Immersion type rotational-flow water port for steelmaking continuous casting

A continuous casting and immersion technology for steelmaking, applied in casting equipment, casting molten material containers, metal processing equipment, etc., can solve problems such as difficult removal of inclusions, deep jet impact of straight nozzle, and decline in casting slab quality, and achieve Promote the floating of inclusions, reduce the impact depth, and reduce the effect of quality loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

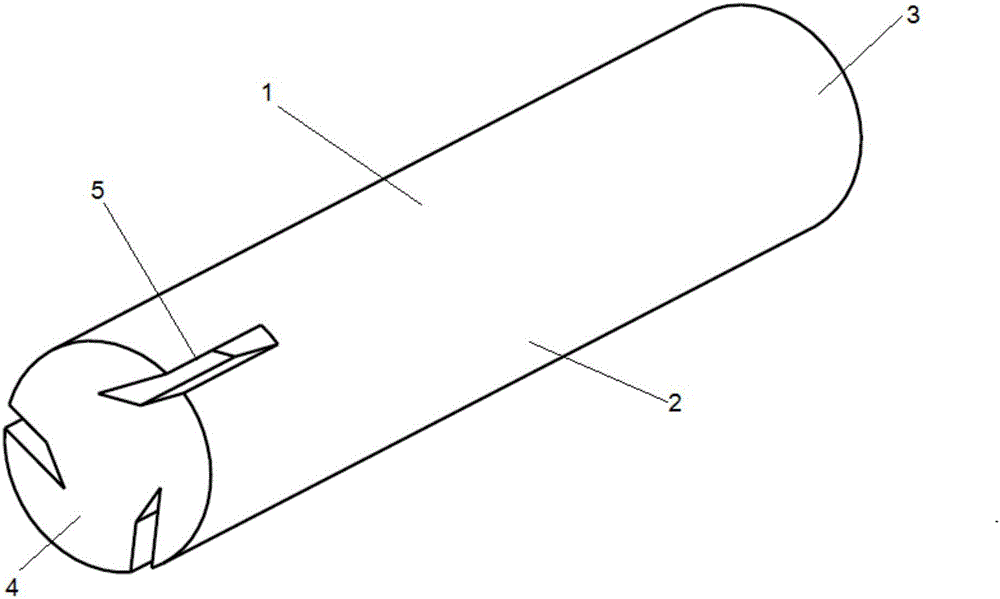

[0018] see figure 1 , a submerged swirl nozzle for steelmaking and continuous casting, which has:

[0019] The nozzle body, the nozzle body is cylindrical in shape, and the nozzle body is provided with a cylindrical inner cavity;

[0020] The open end of the cylindrical inner cavity of the nozzle body is the inlet of the nozzle, and the closed end of the cylindrical inner cavity of the nozzle body is the bottom of the nozzle;

[0021] The bottom of the nozzle is also provided with a nozzle outlet, the nozzle outlet is arranged on the nozzle wall of the nozzle body, and the lower end of the nozzle outlet runs through the bottom of the nozzle; the inner side of the nozzle outlet communicates with the inside of the nozzle and deviates fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com