Patents

Literature

42results about How to "Good for going straight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

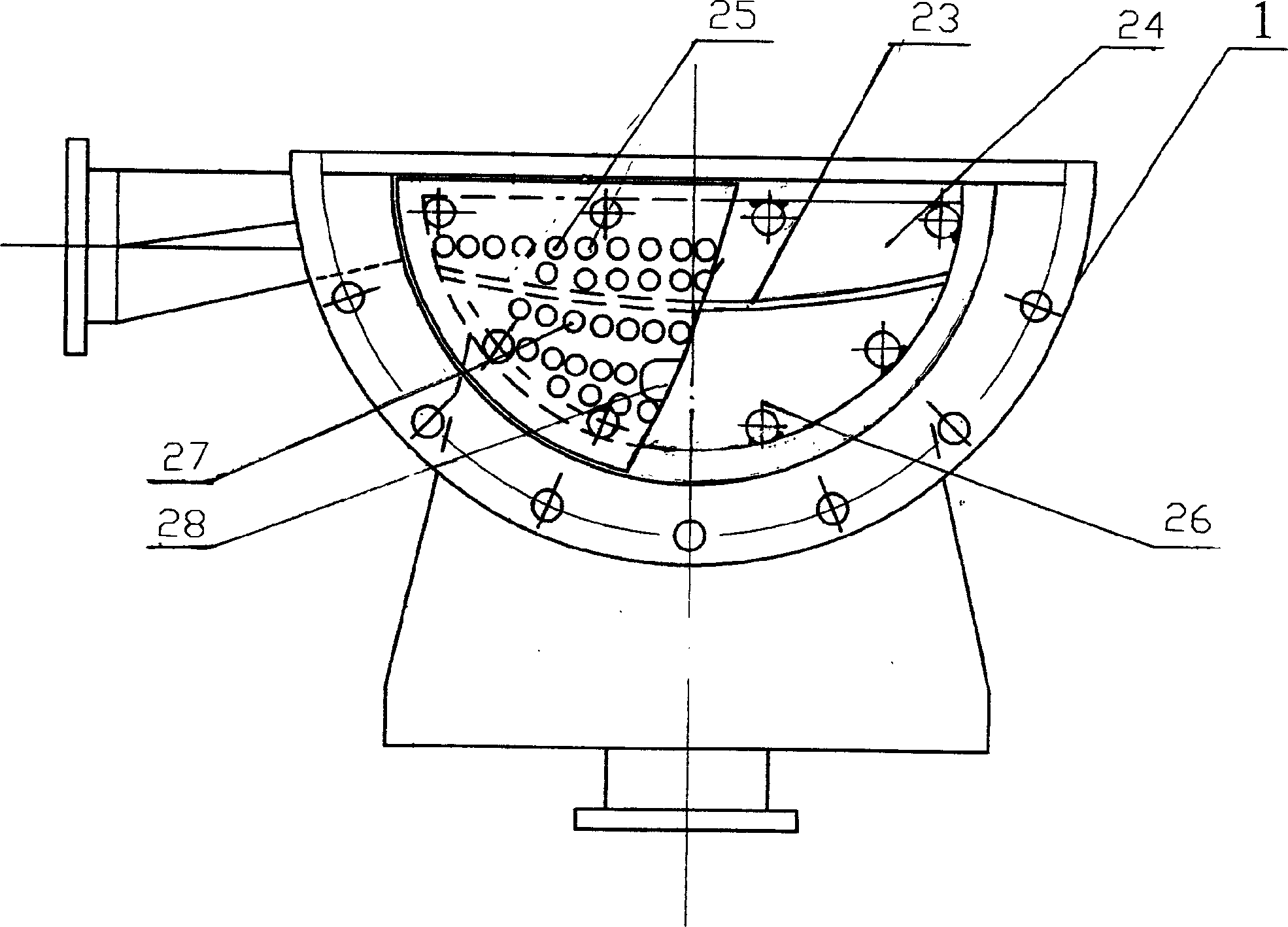

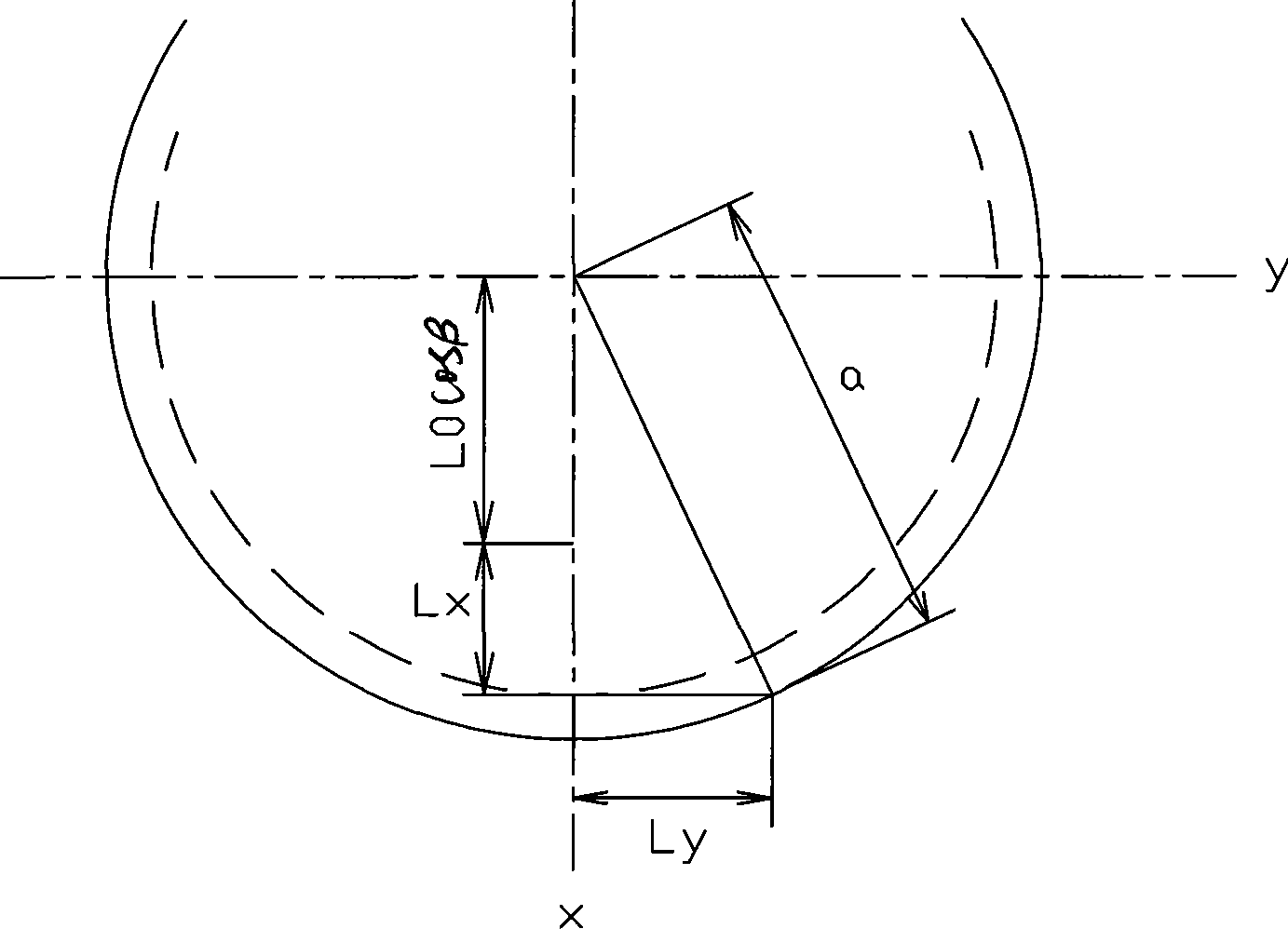

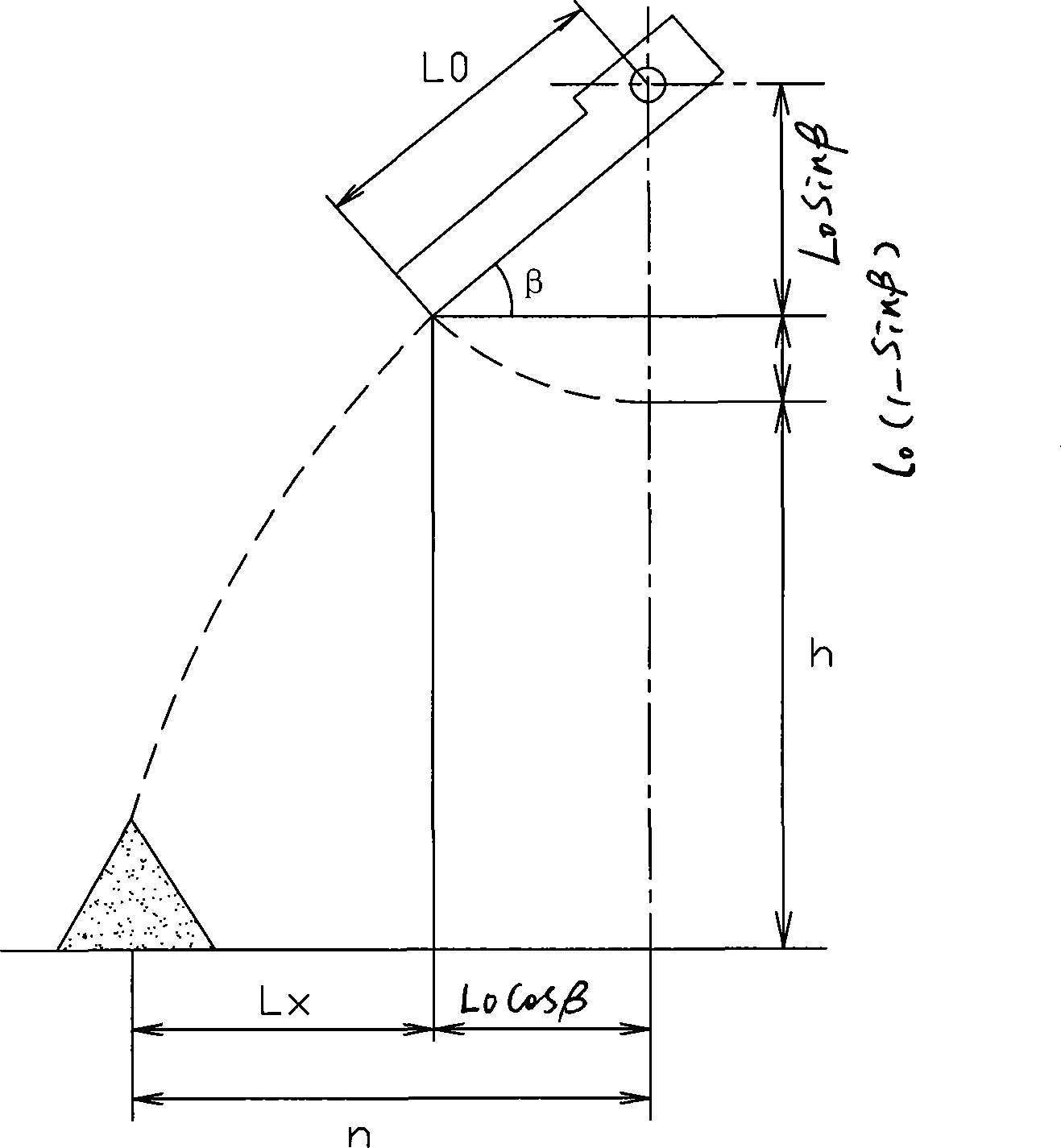

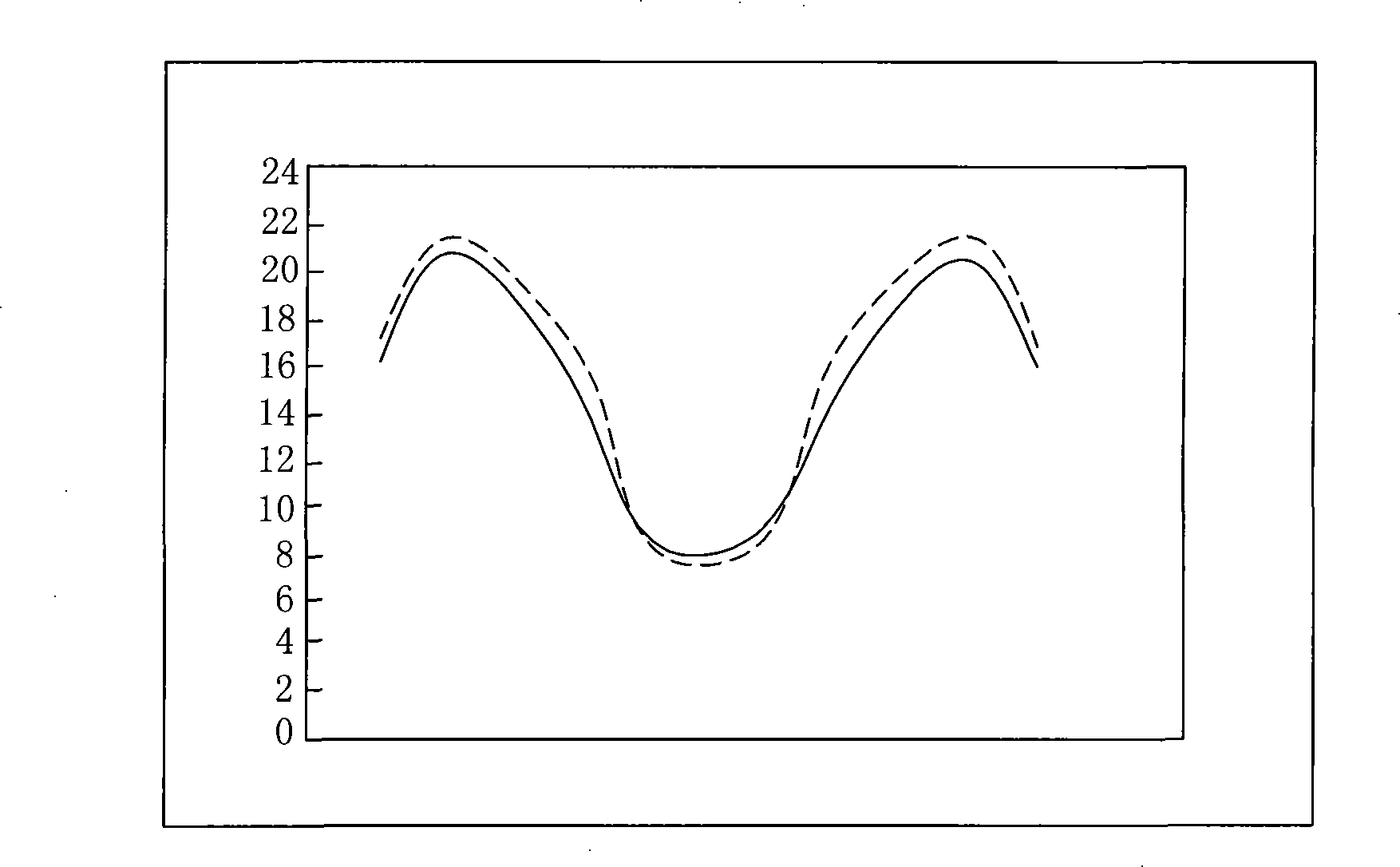

Blast furnace chute polycyclic distributing method

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

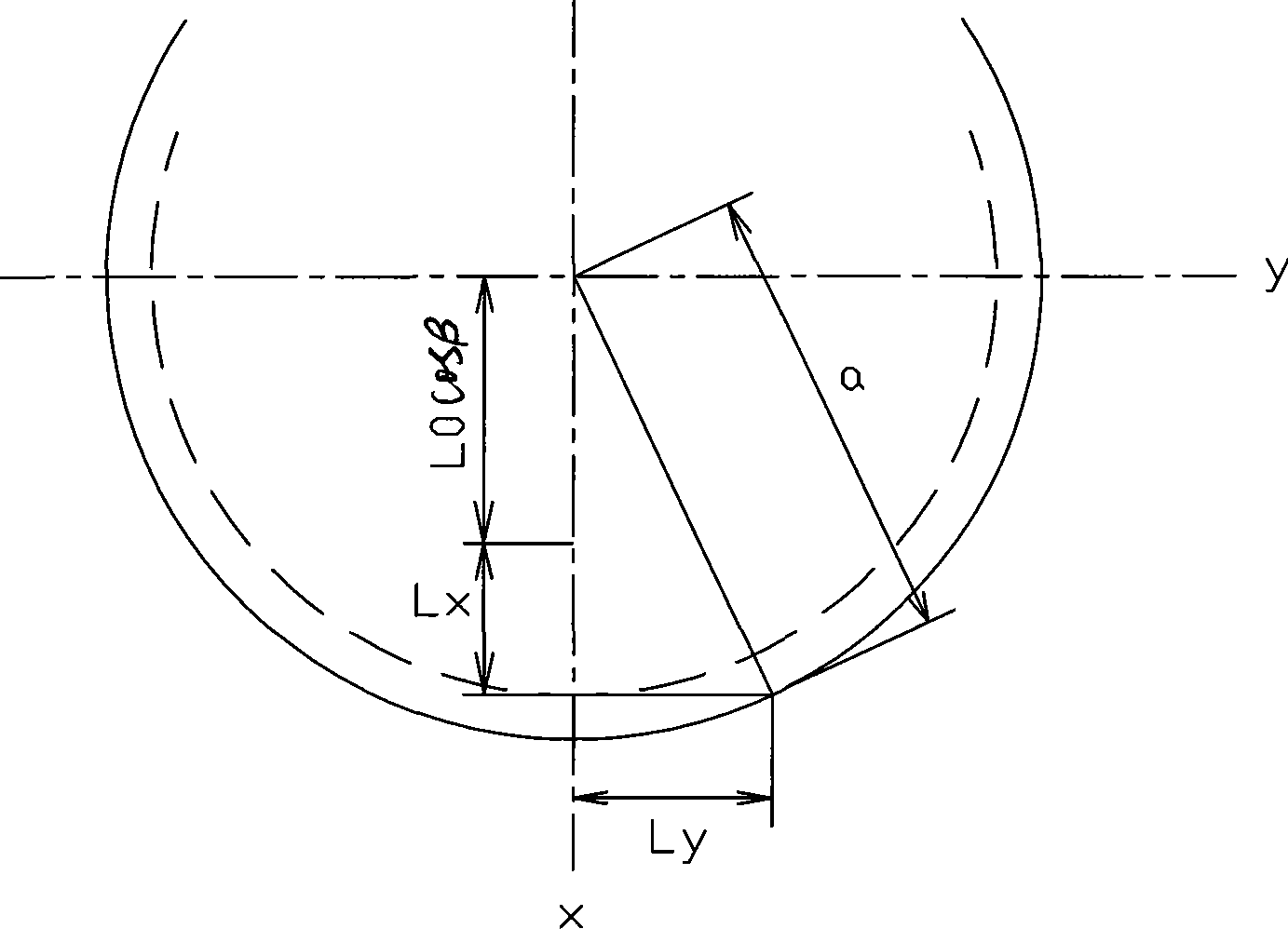

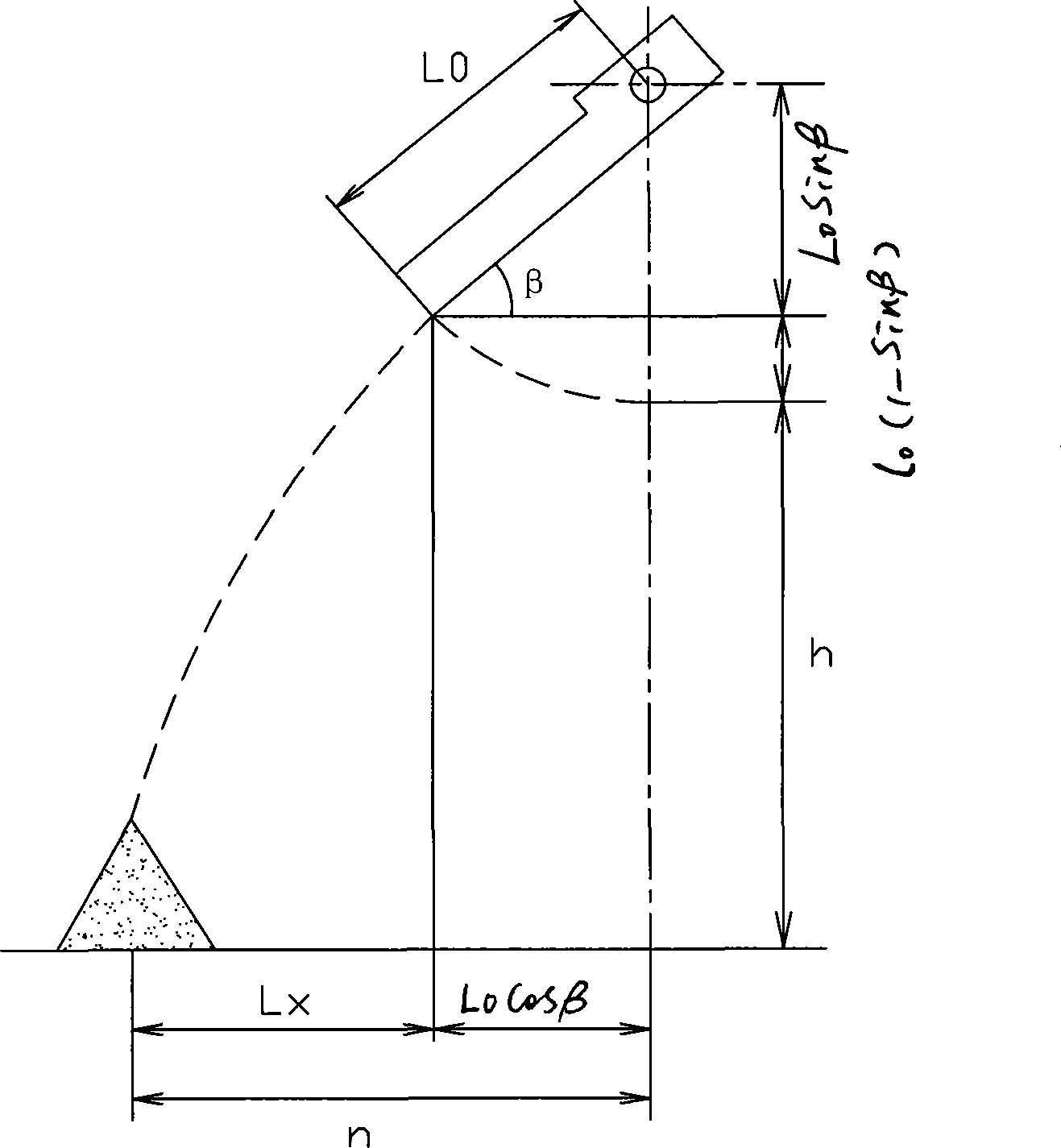

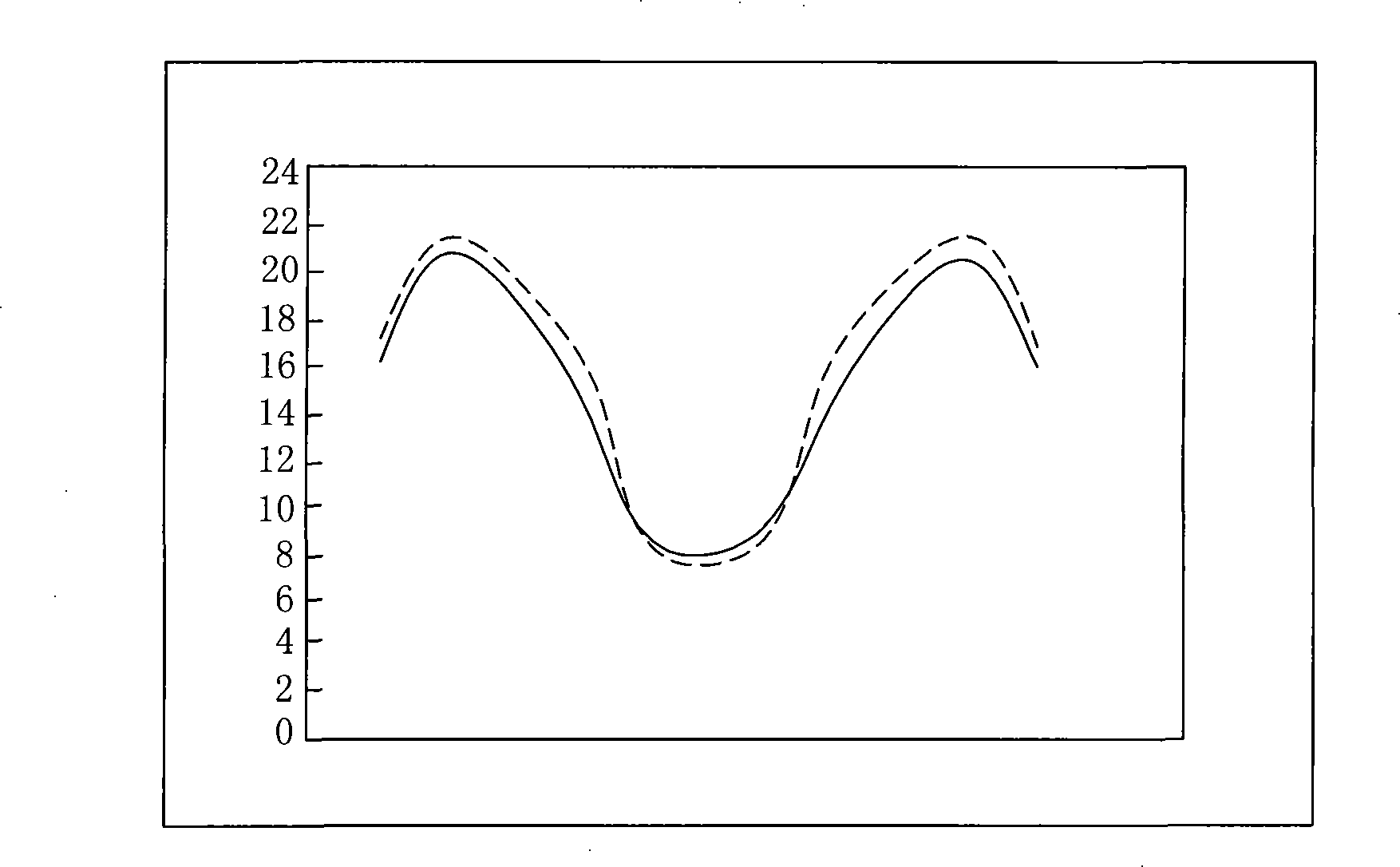

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

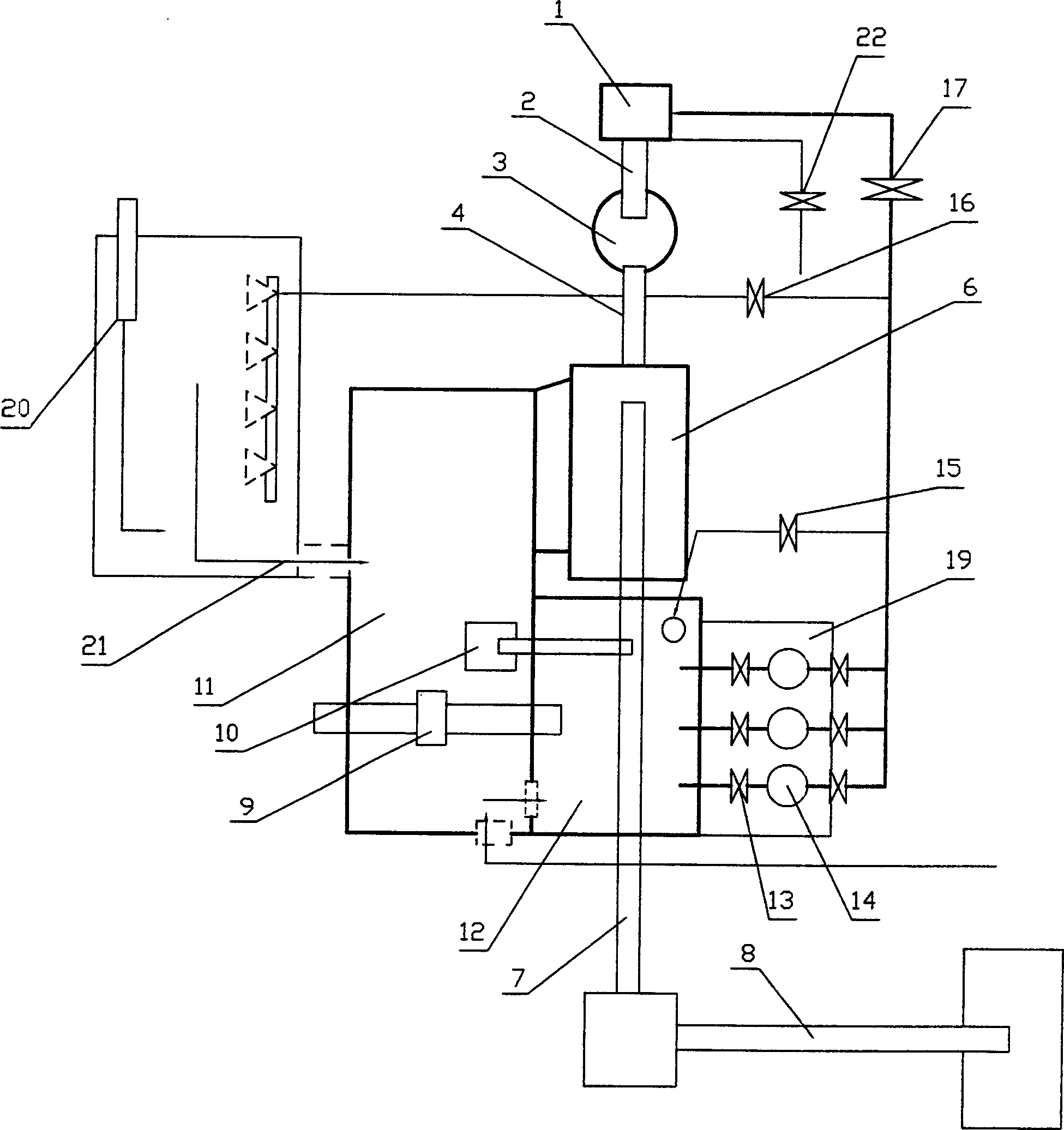

Blast furnace cinder water quenching processing unit

ActiveCN1769498ASimple configurationReasonable configurationRecycling and recovery technologiesCooling towerQuenching

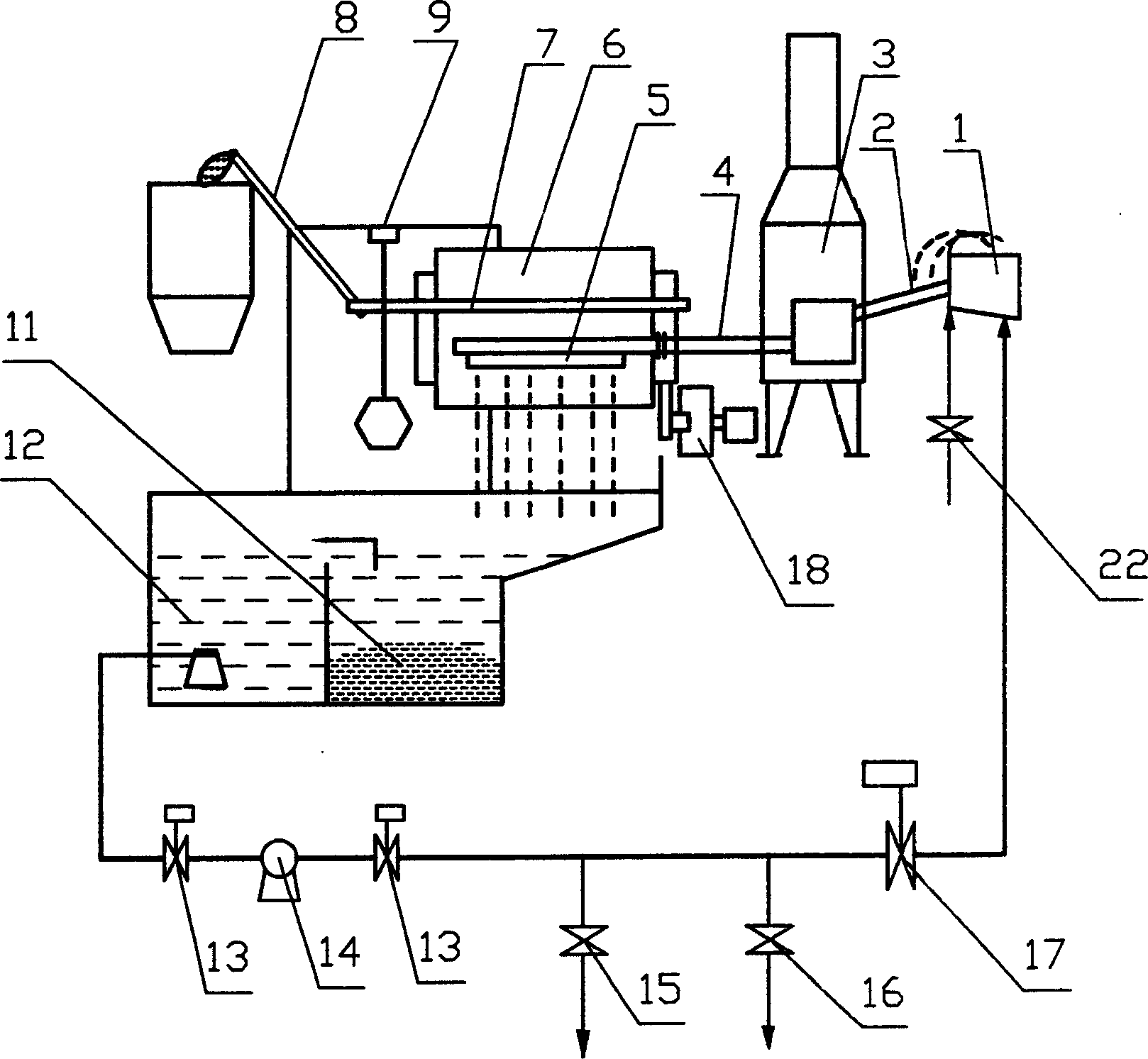

This invention belongs to the molten slag treatment, especially relates to the blast furnace molten slag treating apparatus. The slag ditch connects with the granulating device and slag flume, the down part of the slag flume connects with the communicating pipe, the distributing trough that connects with the communicating pipe extends into the rotating drum filter, the belt device in the canister connects with the rotating belt device to form a finished articles warehouse; the down part of the rotating filter is arranged with the storage cabinet, laying-up basin, which are connected by the overflow on the pool wall, the dregs cleaning device is arranged on the storage cabinet the laying-up basin connects with the granulating device by the tube connector, valve and dregs cleaning pump. The device fault rate is low, the dregs punching out rate reaches up to more than 99úÑ, which is propitious to the operation and steady production of the blast furnace. And the dreg cleaning water and the sewage is used in closed cycle, so it can save a lot of pure water.

