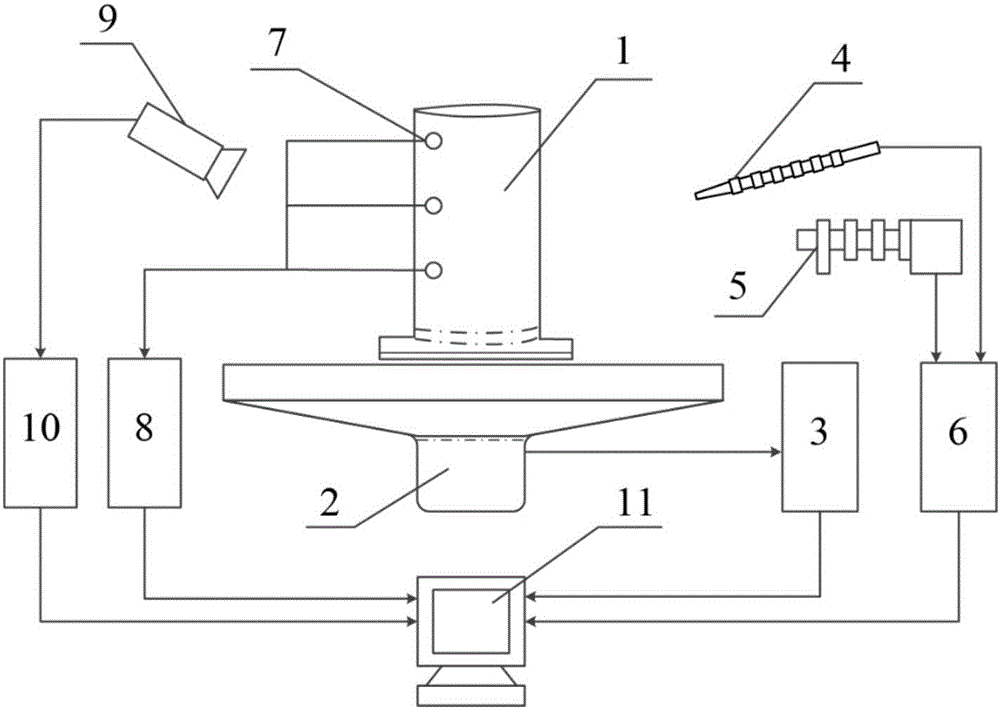

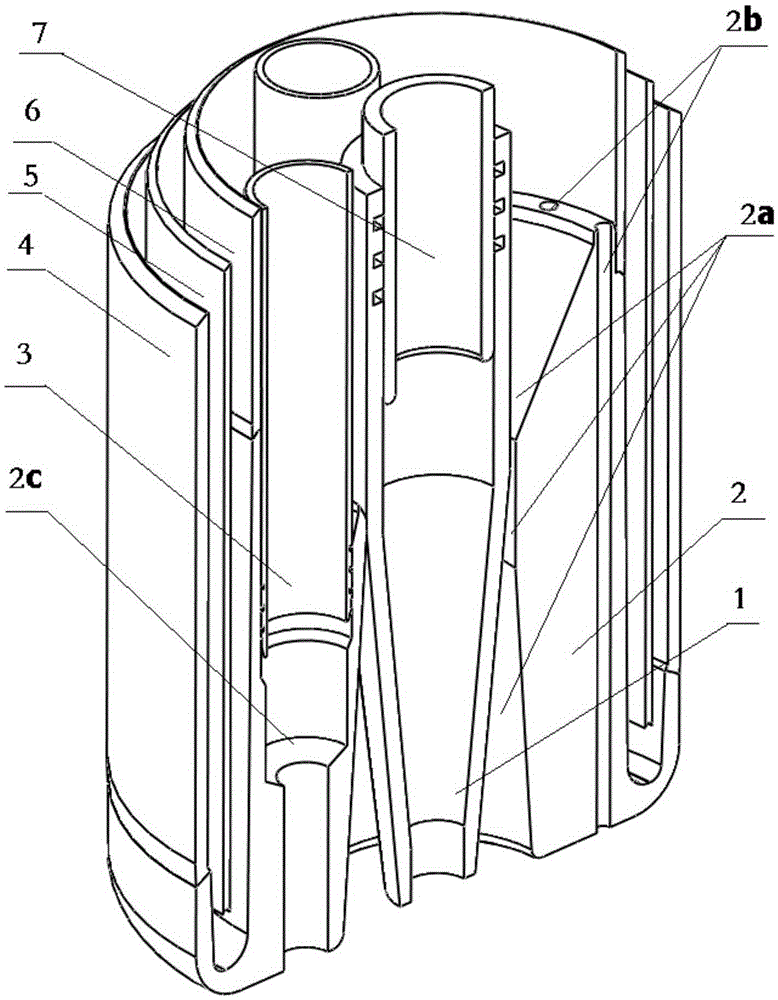

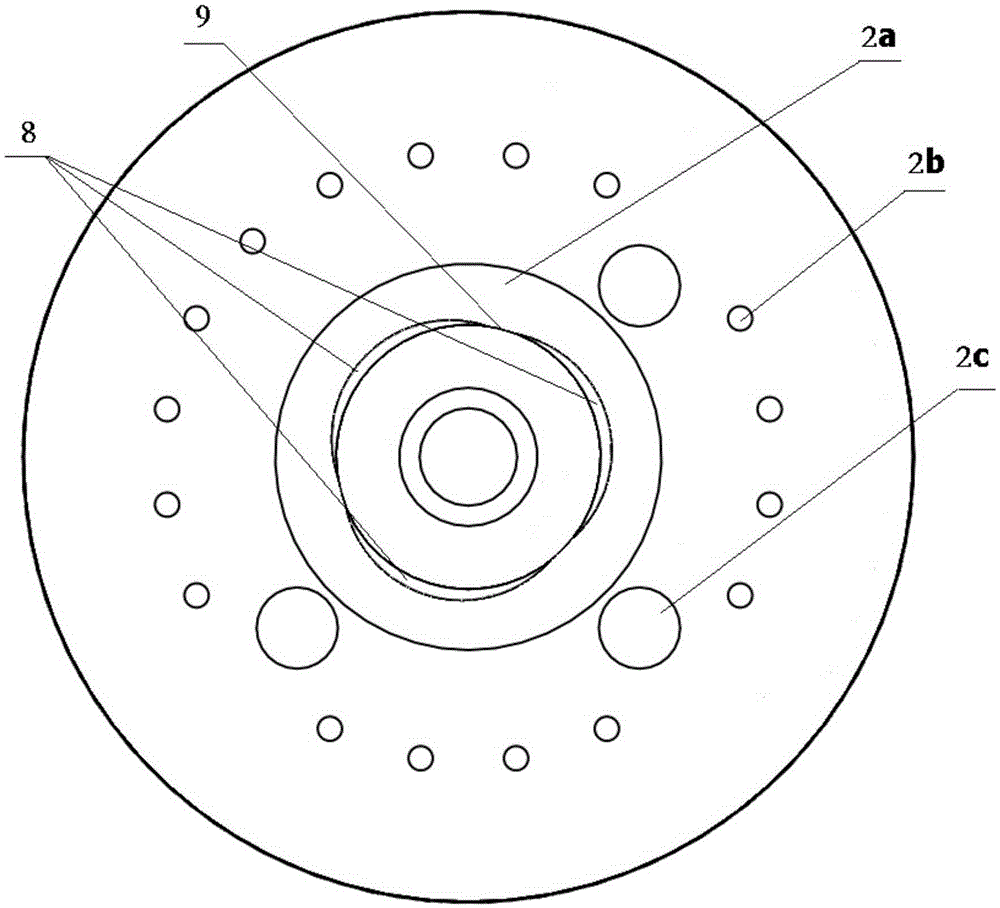

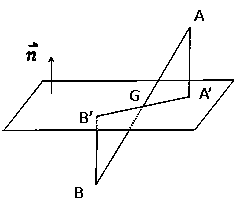

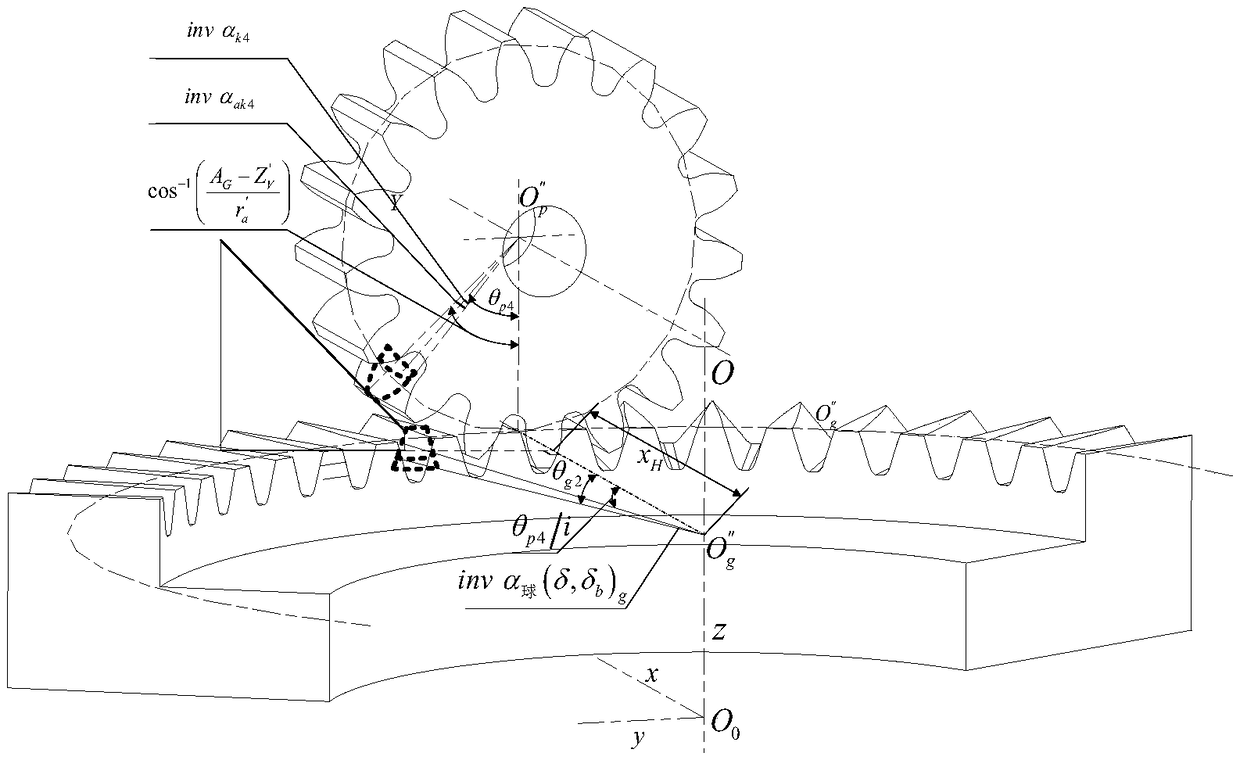

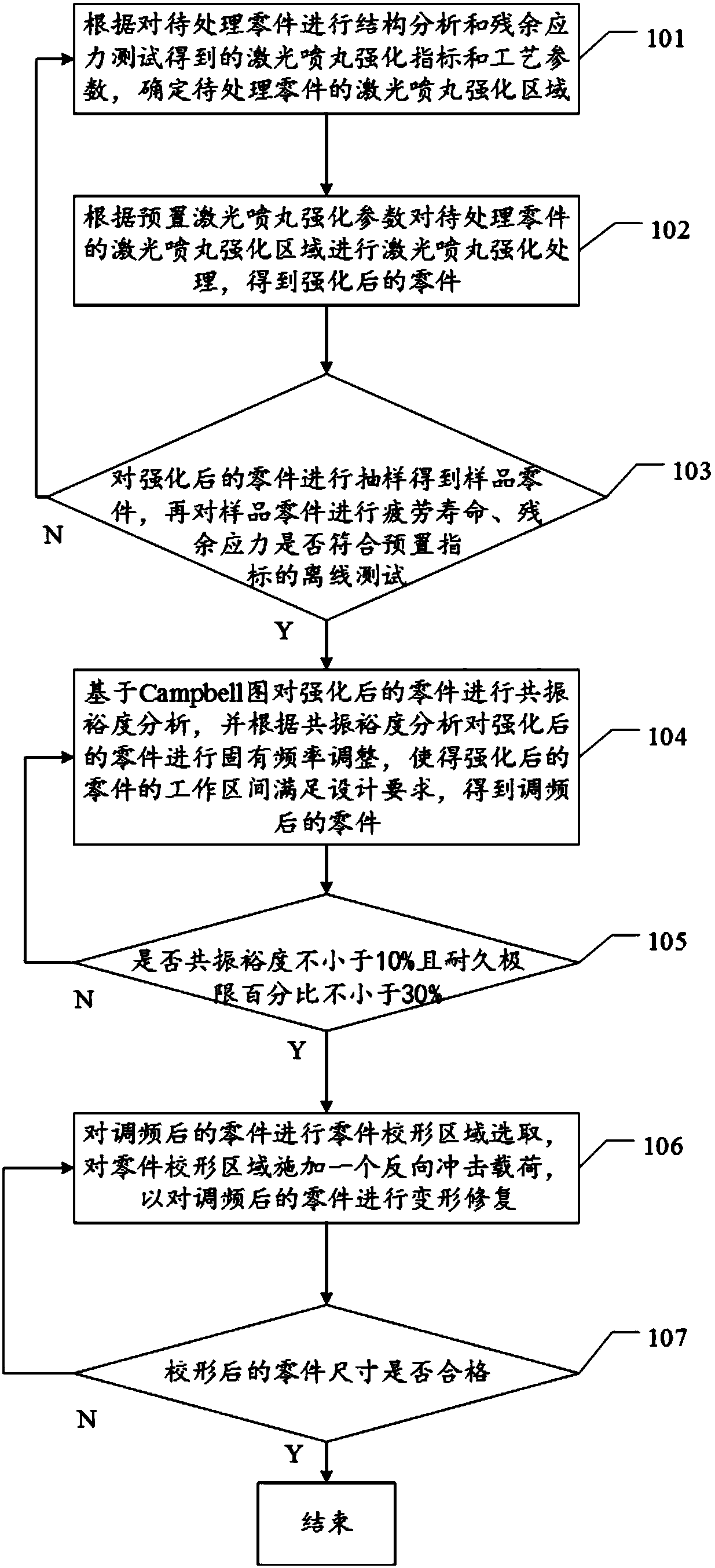

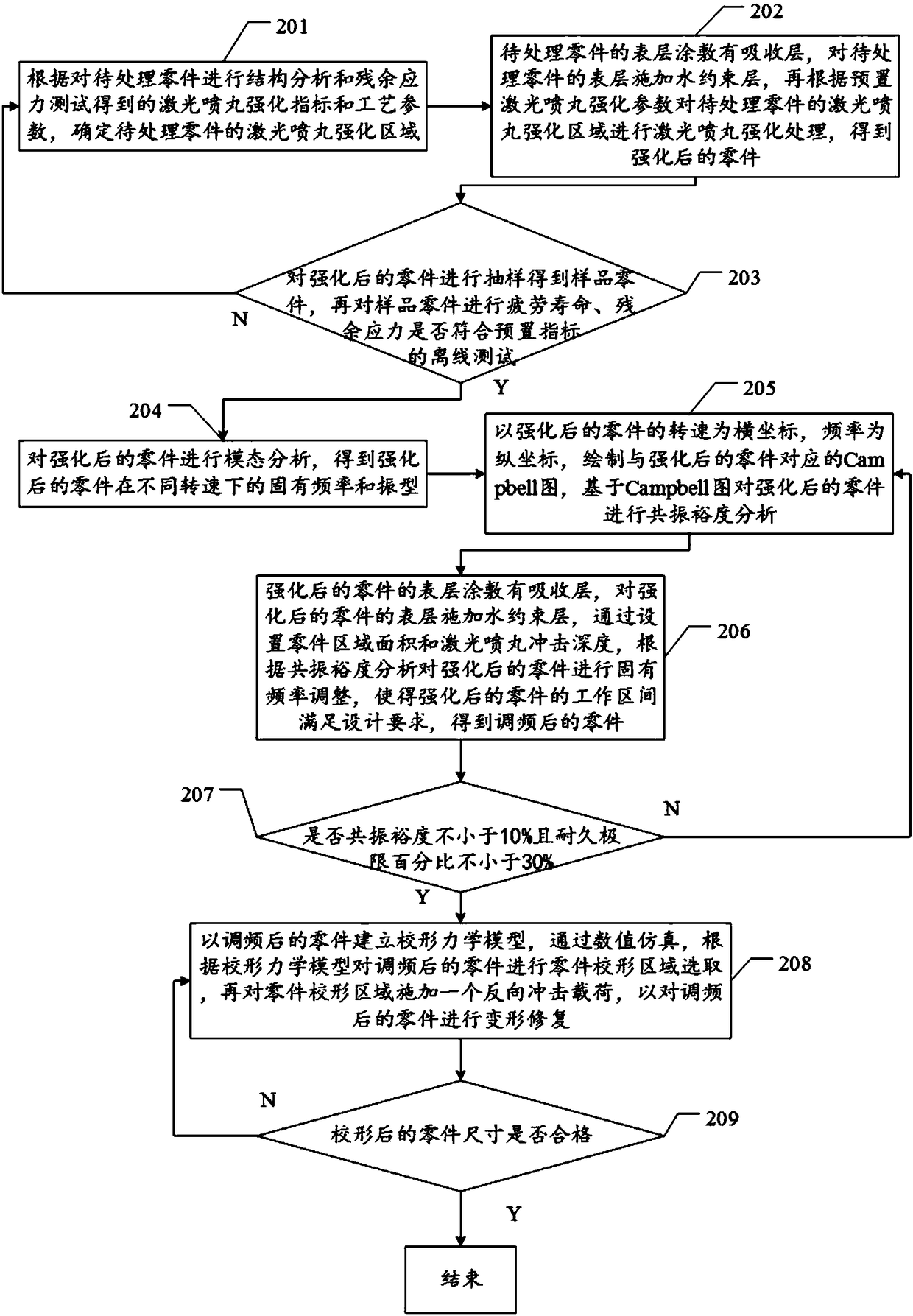

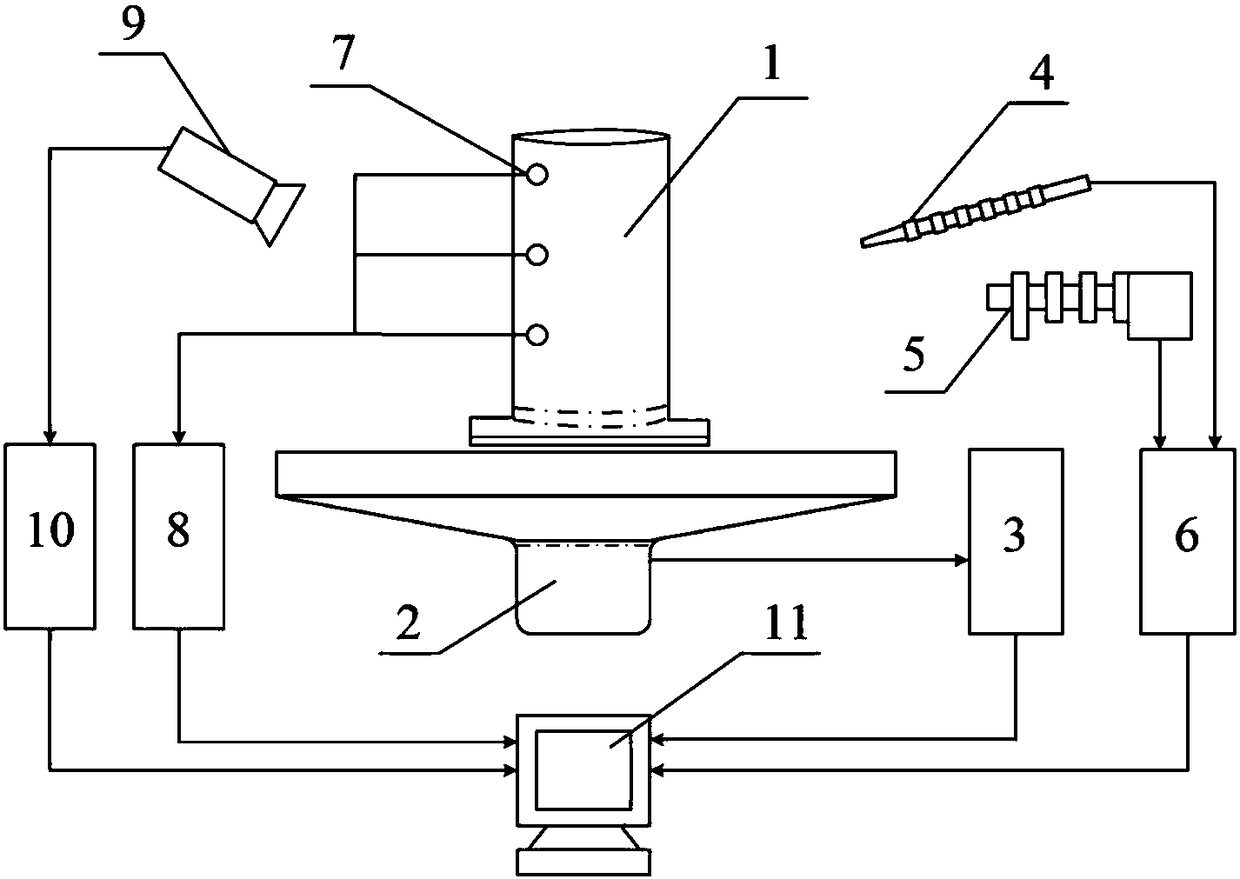

Multiple-unit control method and multiple-unit control device for reverse laser shot peening

ActiveCN106636563ASolving Dimensional Stability ChallengesImprove the strengthening effectProgramme control in sequence/logic controllersAviationMechanical models

The embodiment of the invention discloses a multiple-unit control method and a multiple-unit control device for reverse laser shot peening. The region area and impact depth of laser shot peening treatment are reasonably designed by virtue of the modification characteristic of a surface layer material generated through laser shot peening, and a laminated section is constructed to change the Young moduli of parts, thus the inherent frequency is changed, and the dual purposes of reinforcement and frequency modulation treatment are realized; moreover, modelling analysis is carried out through a mechanical model to optimize a sizing region and parameters with regard to the common problem of structure deformation in the laser shot peening treatment, and repair for the deformation of the parts is realized through reversely loading impact loads, thus the purpose of dimensional stability of the laser shot peening parts is achieved; and moreover, the multiple-unit control method and the multiple-unit control device are capable of meeting the various needs of rotating parts, and in particular, are suitable for high-speed rotating parts bearing aerodynamic loads, such as gas turbine blades, aviation engine blades and the like.

