Connectable spiral plate deep dynamic compaction device and construction method thereof

A connection type, spiral plate technology, applied in basic structure engineering, soil protection, construction and other directions, can solve the problems of poor treatment effect, construction vibration and noise, and achieve easy secondary ramming, improve quality, material High utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Below in conjunction with accompanying drawing, patent of the present invention is described further.

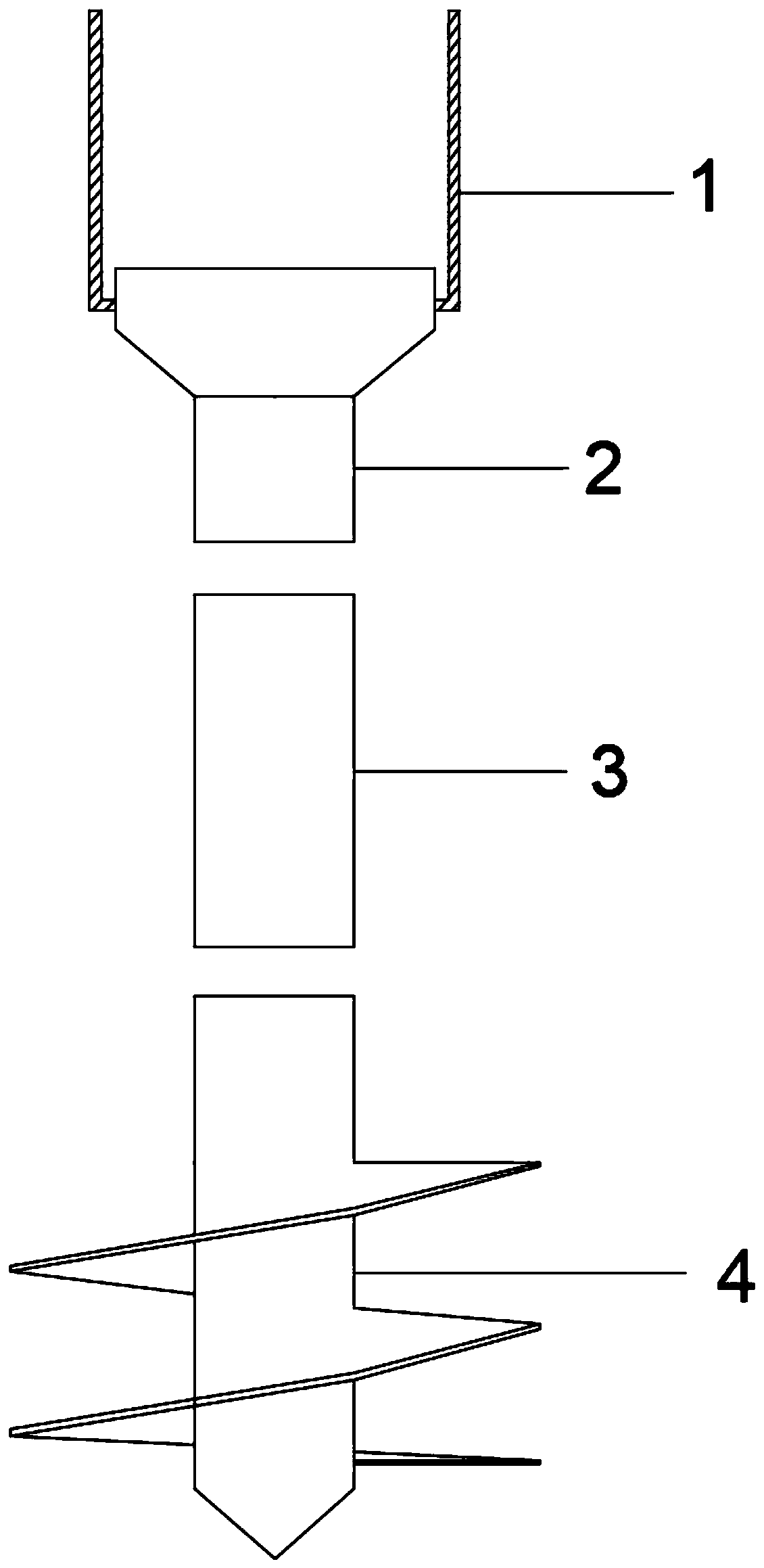

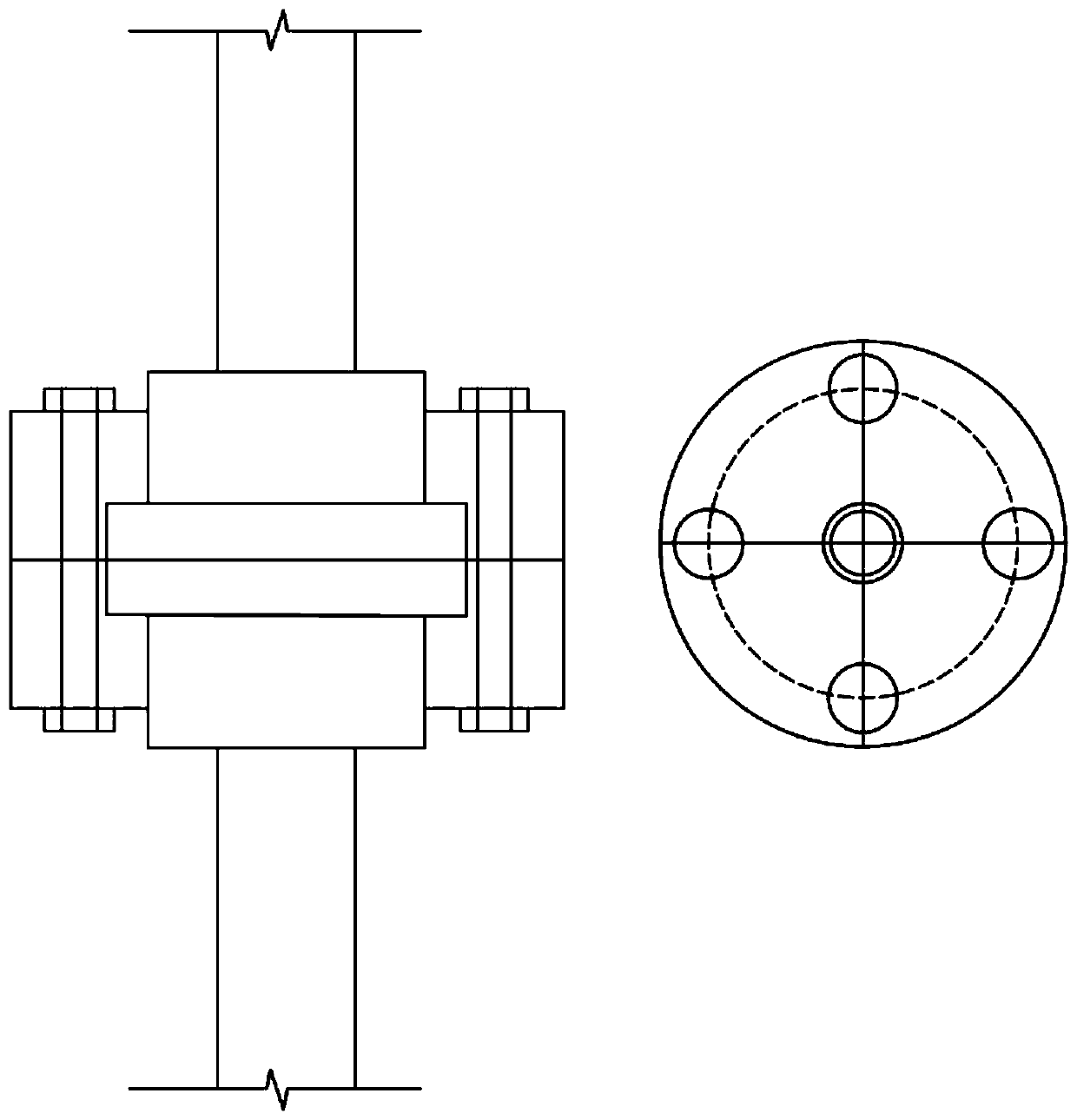

[0026] Such as figure 1 As shown, a connectable spiral plate deep layer dynamic compaction device includes a soundproof steel drum (1), a conical pile cap (2), a connectable pile body (3) and a spiral plate drill bit (4). Wherein the round platform pile cap (2) is connected to the upper end of the connectable pile body (3) through a flange, and the spiral plate drill bit 4 is connected with the lower end of the connectable pile body through a flange, as figure 2 shown. There is a sound-insulating steel drum (1) on the round table-shaped pile cap (2), the diameter of the sound-proof steel drum (1) is slightly larger than the diameter of the drop hammer, and the inner wall of the sound-proof steel drum (1) is provided with thin-walled foam, which can effectively reduce noise; The thickness of the upper edge of the pile cap 2 is 1 / 2 of the total thickness of the circu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com