Owner:MAANSHAN IRON & STEEL CO LTD

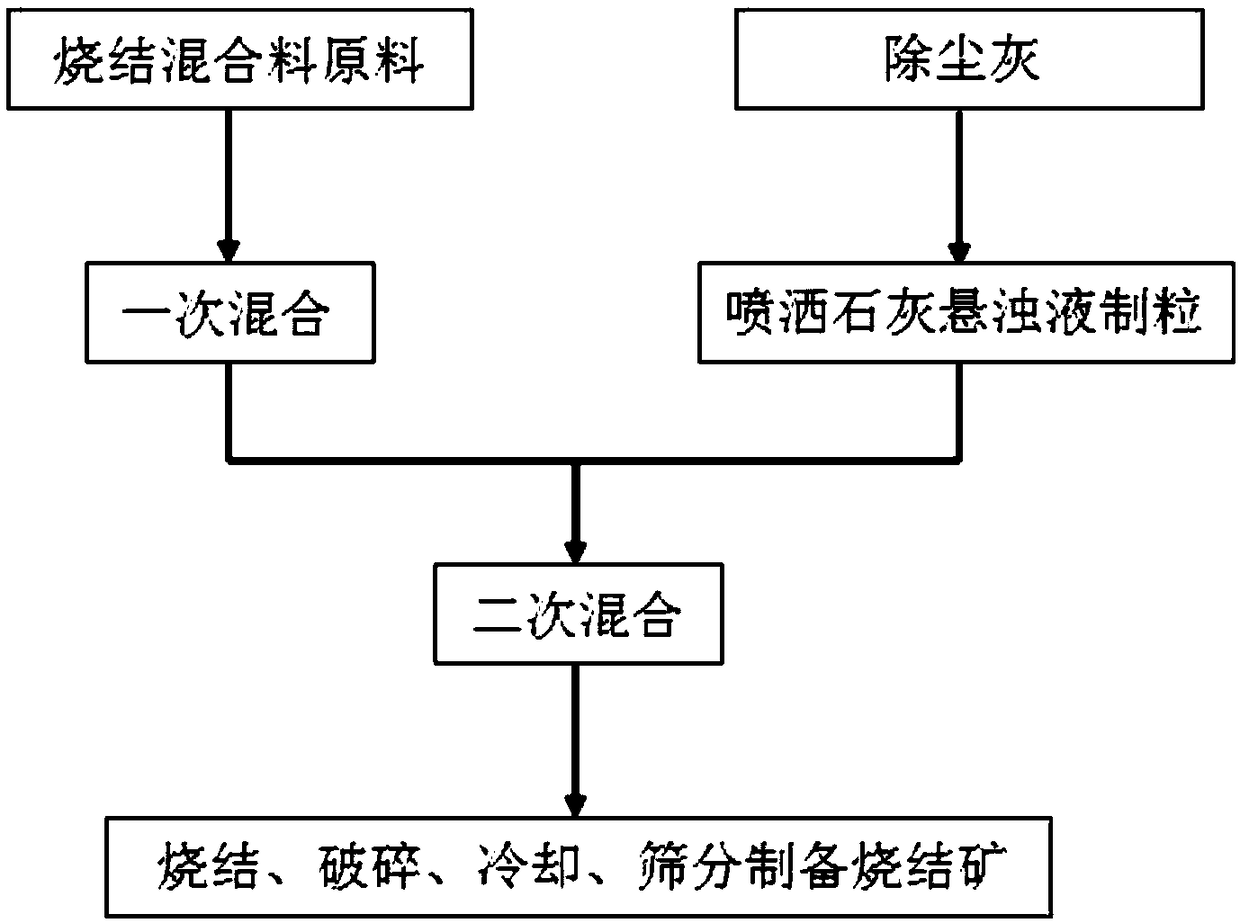

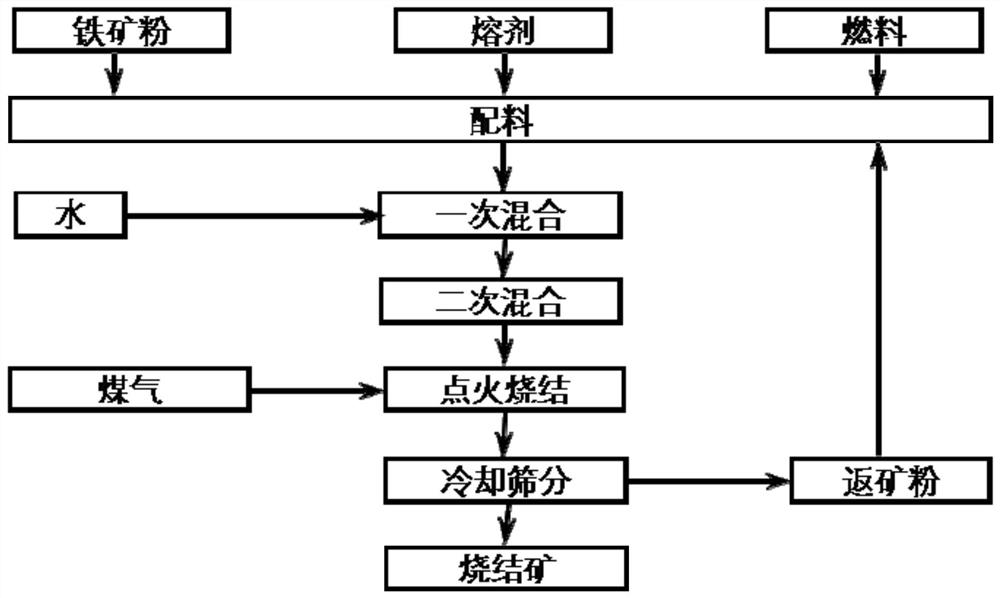

Method for treating iron-bearing dust using sintering process

The invention discloses a method for treating iron-bearing dust using a sintering process. The method includes the steps that lime suspension liquid is sprayed in dedusting ash, granulating is carriedout to obtain dedusting ash particles; the dedusting ash particles are added into a sintered mixture, and a sintered mixing material is obtained by mixing and granulating; and the sintered mixing material is distributed, sintered, broken, cooled and screened to prepare a sinter. According to the method for treating the iron-bearing dust using the sintering process, by spraying slaked lime suspension liquid on the surface of the dedusting ash with fine particle size and poor granulability, and the dedusting ash is agglomerated into dedusting ash small particles using viscosity and wettabilityof the slaked lime suspension liquid; the dedusting ash particles are added into the sintered mixture, after mixing and granulating, dedusting ash particles coated with iron ore powder on the externalare formed, separate combustion and mineralization are carried out in the sintering process, and influence of the dedusting ash particles on the composition of a sintered liquid phase is avoided; during the cooling process, the internal cooling speed of the particles is low, the bonding phase strength is improved advantageously, thus the sinter strength and average particle size are improved, low-temperature reduction pulverization of the sinter is obviously inhibited, and the quality of the sinter is obviously improved.