Owner:GUANGDONG UNIV OF TECH

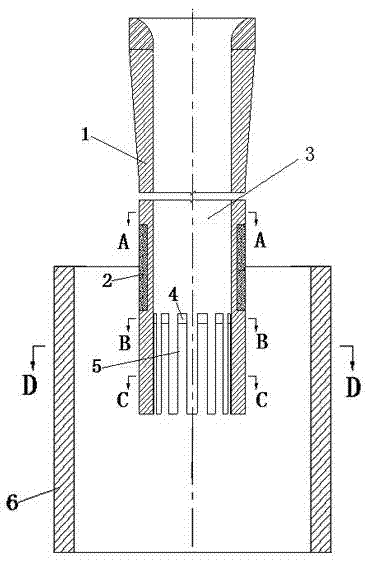

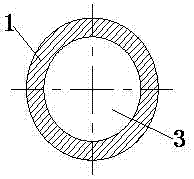

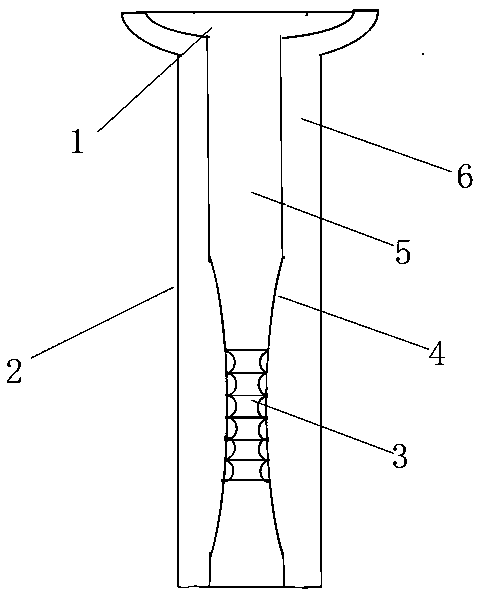

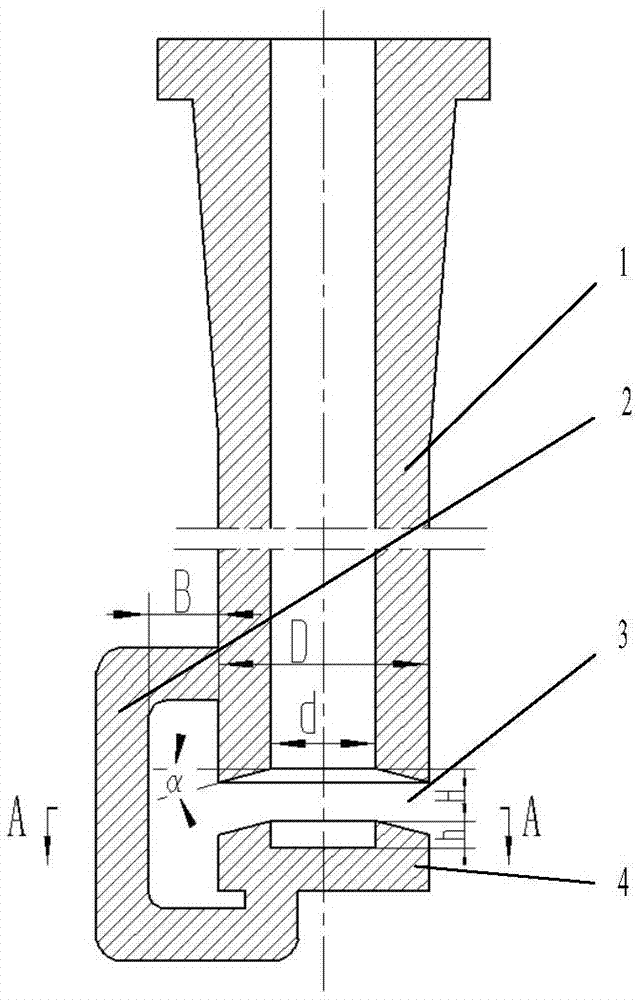

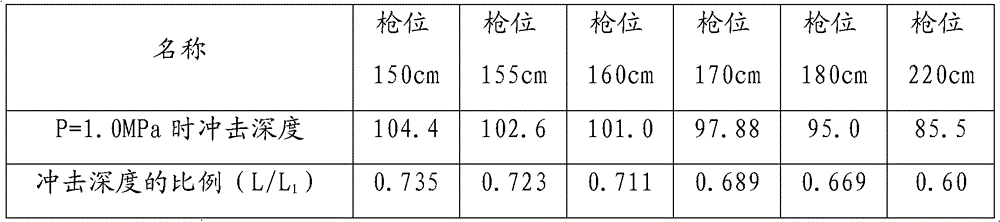

Ring groove coherent jet nozzle structure

ActiveCN105256107AImprove performanceNo increase in blow pit depthUltrasound attenuationMelting tank

The invention provides a ring groove coherent jet nozzle structure. The ring groove coherent jet nozzle structure comprises a nozzle core tube and a nozzle outer tube, wherein a centre hole and throttling holes distributed around the center hole are formed in the nozzle outer tube; the nozzle core tube is inserted into the center hole; the nozzle core tube and the nozzle outer tube are positioned by a positioning structure; the external contour of the nozzle core tube and the inner contour surface of the nozzle outer tube center hole form a porous ring groove type gas channel and a conical annular gas channel. Through the ring groove coherent jet nozzle structure, the surrounding and accompanying flow is added at the outer layer of supersonic jet flow, so that the central supersonic jet flow is low in expansion and attenuation; the supersonic jet flow is relatively long; when the ring groove coherent jet nozzle structure is applied to an RH vacuum refining furnace top lance, the penetration depth and the stirring strength of oxygen jet flow to a melting tank can be improved; meanwhile, the jet flow speed is slowly attenuated, so that the blowing gun position of an oxygen gun can be improved; the impact depth of the jet flow on the molten steel is not influenced; the service life of an oxygen gun nozzle is prolonged.

Owner:CISDI ENG CO LTD +1

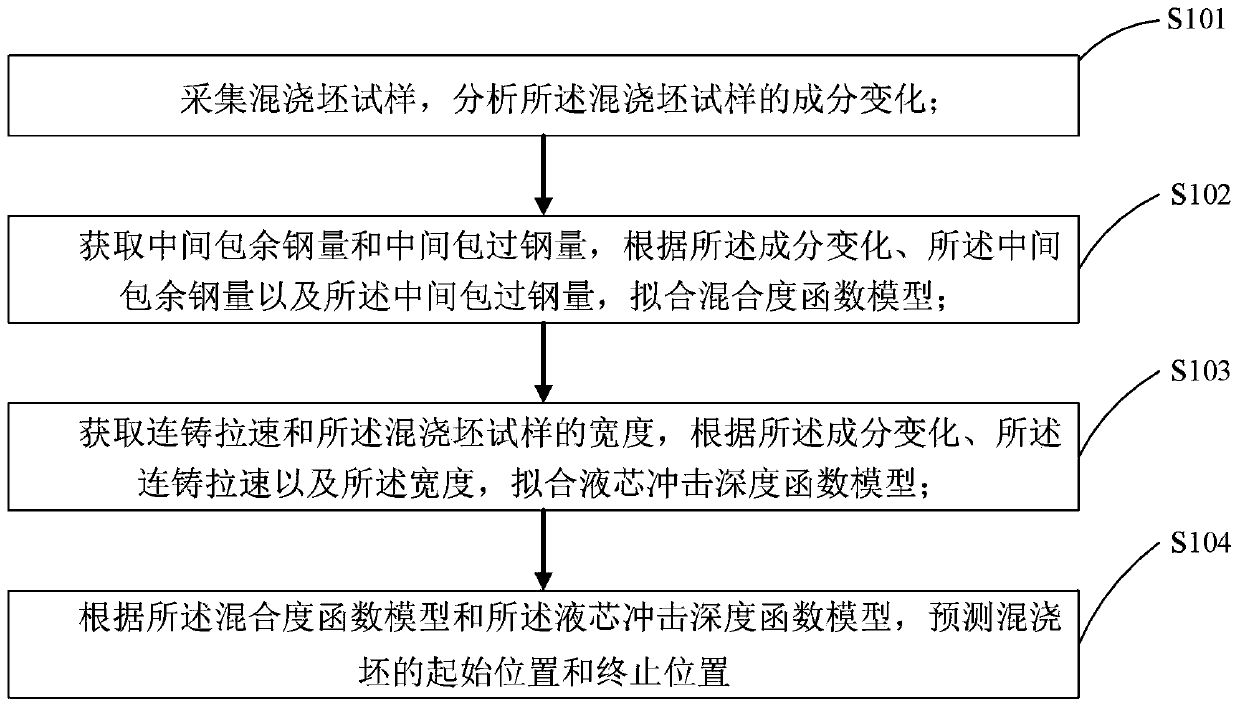

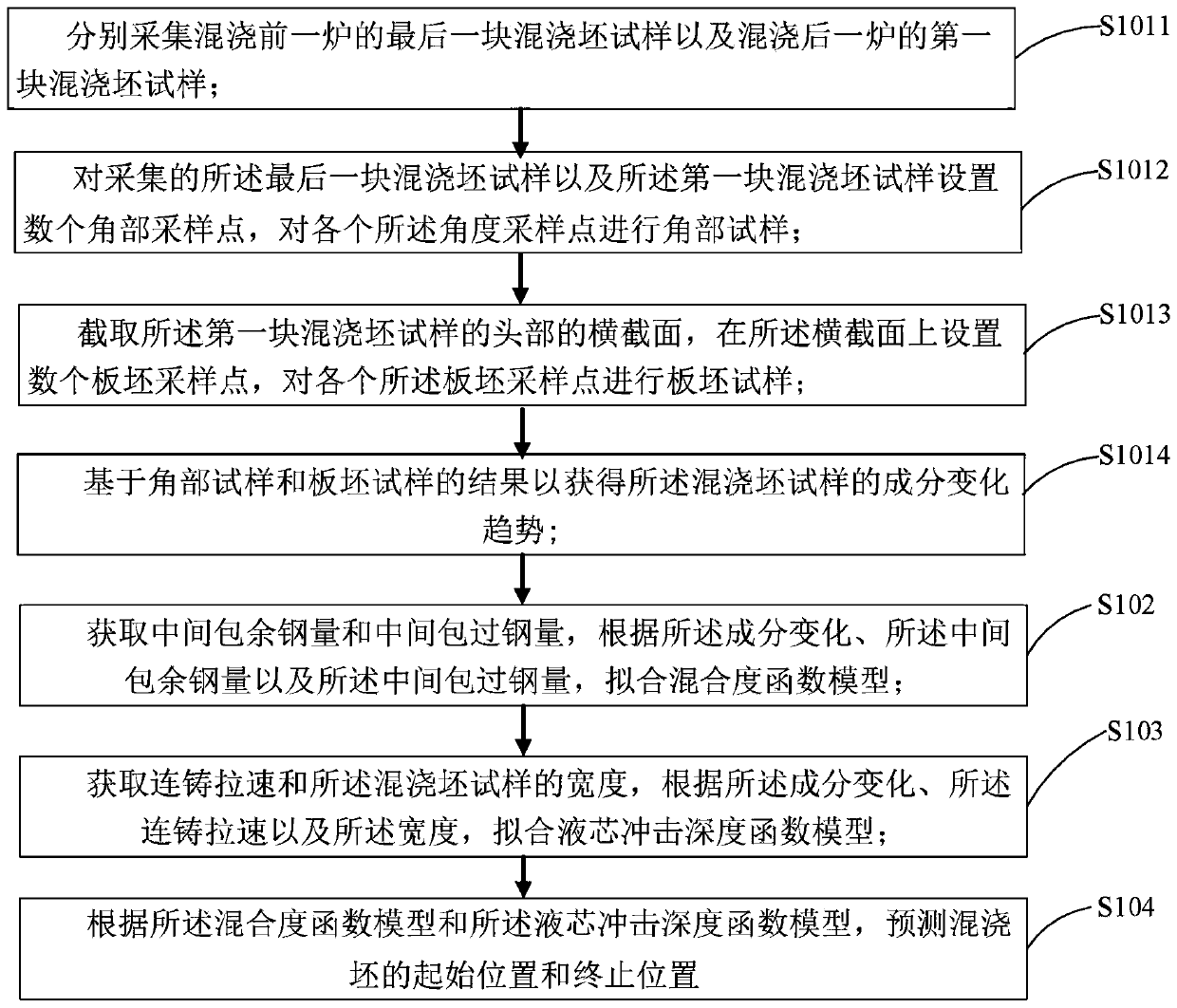

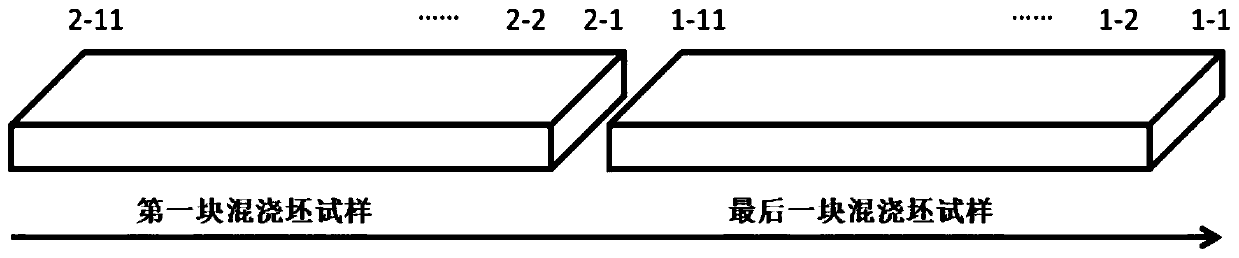

Component change prediction method and system for special steel type mixed casting blank

ActiveCN110261566APredicted starting positionJudging the handover positionAnalysis by thermal excitationComplex mathematical operationsLiquid coreWater model

The invention belongs to the technical field of steel manufacturing, and particularly relates to a component change prediction method and system for a special steel type mixed casting blank, and particularly relates to a component change prediction method for a special steel type mixed casting blank. The method comprises the following steps of: collecting a mixed casting blank sample, and analyzing the component change of the mixed casting blank sample; acquiring the tundish residual steel quantity and the tundish steel production capacity, and fitting a mixing degree function model according to the component change, the tundish residual steel quantity and the tundish steel production capacity; acquiring the continuous casting pulling speed and the width of the mixed casting blank sample, and fitting a liquid core impact depth function model according to the component change, the continuous casting pulling speed and the width; and according to the mixing degree function model and the liquid core impact depth function model, predicting the initial position and the final position of the mixed casting blank, wherein the mixing degree function model and the liquid core impact depth function model are established without depending on laboratory digital analog calculation or water model experiments, so that the prediction accuracy is high.

Owner:LIANYUAN IRON & STEEL GROUP CO LTD +1

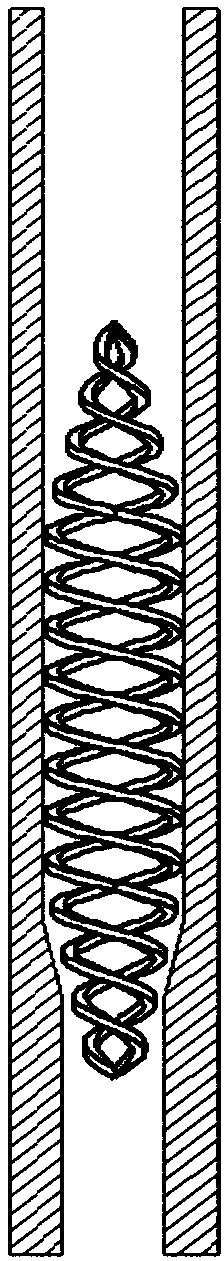

Self rotational flow long water gap for continuous casting

The invention belongs to the technical field of continuous casting and discloses a self rotational flow long water gap for continuous casting. The self rotational flow water gap is composed of a longwater gap body and a rotational flow guiding device and is characterized in that the rotational flow guiding device is arranged in the long water gap body and is a spiral guide rail; and the maximum external diameter of the spiral guide rail is not greater than the internal diameter of the long water gap body. The self rotational flow long water gap can fully express the centrifugal effect of rotational flow continuous casting, enables molten steel outflow to disperse and enter a tundish, reduces impact depth, increases upper backflow, facilitates floating of steel slag and production of cleansteel, can reduce residual volume of molten steel in a large package and facilitates energy conservation and emission reduction.

