Umbrella-type submersed nozzle of crystallizer for continuous-cast round billets

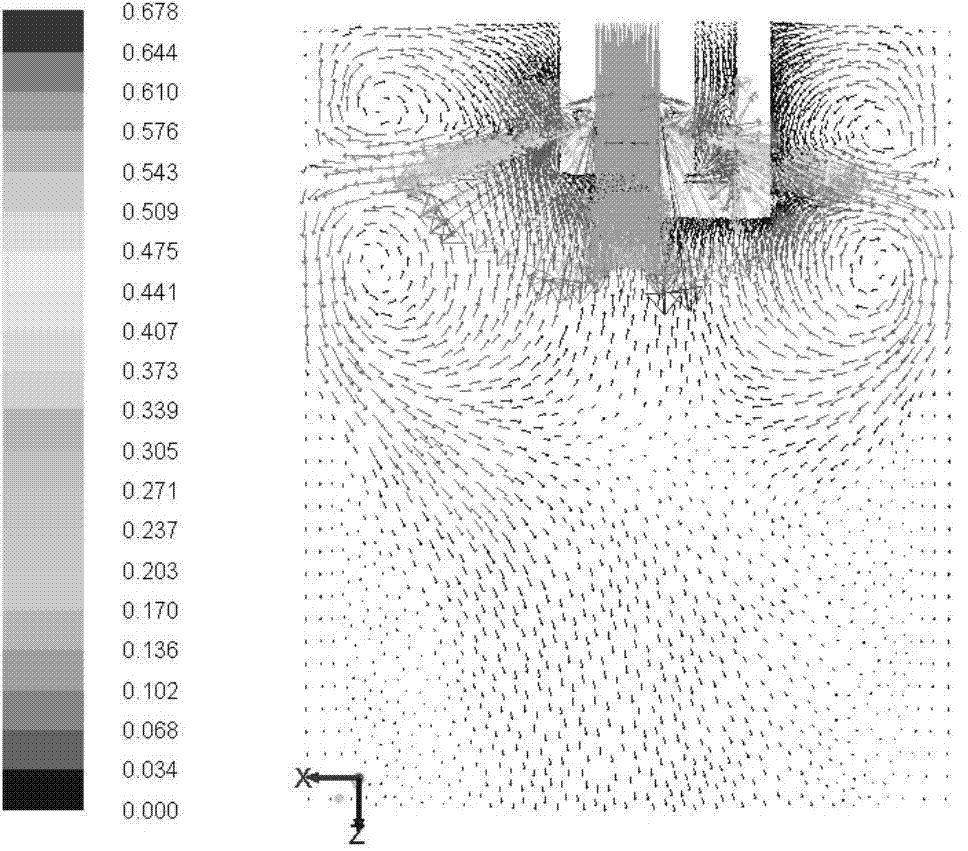

A continuous casting round billet and crystallizer technology, applied in the direction of casting melt container, casting equipment, metal processing equipment, etc., can solve the problems of uneven distribution of flow field and temperature field, increase of scour range, etc., and achieve reasonable distribution of steel flow , improve the quality, reduce the effect of impact depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only partial embodiments of the present invention.

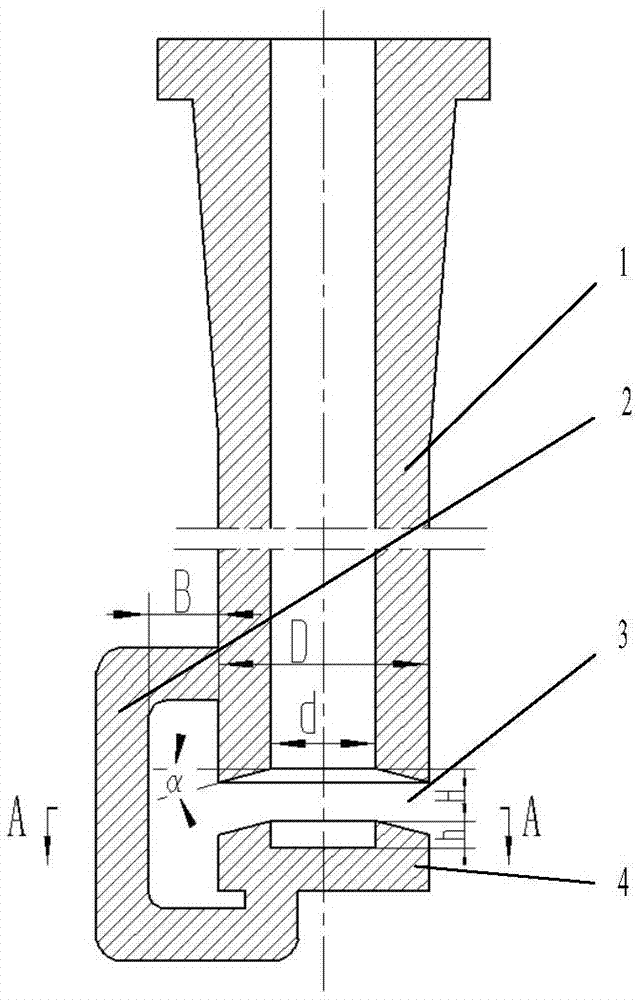

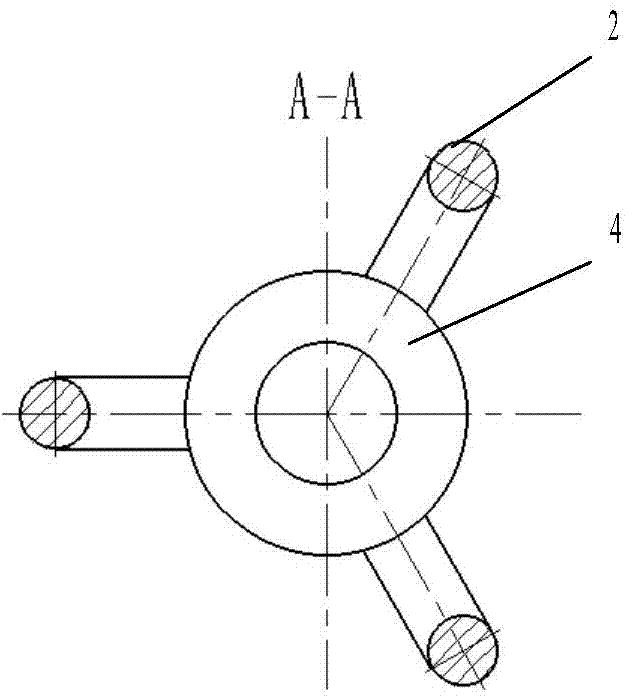

[0027] see figure 1 , the umbrella-shaped submerged nozzle of the continuous casting round billet crystallizer provided by the present invention is composed of the nozzle side wall 1, the side support hanging column 2, the side outlet 3 and the bottom concave plate 4. These four parts are generally made of aluminum carbon or quartz. Refractory materials are formed by isopressing. For continuous casting of round slabs with a section diameter of 600 mm, the parameter dimensions of each part of the nozzle of the present invention are: the inner diameter d of the side wall 1 of the nozzle is Φ60 mm, the outer diameter D is Φ120 mm; the height H of the lateral outlet 3 is 30 mm, The downward inclination angle α of the lateral outlet 3 is 15°; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com