Owner:BEIJING SHOUGANG CO LTD

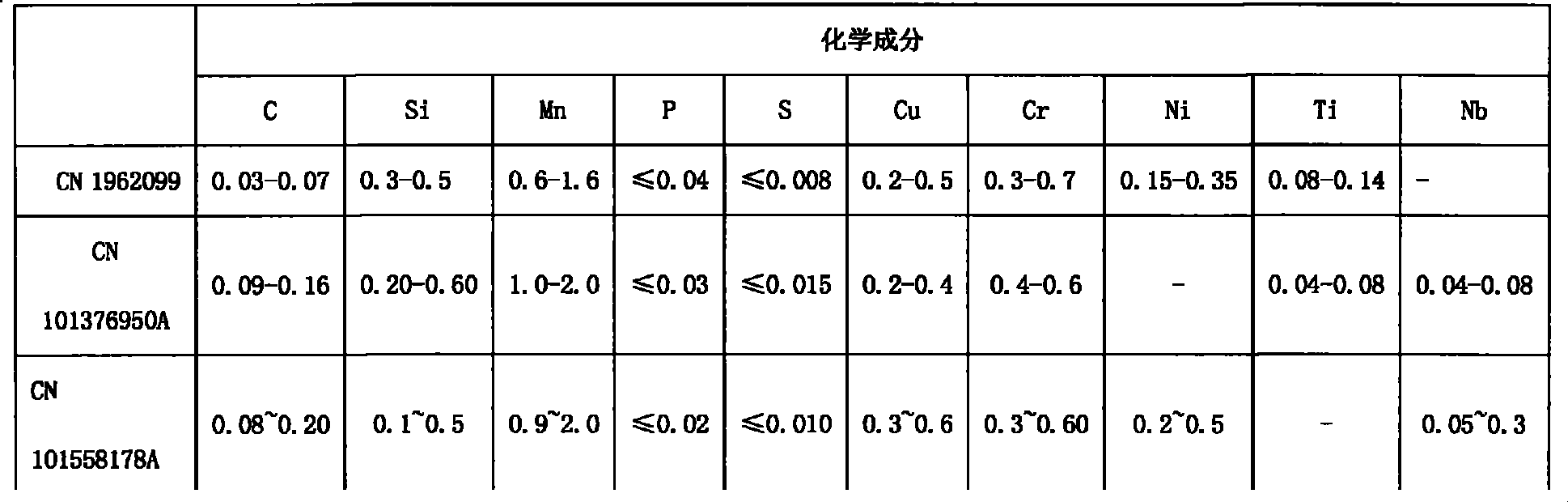

700MPa-grade cold rolled steel plate with high weather resistance and preparation method thereof

InactiveCN102011060AHigh standardAbundant resourcesTemperature control deviceBell type furnacesWeather resistanceChemical composition

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Catalytic combustion improver for blast furnace coal injection and application method thereof

ActiveCN103013616APromote combustionImprove the reducing atmosphereSolid fuelsBlast furnace detailsChemical reactionDolomite

The invention discloses a catalytic combustion improver for blast furnace coal injection and an application method thereof. The catalytic combustion improver is prepared from the following raw materials in percentage by mass through milling and mixing: 1-5% of ferrocene or potassium permanganate, rare metal catalysts including 1-2% of lanthanum oxide and cerium oxide, 30-35% of calcium peroxide, 15-20% of magnesium peroxide, 15-20% of active manganese dioxide and 1-3% of copper sulfate, and a carrier including 15-20% of calcium carbonate or dolomite, wherein the particle size of the product is 0.076 mm, and the content is greater than or equal to 95%. The catalytic combustion improver for blast furnace coal injection, disclosed by the invention, is used in a pulverized coal mass rate of 0.4-0.45%, the particle size of pulverized coal is required to be 0.076 mm, and the content of pulverized coal is required to be greater than or equal to 50%. According to the invention, through prompting the early release of coal chemical energy, the combustion efficiency of pulverized coal is increased, and the purposes of saving energy and reducing consumption are achieved. After a catalytic combustion improver product disclosed by the invention is added into pulverized coal, through a chemical reaction, C-C bonds in the pulverized coal are forcedly fractured, therefore, the ignition temperature of the pulverized coal is reduced, and the pulverized coal is completely combusted in a short time.

Owner:MAANSHAN JIUPENG JIATENG MACHINERY IND

Grouting method of blast furnace taphole duct

InactiveCN103757166AGuaranteed smoothnessGood for going straightBlast furnace componentsBlast furnace detailsSlagRefractory

The invention provides a grouting method of a blast furnace taphole duct. The method comprises the following steps: firstly, drilling a hole which is 2.8-3.2m deep in the taphole by using a tapping machine; blocking a seal gun head on a taphole clay sleeve by using a clay gun; connecting a grouting pipe of a mudjacking machine on a grouting interface at the side of the seal gun head, and then pressing an amorphous refractory material into a taphole duct by using the mudjacking machine, controlling the pressure of the mudjacking machine at 2-2.2MPa, controlling the flow rate of the amorphous refractory material at 1-5m<3> / h; continuing to keep the pressure of the mudjacking machine for 2-5 minutes after grouting until the amorphous refractory material is rapidly dried and condensed. By adopting the grouting method, air mixing of the taphole can be reduced, splashing of the taphole is prevented, the discharge smoothness of the slag is ensured, production of a blast furnace is facilitated, the probability of an accident is effectively reduced, and the flushing and casting stability of the blast furnace is improved.

Owner:ANGANG STEEL CO LTD

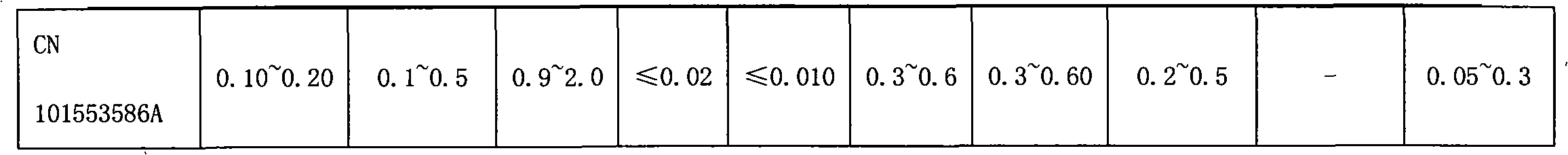

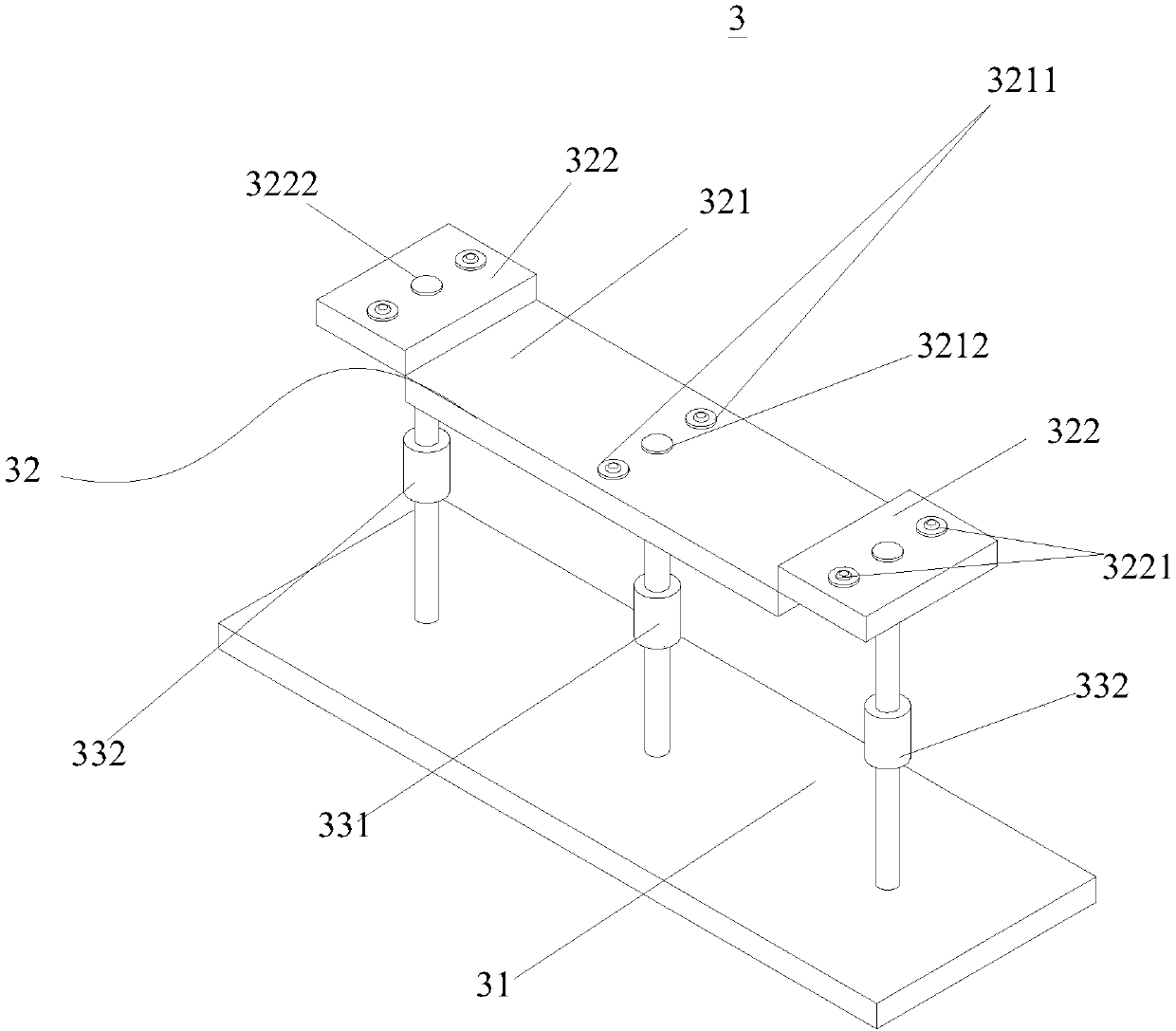

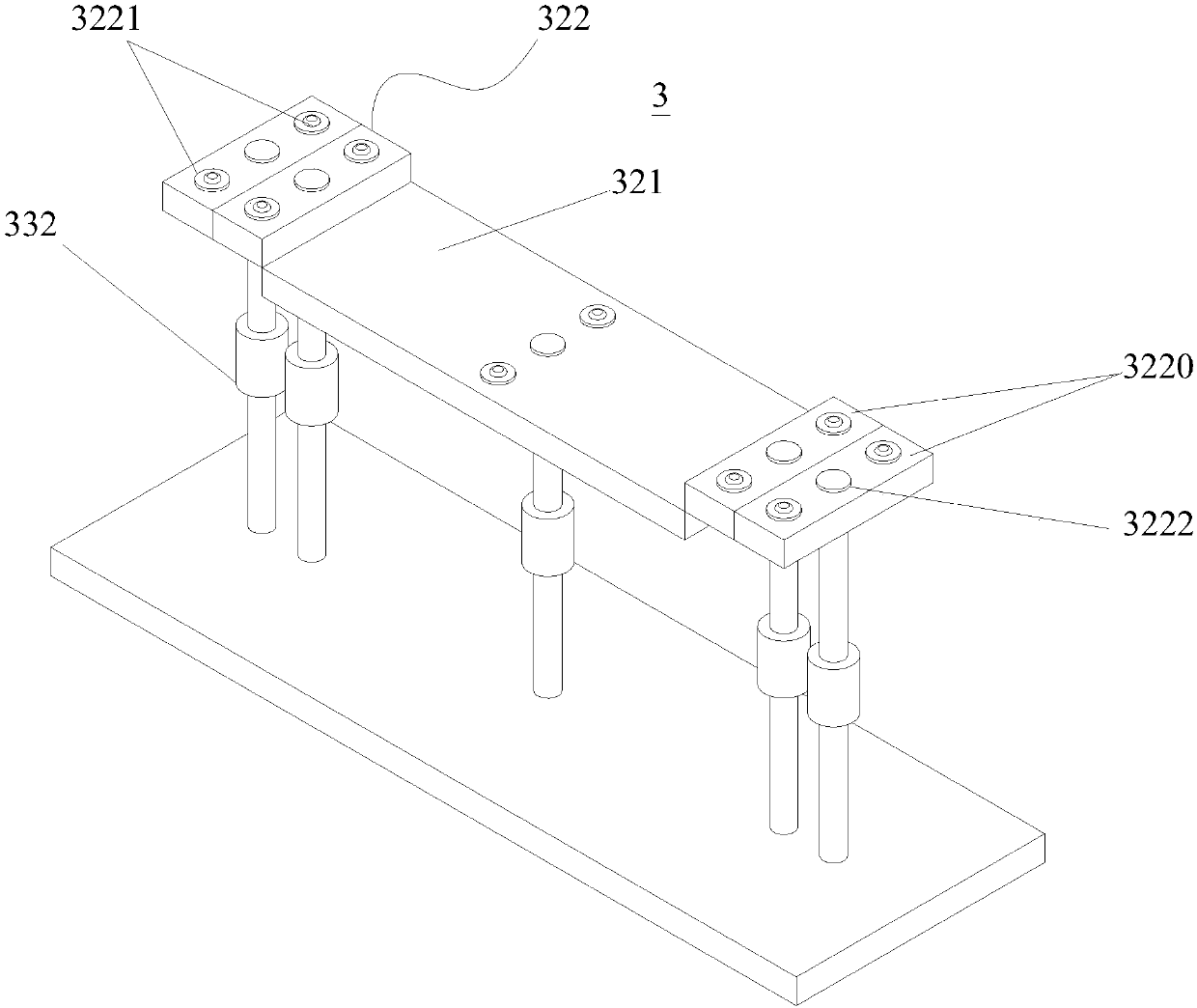

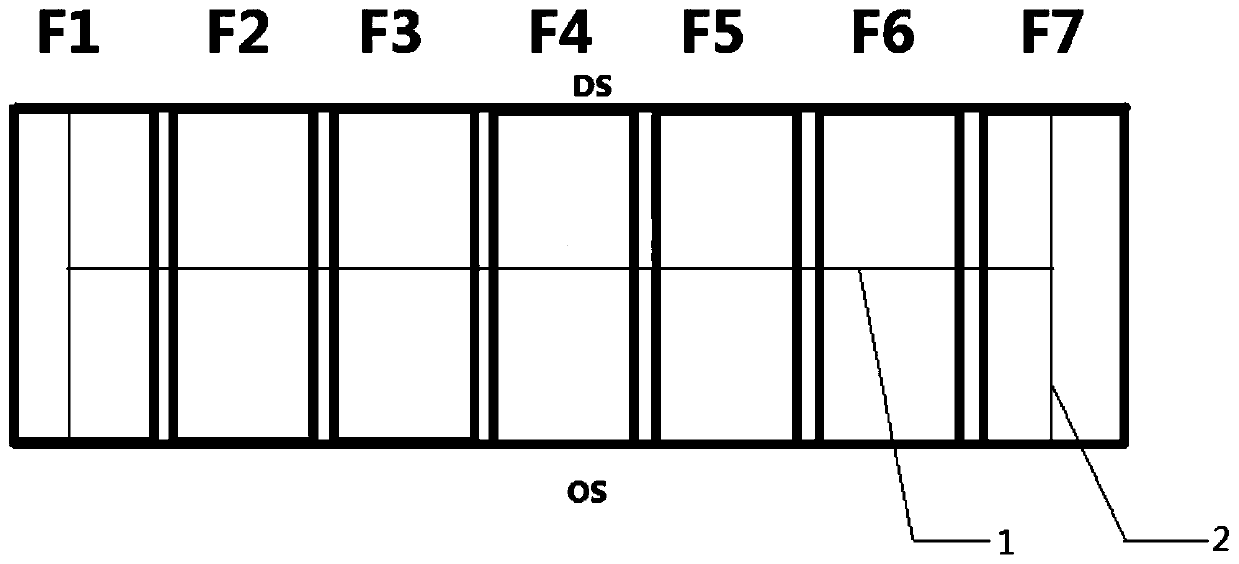

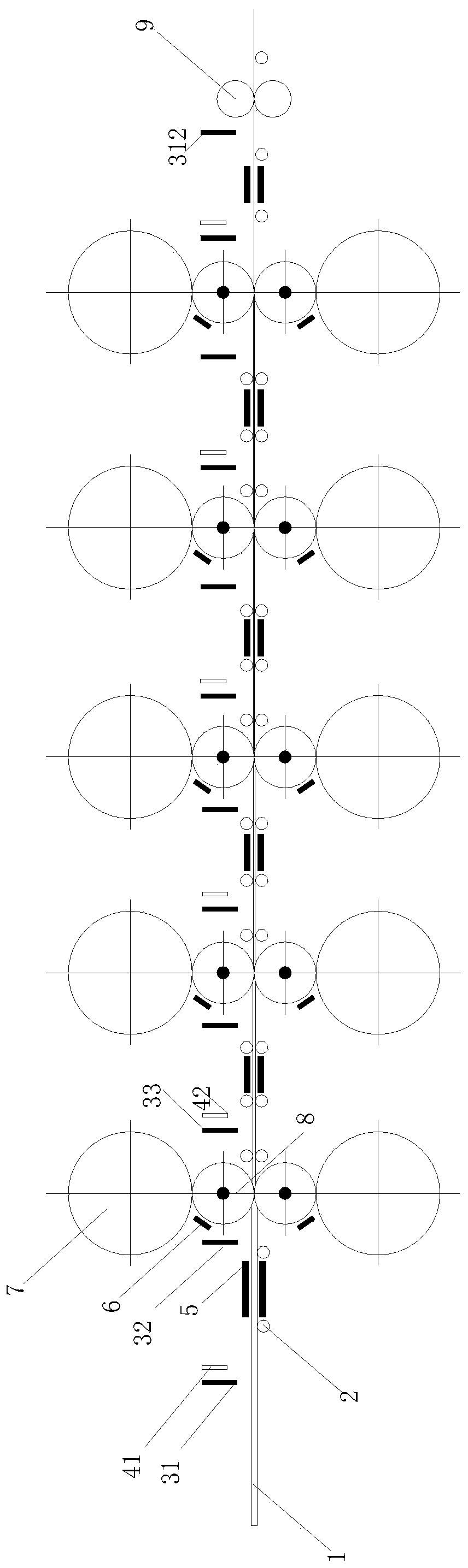

Adaptive heating system for temperature distribution during warm rolling of magnesium alloy strips

InactiveCN110116141AAchieving Custom Temperature ProfilesHigh temperature control accuracyTemperature control deviceWork heating devicesHeating systemMagnesium alloy

The invention discloses an adaptive heating system for temperature distribution during the warm rolling of magnesium alloy strips. The system includes a pedestal, a heating assembly, a middle displacement adjustment mechanism, edge displacement adjustment mechanisms and a controller; the heating assembly is arranged on the pedestal in a supported manner, and are arranged in the width direction ofa magnesium alloy strip; the heating assembly at least includes a middle heater and edge heaters arranged on the two sides of the middle heater; the middle heater is provided with middle temperature measurement instruments and a middle displacement sensor; the edge heaters are provided with edge temperature measurement instruments and edge displacement sensors; the middle displacement adjustment mechanism adjusts the spacing between the middle heater and the middle part of the magnesium alloy strip; the edge displacement adjustment mechanisms adjust the spacing between the edge heaters and theedge parts of the magnesium alloy strip; and the controller is connected to the middle heater, the edge heaters, the middle temperature measurement instruments, the middle displacement sensor, the edge temperature measurement instruments, the edge displacement sensors, the middle displacement adjustment mechanism and the edge displacement adjustment mechanisms.