Owner:东北大学秦皇岛分校

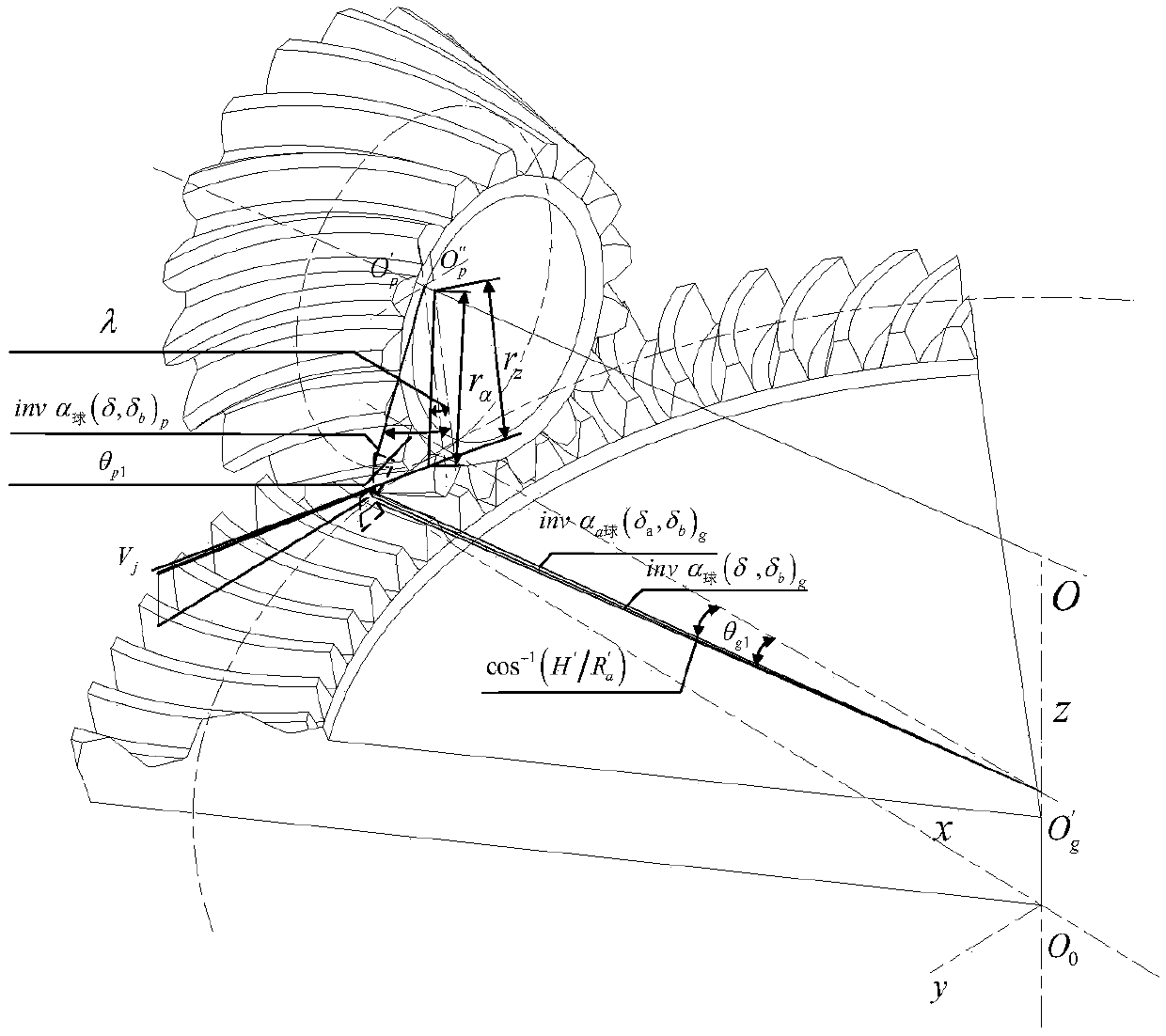

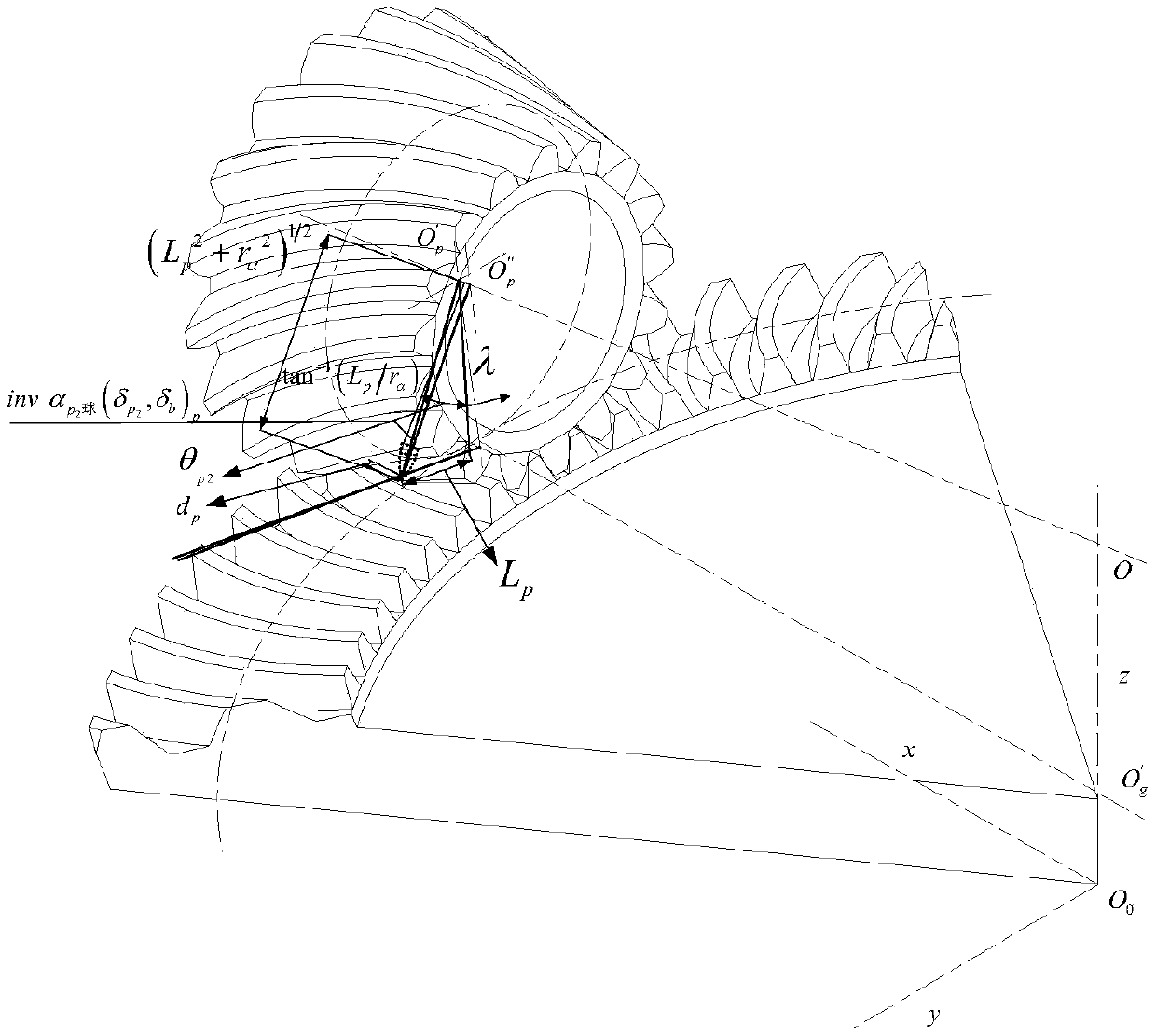

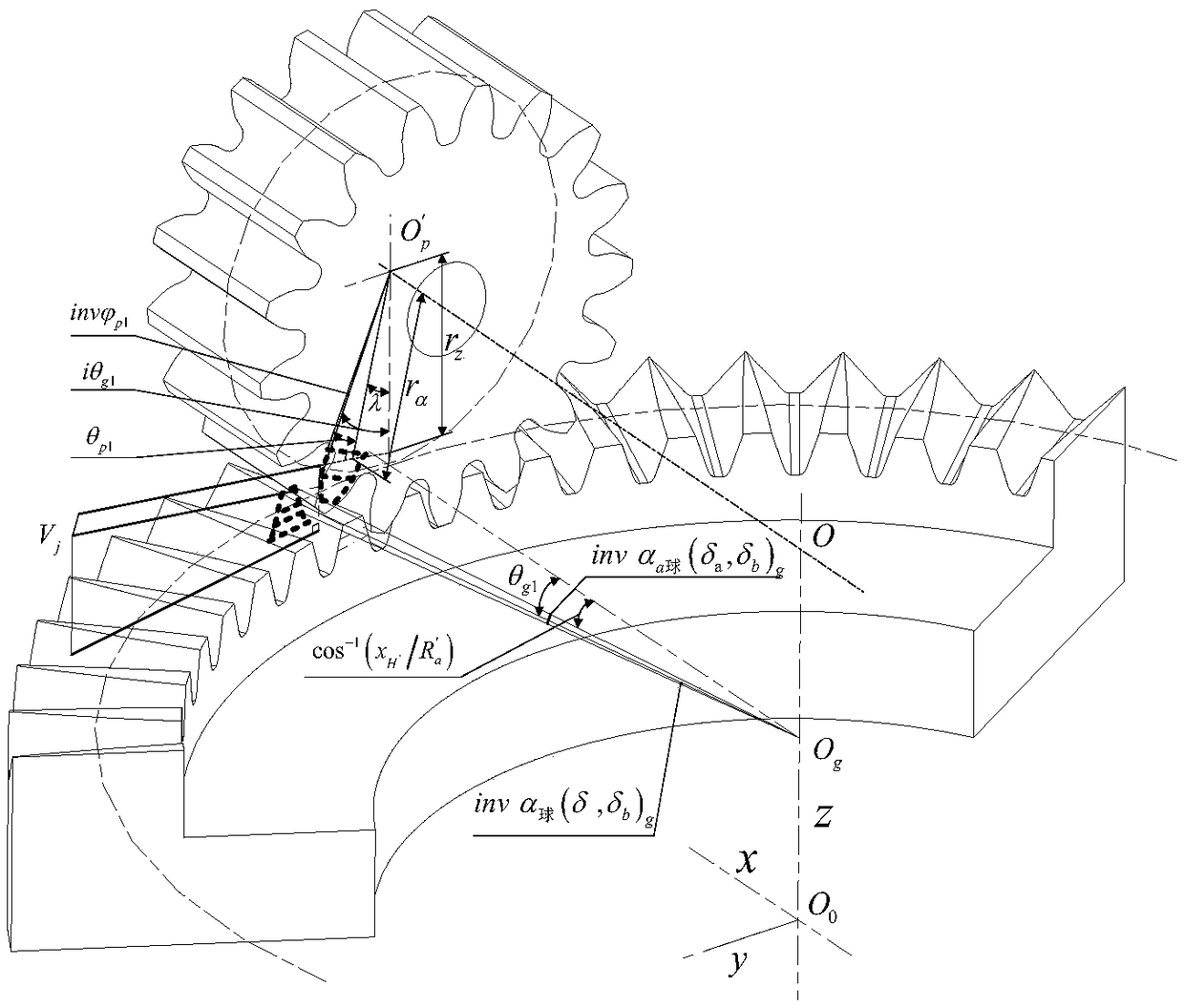

A method for optimizing the layout of oil injection lubrication nozzles ofa helical bevel gear for an aerospace

ActiveCN109543304ALubrication effect is convenient and intuitiveImprove the lubrication effectGeometric CADSustainable transportationAviationJet injection

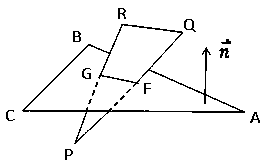

The invention discloses a method for optimizing the layout of oil injection lubrication nozzles of a helical bevel gear for an aerospace. The lubricating effect of gear can be judged by calculating the impact depth of lubricating oil sprayed on the surface of gear teeth, so as to optimize the layout of nozzle parameters, The calculation steps of the mathematical model are as follows: the spatial relationship between the involute and the involute of the spiral bevel gear, and the geometrical operation are used to obtain the spatial position of the large and small gears and the position change of the oil jet line in a period of time (the relationship between the initial time spiral bevel gear pair and the jet line is shown in the drawing) As shown in the figure, at the same time, according to the time that the gear meshing angle is equal to the jet injection time, the impact depth of the lubricating oil on the large and small gears is obtained.The method for calculating the mathematicalmodel of the impact depth is simple and can improve the oil injection lubrication performance and the effect of the gear.

Owner:CENT SOUTH UNIV

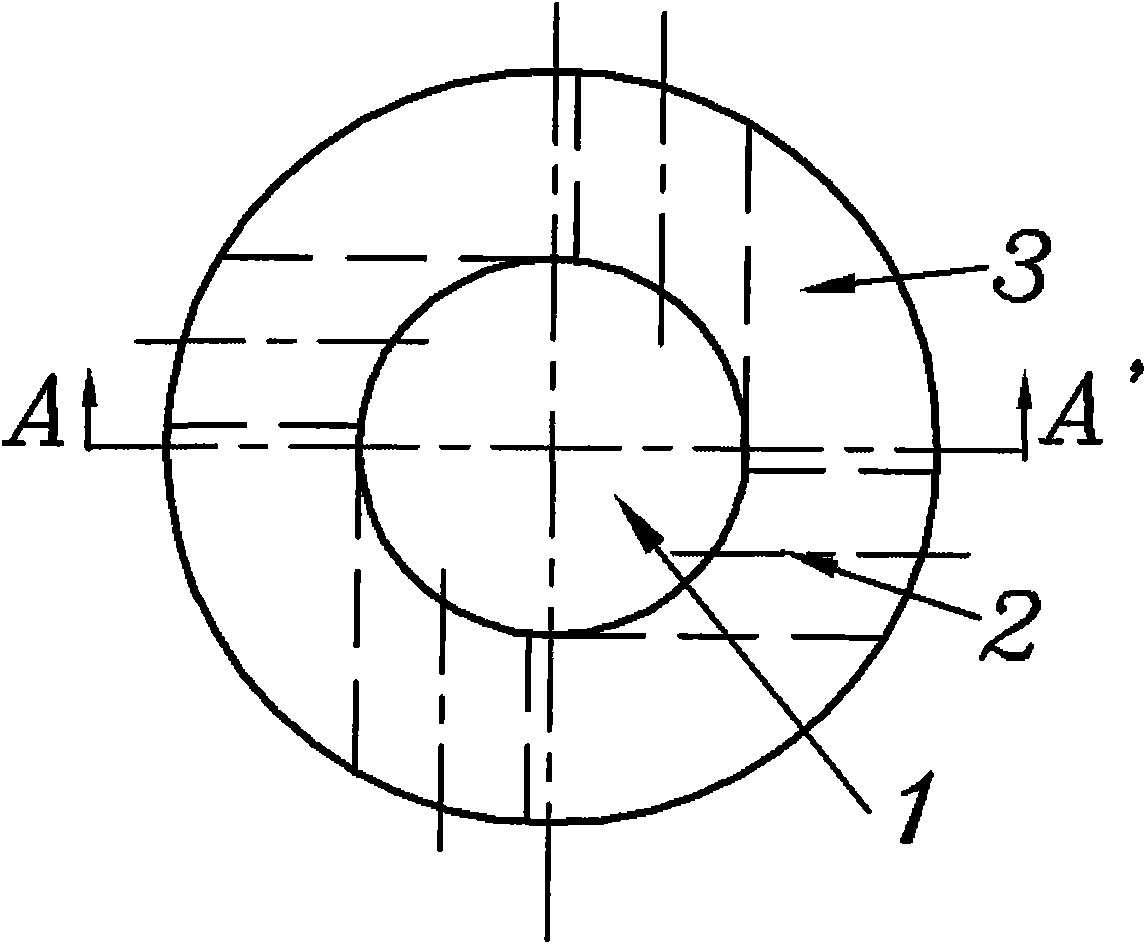

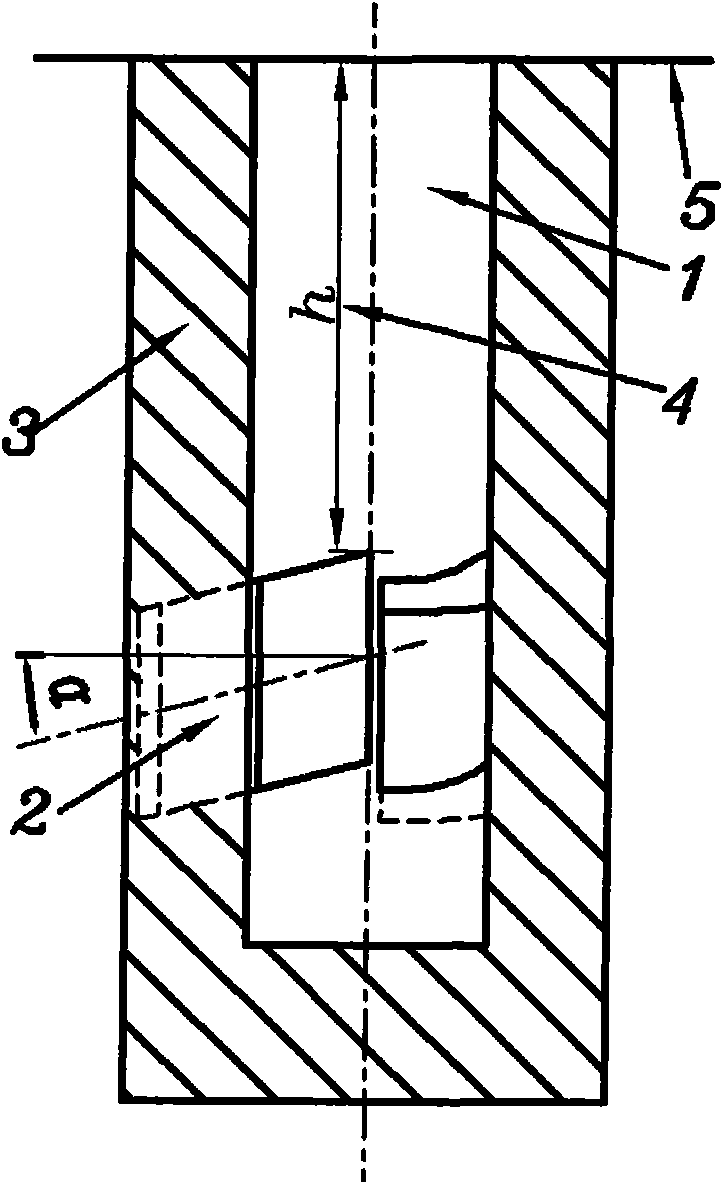

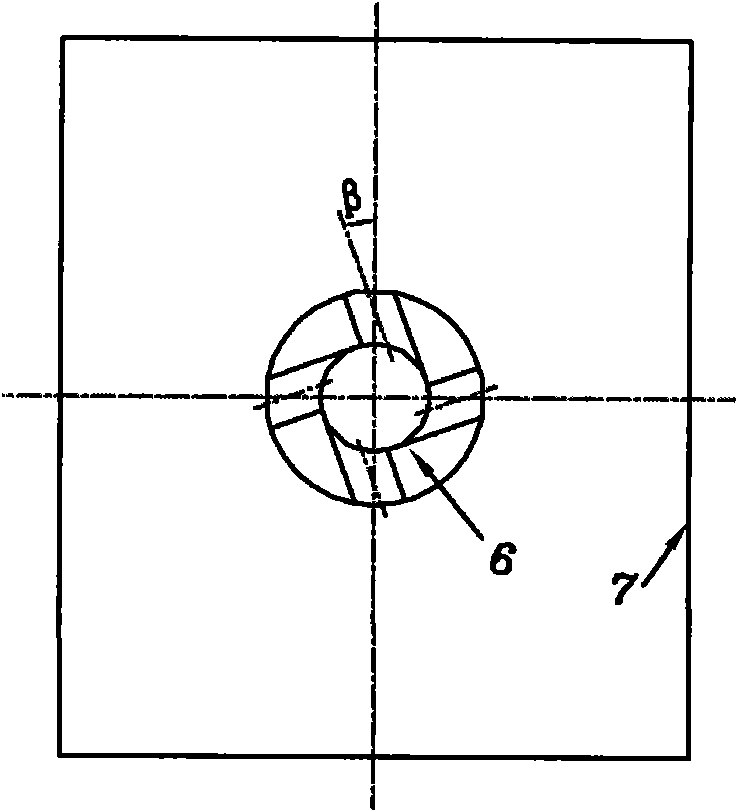

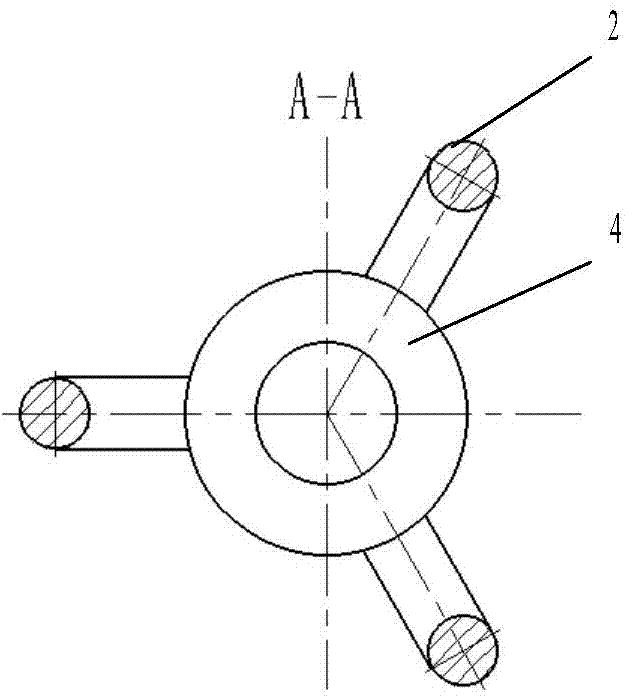

Pinwheel-shaped and tree root-shaped quarter section tangential water gap for continuous casting

InactiveCN101890495ASimple structureEasy to process and produceMelt-holding vesselsTree rootSlant angle

The invention discloses a pinwheel-shaped and tree root-shaped quarter section tangential water gap for continuous casting and belongs to the technical field of continuous casting. Peripheral lines of four side holes of the water gap is tangential to a centre hole of the water gap, and the four side holes form a downward slant angle alpha in an orifice direction, wherein alpha is 10 to 25 degrees; and when used for casting, the quarter section tangential water gap needs to be immersed in a certain depth h below the liquid steel level, wherein h is 100 to 130mm. The product has the advantages of simple structure, easy processing and production, and contribution to reducing the production cost of a casting blank; when the water gap is used for casting, the liquid steel in a crystallizer not only forms upper reflux and lower reflux, but also forms a strong horizontal whirlpool, so that the water gap contributes to reducing the impact depth of the liquid steel, promoting inward agglomeration and growth of impurities and bubbles and upward flotation, restraining liquid level fluctuation and removing a dead zone of the liquid steel below a crescent moon surface; and the impact area range of the side holes of the water gap is reduced to a certain extent, the impact degree of the liquid steel is lightened, and the formed horizontal whirlpool can enable the shell thickness of the casting blank to be distributed on the cross section of the crystallizer uniformly and circumferentially.

Owner:UNIV OF SCI & TECH BEIJING

Refrigerator door stamping device with locating groove

InactiveCN106694675AAvoid damageAccurateMetal-working feeding devicesPositioning devicesHydraulic cylinderEngineering

The invention discloses a refrigerator door stamping device with a locating groove. The refrigerator door stamping device comprises a base; vertically-placed supporting plates are welded on the two sides of the top of the base correspondingly; horizontally-placed connecting plates are welded on the tops of the two supporting plates; vertically-arranged sliding rails are welded on the inner side walls of the two supporting plates correspondingly; sliding blocks are slidably mounted on the two sliding rails; connecting rods are welded on the tops of the sliding blocks; and upper stamping moulds are fixed at the bottoms of the sliding blocks through fastening bolts. The locating groove is formed in the middle of the top of the base; a limiting groove is formed in the bottom of the locating groove; a buffering groove is formed in the bottom of the limiting groove; a plurality of buffering devices are fixed to the bottom of the buffering groove in a rectangular array mode; and a lower stamping mould is mounted in the limiting groove. Through the design of hydraulic cylinders, the impact depth of an impact block can be controlled to adjust the depths of different refrigerator doors, because the needed impact depths for different types of refrigerator doors are not the same.

Owner:滁州美业科技股份有限公司

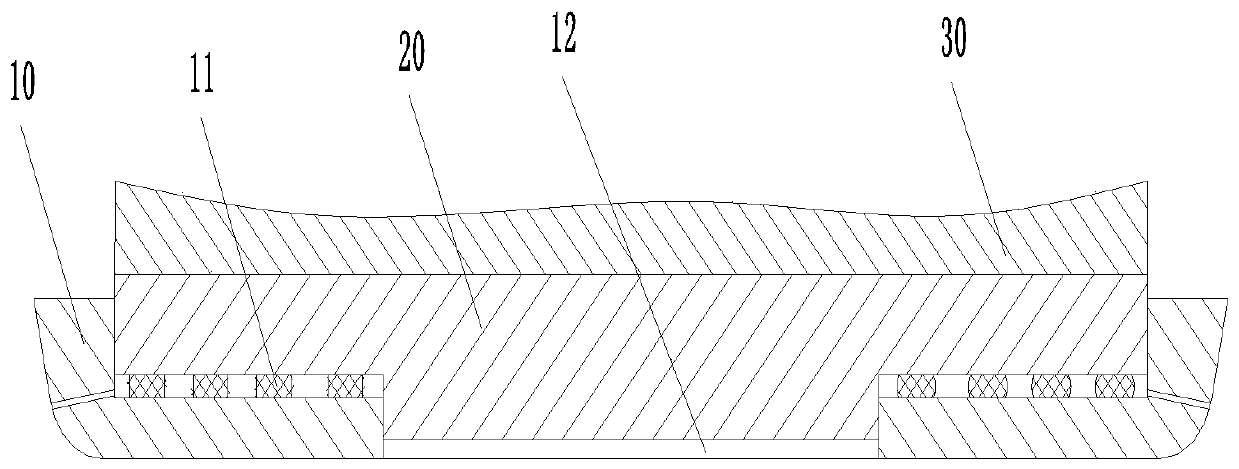

Adjustable compaction machine

The invention provides an adjustable compaction machine. The machine comprises a rack, a rammer disposed on the front end of the rack, a transmission device which drives the rammer to make periodic lifting motion under gravity effects, a control device which is disposed inside the rack and used to control work of the transmission device as well as an adjustment device which is firmly disposed on the rack and used to adjust an impact depth of the rammer. The rammer can be a flat-top rammer which is used for compaction of backfill soil, and can also be a sharp-head impact block which can be used for positioned punching. The machine provided by the invention can adjust an impact distance of the rammer in time according to a height of ground compaction and is applicable to compaction of low-lying parts or raised ground surfaces.

Owner:邳州市滨河中小企业管理服务有限公司

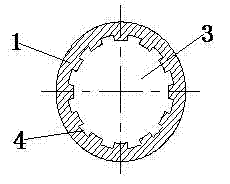

Straight-through type continuous casting immersion-type water gap

The invention belongs to the technical field of the industrial continuous casting, and particularly relates to an immersion-type water gap device used for a square-billet and round-billet continuous casting crystallizer. The immersion-type water gap comprises a vertically-through tubular body, wherein an inner cavity is defined by the body; the outer surface of the side wall of the body is sheathed with a slag line; the inner surface of the side wall of the body is dug with a plurality of grooves; the tail ends of the grooves penetrate through the side wall of the body; and a plurality of long and narrow notches connected with the tail ends of the grooves are formed on the bottom of the side wall of the body. According to the immersion-type water gap disclosed by the invention, the molten steel impacting depth can be lowered, molten steel temperature ingredients are accelerated to be even, and the casting blank quality is improved. The immersion-type water gap used for the square-billet and round-billet continuous casting crystallizer has the characteristics of simple structure, obvious effect and low cost and is suitable for popularizing.

Owner:启东市希士水泥有限公司

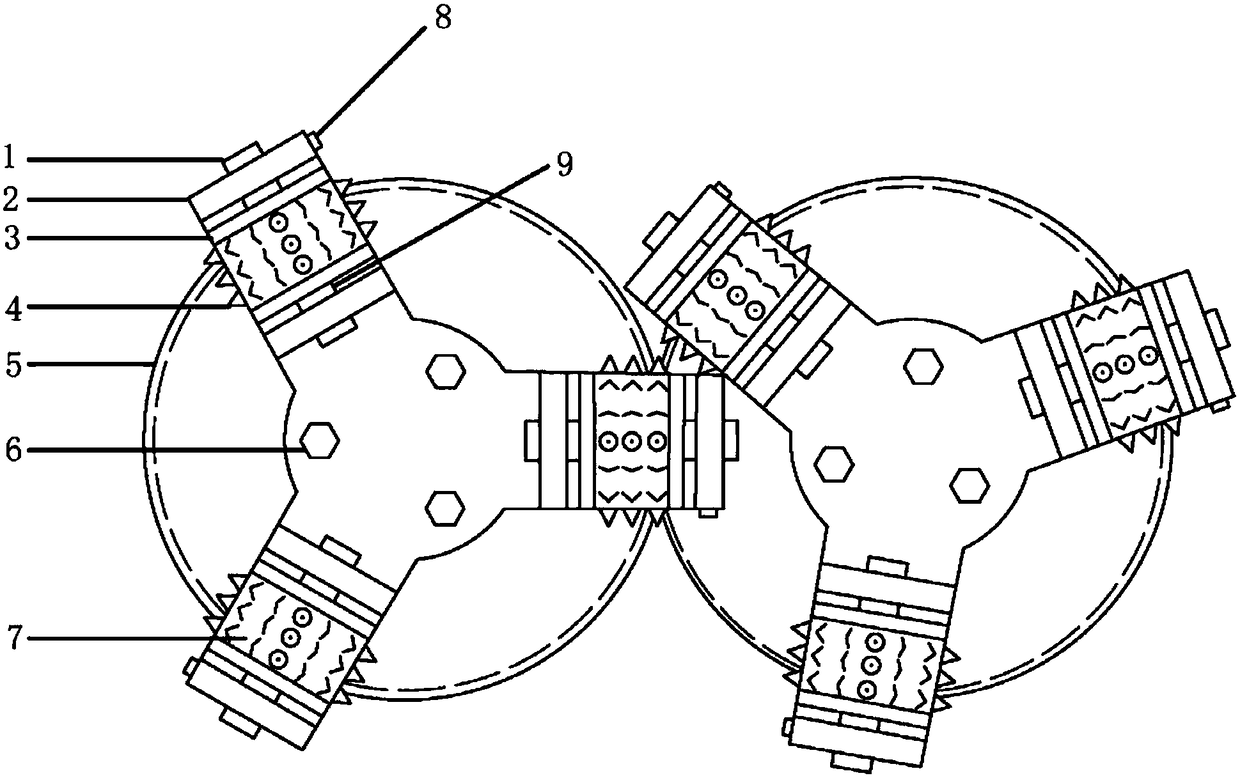

Concrete scabbler head and concrete scabbler using same

InactiveCN108265601AEvenly distributedGuaranteed uptimeRoads maintainenceBridge engineeringGear wheel

The invention belongs to the technical field of road or bridge engineering machinery and discloses a concrete scabbler head. The concrete scabbler head comprises wheel racks, wheels, wheel axles, bearings, dustproof bearing covers and a gear shaft and is characterized in that the wheels are mounted on the wheel racks, the wheel axles penetrate the wheels to fix the wheels to the wheel racks, the gear shaft is fixed with the wheel racks, the wheel racks rotate along with the gear shaft, the wheels rotate by using the wheel axles as the centers, and the wheels are provided with protrusions. By the concrete scabbler head, uniform scabbling, uniform concrete scabbling strength and effect and consistent impact depth can be achieved.

Owner:于法俭

Square billet hyperbolic-type submersed nozzle and manufacturing method thereof

ActiveCN110170641AReduce the cross-sectional areaHigh speedMelt-holding vesselsEngineeringMolten steel

The invention belongs to the technical field of square billet continuous casting production and discloses a square billet hyperbolic-type submersed nozzle and a manufacturing method thereof. The method comprises the steps including designing of a hyperbolic-type nozzle; counterboring; tool machining; machining of the hyperbolic-type nozzle; spraying and the like. According to the method, by designing the shape of an internal hyperbolic-type channel of the nozzle, by means of the characteristic that the upper curvilinear section areas are gradually decreased, the volume proportion of a cavity in the upper portion of the nozzle is controlled, and the tendency that gas suction of the nozzle causes secondary oxidation is reduced; and by means of the characteristic that the lower curvilinear section areas are gradually increased, steel flow flows downwards in a dispersed mode, the impact depth in a crystallizer of molten steel is decreased, and the flow behavior of the molten steel in the crystallizer can be improved easily. According to the square billet hyperbolic-type submersed nozzle and the manufacturing method thereof, the portion, in the hyperbolic top position, of the channel ismachined into a ring shape, backflow formed after multiple times of reducing of the steel flow is mainly used for disturbing a center flow, the flowing speed of the center flow is decreased, and thesteel flow is controlled to decelerate on the whole.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

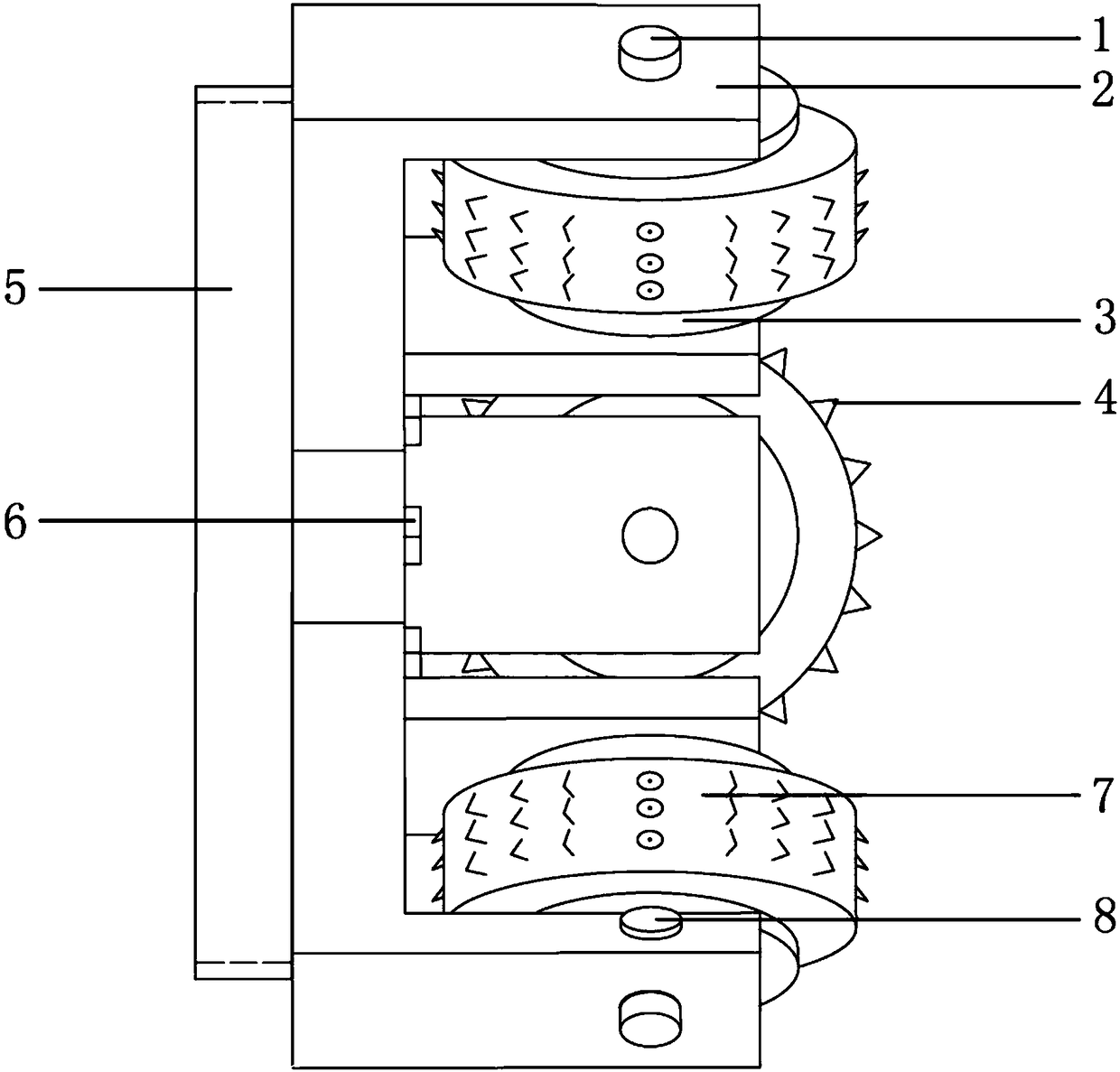

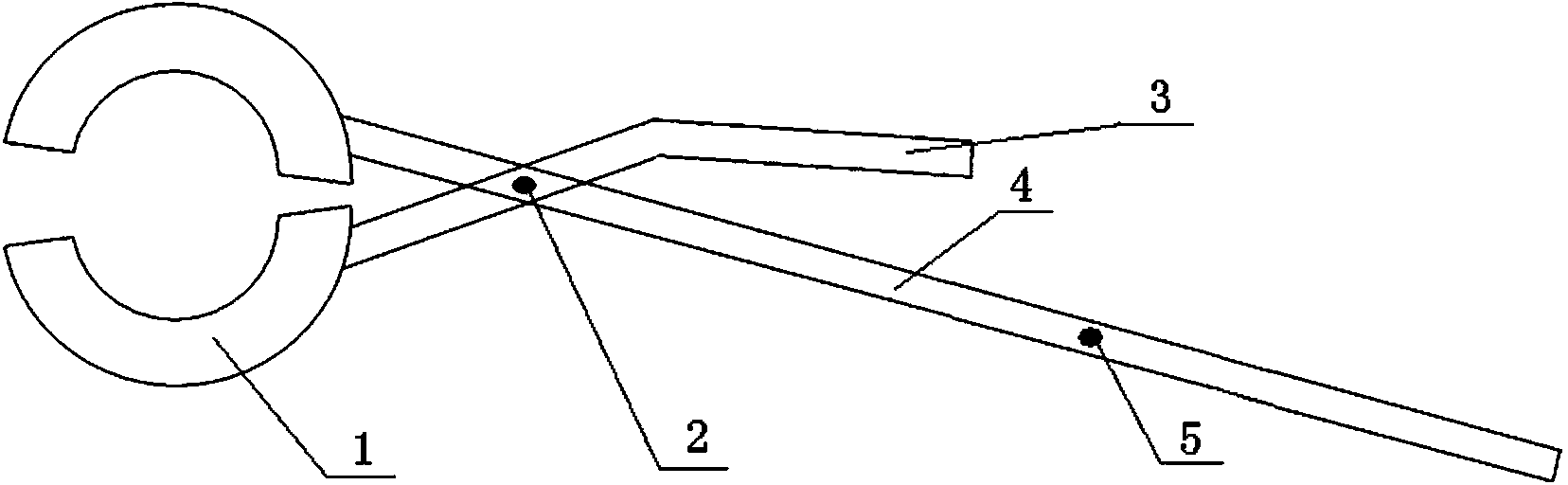

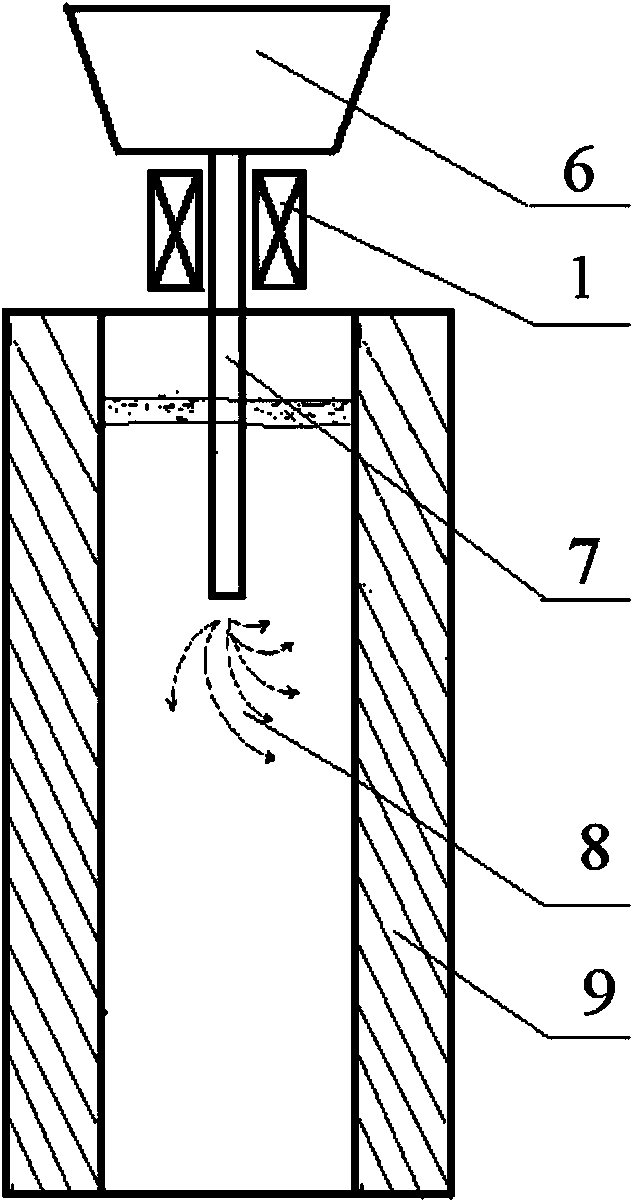

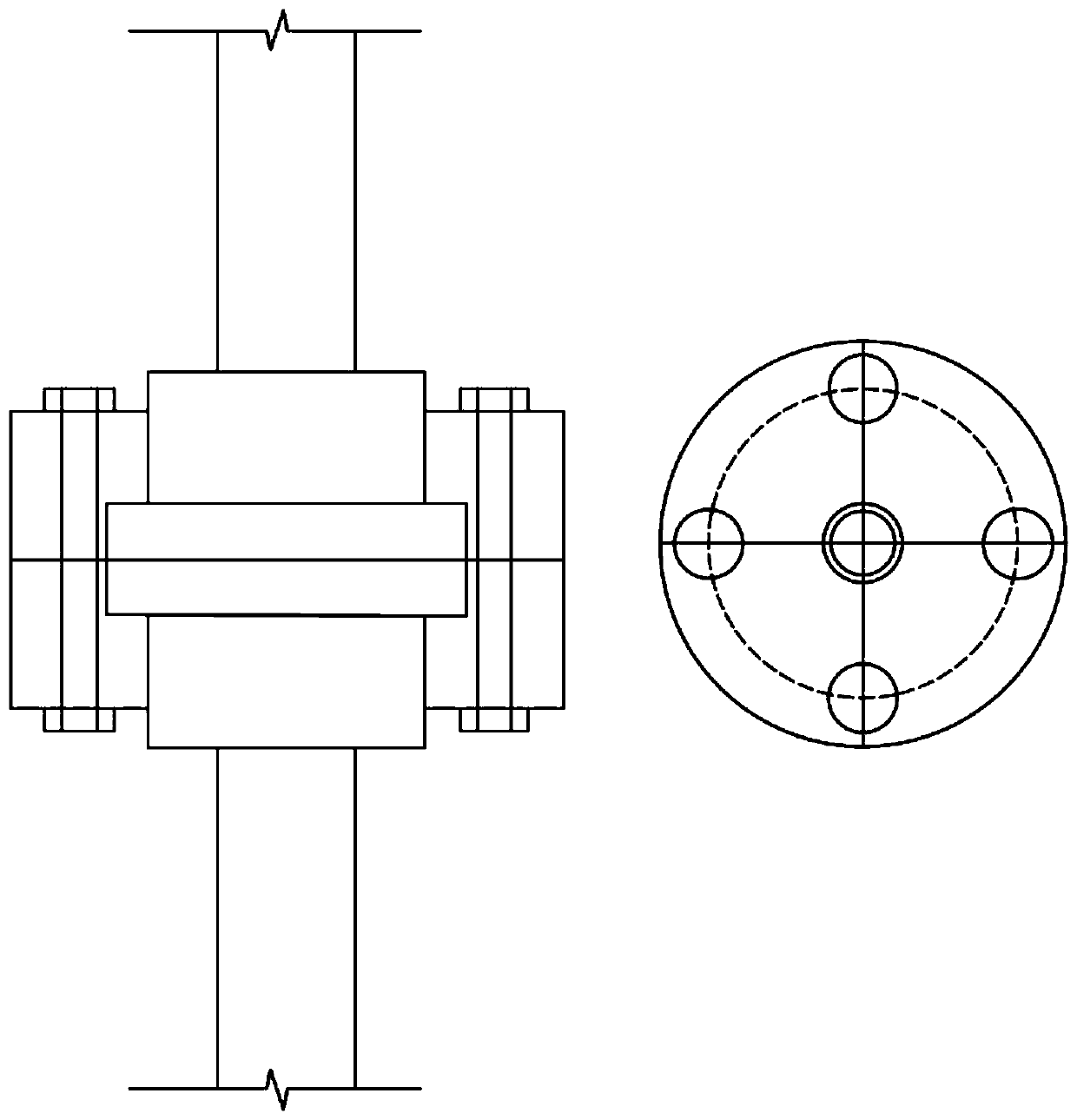

Device and method for reducing small casting blank molten steel impact depth

The invention provides a device and method for reducing the casting blank molten steel impact depth. The device is composed of electromagnetic stirrers, a pincerlike handle, a pin shaft and a support. The front portion of a straight rod and the front portion of a bent rod of the pincerlike handle are hinged together through the pin shaft, and the front end of the straight rod and the front end of the bent rod are respectively and fixedly provided with one semicircular electromagnetic stirrer. Before casting, the two semicircular electromagnetic stirrers are installed outside a water gap between a tundish and a crystallizer in an opposite buckling mode. During casting, the electromagnetic stirring current is controlled to be 20-400A, the stirring frequency is controlled to be 1-100 Hz, and the stirring power is determined according to the horizontal-direction speed V1 and the vertical-direction speed V2 of molten steel, and V1 / V2 ranges from 0.5 to 2. The device and method for reducing the casting blank molten steel impact depth are easy to implement, have no pollution, and can effectively reduce the impact depth of small square billet water gap molten steel, facilitate upward floating of gas and impurities in the molten steel, reduce the content of gas and impurities in solidified casting blanks, reduce casting blank defects and internal stress, and improve casting blank quality.