Owner:BAOSHAN IRON & STEEL CO LTD

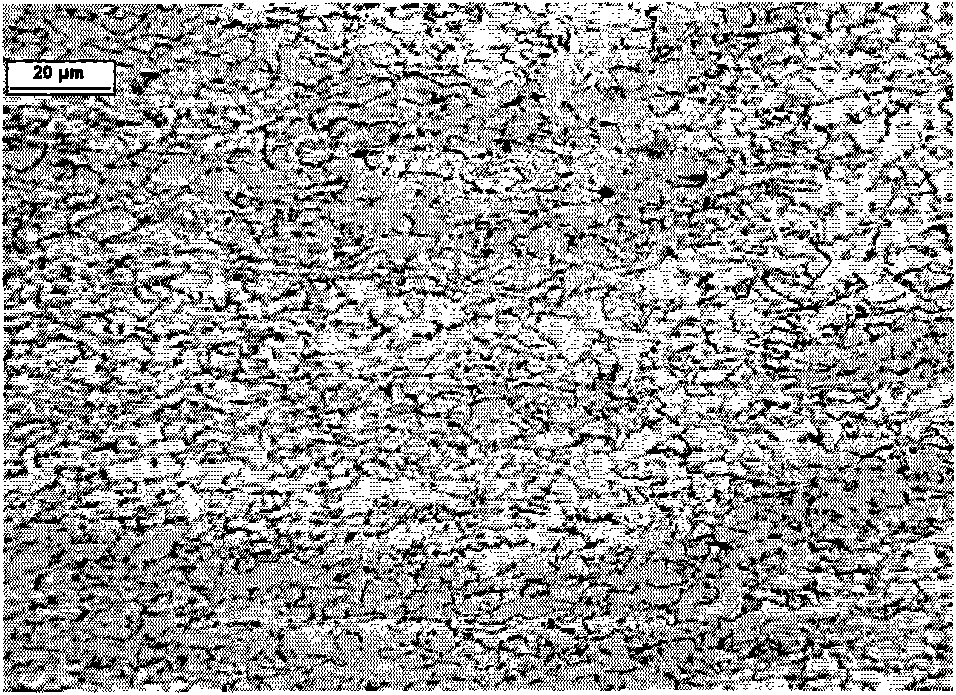

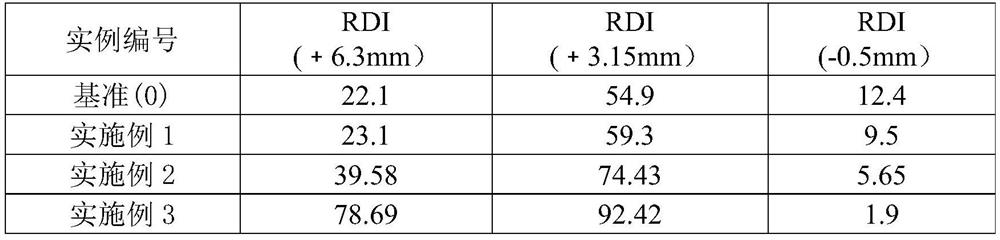

Iron ore concentrate for increasing low-temperature reduction pulverization rate of iron ore sinter and preparation method

The invention discloses iron ore concentrate for increasing the low-temperature reduction pulverization rate of iron ore sinter and a preparation method. The iron ore concentrate is prepared from thefollowing components in percentage by mass: 55%-60% of Fe2O3, 15.5%-17.5% of FeO, 1%-2% of CaO, 7%-9% of SiO2, 1.1%-1.3% of Al2O3, 3.0%-4.0% of MgO, 0.8%-1.0% of BaO, 1.2%-1.5% of MnO and 8.0%-10.0% of burning loss. Compared with the prior art, the low-temperature reduction pulverization rate RDI (+ 3.15 mm) of the sinter can be increased by 30%-40%, the blast furnace charging quality is remarkably improved, and smooth operation of a blast furnace is facilitated. In addition, the iron ore concentrate is directly added into iron ore powder to form a sintering raw material together with flux andfuel, no additive needs to be additionally added, no equipment needs to be modified, and the method for improving the sinter charging quality is easy to operate and easy to apply and popularize.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

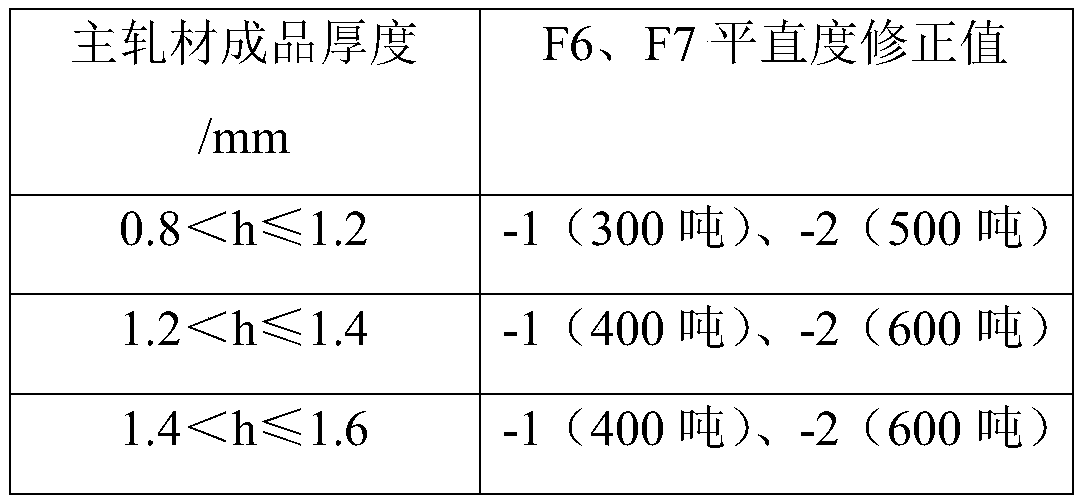

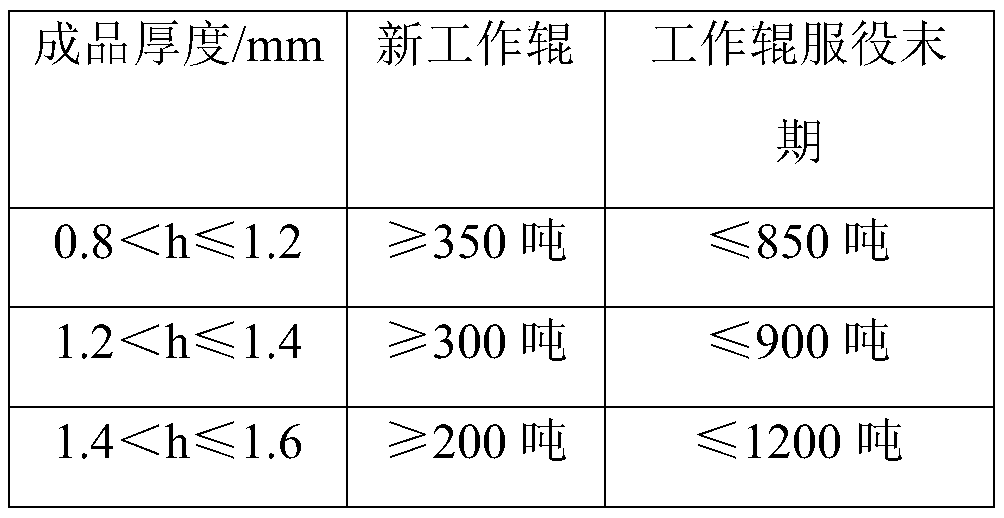

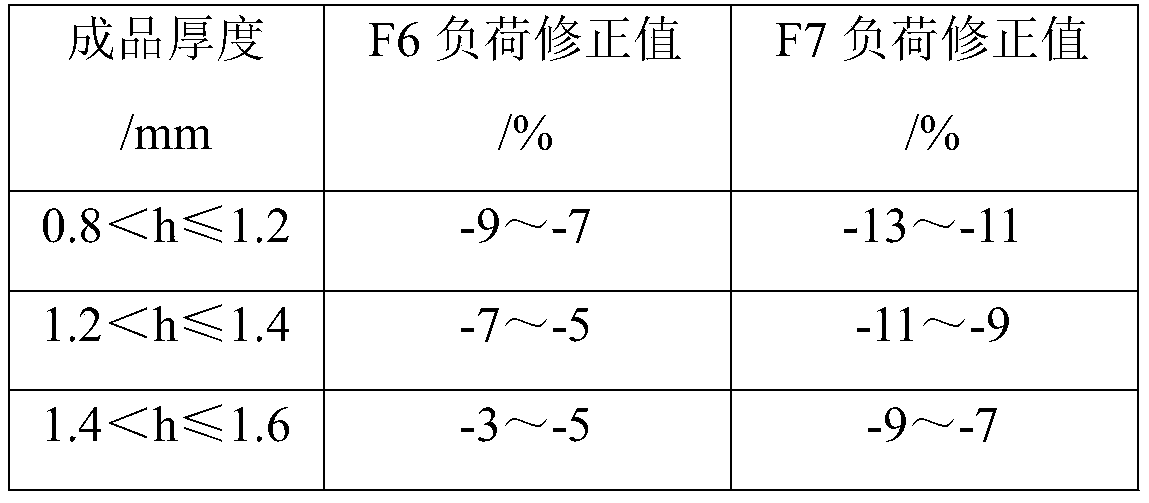

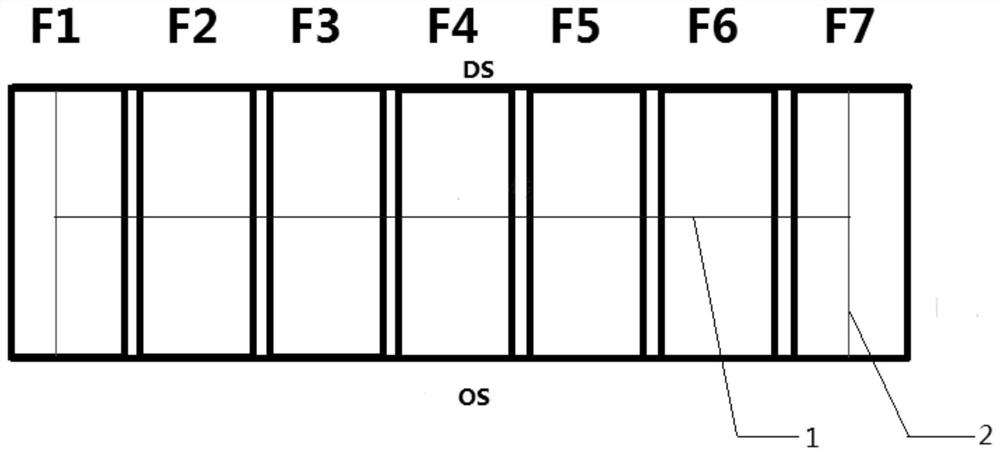

Control method for eliminating upwarp phenomenon of short-process ultra-thin strip steel

ActiveCN110216151ASolving process is unstableLarge-scale production with high stabilityRare end control deviceMetal rolling arrangementsInstabilityReduction rate

The invention discloses a control method for eliminating the upwarp phenomenon of short-process ultra-thin strip steel. The control method comprises the steps of controlling the rolling pressure of working rolls of a rolling mill, the belt threading speed of strip steel, dust and water removal time sequence, micro double-side-wave rolling, uneven wear to the working rolls and conditions and parameters of the reduction rate. Compared with the prior art, the control method has the advantages that the problem that a rear-section rack becomes warped during short-process ultra-thin strip steel rolling is solved; the technical problems of instability of the short-process ultra-thin strip steel rolling process can be solved; and the purpose of high-quality and high-stability scale production of the short-process rolled ultra-thin strip steel is achieved.

Owner:武汉钢铁有限公司

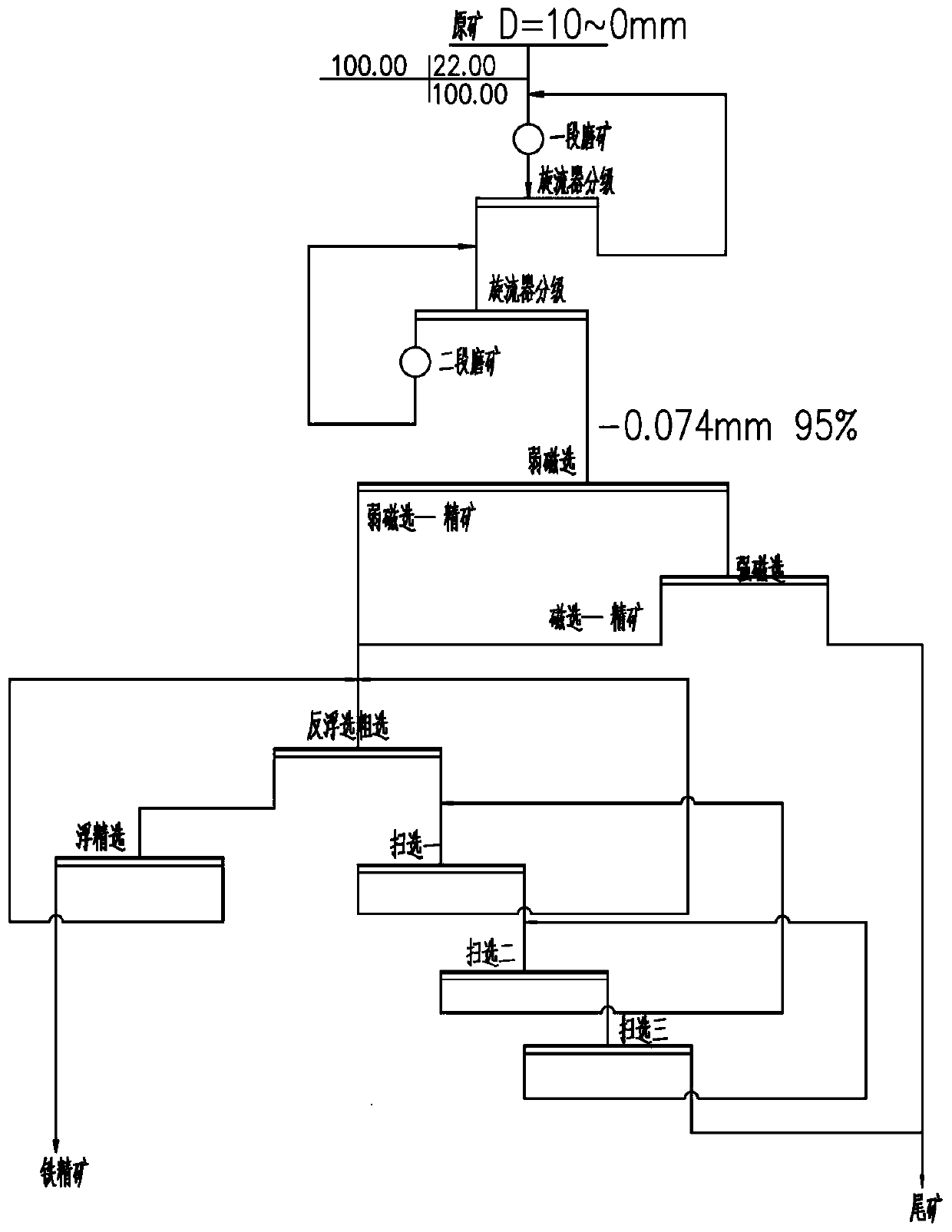

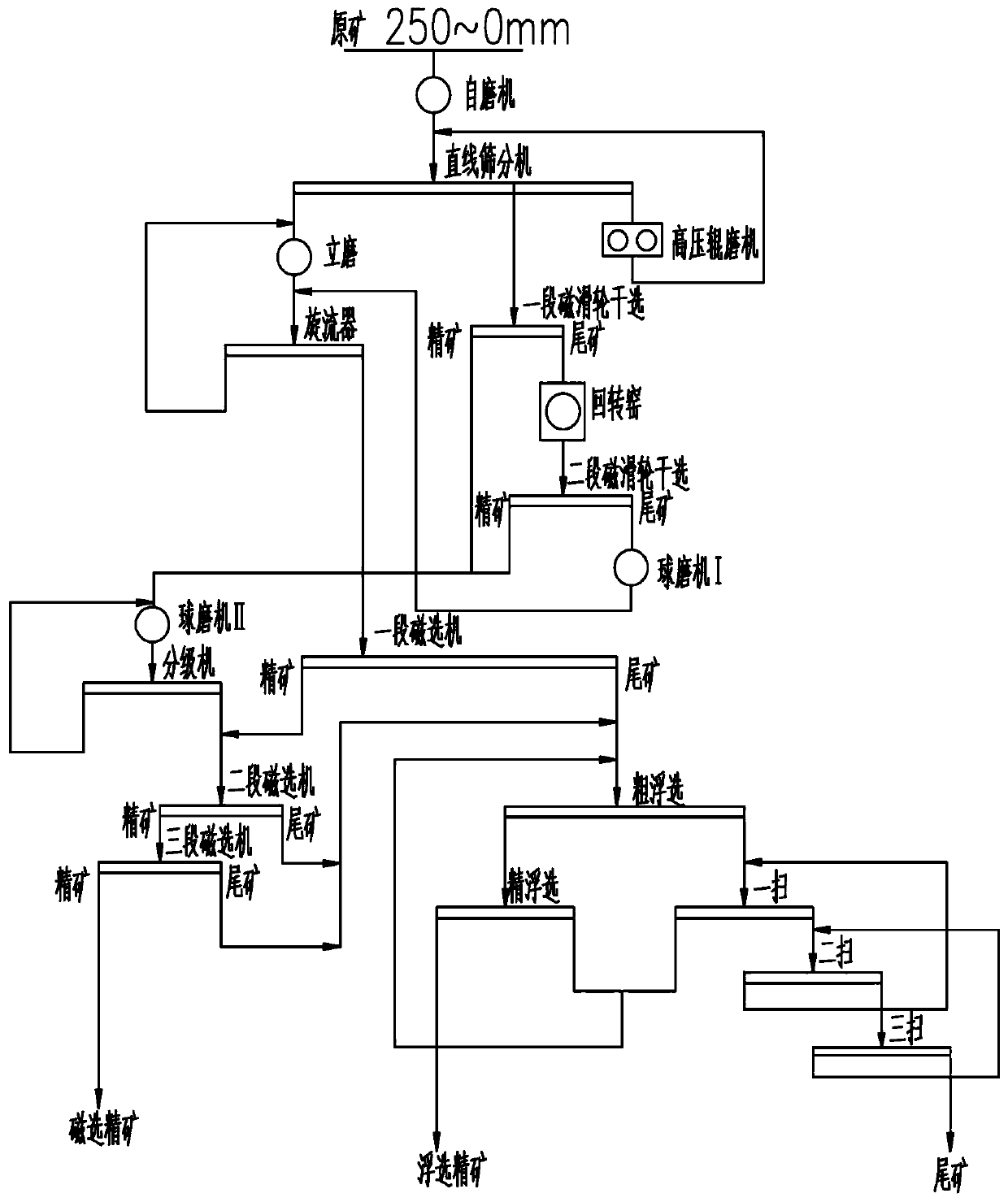

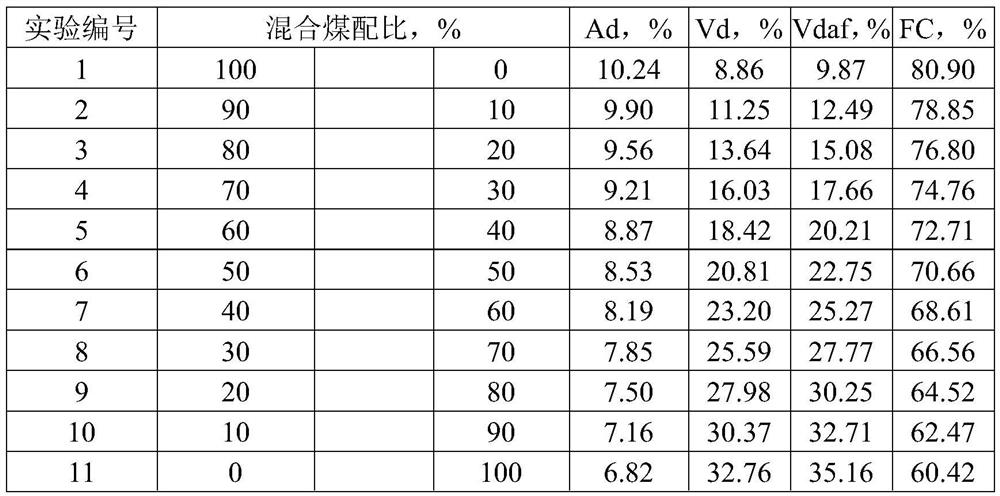

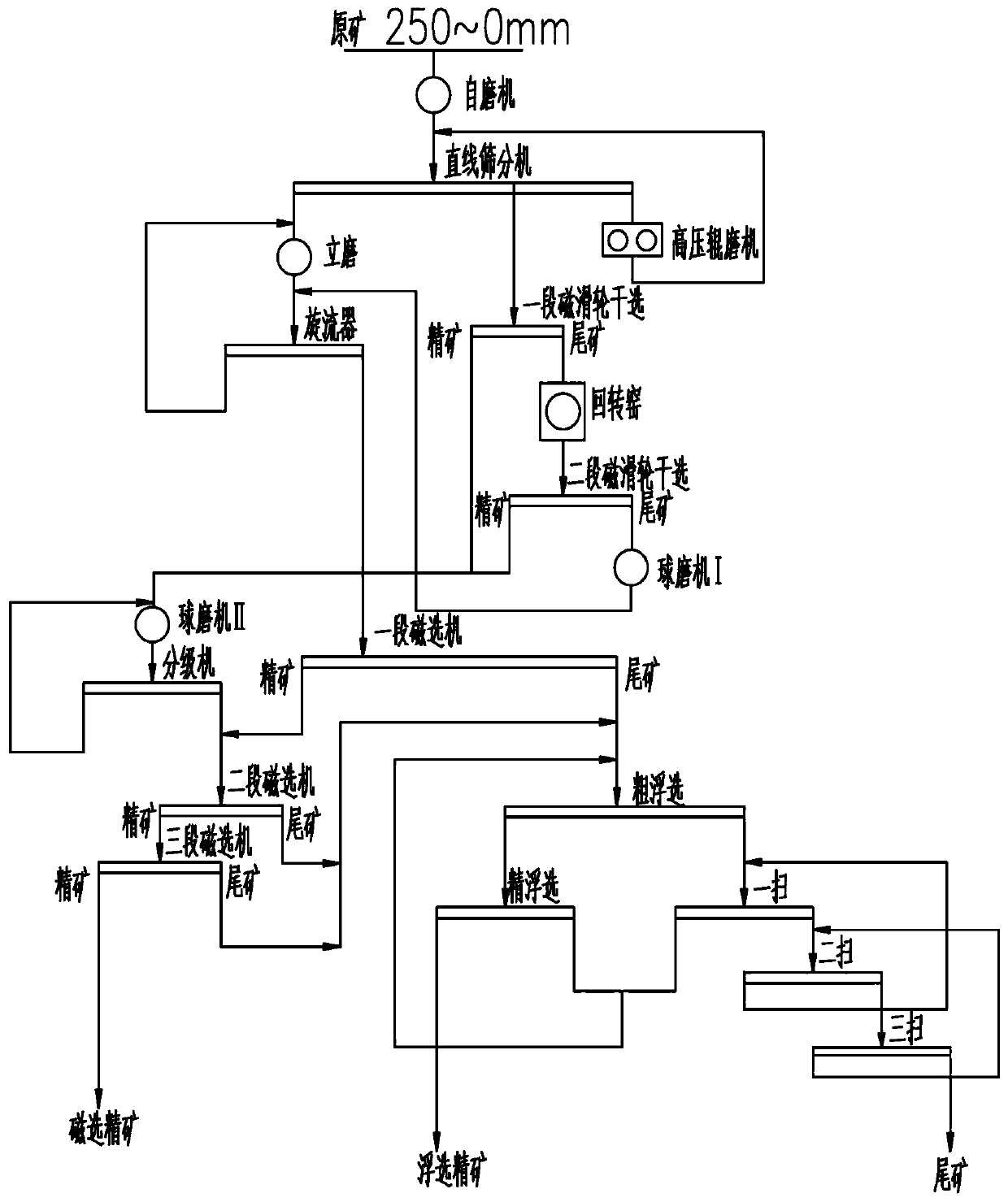

Mineral processing technology for processing mixed iron ore difficult to separate and with various iron minerals