Owner:ANGANG STEEL CO LTD

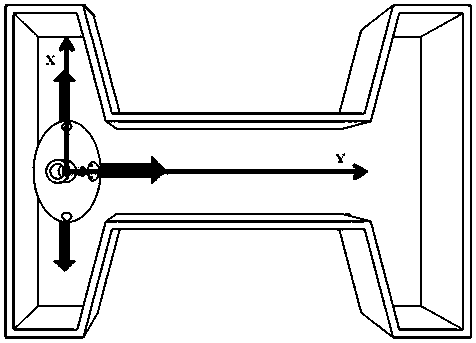

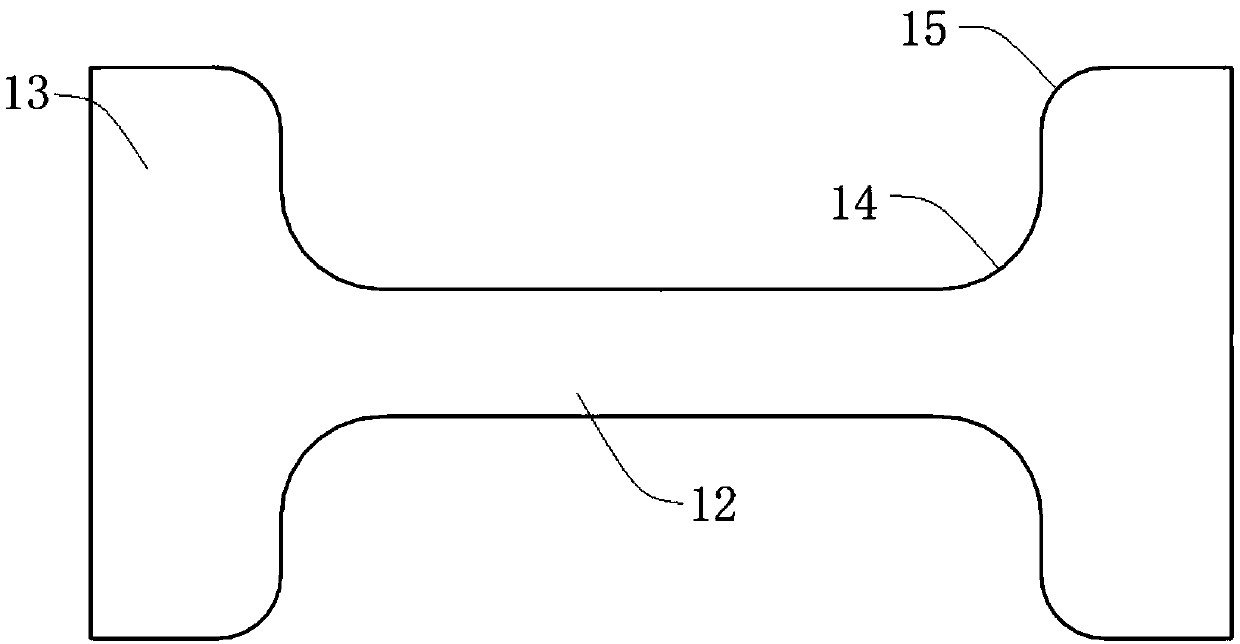

Crystallizer submersed nozzle of beam blank single-point nonequilibrium protective casting and using method

The invention discloses a crystallizer submersed nozzle of beam blank single-point nonequilibrium protective casting and a using method and belongs to the technical field of beam blank continuous casting. The nozzle comprises an isometric section and a reducing section, wherein the cross section of the inner side of the isometric section is round, the isometric section and the reducing section areconnected to form a submersed nozzle body, the cross section of the inner side of a joint of the isometric section and the reducing section is round, the inner cross section of an free end of the reducing section is oval; and a through hole X, a through hole Y and a through hole Z are formed in the reducing section in the X direction, the Y direction and the Z direction. During the beam blank single-point nonequilibrium protective casting, flow speed of molten steel can be reduced, the impact depth of the molten steel in a crystallizer is reduced, a flow field and a temperature field are homogenized, the washout to a wall surface of the crystallizer is not caused, and casting blank condensation is not influenced, an obtained product is few in defects and high in quality, and the crystallizer submersed nozzle has the advantages of being simple in structure, convenience in using method and easy in implementation.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

A Method of Improving the Life of Turbine Blades Based on Laser Double-side Shock Technology

ActiveCN104862468BHighlight substantive featuresSignificant progressBlade accessoriesMachines/enginesHigh energyTurbine blade

The invention relates to a method for improving the service life of turbine blades based on laser double-sided shock technology. Firstly, Nd:YAG pulsed lasers are used to perform equal-energy laser beam splitting; then, using flowing water as a constrained layer, the blades are impacted and strengthened at the same time by using gradient facula overlapping ratios. At the root, the fixture fixes the turbine blade, using high-energy and large-spot pulsed laser with a 90% overlap rate to impact the bottom of the blade root on both sides at the same time; The lap rate of the previous impact minus 10% is used for impacting; until the lap rate is 0, the laser shock strengthening of the blade root is completed. It makes up for the shortcomings of insufficient impact depth of mechanical shot peening, and adopts a gradual lapping rate to impact the root of the blade to make the distribution of the residual stress field smoother; adopts the laser double-sided impact method to avoid deformation and damage of the blade caused by single-sided laser impact. Simultaneous impact makes the front and back of the blade bear the same force.

Owner:WENZHOU UNIVERSITY

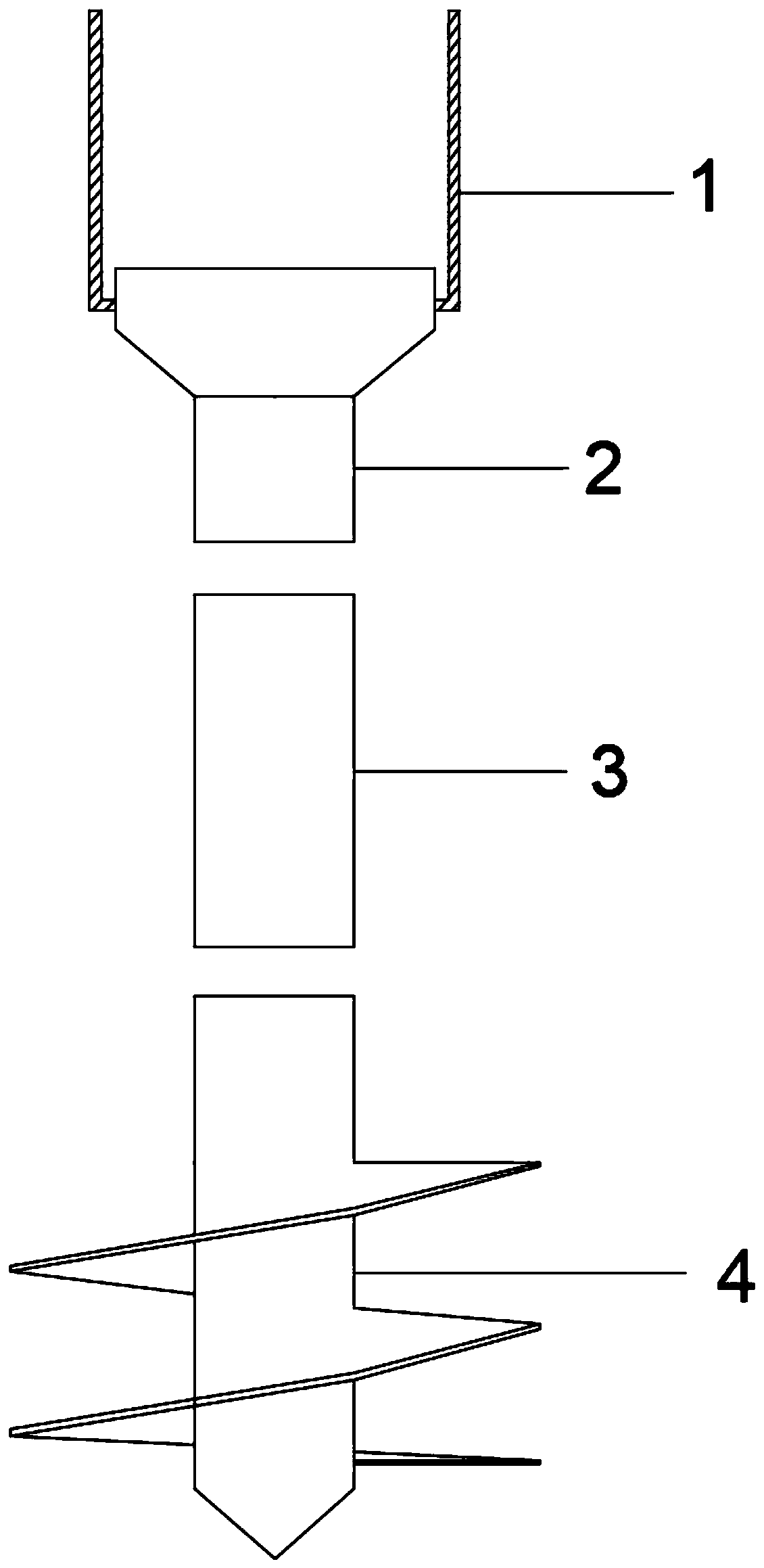

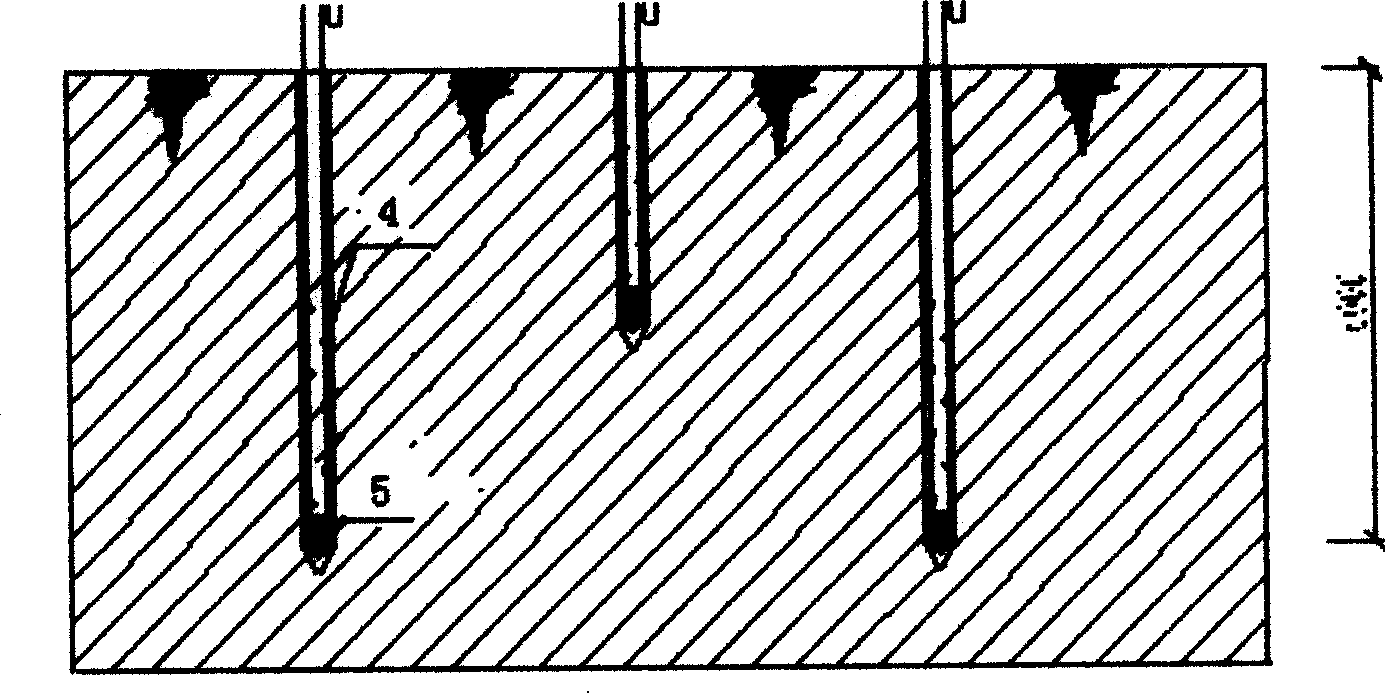

Connectable spiral plate deep dynamic compaction device and construction method thereof

The invention belongs to the field of civil engineering, and discloses a connectable spiral plate deep dynamic compaction device. The connectable spiral plate deep dynamic compaction device includes three parts of a round table type pile cap, a connectable pile body and a spiral plate drill bit, wherein the round table type pile cap is connected to the upper end of the connectable pile body through a flange, and the spiral plate drill bit is connected to the lower end of the connectable pile body through a flange. The invention further discloses a construction method of the connectable spiralplate deep dynamic compaction device. According to the connectable spiral plate deep dynamic compaction device, the large round table type pile cap can make a pile under dynamic compaction stress uniformly, and the dynamic compaction consolidation area is expanded; a sound-proof steel barrel is arranged on the upper part of the pile cap, and the noise can be effectively reduced; the ramming depthof the connected pile body can be increased or decreased according to the engineering requirements; and the spiral plate drill bit is spirally drilled into a soil body, the difficulty of constructionis reduced, the noise is low, after drilling to the tamping calibration depth, deep dynamic compaction is conducted, and the effective impact depth of ramming is greatly increased; and the structure is simple, the practicability is high, the stability is good, and the application prospects are wide.

Owner:HOHAI UNIV

Virtual Digital Sculpture Method Based on Natural Gesture

ActiveCN106406875BExact joint coordinatesHuman-computer interaction is naturalInput/output for user-computer interactionSoftware designDigital sculptingDeformation effect

A virtual digital sculpting method based on natural hand gestures, comprising the following steps: hand gesture position acquisition, the hand gesture position being acquired by means of leap motion; and virtual sculpture modelling. When implementing virtual sculpting tasks, there are two main models, one being a constructed model to be sculpted, and one being a virtual hand model constructed of joint coordinates acquired by means of leap motion; when the human hand moves under leap motion, controlling the virtual hand to make a slight impact on the fixed model to be sculpted, detecting whether there is an intersection point at the impact site by means of a three dimensional space triangle and triangle intersection algorithm, and the intersecting line position and, on the basis of a calculation of the impact depth, using a virtual sculpting deformation algorithm to perform real-time modification of the intersection point position coordinates, thereby achieving a sculpting deformation effect.

Owner:SOUTH CHINA UNIV OF TECH

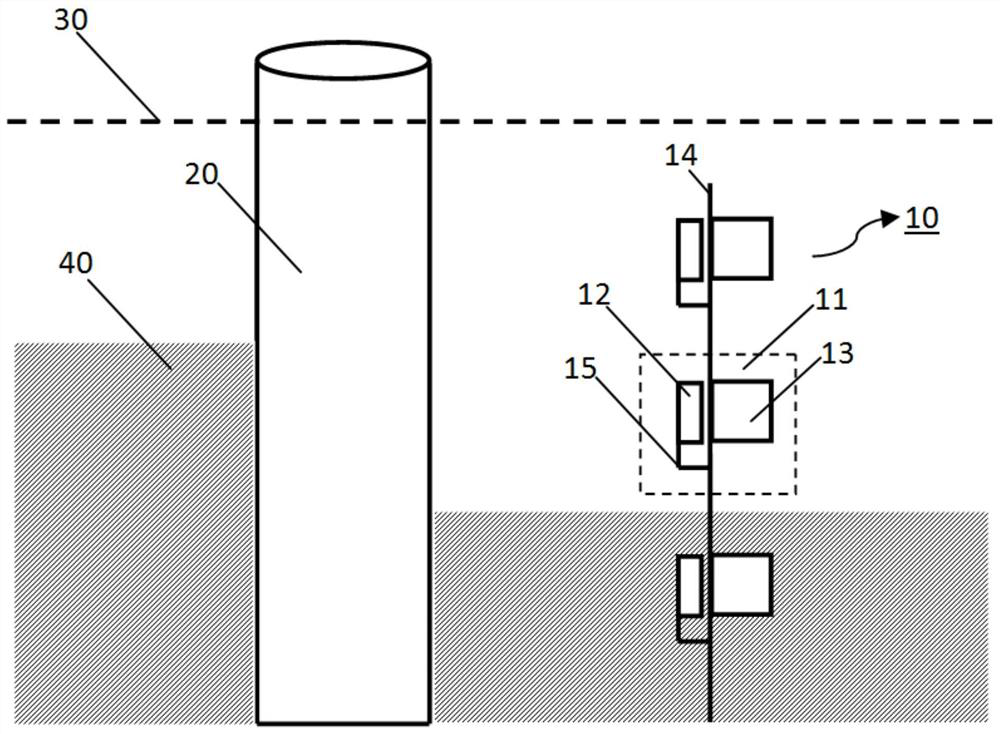

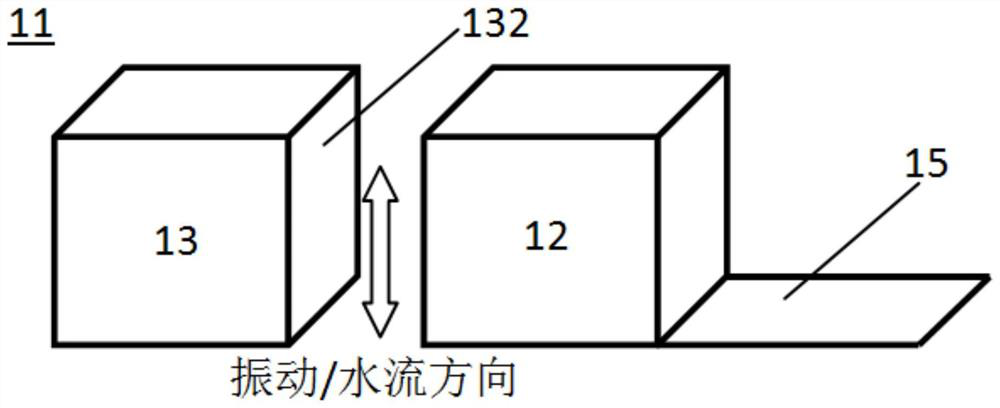

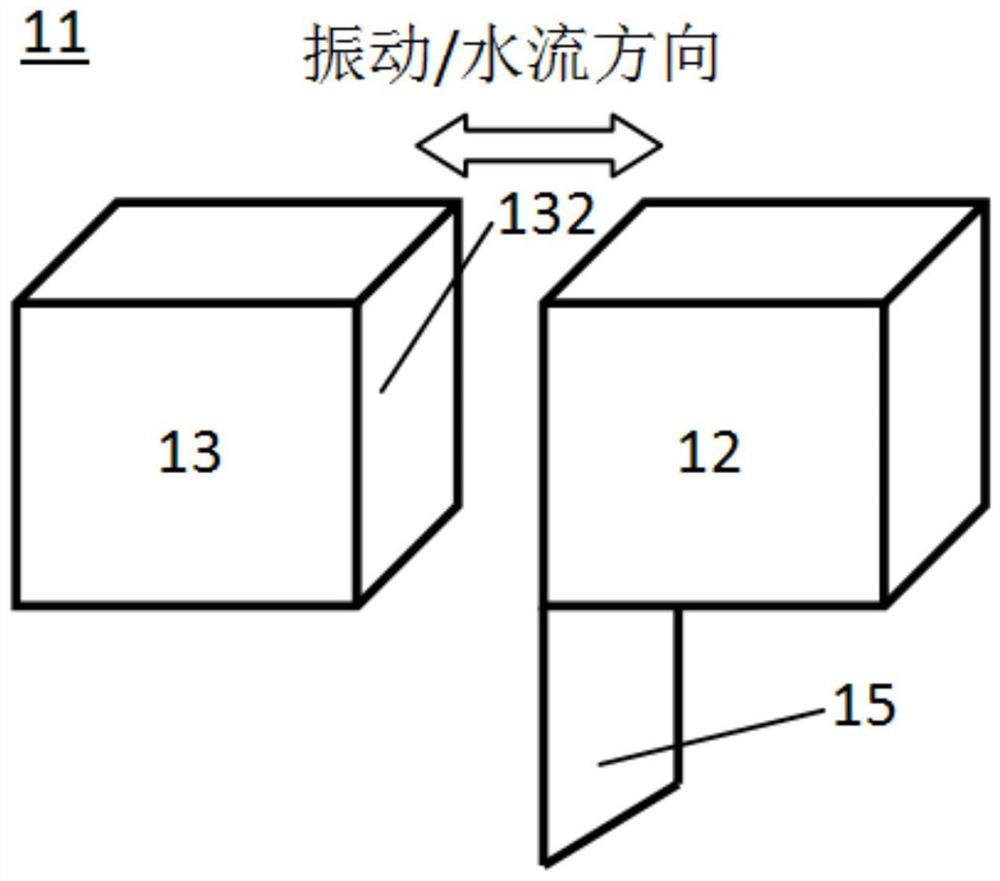

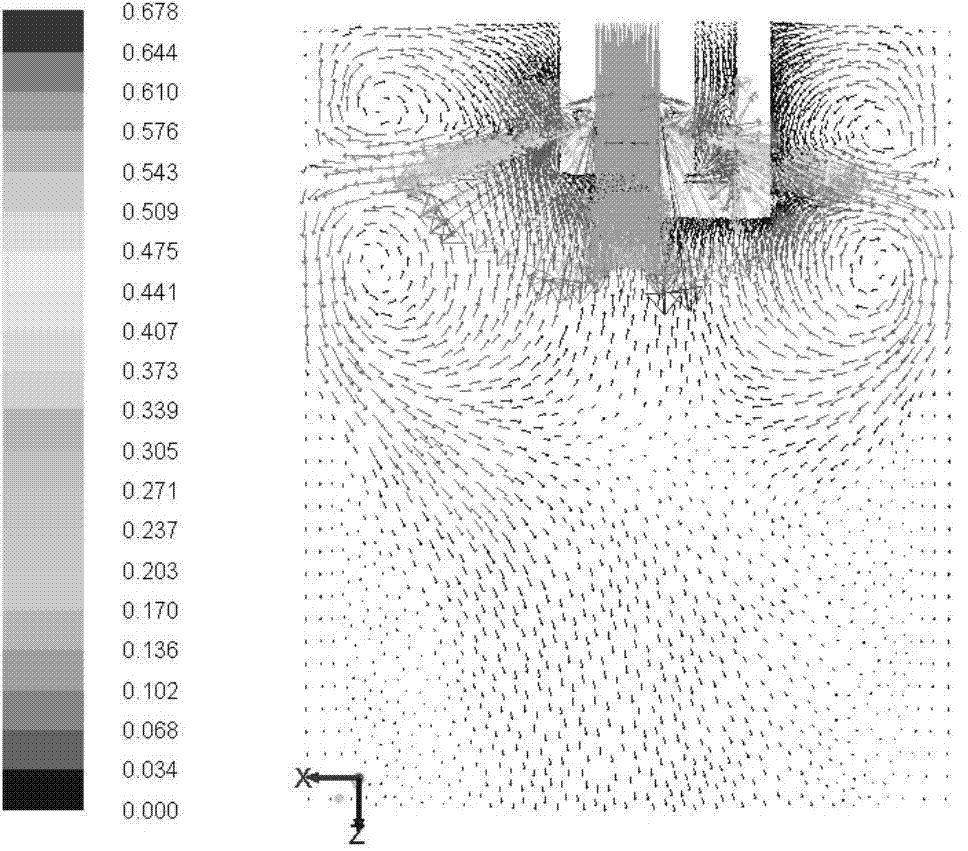

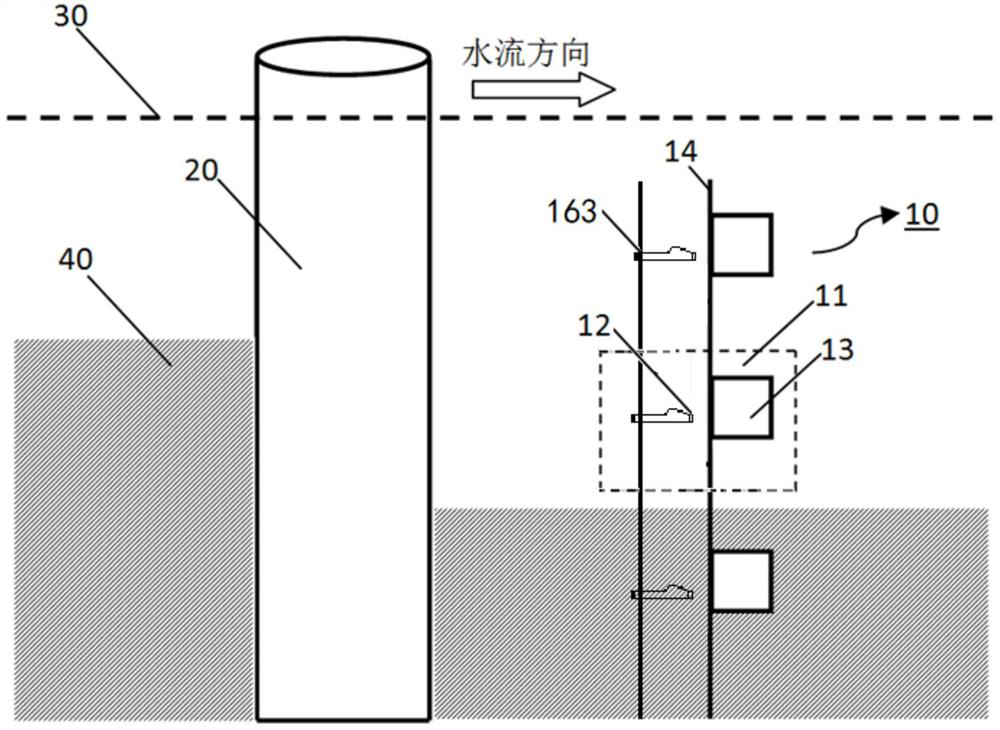

Water flow impact depth monitoring device of intelligent flood control early warning system

PendingCN112815927AGuaranteed stabilityLow costMeasuring open water depthHydrometryEarly warning system

The invention relates to the technical field of hydrological monitoring, and particularly relates to a water flow impact depth monitoring device of an intelligent flood control early warning system. The device comprises a controller, a fixing column and a plurality of impact sensing units. The fixing column is vertically inserted into riverbed sediment beside a pier, the impact sensing units are evenly arranged on the fixing column in the vertical direction, and the signal output ends of the impact sensing units are electrically connected with the signal input end of the controller. The impact sensing units which are buried in the sediment and are vertically and linearly arranged are adopted, the position of the sediment impacted by a water flow is obtained in a magnetic field change detection mode, then an impact depth is obtained, and the device is low in cost, simple in structure and easy to arrange in a large number.

Owner:HUBEI PROVINCIAL WATER RESOURCES & HYDROPOWER PLANNING SURVEY & DESIGN INST

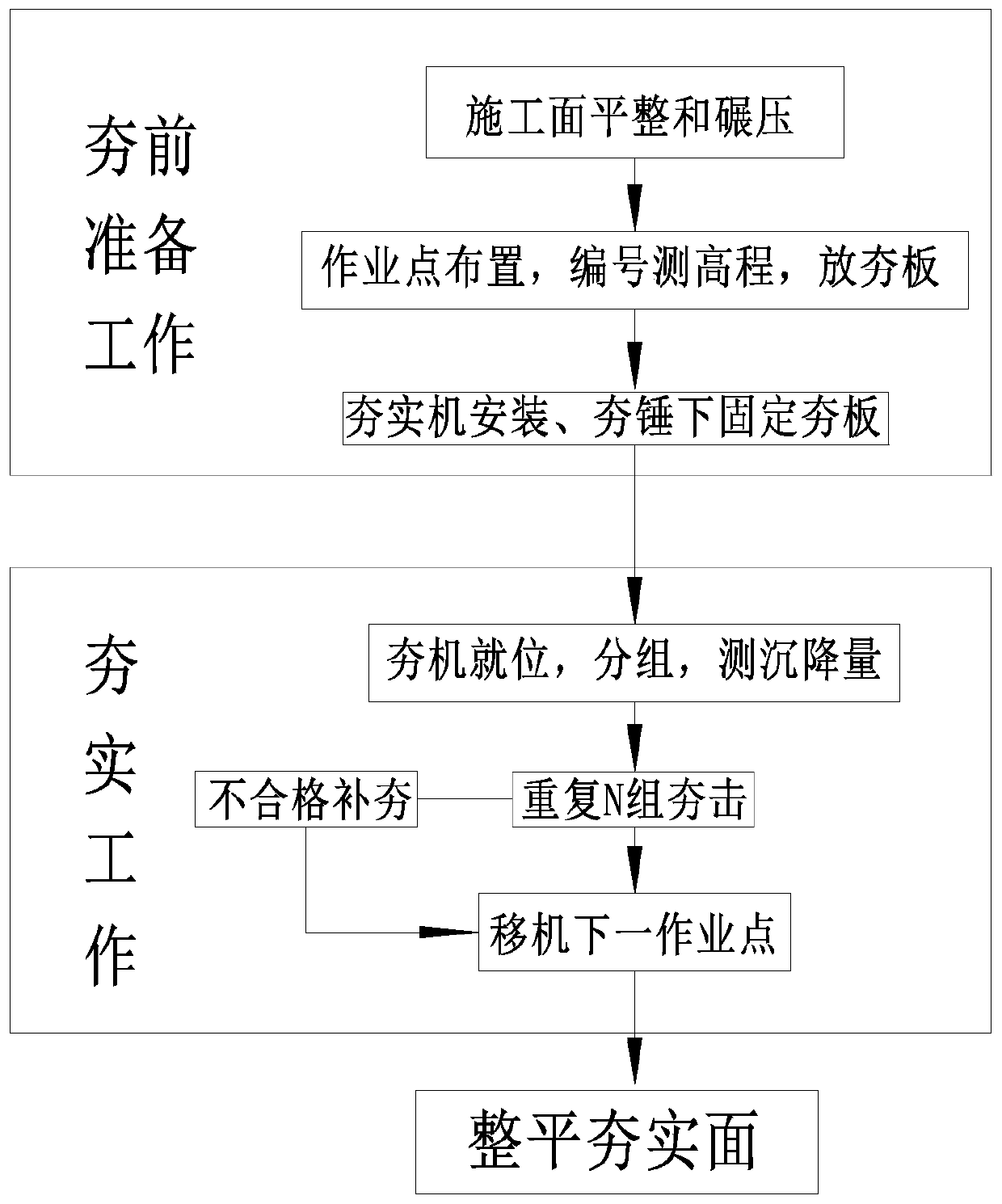

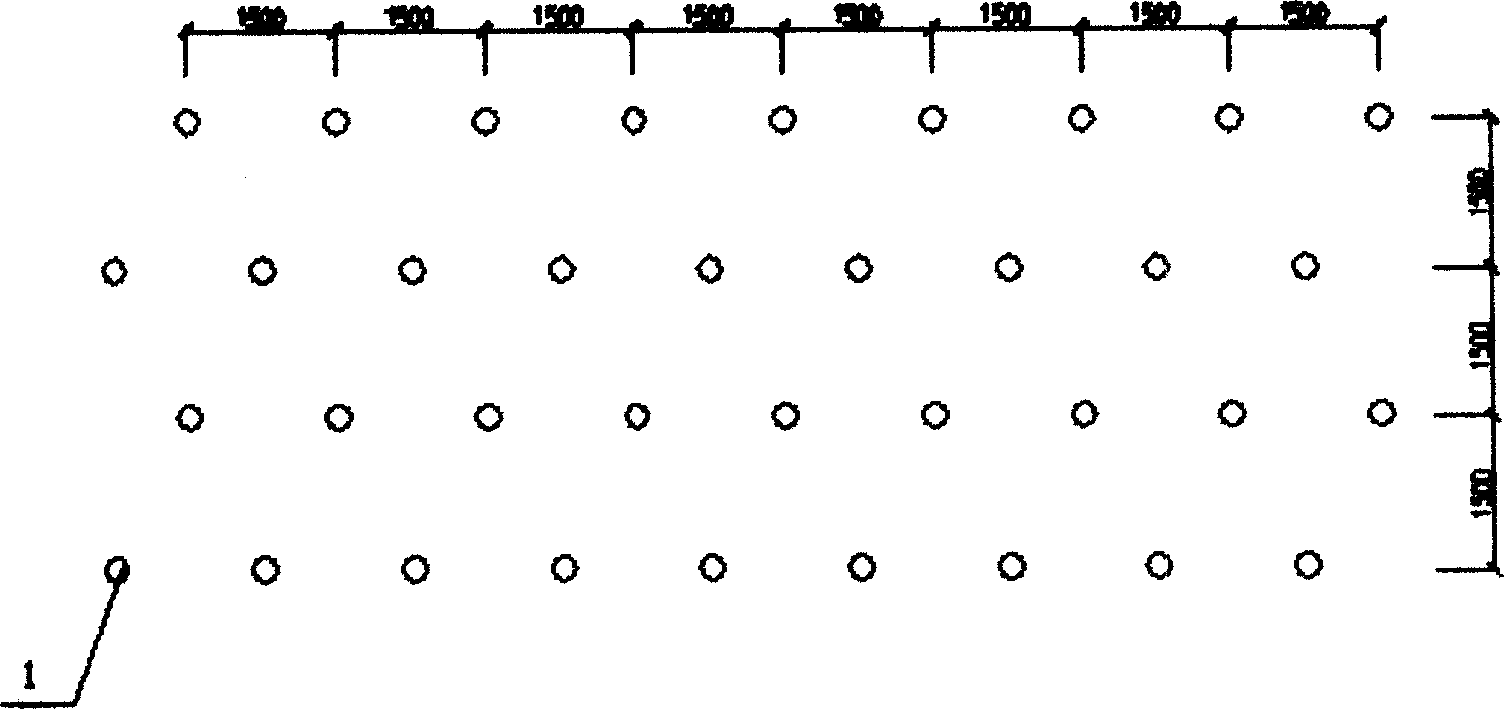

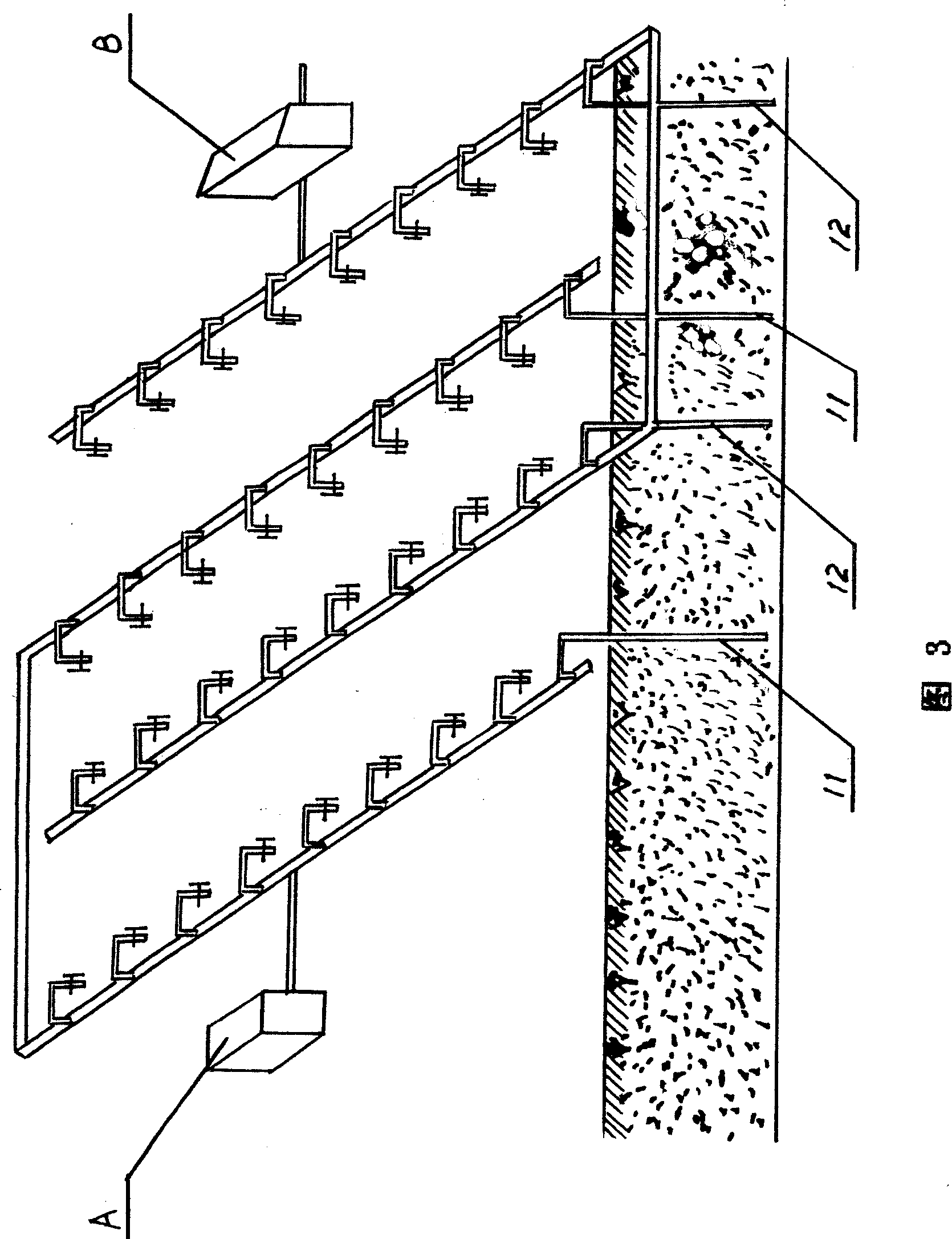

Method for performing backfilling and hydraulic ramming on stage back of bridges and culverts

ActiveCN110106857ASolve the problem of insufficient tampingEasy to moveSoil preservationLow noiseDynamic compaction

The invention discloses a method for performing backfilling and hydraulic compaction on the stage back of bridges and culverts, and belongs to the technical field of backfilling construction of the stage back of the bridges and culverts. The method for performing backfilling and hydraulic compaction on the stage back of the bridges and culverts comprises the following steps that step 1, preparingwork before tamping is carried out; specifically, A1, a construction surface is leveled and rolled; A2, operation point layout is carried out, numbering and elevation measurement are carried out; A3,a rammer compactor is installed, a compaction plate is fixed to the lower part of a rammer; step 2, compaction work is carried out; specifically, B1, the rammer compactor is in place, every three hammers are taken as a group, and the settlement of each group is measured; B2, N groups of compaction is repeated; and B3, a machine is moved to the next operation point; step 3, the compaction surface is leveled after all the compaction points are rammed; and step 4, quality inspection is carried out. Compared with the traditional dynamic compaction technology, the method for performing backfillingand hydraulic compaction on the stage back of the bridges and culverts is small in an acting force peak value, high in striking frequency, soft in action and not prone to shearing a filling layer streamline; compared with vibration compaction technology, the compaction energy is high, penetration ability is high and uniform, impact depth is large, and relatively uniform compactness can be obtainedin a larger depth range. The method for performing backfilling and hydraulic compaction on the stage back of the bridges and culverts has the advantages of high strength, high efficiency, low energyconsumption, low noise, energy conservation and environmental protection.