ActiveCN109692752AAvoid over crushingHigh recovery rateWet separationChemical reactionReverse flotation

The invention relates to a mineral processing technology for processing mixed iron ore difficult to separate and with various iron minerals. The mineral processing technology is characterized in thatraw ore with iron grade being of 21-23% and particle size being of 250mm-0mm is fed in a self-grinding machine to obtain a self-grinding product with the particle size being of 30mm-0mm, the self-grinding product is fed in a double-layer linear vibrating screen to obtain three kinds of screened products with the particle sizes separately being of +10mm, 10mm-1mm and 1mm-0mm, and the three kinds ofscreened products are subjected to different grading processing of grind grading, dry magnetic separation, wet magnetic separation and reverse flotation operation to obtain ore with concentrate gradebeing more than 64.5%. The mineral processing technology has the advantages that (1), through introduction of a high-pressure grinding roller closed circuit crushing autogenous mill stone, capacity of the autogenous mill is released; (2), a novel rotary kiln structure with chemical reaction and reduction reaction being conducted step by step is adopted, and the percent conversion of the magneticore is improved; and (3), compared with an original technology, the concentrate grade is improved by nearly 5 percentage points.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

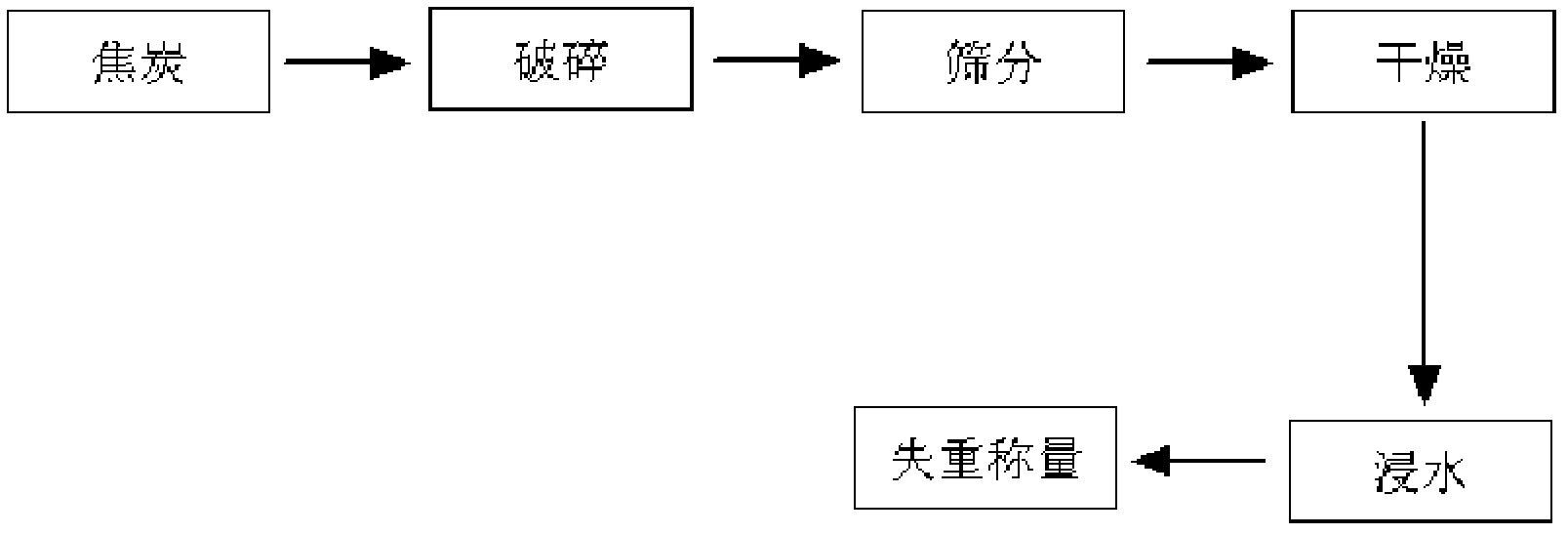

Method for determining saturated moisture of coke

ActiveCN102621028AQuality assuranceConducive to follow-up productionWeighing by absorbing componentEnvironmental engineeringForced-air

The invention discloses a method for determining saturated moisture of coke, comprising crushing treatment on the coke and drying treatment on the coke. The method comprises the following steps of: crushing appropriate amount of coke sample acquired from a production field, and screening the crushed coke according to different fractions within the particle size range of 5-30mm; placing the coke at different fractions into a drying box, and carrying out full forced air drying at the temperature of 95-115 DEG C; mixing the dried coke according to weight percentage of different fractions, and immersing the mixed coke into water to be fully soaked; and weighing the soaked coke on a balance, and calculating content of the saturated moisture of the coke when reading of the balance is stable. The invention provides a method for determining the saturated moisture of the coke for the coke with high moisture content in production, thus being beneficial to finding that whether excessive moisture is contained in the coke to judge whether excessive water is sprinkled into the coke, being beneficial to coke quality monitoring and improving use quality of the coke and being beneficial to reducing usage of the coke and production cost in a smelting reduction process.

Owner:XINJIANG BAYI IRON & STEEL

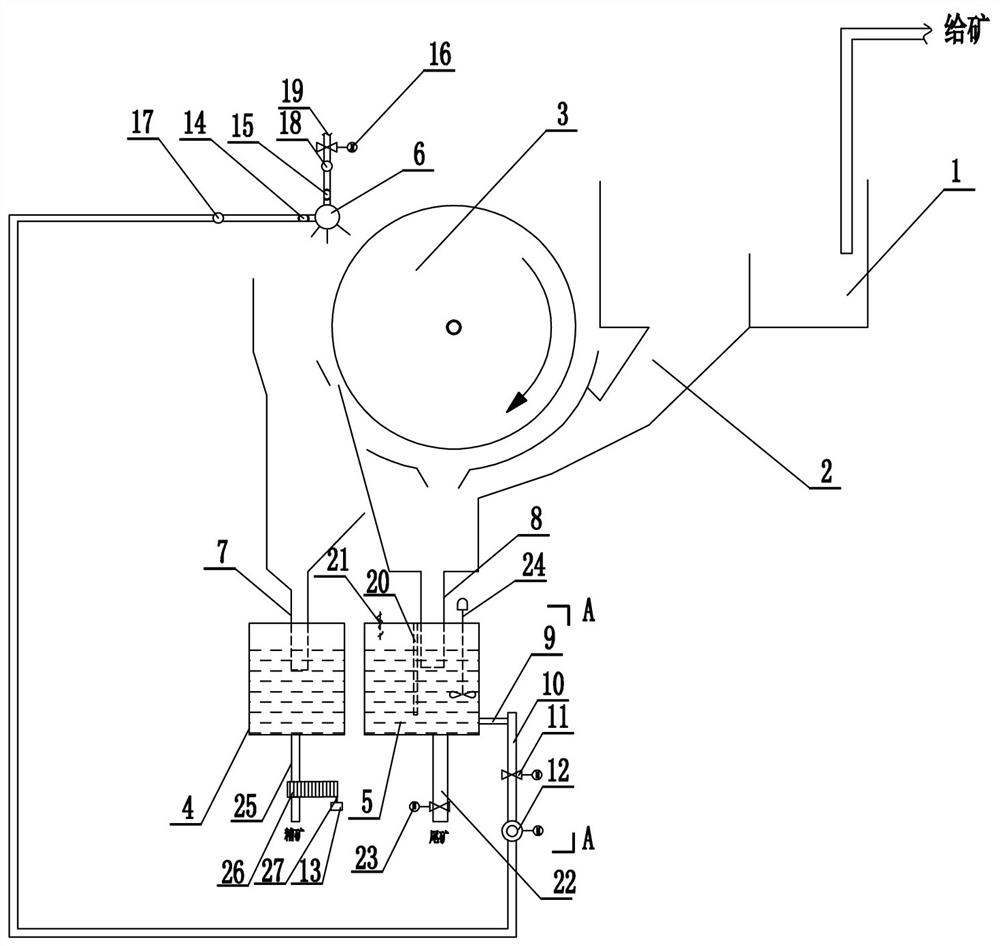

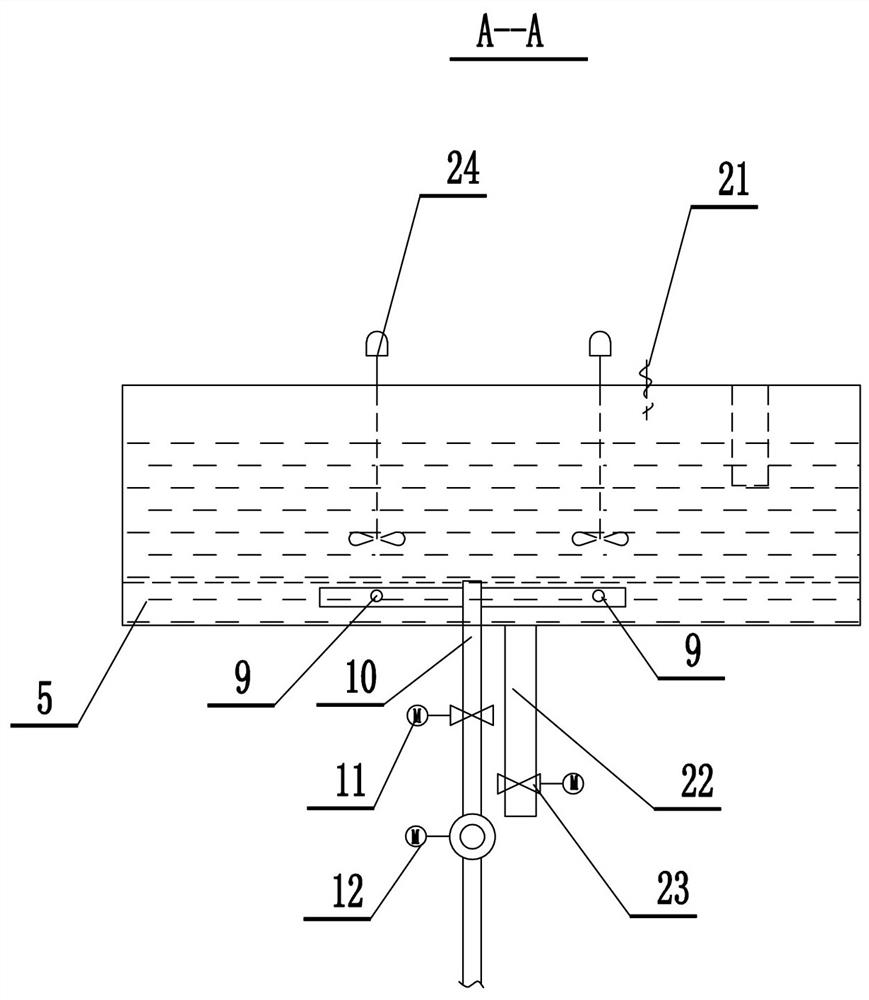

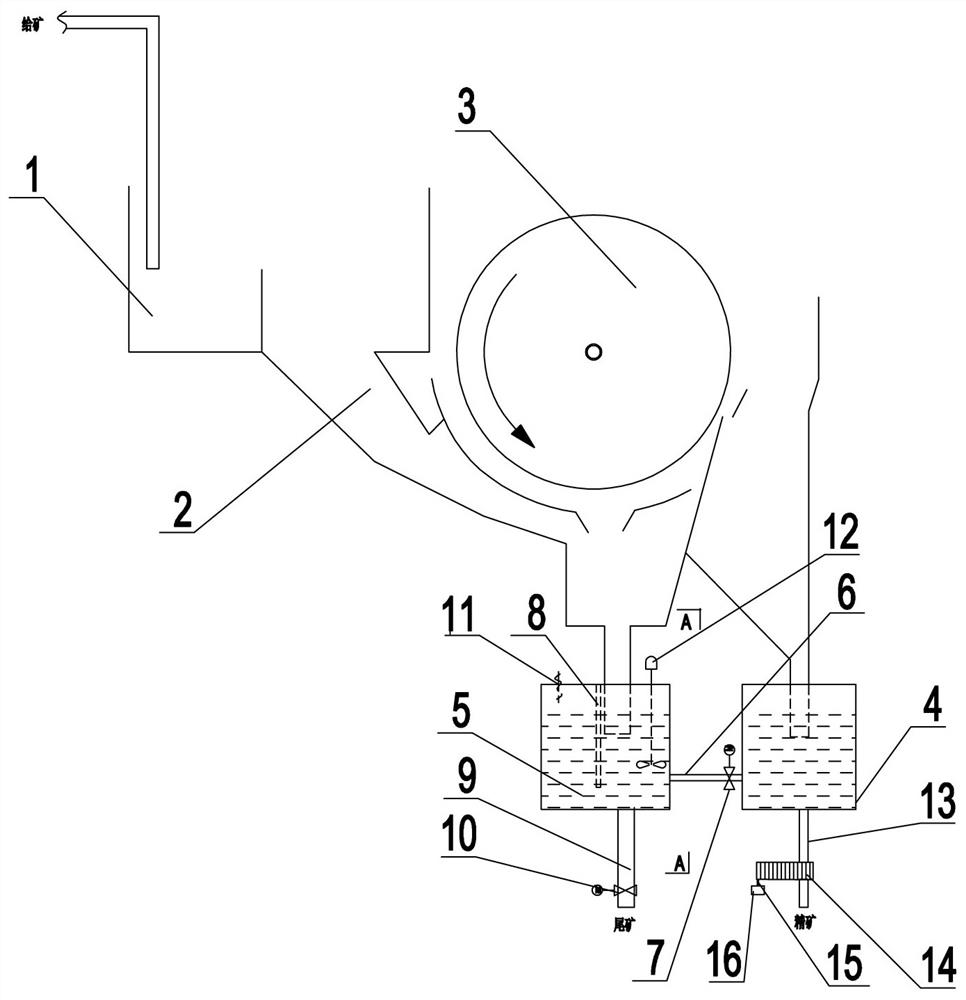

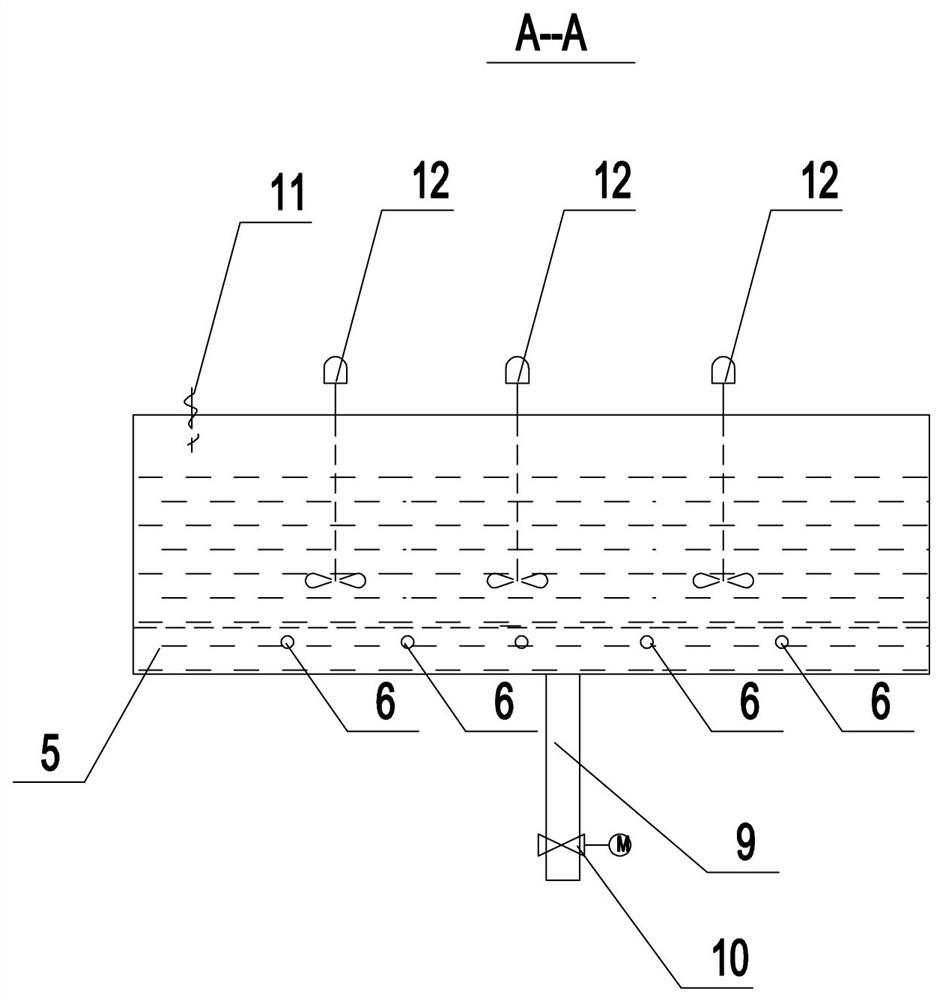

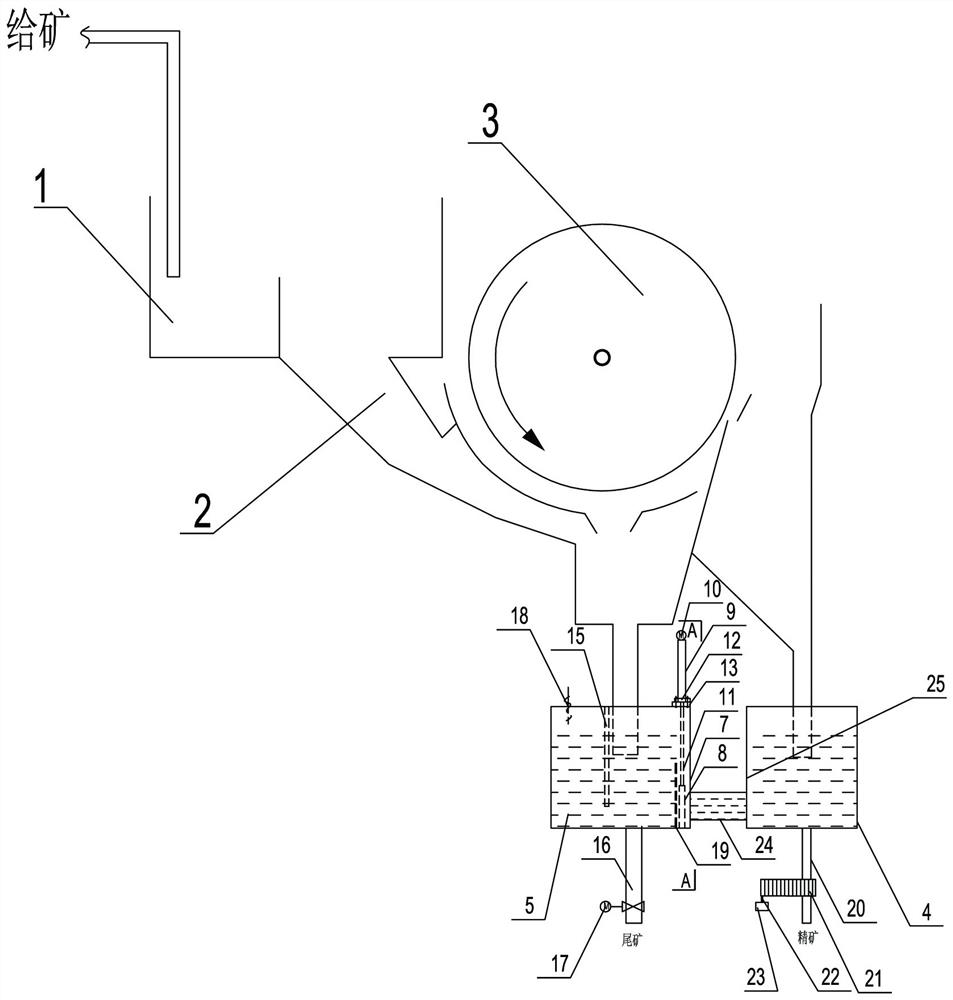

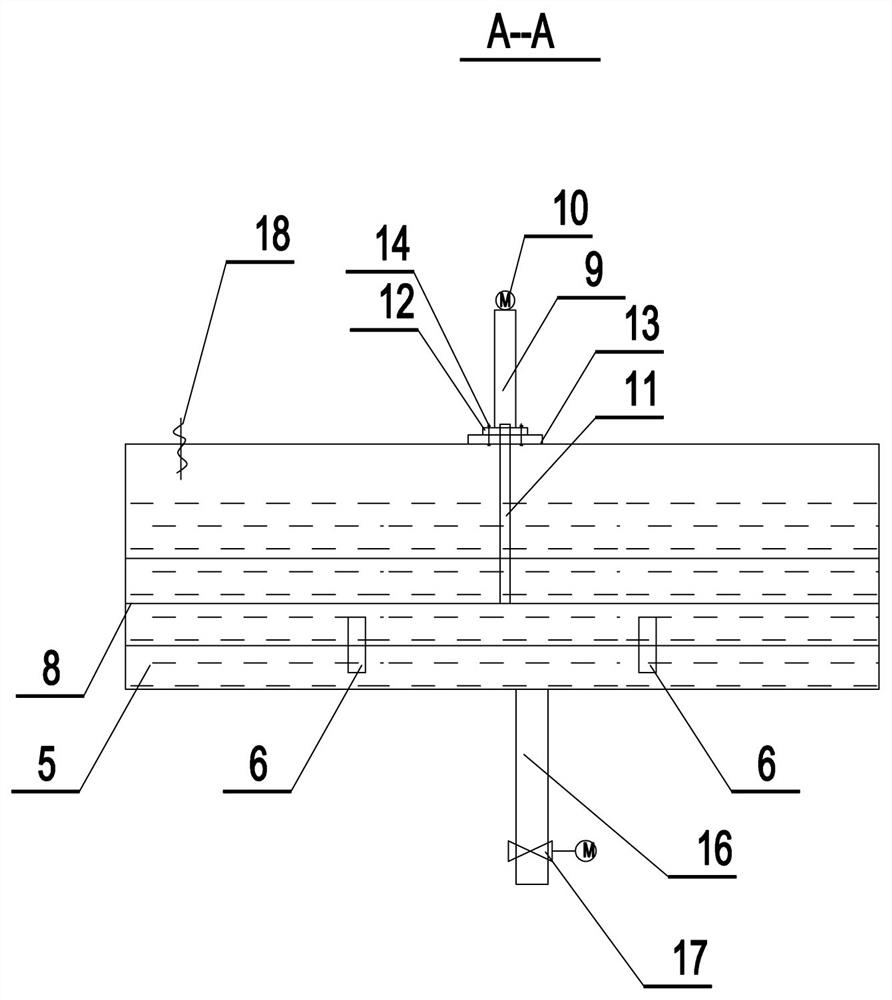

Online ore mixing device for concentrate product of magnetic separator

PendingCN112495580AIncrease productionImprove economic efficiencyElectrostatic separationEarth material testingMagnetic separatorOre concentrate

An online ore mixing device for concentrate products of a magnetic separator comprises a separation groove of a drum type magnetic separator, a separation drum, a concentrate washing water pipe, a concentrate box, a concentrate box ore discharging pipe, a tailing box and a control box, and is characterized in that the ore mixing device is connected between the tailing box and the concentrate washing water pipe, and a concentrate grade detection mechanism is arranged on the concentrate box ore discharge pipe. The ore mixing device comprises an ore distribution pipe, an ore return main pipe, anelectric knife gate valve I, a pressure pump and a tailing joint; and the concentrate grade detection mechanism consists of a sampler and an automatic grade instrument. The device has the advantages that the amount o tailings mixed into the concentrate box is controlled by controlling the opening degree of a valve on a return main pipe of the tailing box and using the valve as concentrate flushingwater, so that the concentrate grade is adjustable, the concentrate grade of the overhigh single magnetite is finally controlled to be 68%-69%, the concentrate yield and the iron recovery rate are increased, and blast furnace smelting is facilitated.

Owner:中冶北方(大连)工程技术有限公司

Blast furnace cooling wall damage rapid leakage detection method

InactiveCN111593152AEnsure safe productionGood for going straightCooling devicesExpansion tankThermodynamics

The invention discloses a blast furnace cooling wall damage rapid leakage detection method. The method comprises the following steps that when a soft water system pipeline outside a furnace body leakswater, or a cooling wall body and a water pipe in a soft water system inside the furnace body are damaged and leak water into the furnace, the liquid level of an expansion tank cannot be stabilized and continuously drops, and when a blast furnace soft water closed circulating cooling system, the water quality index of the soft water in the period of time is detected, wherein the PH value index change trend decreases progressively; and when the cooling wall is damaged, coal gas can be detected in a degassing tank and the expansion tank of the soft water closed circulation cooling system, underthe normal production state of a blast furnace, the working condition of a flap flowmeter mounted on each soft water return pipeline of the cooling wall is observed, when water flows in cooling wallwater return pipe flap flowmeter has obvious bubble and white turbidity phenomena, it shows that the cooling wall water pipeline is abnormal, and longitudinal series connection cooling wall comprisingcooling water pipeline may be damaged.

Owner:XINJIANG BAYI IRON & STEEL

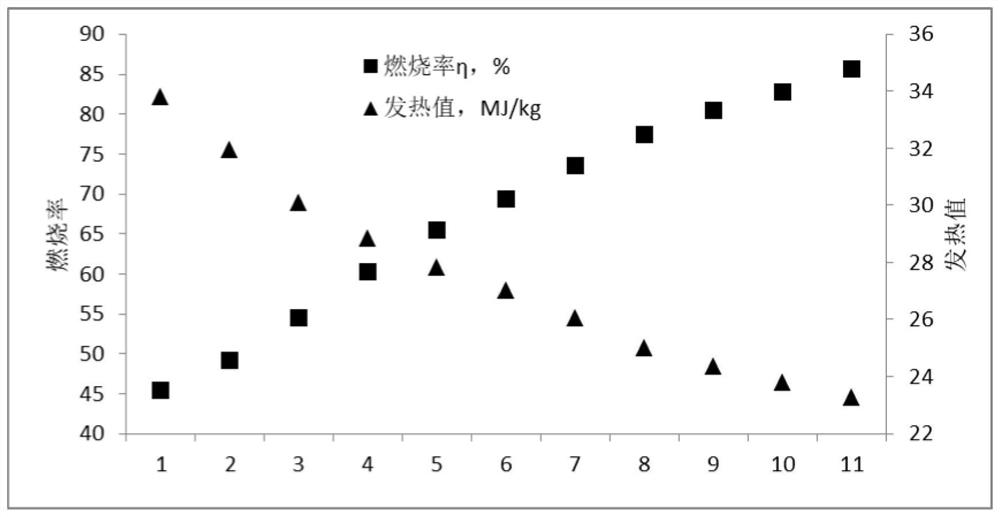

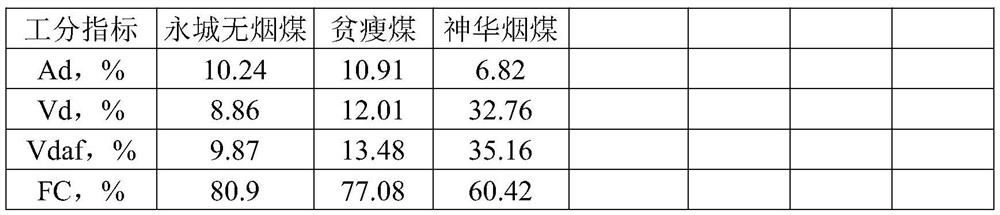

Method for matching mixed coal with relatively high heating value

PendingCN114214473AIncrease the actual coal char replacement ratioGood for furnace conditionBlast furnace detailsProcess engineeringAnthracite

The invention discloses a matching method of mixed coal with a relatively high heating value. The method comprises the following steps: 1) selecting bituminous coal and anthracite as components of the mixed coal; 2) designing a 6-17 coal blending scheme according to all-anthracite injection and all-series coal blending thoughts of all-anthracite injection, designing a coal injection framework according to anthracite proportion decreasing by m% and bituminous coal increasing by m%, and determining the matching ratio of mixed coal, m being 6.25-20; and 3) selecting the scheme with the highest intersection degree of the combustion rate and the exothermic value index as the scheme of the invention. The anthracite and the bituminous coal are mixed and injected according to a certain proportion, and meanwhile, the dry basis volatile component and the ash content of the mixed coal are well controlled, so that combustion can be mutually promoted, the actual coke replacement ratio of a blast furnace is increased, the explosiveness of the mixed coal powder is greatly reduced, the combustion performance is relatively improved, the generation amount of unburned coal powder is reduced, and the production cost is reduced. And smooth operation of the blast furnace is facilitated.

Owner:武汉钢铁有限公司

A beneficiation process for processing refractory mixed iron ore containing various iron minerals

The invention relates to a mineral processing technology for processing mixed iron ore difficult to separate and with various iron minerals. The mineral processing technology is characterized in thatraw ore with iron grade being of 21-23% and particle size being of 250mm-0mm is fed in a self-grinding machine to obtain a self-grinding product with the particle size being of 30mm-0mm, the self-grinding product is fed in a double-layer linear vibrating screen to obtain three kinds of screened products with the particle sizes separately being of +10mm, 10mm-1mm and 1mm-0mm, and the three kinds ofscreened products are subjected to different grading processing of grind grading, dry magnetic separation, wet magnetic separation and reverse flotation operation to obtain ore with concentrate gradebeing more than 64.5%. The mineral processing technology has the advantages that (1), through introduction of a high-pressure grinding roller closed circuit crushing autogenous mill stone, capacity of the autogenous mill is released; (2), a novel rotary kiln structure with chemical reaction and reduction reaction being conducted step by step is adopted, and the percent conversion of the magneticore is improved; and (3), compared with an original technology, the concentrate grade is improved by nearly 5 percentage points.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