Owner:CHINA MCC17 GRP

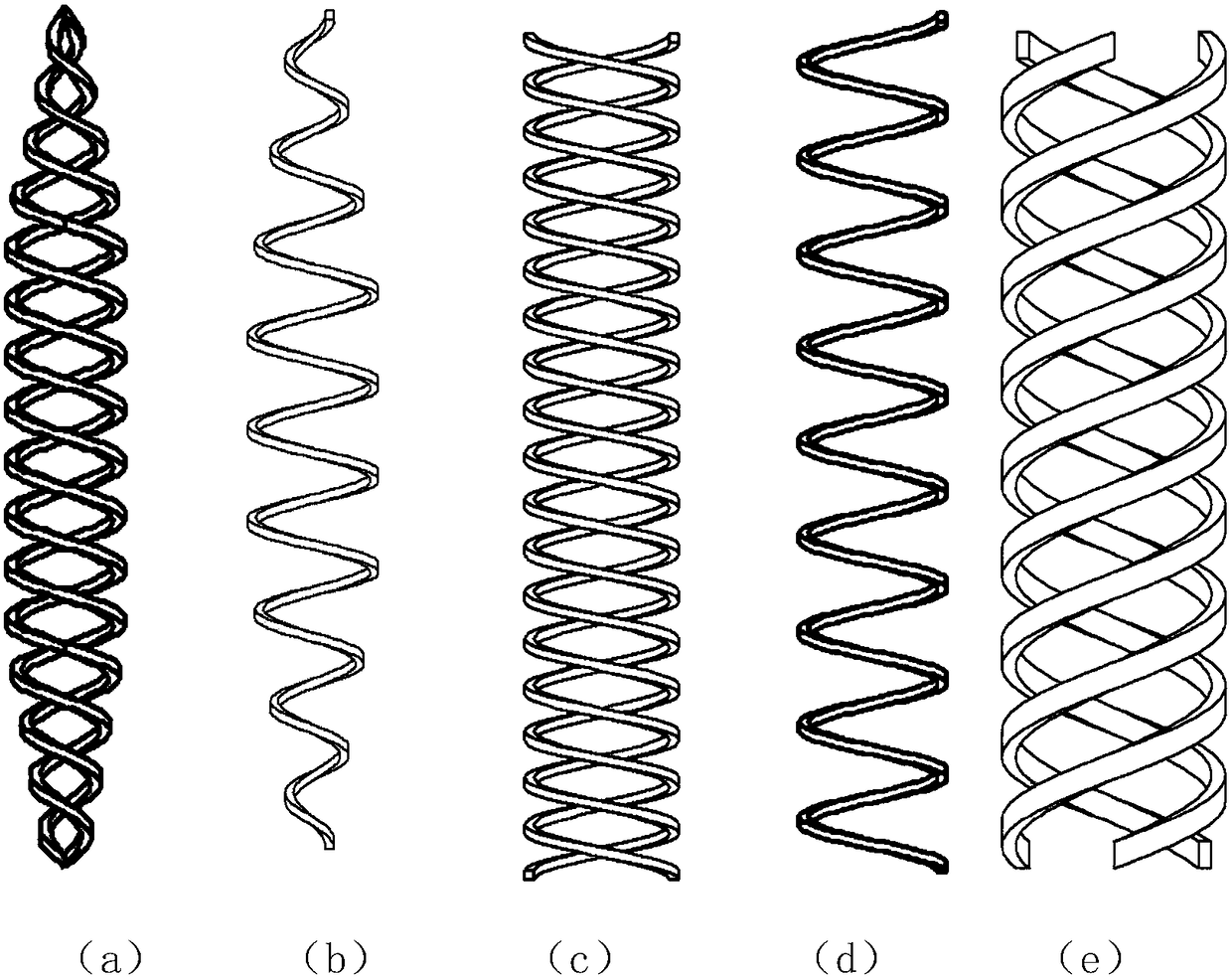

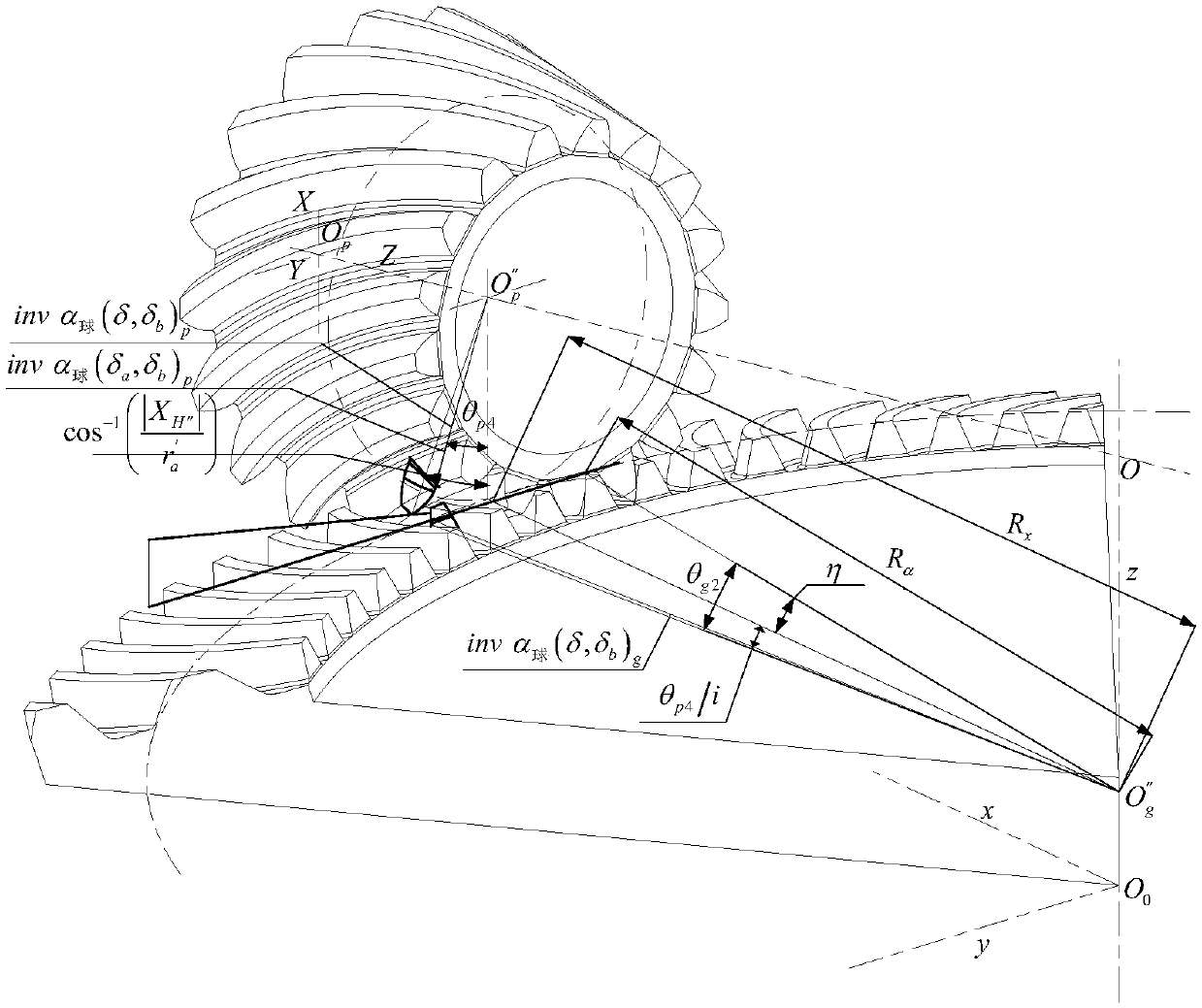

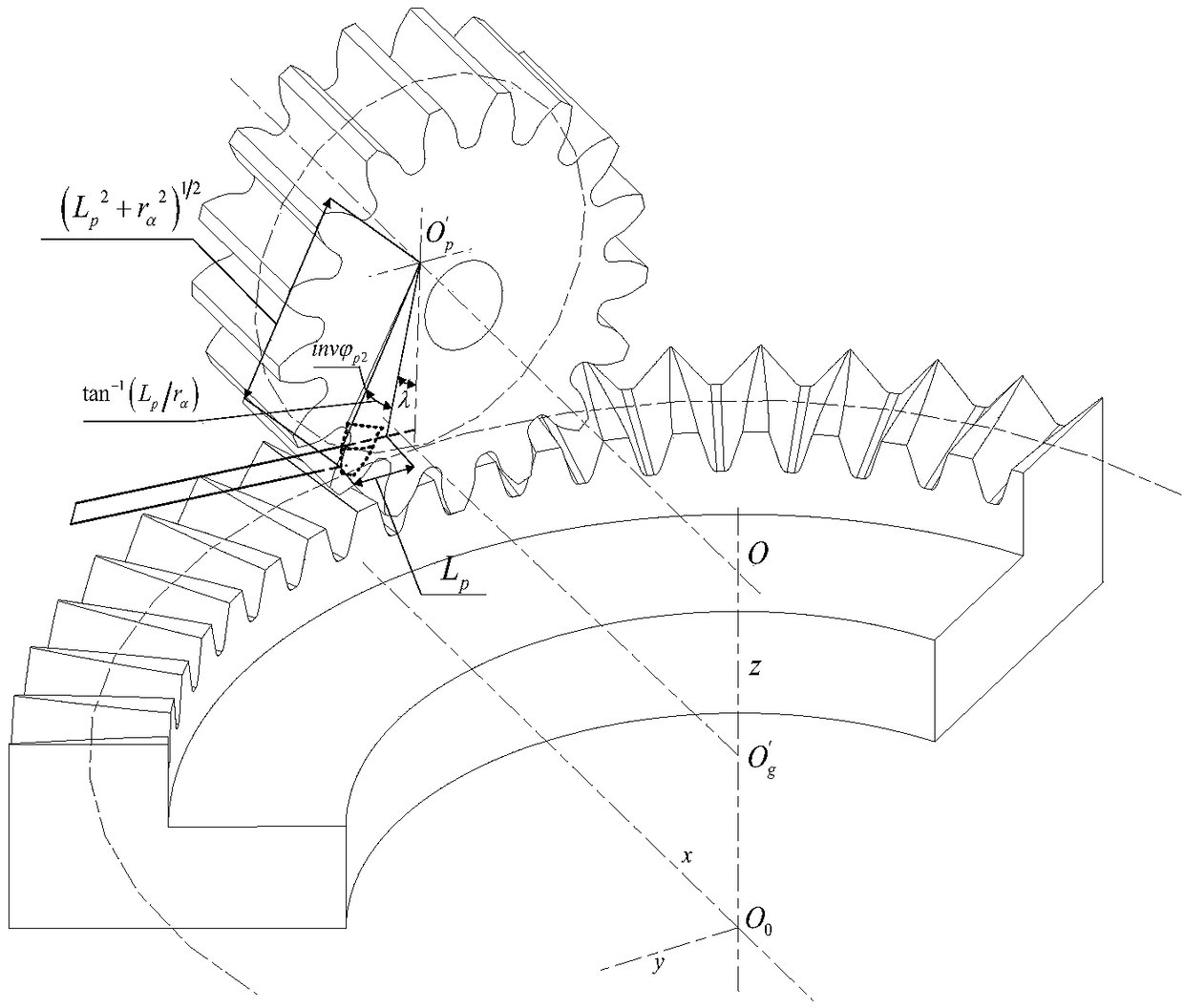

A method for optimizing that layout of oil injection lubrication nozzles of aeronautical orthogonal spur gear is disclose

ActiveCN109376472ALubrication effect is convenient and intuitiveImprove the lubrication effectGeometric CADSustainable transportationAviationJet injection

The invention discloses a method for optimizing that layout of oil injection lubrication nozzles of aeronautical orthogonal spur gear . The lubrication effect of gear can be judged by calculating theimpact depth, so as to optimize the layout of nozzle parameters, The calculation steps of the impact depth are as follows: The involute function of the spur gear and the space position relation of thetooth surface of the face gear, A spur gear in a period of time is obtained by geometrical operation, the change of the space position of the face gear and the position of the jet line of the lubricating oil (the relationship between the face gear pair and the jet line at the initial time is shown in the figure), At that same time, accord to the fact that the time taken for the gear meshing and rotate angle is equal to the jet injection time, The impact depth of the lubricating oil on the spur gear and the face gear is obtained, so as to judge the quality of the corresponding nozzle layout according to the principle that the greater the impact depth is, the better the lubricating effect is. Therefore, the invention can evaluate the oil injection lubricating performance of the face gear, and can be used as a nozzle layout optimization design method.

Owner:CENT SOUTH UNIV

A reverse laser peening multi-element control method and device

ActiveCN106636563BSolving Dimensional Stability ChallengesImprove the strengthening effectProgramme control in sequence/logic controllersAviationMechanical models

The embodiment of the invention discloses a multiple-unit control method and a multiple-unit control device for reverse laser shot peening. The region area and impact depth of laser shot peening treatment are reasonably designed by virtue of the modification characteristic of a surface layer material generated through laser shot peening, and a laminated section is constructed to change the Young moduli of parts, thus the inherent frequency is changed, and the dual purposes of reinforcement and frequency modulation treatment are realized; moreover, modelling analysis is carried out through a mechanical model to optimize a sizing region and parameters with regard to the common problem of structure deformation in the laser shot peening treatment, and repair for the deformation of the parts is realized through reversely loading impact loads, thus the purpose of dimensional stability of the laser shot peening parts is achieved; and moreover, the multiple-unit control method and the multiple-unit control device are capable of meeting the various needs of rotating parts, and in particular, are suitable for high-speed rotating parts bearing aerodynamic loads, such as gas turbine blades, aviation engine blades and the like.

Owner:GUANGDONG UNIV OF TECH

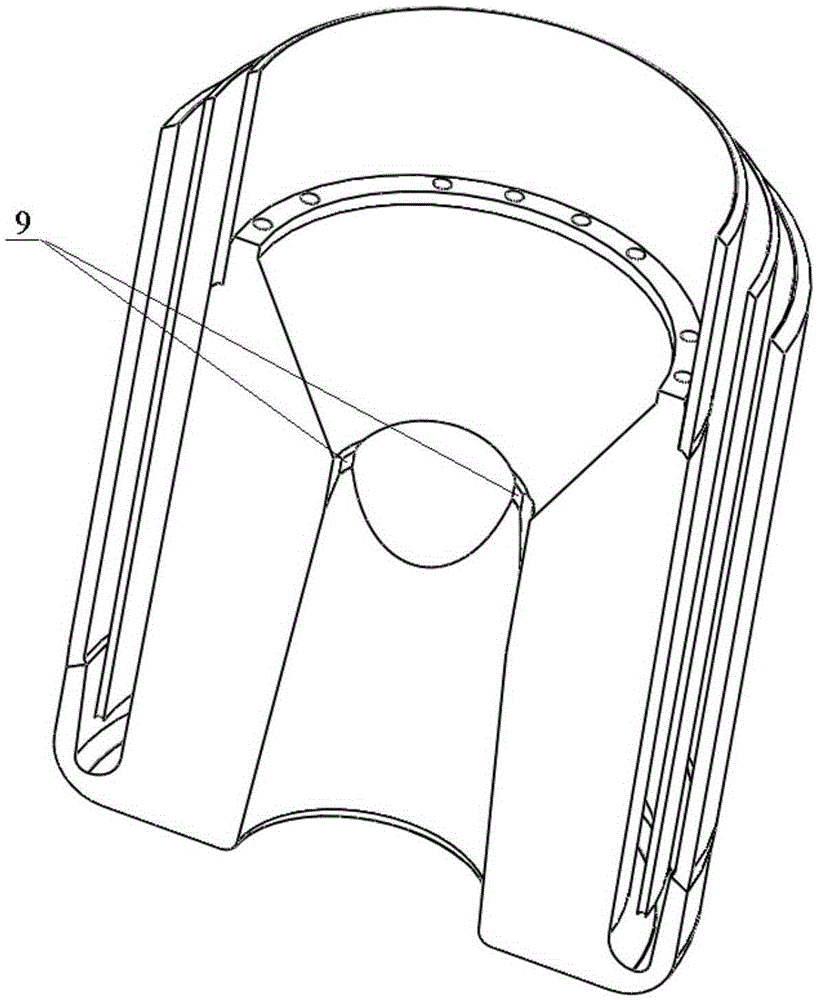

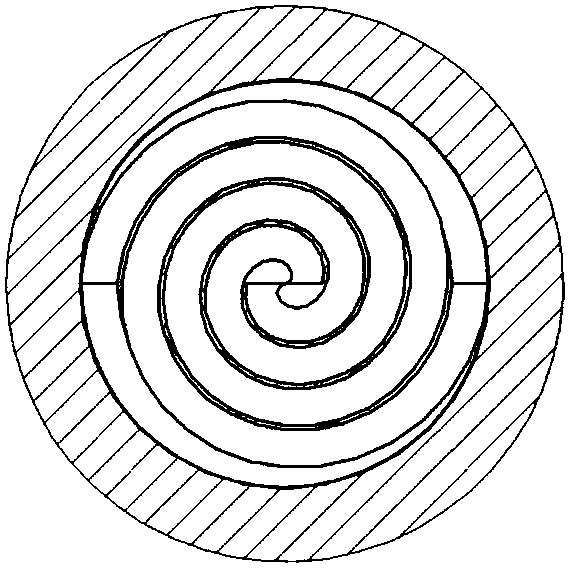

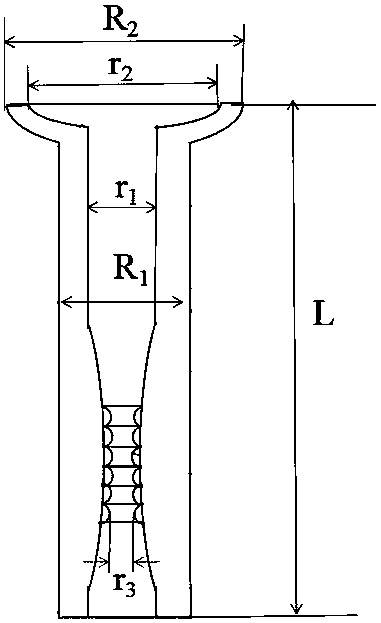

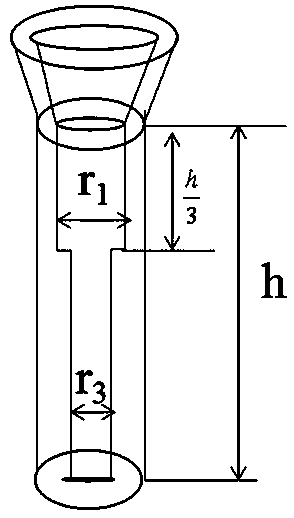

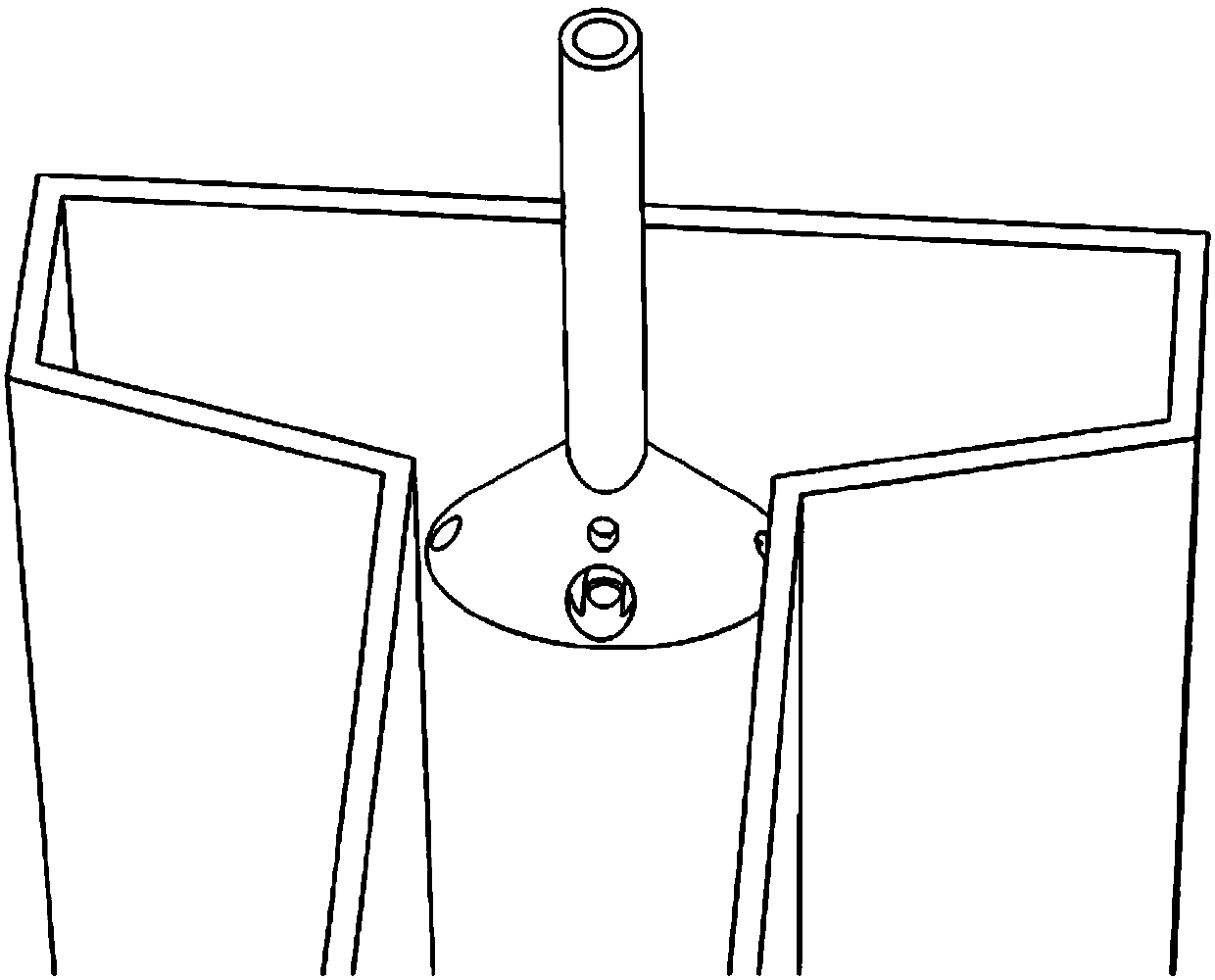

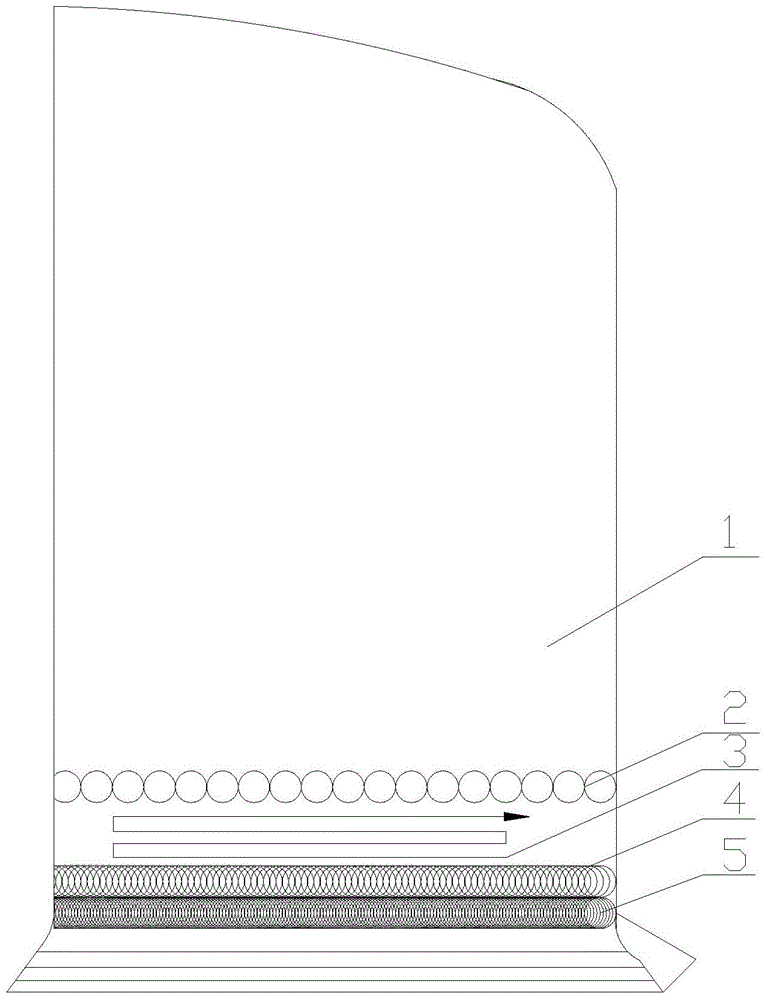

Umbrella-type submersed nozzle of crystallizer for continuous-cast round billets

ActiveCN103769570ADisadvantages affecting uniform solidificationReduce impact depthMelt-holding vesselsEngineeringMolten steel