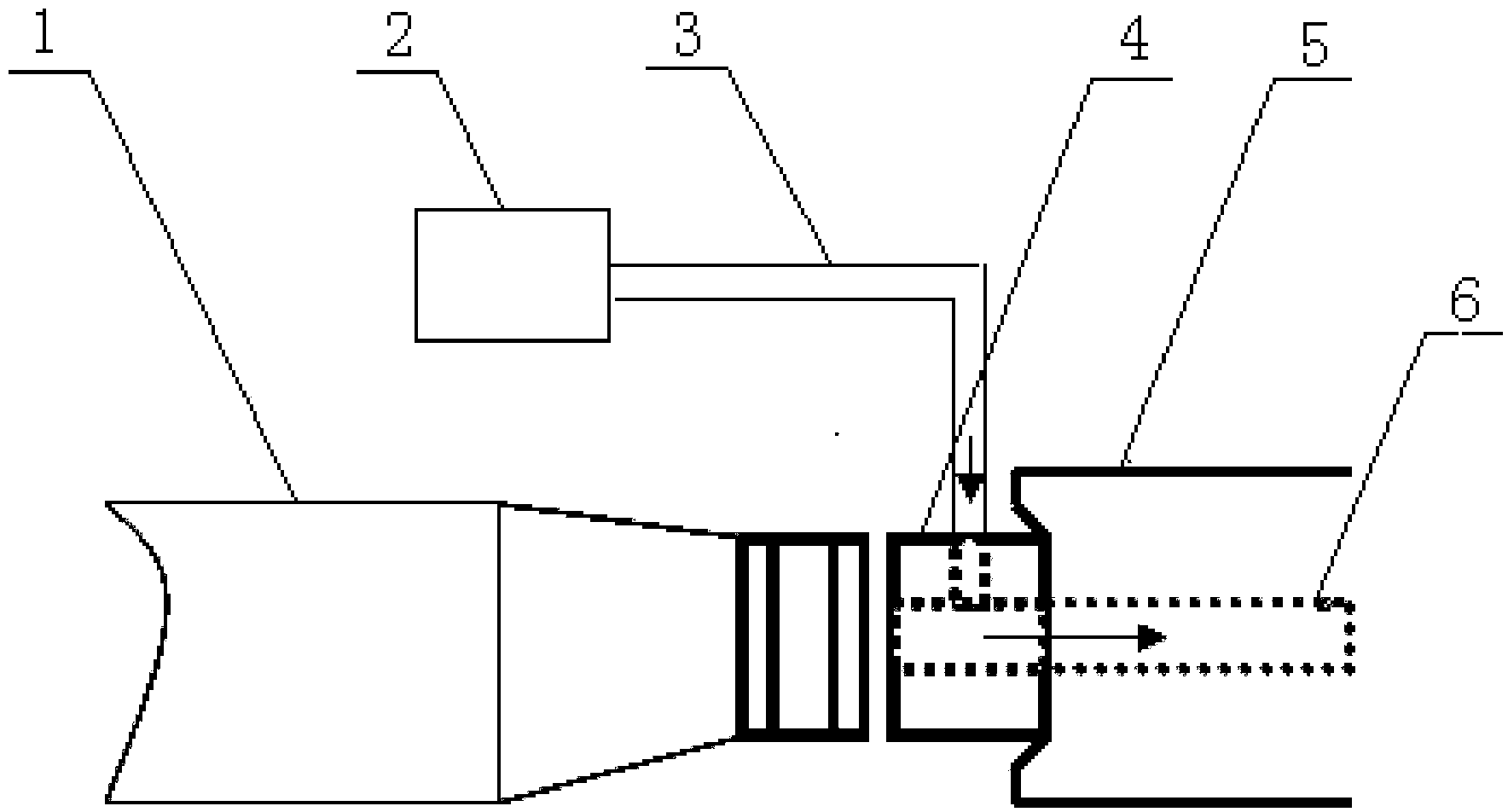

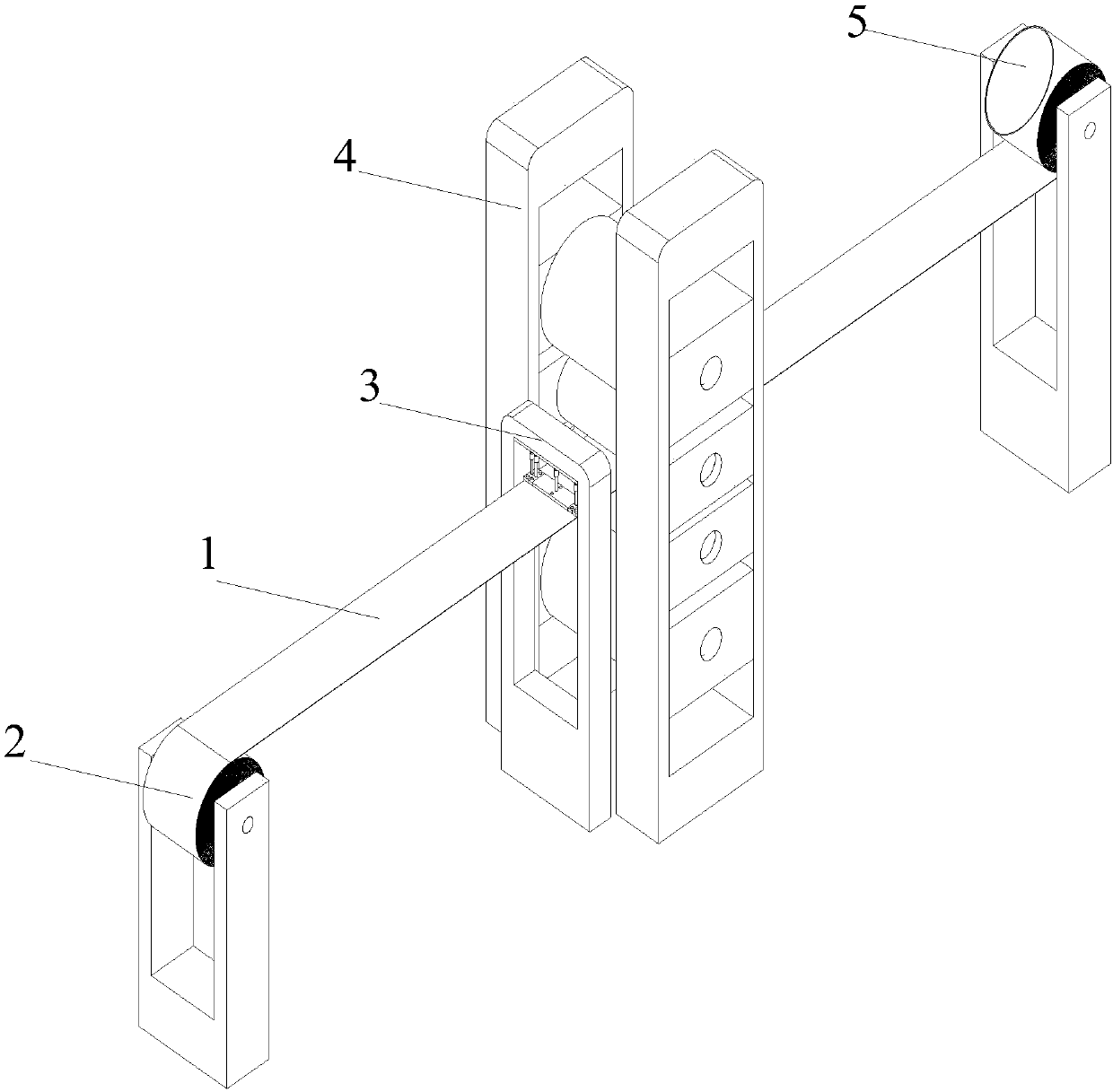

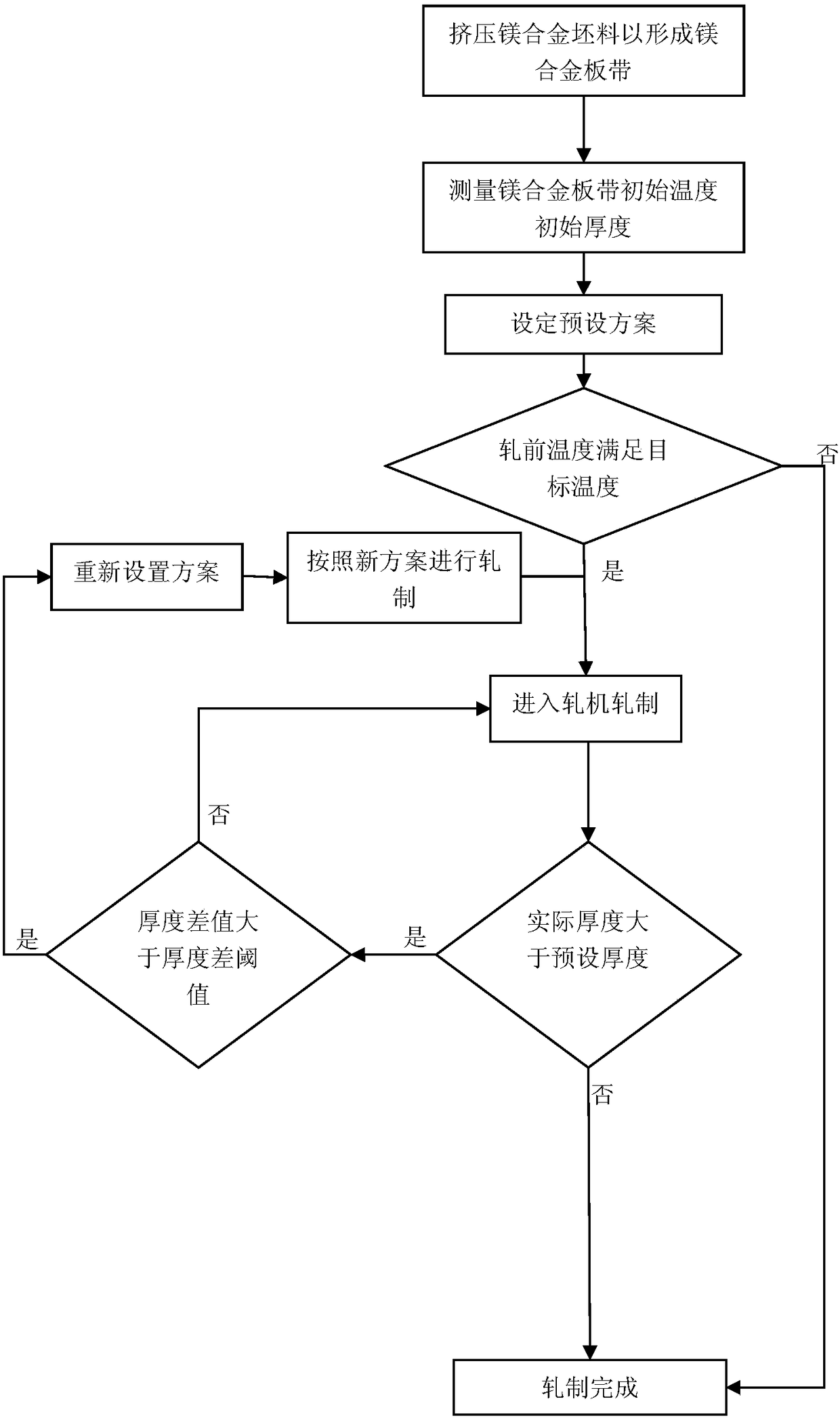

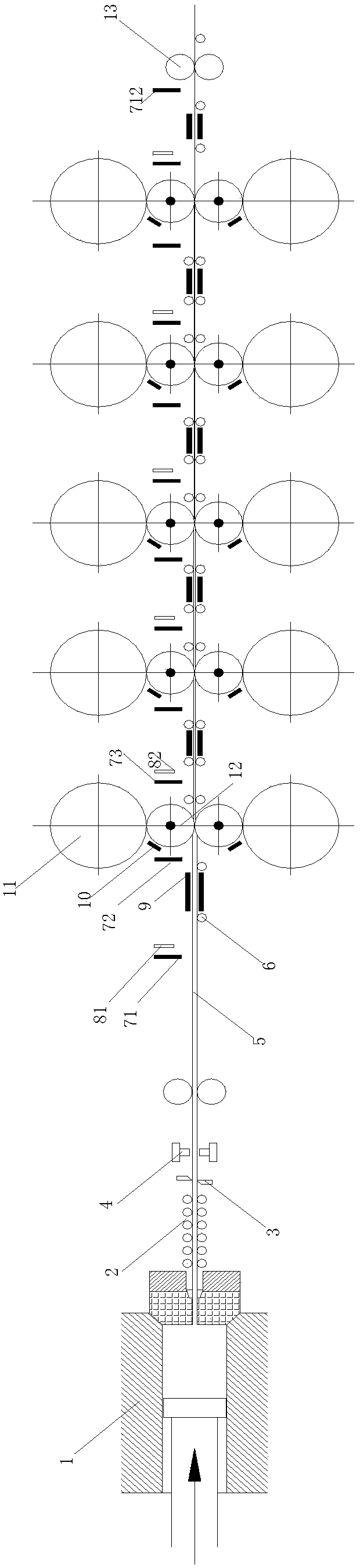

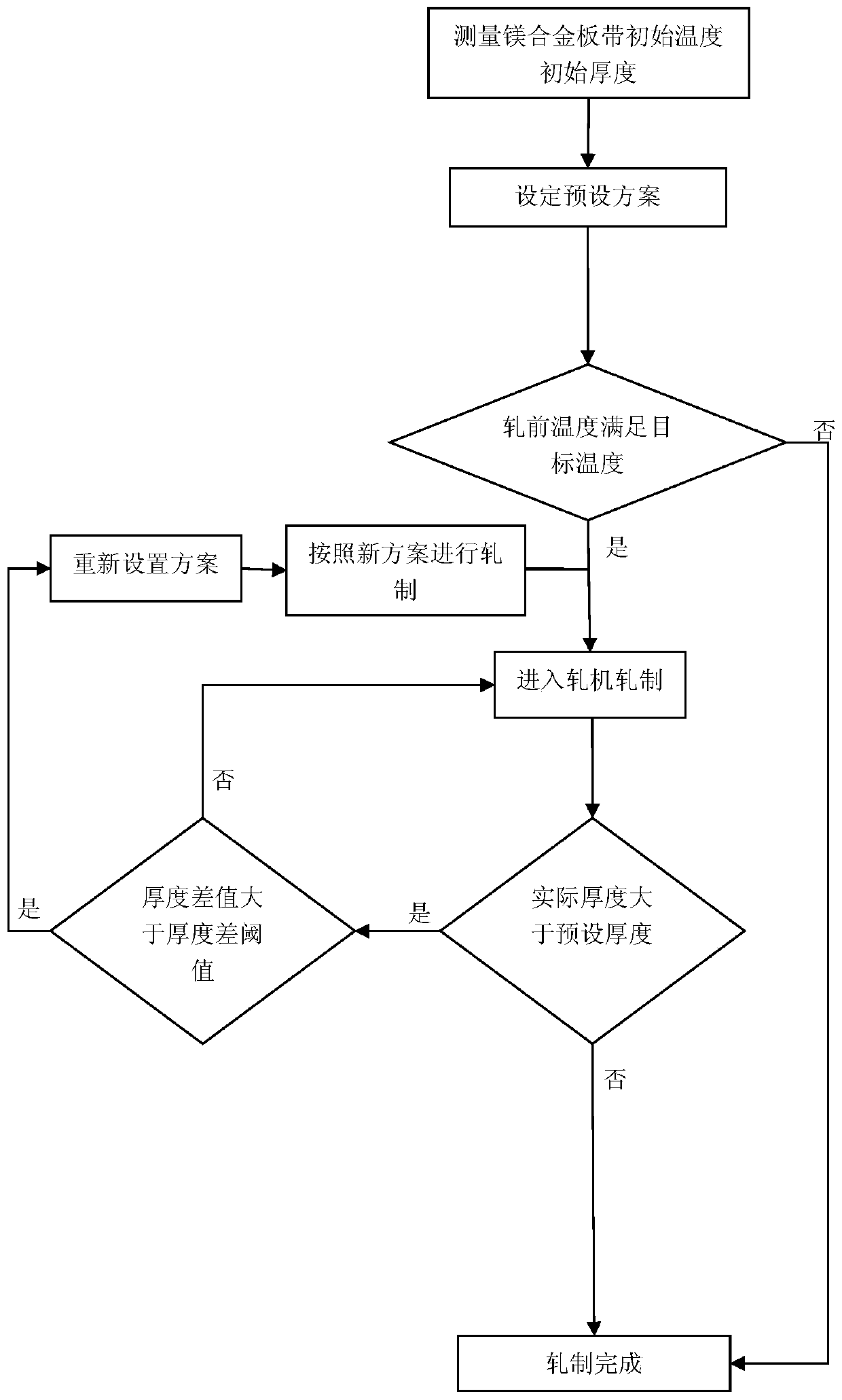

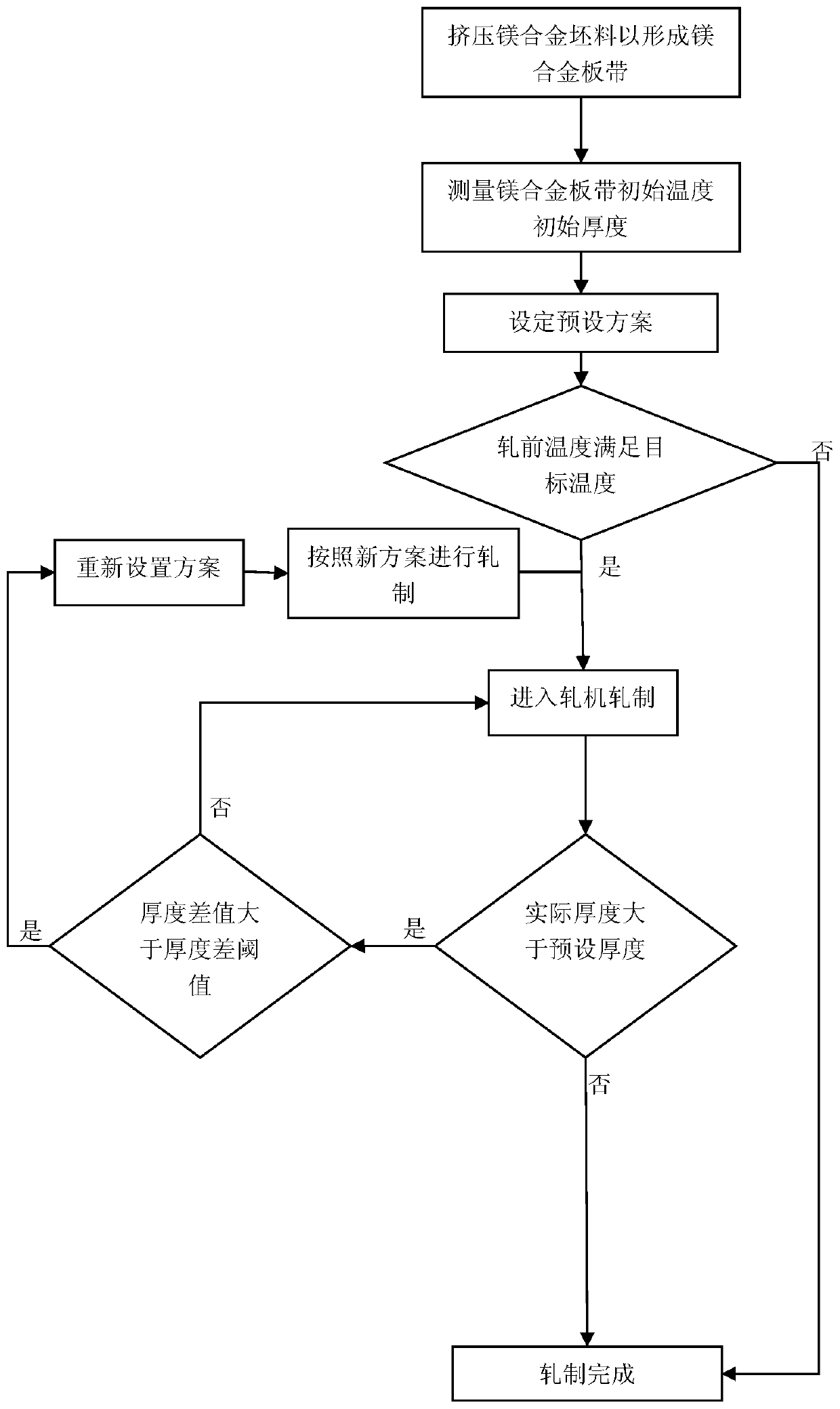

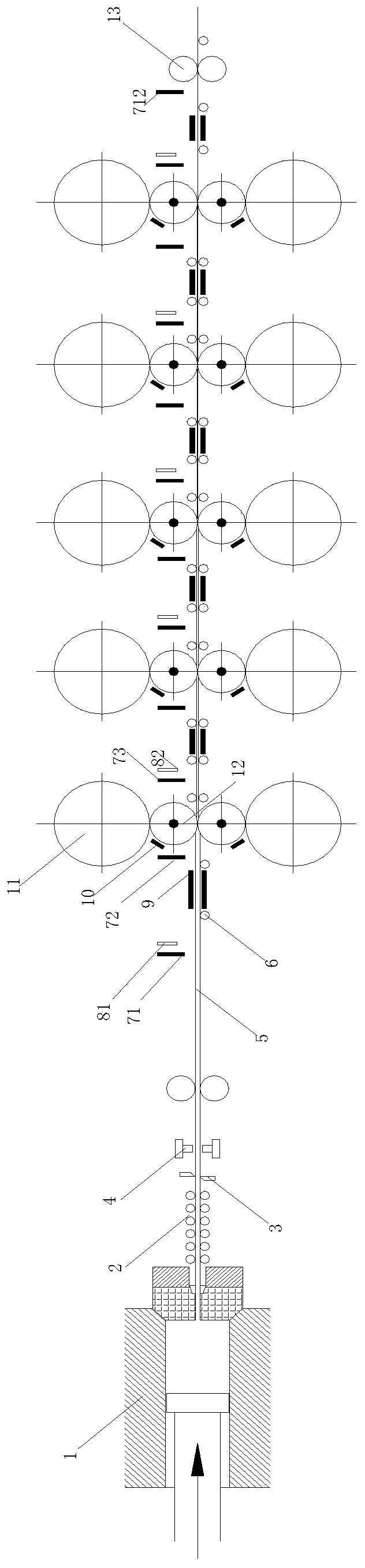

Magnesium alloy continuous extrusion and temperature controlled continuous rolling production method and system

ActiveCN108787779AControllable temperature accuracyHigh continuous production efficiencyTemperature control deviceRollsTemperature controlContinuous rolling

The invention discloses a magnesium alloy continuous extrusion and temperature controlled continuous rolling production method. The method includes the following steps: (1) extruding magnesium alloy billet into magnesium alloy plates and strips; (2) measuring initial temperature and initial thickness of the magnesium alloy plates and strips, and obtaining and inputting a preset scheme according tothe measured initial temperature and initial thickness, wherein the scheme at least includes a preheating scheme and a rolling scheme for rolling passes and the rolling scheme at least includes the rolling passes and pre-press quantity of the rolling passes; (3) rolling; and (4) completing the rolling. The magnesium alloy continuous extrusion and temperature controlled continuous rolling production method adopts a rolling method of combining the continuous extrusion and on-line temperature controlled rolling, realizes the efficient continuous operation of the continuous extrusion and temperature controlled rolling process of the magnesium alloy billet through adaptive control of the extrusion and rolling process of the magnesium alloy billet, and matches real-time state of the plates andstrips, which is beneficial to improve the smoothness of the rolling process and the stability of the product quality.

Owner:CHINA BAOWU STEEL GRP CORP LTD +1

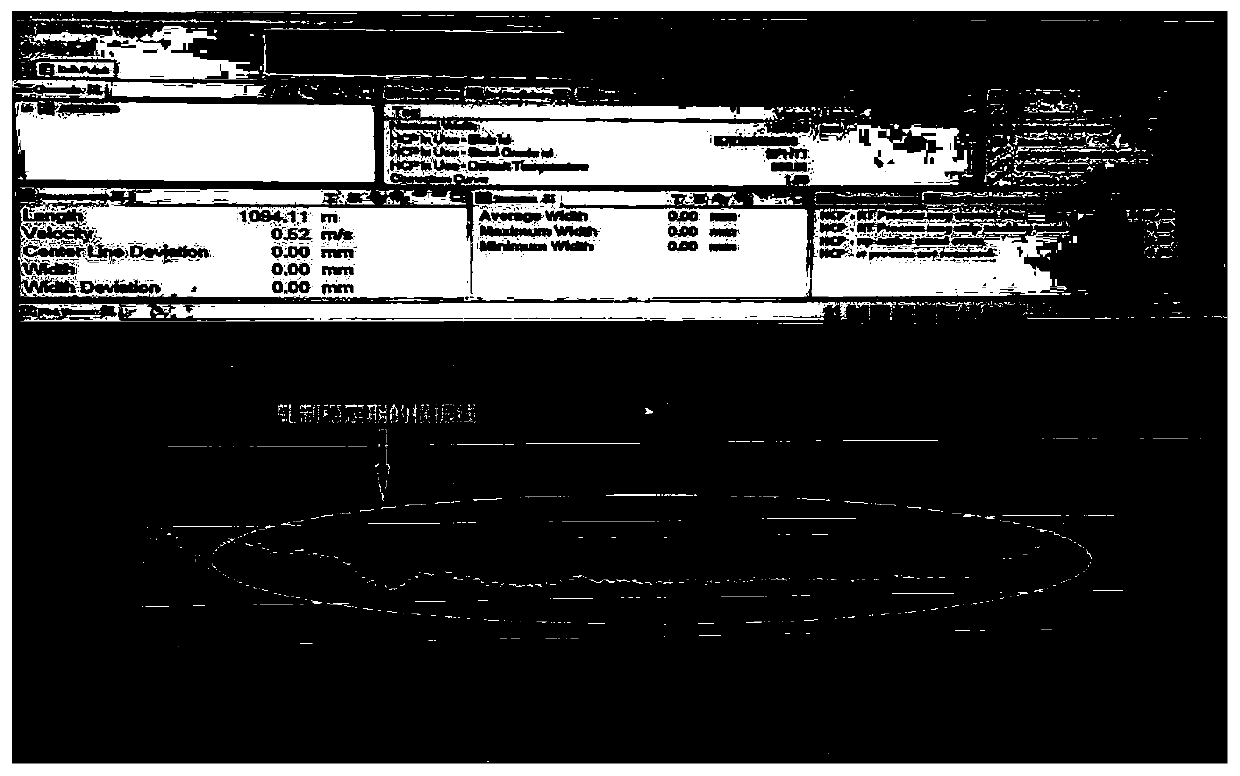

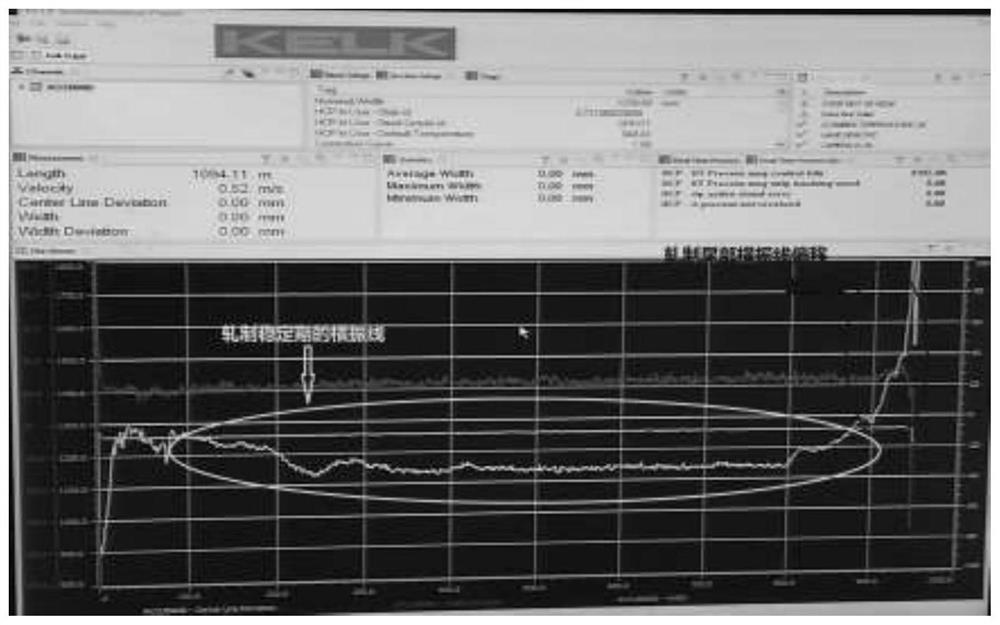

Control method for eliminating horizontal-vibration linear offset of tail of short-process thin strip steel

ActiveCN110355216ASolve the problem of horizontal vibration line offsetQuality improvementRare end control deviceMetal rolling arrangementsStrip steelBending force

The invention discloses a method for eliminating a horizontal-vibration linear offset of the tail of short-process thin strip steel. The control method can eliminate the horizontal-vibration linear offset of the tail of short-process thin strip steel by control over centering of guide plates of rolling mills through measurement of rolling central lines, control over tail sleeving of loops, controlover the rolling force and roll bending force, control over the time sequence of a water system, control over the rolling tonnage of working roller, and control over the temperature of plate blanks.By adoption of the control method, the problem of the horizontal-vibration linear offset of the tail of ultra-thin CPS materials is solved; the technical problem that the plate shape of the tail of ultra-thin strip steel rolled through a short process is difficult to control, and consequentially, tail whipping and instable production are caused is solved; and high-quality and high-stability large-scale production of the ultra-thin strip steel rolled through the short process is realized.

Owner:武汉钢铁有限公司

Concentrate grade adjusting device of drum magnetic separator

PendingCN112517240AIncrease productionHigh recovery rateElectrostatic separationMagnetic separationSlagMining engineering

The invention relates to a concentrate grade adjusting device of a drum magnetic separator, which comprises an ore feeding box of the drum magnetic separator, a separation groove, a permanent magnet separation drum, a concentrate box, a concentrate box ore discharge pipe, a tailing box, a tailing box ore discharge pipe and a control box, and is characterized in that a tailing conveying mechanism consisting of an ore separation pipe and an electric knife gate valve is arranged between the tailing box and the concentrate box, and a concentrate grade detection mechanism consisting of a sampler and an automatic grade instrument is arranged on the concentrate box ore discharge pipe; and the electric knife gate valve and the automatic grade instrument are electrically connected with the controlbox. The device has the advantages that the amount of the tailings fed into the concentrate box is controlled by controlling the opening degree of a valve of an ore distribution pipe of the tailing box, the grade of the concentrate is adjustable, the yield of the concentrate and the recovery rate of iron are increased, economic benefits are improved, the fluidity of slag during ironmaking is improved, and smooth operation of a blast furnace is facilitated.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

A method and system for adaptive temperature-controlled continuous rolling of magnesium alloys

ActiveCN108787762BGood for going straightHigh selectivityTemperature control deviceMeasuring devicesTemperature controlSelf adaptive

The invention discloses a self-adaptive temperature-control continuous rolling method for a magnesium alloy. The self-adaptive temperature-control continuous rolling method comprises the following steps of: (1) measuring an initial temperature and an initial thickness of a magnesium alloy plate strip, and obtaining and outputting a preset scheme according to the measured initial thickness and themeasured initial temperature, wherein the scheme at least comprises a preheating scheme and a rolling scheme of each rolling pass, and the rolling scheme at least comprises rolling passes and pre-pressing amount of each rolling pass; (2) rolling; and (3) completing rolling. The self-adaptive temperature-control continuous rolling method for the magnesium alloy disclosed by the invention measures the initial temperature and the initial thickness of the magnesium alloy plate strip; and a plate strip thickness measuring system is combined with a temperature measuring system, so that preset and real-time self-adaptive regulation is performed on the magnesium alloy plate strip rolling process by setting the preset scheme, and therefore, online temperature-control controlled rolling of the magnesium alloy plate strip is achieved. The method is beneficial for improving smooth performing of the rolling process and stabilizing product quality, and has the advantages of being less in manual intervention and realizing automatic production easily.