The invention discloses an umbrella-type submersed nozzle of a crystallizer for continuous-cast round billets. The umbrella-type submersed nozzle comprises a nozzle side wall with an inner hole formed in the upper portion, a concave bottom plate with the lower portion closed, at least one side support hanging column for connecting the nozzle side wall and the concave bottom plate into a whole, and a lateral outlet arranged on the lower portion of the nozzle side wall. The lateral outlet is an annular outlet penetrating through the circumferential side wall of the whole nozzle, and the annular outlet inclines downward by an angle of alpha and is shaped like an umbrella. Molten steel can be injected in through the inner hole of the nozzle side wall and evenly flows out of the lateral outlet in the circumferential direction. Compared with the prior art, the umbrella-type submersed nozzle has the advantages that green billet shells will not be scoured or damaged, and thus the thickness of the billet shells is uniform in the circumferential direction; the flow field of the molten steel in the crystallizer is reasonable in distribution, an upper ring flow and a lower ring flow are formed in the upper flow field of the crystallizer, and thus casting powder can be molten easily; the impact depth of the molten steel is small, and thus gas and inclusions can float up easily. The superiority of the umbrella-type submersed nozzle can be better played for continuous cast of round billets with the diameter of the fracture surfaces of the cast billets larger than 400 mm.

Owner:YANSHAN UNIV

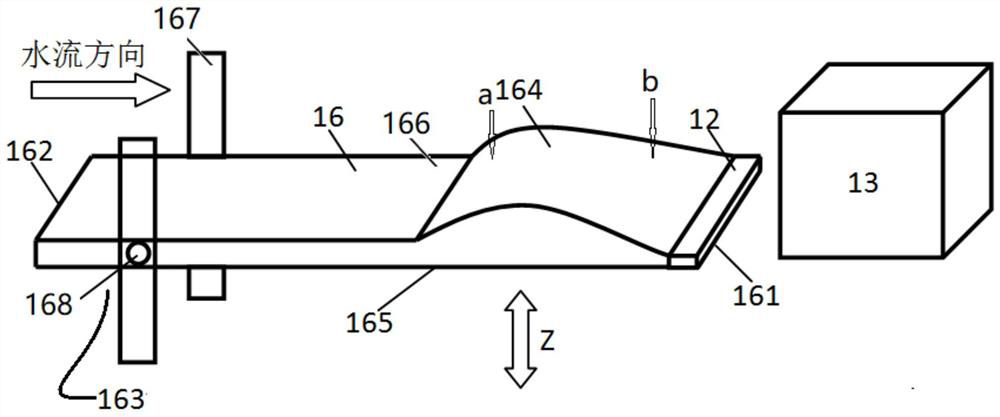

Water flow impact depth monitoring device of intelligent flood control early warning system

InactiveCN112857201AGuaranteed stabilityLow costElectric/magnetic depth measurementFluid speed measurementHydrometryEarly warning system

The invention relates to the technical field of hydrological monitoring, in particular to a water flow impact depth monitoring device of an intelligent flood control early warning system. The device comprises a controller, a switching mechanism, a rotating plate and a plurality of impact sensing units, the impact sensing units are buried in sediment in the direction perpendicular to the water surface, and each impact sensing unit comprises a magnetic device and a magnetic sensing element opposite to the magnetic device; and the signal output end of the impact sensing unit is electrically connected with the signal input end of the controller, each magnetic device is connected with the switching mechanism through a rotating plate, the magnetic devices are fixedly arranged at one ends of the rotating plate, the other end of the rotating plate is rotationally connected with the switching mechanism, an arc-shaped protruding part is arranged on the upper end face of the rotating plate, and the lower end face of the rotating plate is a plane. The impact sensing units which are buried in the sediment and are vertically and linearly arranged are adopted, the position of the sediment impacted by water flow is obtained in a magnetic field change detection mode, then the impact depth is obtained, and the device has the advantages of being low in cost, simple in structure and easy to arrange in a large number.

Owner:HUBEI PROVINCIAL WATER RESOURCES & HYDROPOWER PLANNING SURVEY & DESIGN INST

Nylon thin film composite material for lithium ion polymer battery outer membrane

InactiveCN103254633BImprove impact resistanceImprove cold resistanceCell component detailsElastomerEpoxy

The invention discloses a nylon film composite material for an outer film of a lithium-ion polymer battery, aiming at providing a nylon film composite material which is stable in thermal property, not easy to absorb moisture, puncture-resistant, high in dry-state and low-temperature impact strength, non-deformable in case of absorbing water, good in multi-layer coextrusion compounding compatibility, balanced in flow extension, and capable of realizing no breakage of a corner in case of an impact depth of 3-12 mm or more. The nylon film composite material disclosed by the invention is realized via the following technical scheme: 8-12 wt% of maleic anhydride (MAH), MAH-blended K resin and graft K-MAH grafted POE (polyolefin elastomer) blend material are contained in a nylon filling body; the nylon filling body takes maleic anhydride grafted polyethylene and ethylene propylene terpolymer rubber as interface compatibilizers; a maleic anhydride grafted elastomer carboxylic acid group is reacted with a polyamide end group or a polyamine group in a main chain to form a grafted copolymer; and epoxy resin siloxane hydrolysate is reacted with an amide group molecular-chain amino group to polymerize the composite material with a multi-element interwoven network. According to the composite material disclosed by the invention, the problem of the phenomenon that PA (polyamide) film heat seal is easy to fold, layer and break at a certain corner is solved.

Owner:刘继福

Rat model with growth hormone deficiency after cerebral trauma

InactiveCN103622760AConducive to large-scale deploymentSurgical veterinaryEndocraniumIdiopathic growth hormone deficiency

The invention relates to a rat model with growth hormone deficiency after cerebral trauma. The model is manufactured by virtue of the following steps: fixing and narcotizing a rat; shaving off hair in the top of a rat head; sterilizing the operation area; making a 3cm long cut along the median line of the head, fixing bilateral scalps, peeling periosteums, exposing bilateral frontal lobes, and performing a bilateral frontal lobes craniotomy by using a drill. Craniotomy is performed between the bregmatic fontanel and the lambdoidal suture and 3cm from the central line, endocranium cannot be injured, the diameter of a bone flap can be 5mm more than the diameter of the head part of an impactor; a controlled cortical impact operation is performed by utilizing a CCI (chronic constriction injury) impactor, wherein impact parameters include the impact speed of 3.5m / s, the impact depth of 1.5mm, and the stay time of 400m sec. The bone flaps are not returned, and the head cut is sutured after the operation.

Owner:首都医科大学康复医学院

Method for harnessing chemical production thiamine crystallization tank region local geological foundation pollution

Owner:上海宝冶工程技术有限公司

Electro-magnetic braking device for controlling molten metal flow in continuous cast crystallizer

The invention relates to an electromagnetic brake device for controlling the flow of metal liquid in a continuous casting crystallizer. The device is composed of a magnetic core which semi-surrounds the side wall of the crystallizer, an excitation coil and magnetic poles, the magnetic pole is arranged in a narrow-surface area which is inclined to the crystallizer, the magnetic pole simultaneouslycovers the surface area of the metal liquid which is in the vicinity of the narrow surface of the crystallizer and the area of an impact point of the outflow of a nozzle on the height, a static magnetic field is generated between two pairs of the magnetic poles by imposing the current on the excitation coil, the surface flow of the metal liquid which is in the vicinity of the narrow surface of the crystallizer and the flow of the area of the impact point of the outflow of the nozzle of the metal liquid in the crystallizer are simultaneously controller by the static magnetic field. The electromagnetic brake device has the advantages that: the electromagnetic brake device can simultaneously effectively inhibit the surface slag entrapment of the metal liquid which is in the vicinity of the narrow surface of the crystallizer and the impact depth of the metal liquid of the outflow of the nozzle, promote the upward floating and removal of inclusions, bubbles and other heterophase substancesof the front edge of a metal coagulation shell and weaken the influence degree of the immersion depth of the nozzle and the angle of the outflow of the nozzle on the electromagnetic brake effect during the changes; furthermore, the electromagnetic brake device has simple form and small structural size, the volume and weight ratios are greatly reduced compared with the volume and weight ratios of the electromagnetic brake device of the full-frame one-section and the full-frame two-section, thus saving energy and reducing consumption.

Owner:NORTHEASTERN UNIV LIAONING

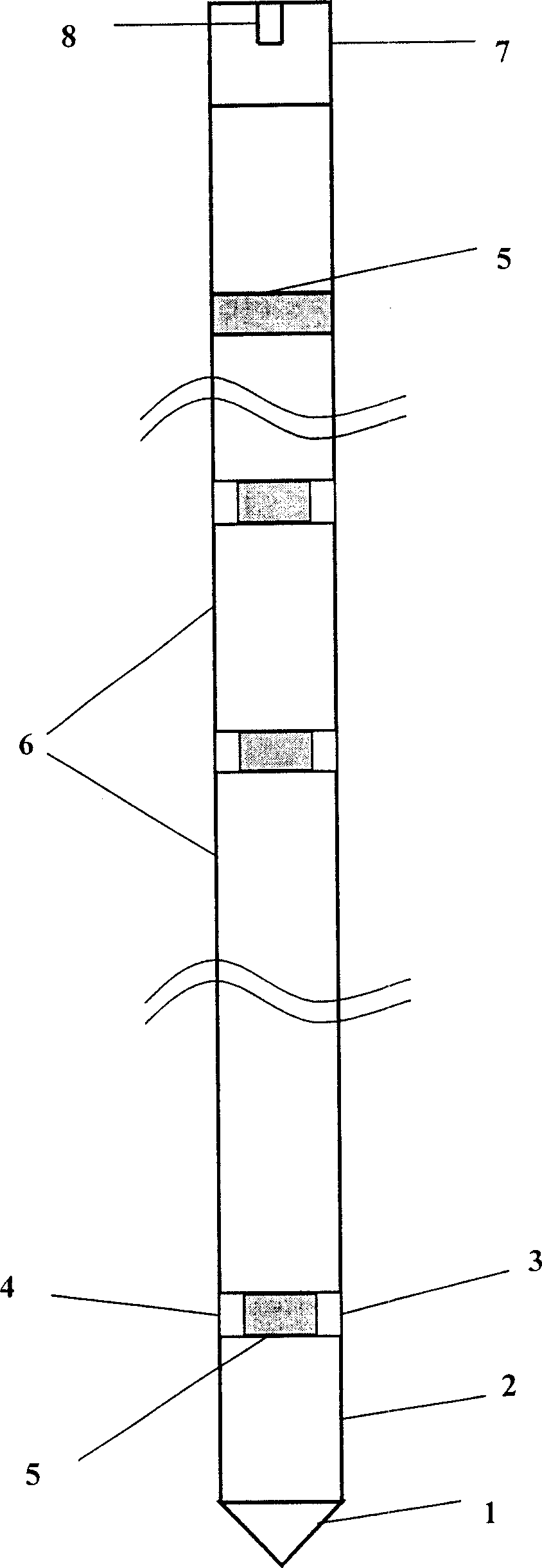

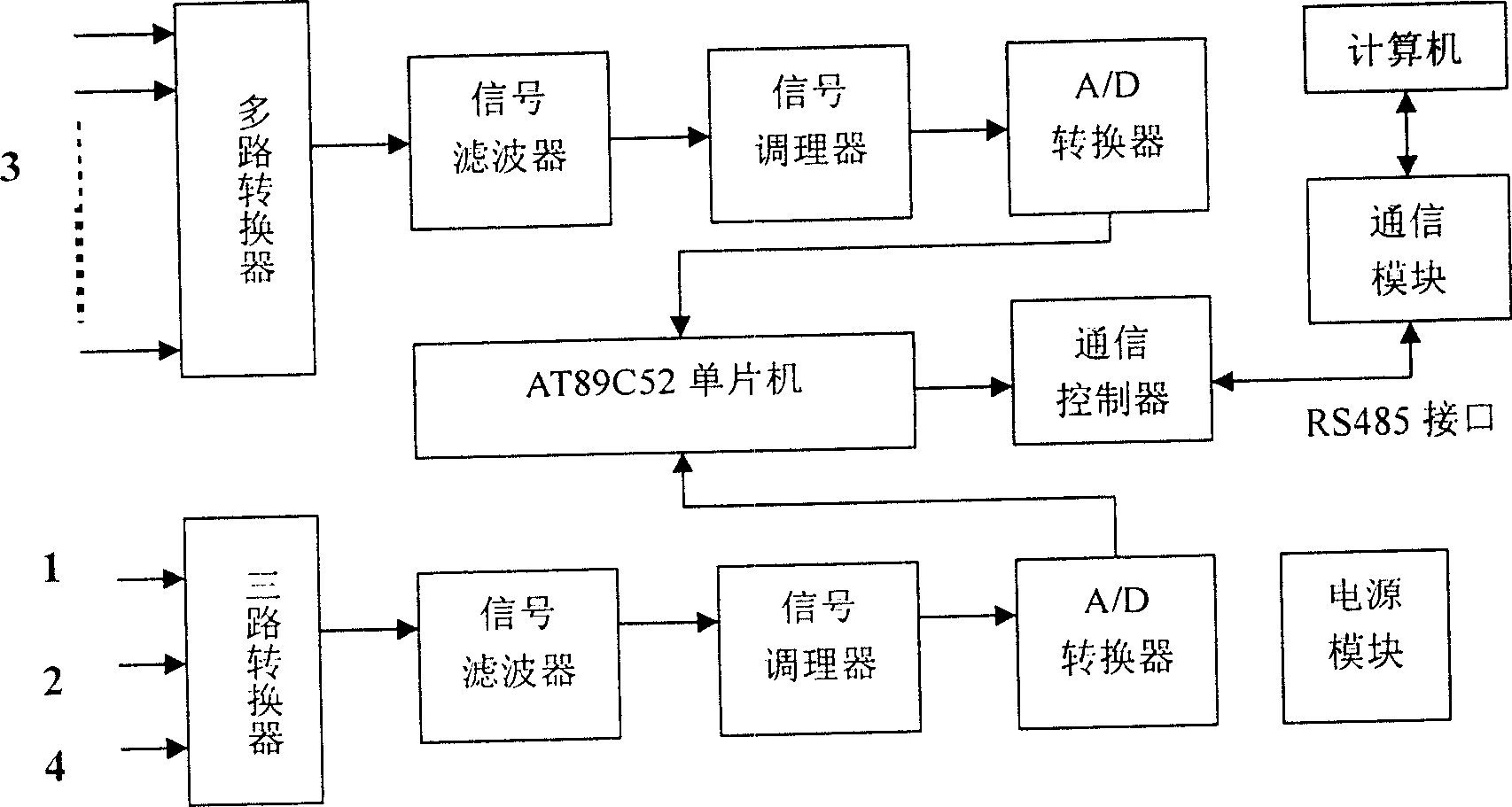

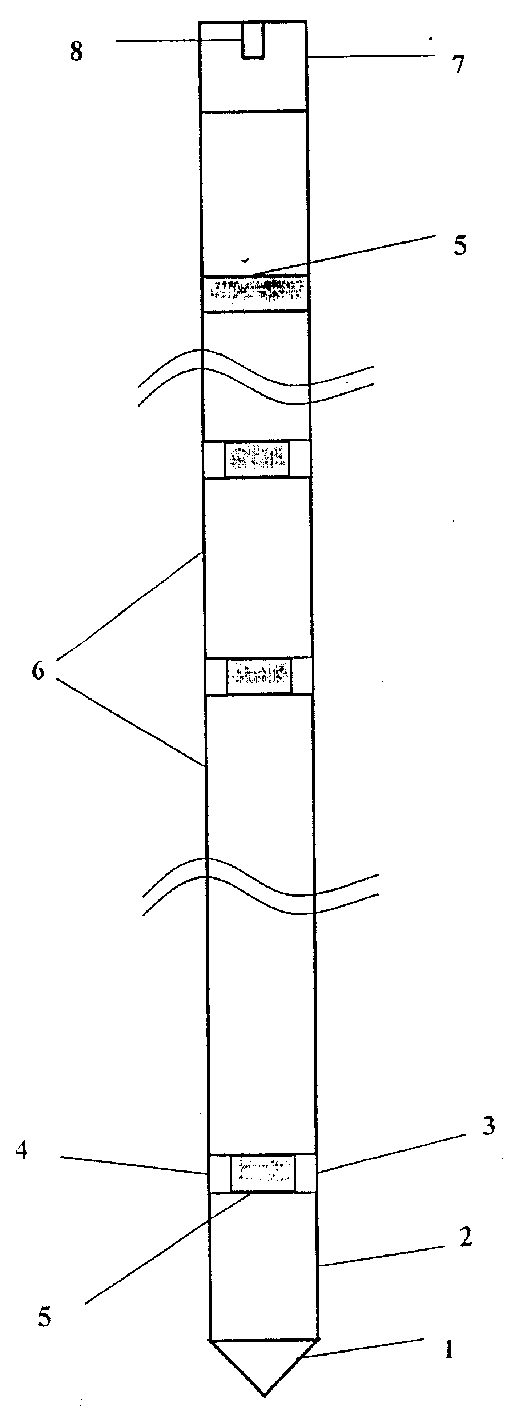

Detector for soil-body in-situ hole pressure and affecting depth under wave action

Under the action of waves, the in-situ pore pressure and impact depth monitoring device of the soil has a measuring rod composed of a sleeve, a cone tip resistance sensor at the front end, a side friction resistance sensor and a pore water pressure sensor behind its position, and a corresponding data acquisition device. The utility model is characterized in that it includes a plurality of pore water pressure sensors arranged on the joint and arranged on the long measuring rod by connecting sleeves at both ends with the joint, and a resistivity sensor is also installed on the joint. The invention thus constructed can not only monitor the variation of pore pressure in soil at different depths under the action of waves, but also monitor the impact depth of waves of different sizes, so as to analyze the stability of the soil. At the same time, the resistivity sensor is used to test the resistivity of soil at different depths, so as to analyze the corrosion degree of soil to submarine pipelines and other engineering facilities, and provide a scientific basis for the determination of its embedding depth.

Owner:OCEAN UNIV OF CHINA +1

An adjustable tamping machine

Owner:邳州市滨河中小企业管理服务有限公司

Converter steelmaking phosphorus reservation smelting method

ActiveCN103131817BIncrease residual manganese contentReduce consumptionManufacturing convertersSteelmakingResidual carbon

The invention relates to a phosphorus-preserving smelting method for converter steelmaking, which belongs to the technical field of metallurgy. In this method, the smelting time is divided into three phases: the first, the middle, and the last. By adjusting the amount of lime added, the binary basicity R of the slag is always controlled between 2.0 and 2.8; The mass percentages of the oxygen blowing volume and the total oxygen blowing volume in the first, middle and last phases are controlled at 18-22%, 55-65%, and 18-22% respectively, and the impact depth of the oxygen jet in the early and middle phases is controlled at 100% of the depth of molten steel. 60-70%, and the impact depth of the oxygen jet in the later stage is controlled at 70-80% of the molten steel depth; the residual carbon content of the final molten steel is controlled at 0.05-0.1%. After adopting the present invention, since the peaks of dephosphorization before and after smelting are reasonably balanced and controlled, the retention rate of phosphorus in molten iron can reach 30% to 70% without adding phosphorus-containing ore, thereby realizing the required Phosphorus smelting.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com