Owner:CHINA BAOWU STEEL GRP CORP LTD +1

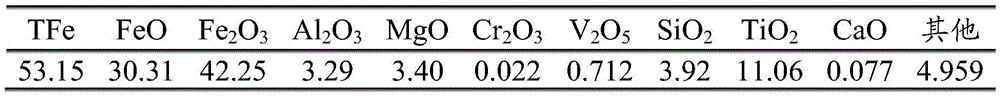

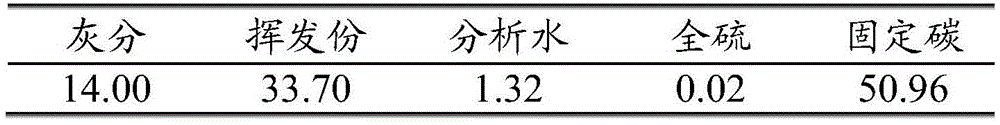

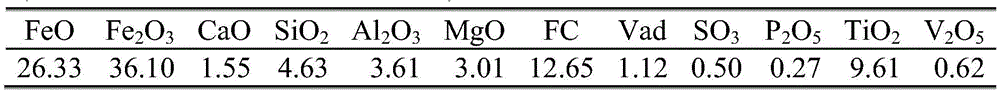

Preparation method of vanadium titanomagnetite hot briquette

ActiveCN103924066BRealize all-vanadium-titanium agglomerationAdaptableShaft furnaceTunnel kilnCarbonization

The invention discloses a method for preparing hot briquettes of vanadium titanium magnetite. The method includes the following steps: (a) crushing and screening vanadium titanium magnetite, coal powder and flux; (b) crushing and screening The final vanadium-titanium magnetite powder, coal powder and flux are calculated and proportioned according to the proportions of 60wt% ~ 80wt%, 20wt% ~ 40wt% and 0wt% ~ 10wt% respectively, and the prepared raw materials are fully mixed to prepare Obtain the first material; (c) heat the first material to a temperature of 100°C to 300°C, and use a hot pressing device to press it into a size of (20~40) mm × (15~30) mm The second material is ellipsoidal particles of ~1100℃, time is 5h~7h. The preparation method of vanadium-titanium magnetite hot briquetting according to the present invention has the characteristics of strong raw material adaptability, high production efficiency, low energy consumption, low cost, etc., and is helpful to improve the smelting level of vanadium-titanium magnetite in my country, and It has good market application prospects.

Owner:NORTHEASTERN UNIV LIAONING

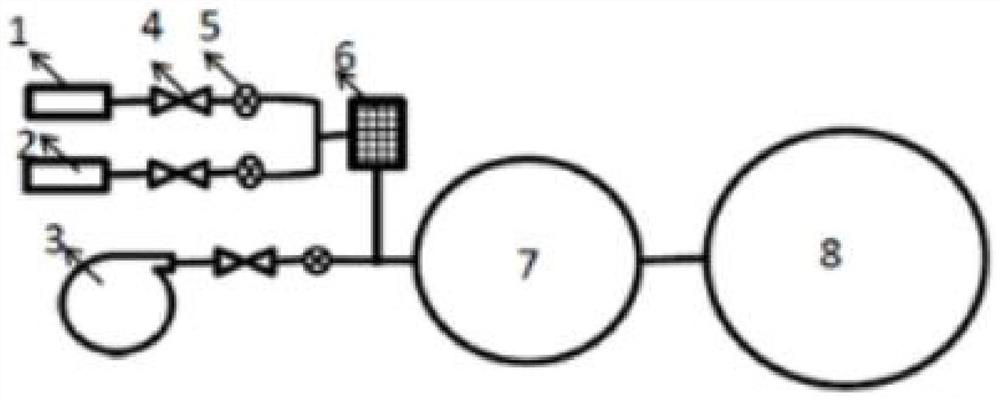

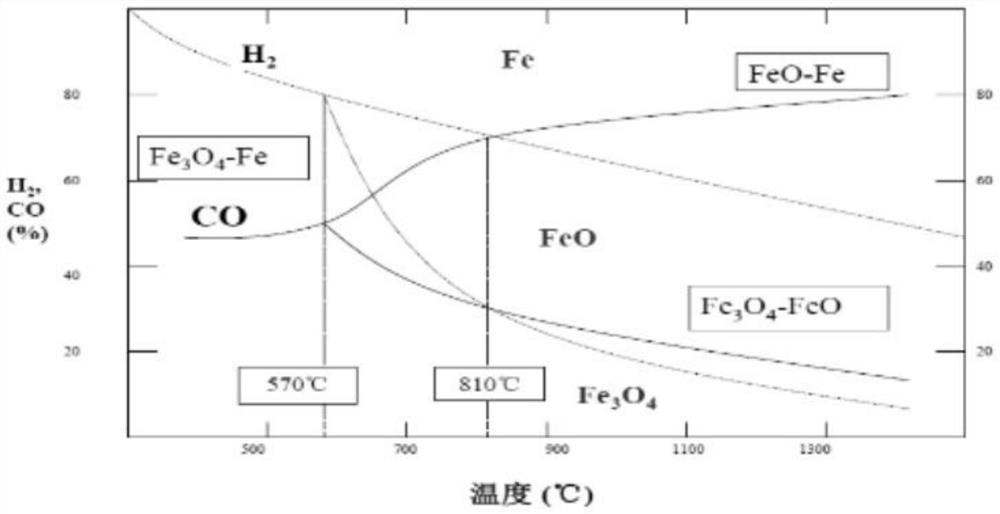

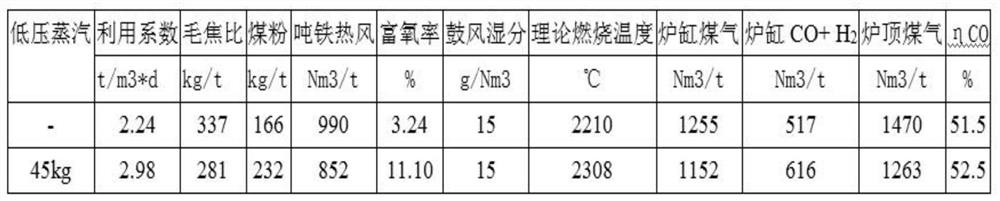

Blast furnace ironmaking technology and method utilizing waste heat steam

InactiveCN112176137AImprove utilization factorShorten smelting timeBlast furnace detailsExhaust gas handlingHot air ovenBlast furnace smelting

The invention discloses a blast furnace ironmaking technology and method utilizing waste heat steam, and relates to the technical field of iron and steel smelting. The blast furnace ironmaking technology and method utilizing the waste heat steam comprise a steam pipe network, an oxygen pipe network and an air blower; the steam pipe network and the oxygen pipe network communicate with a smoke heatexchanger through an automatic valve and an electronic flow meter in sequence; the air blower communicates with a hot blast stove through an automatic valve and an electronic flow meter; the smoke heat exchanger communicates with the hot blast stove; and the hot blast stove communicates with a blast furnace. According to the blast furnace ironmaking technology and method utilizing the waste heat steam, the utilization coefficient of the blast furnace is increased, and the production cost is reduced. Due to the kinetic and thermodynamic characteristics of H2 and CO reduced Fe2O3-Fe3O4-FeO-Fe, the width of an indirect reduction zone is increased, the reduction speed is increased, a high-temperature zone moves downwards, low-temperature reduction pulverization is reduced, the breathability ofraw materials is improved, the blast furnace smelting time is shortened, smooth operation of the blast furnace is facilitated, and the utilization coefficient of the blast furnace is increased.

Owner:MAANSHAN IRON & STEEL CO LTD

Grade-adjustable cylindrical magnetic separator

PendingCN112439547AIncrease productionIncrease contentElectrostatic separationMagnetic separationMagnetiteMagnetic separator

The invention relates to a grade-adjustable cylindrical magnetic separator, which comprises an ore feeding box, a separation groove, a separation cylinder, a concentrate box, a concentrate box ore discharge pipe, a tailing box, a tailing box ore discharge pipe and a control box of the cylindrical magnetic separator, and is characterized in that a full-length separation plate is arranged on the tailing box, and a liquid level meter is arranged above a left side box body; a tailing discharging opening of the separation groove is inserted into the right side box body, two long-strip-shaped ore separation openings are formed in a right side plate of the right side box body in a bilateral symmetry mode, two long-strip-shaped ore inlets are formed in a left side plate of the concentrate box, andthe two long-strip-shaped ore inlets are communicated through an ore separation horizontal groove; gate valve clamping grooves are formed in the two ends of the right side box body, a supporting steel beam is arranged at the top of the tailing box, and a gate valve mechanism is arranged between the clamping grooves and the right side plate. The grade-adjustable cylindrical magnetic separator tailings mixed into the concentrate box is controlled by controlling the opening degree of the ore separation opening of the tailing box, so that the grade of concentrate is adjustable, and finally, the grade of high-quality magnetic separation concentrate of single magnetite is controlled to be 68%-69%.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

A Classification Control Method of Blast Furnace Tuyere Coke Particle Size

ActiveCN106154868BAvoid blindnessBreak through the technical bottleneck of precise particle size classificationProgramme control in sequence/logic controllersSlagQuality control

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

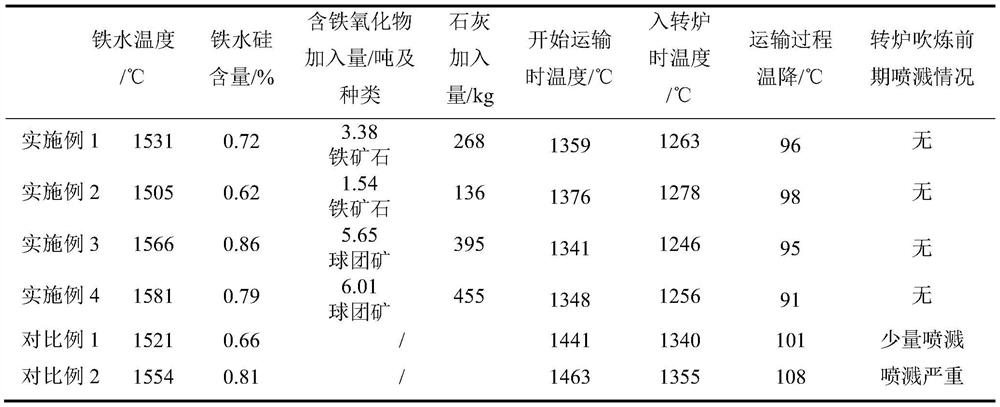

Treatment method of high-temperature high-silicon molten iron

The invention discloses a treatment method of high-temperature high-silicon molten iron, and relates to a ferrous metallurgy technology. The treatment method of the high-temperature high-silicon molten iron is characterized in that iron-containing oxide is added before a ladle or a torpedo ladle receives the high-temperature high-silicon molten iron, and the iron-containing oxide comprises sintered ore, pellet ore and oxide scale, so that the temperature of the molten iron is reduced, and the purpose of reducing the heat dissipation capacity of the molten iron in the conveying process is achieved; when the ladle or the torpedo ladle receives the molten iron, 100-500 kg of lime is added in order to restrain foam slag from overflowing, the particle size range of the lime is 10-20 cm, and therefore splashing caused by rapid rising of the temperature of a molten pool in the early stage of converter blowing is avoided. By reasonably reducing the temperature of the high-temperature high-silicon molten iron, blowing in the earlier stage of the converter blowing is stable, smooth operation of the converter working procedure is facilitated, and the problems that the high-temperature high-silicon molten iron is large in heat loss, and the converter blowing is difficult to stably carry out are solved.

Owner:MAANSHAN IRON & STEEL CO LTD

A kind of ore ball mixing method

ActiveCN111763790BReduce scrollingPrevent moving upBlast furnace detailsProcess efficiency improvementSlagProcess engineering

Owner:XINXING DUCTILE IRON PIPES CO LTD

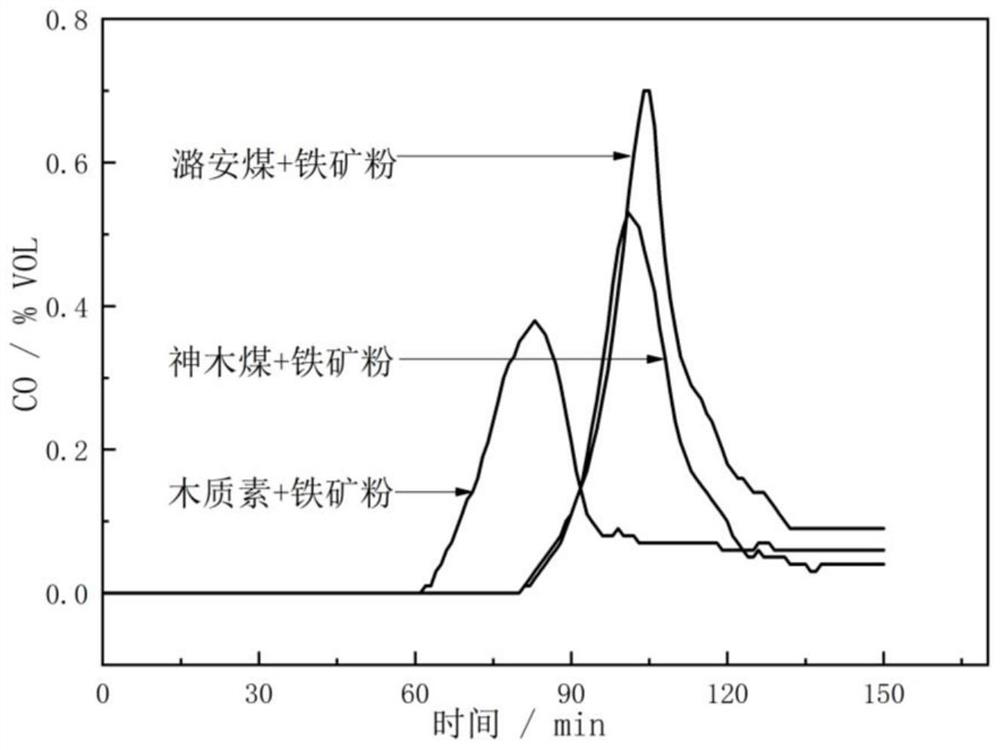

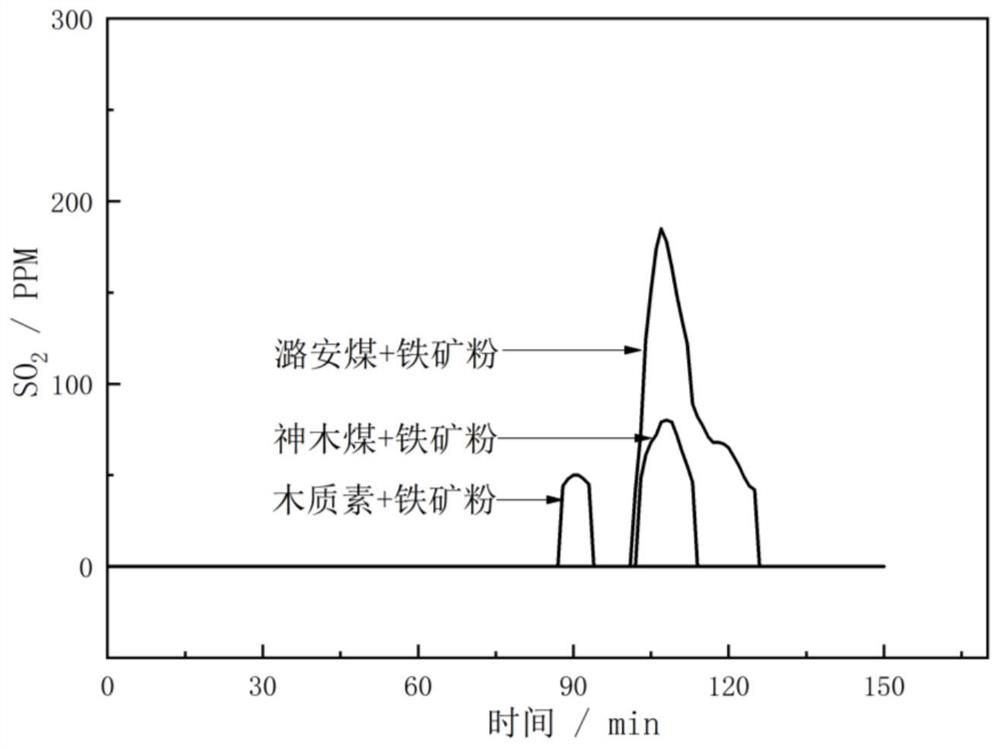

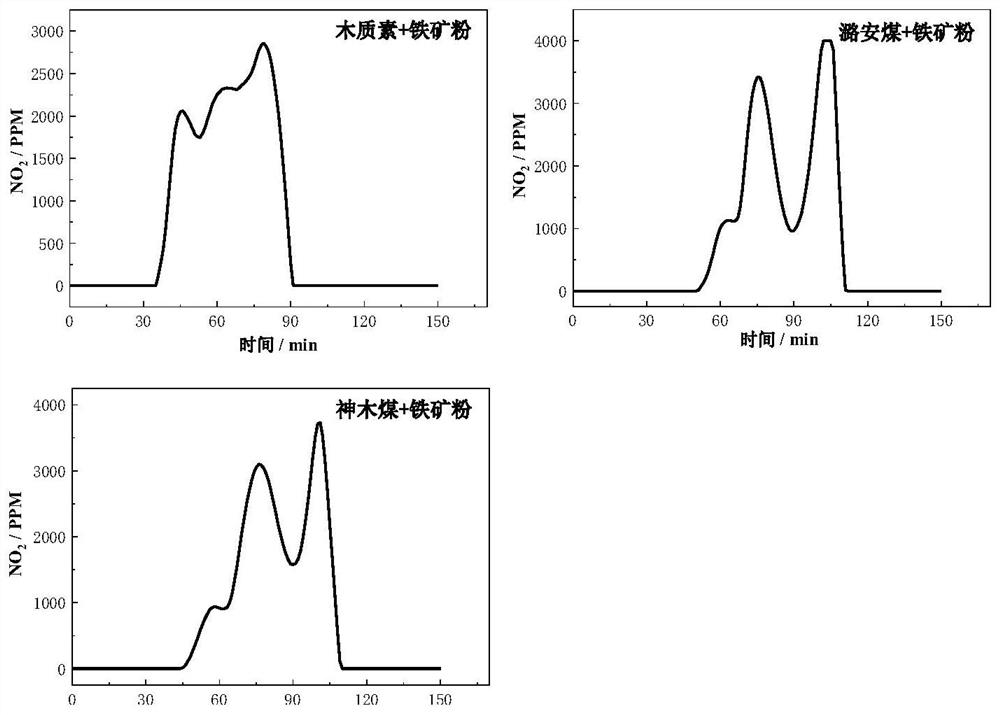

A kind of method adopting lignin as reducing agent to produce direct reduced iron

InactiveCN110387445BIncrease productionEfficient removalFluidised-bed furnacesProcess engineeringEnvironmental engineering

The invention relates to the technical field of ironmaking, in particular to a method for producing direct reduced iron by using lignin as a reducing agent. The invention provides a method for preparing direct reduced iron with energy saving and environmental protection, simple process and high production efficiency, and the method meets the requirements of low energy consumption, low cost and environmental protection in iron and steel production.

Owner:NORTHEASTERN UNIV LIAONING +2

Control Method for Eliminating Transverse Vibration Line Offset at Tail of Thin Strip in Short Process

ActiveCN110355216BSolve the problem of horizontal vibration line offsetQuality improvementRare end control deviceMetal rolling arrangementsTemperature controlStructural engineering

The invention discloses a method for eliminating a horizontal-vibration linear offset of the tail of short-process thin strip steel. The control method can eliminate the horizontal-vibration linear offset of the tail of short-process thin strip steel by control over centering of guide plates of rolling mills through measurement of rolling central lines, control over tail sleeving of loops, controlover the rolling force and roll bending force, control over the time sequence of a water system, control over the rolling tonnage of working roller, and control over the temperature of plate blanks.By adoption of the control method, the problem of the horizontal-vibration linear offset of the tail of ultra-thin CPS materials is solved; the technical problem that the plate shape of the tail of ultra-thin strip steel rolled through a short process is difficult to control, and consequentially, tail whipping and instable production are caused is solved; and high-quality and high-stability large-scale production of the ultra-thin strip steel rolled through the short process is realized.

Owner:武汉钢铁有限公司

Blast furnace chute polycyclic distributing method

InactiveCN101250602BIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

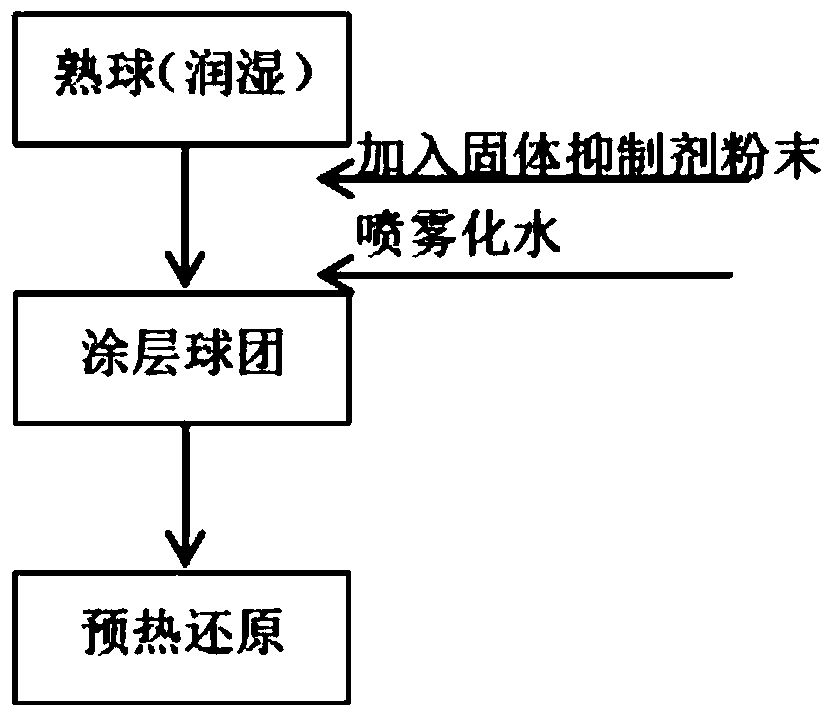

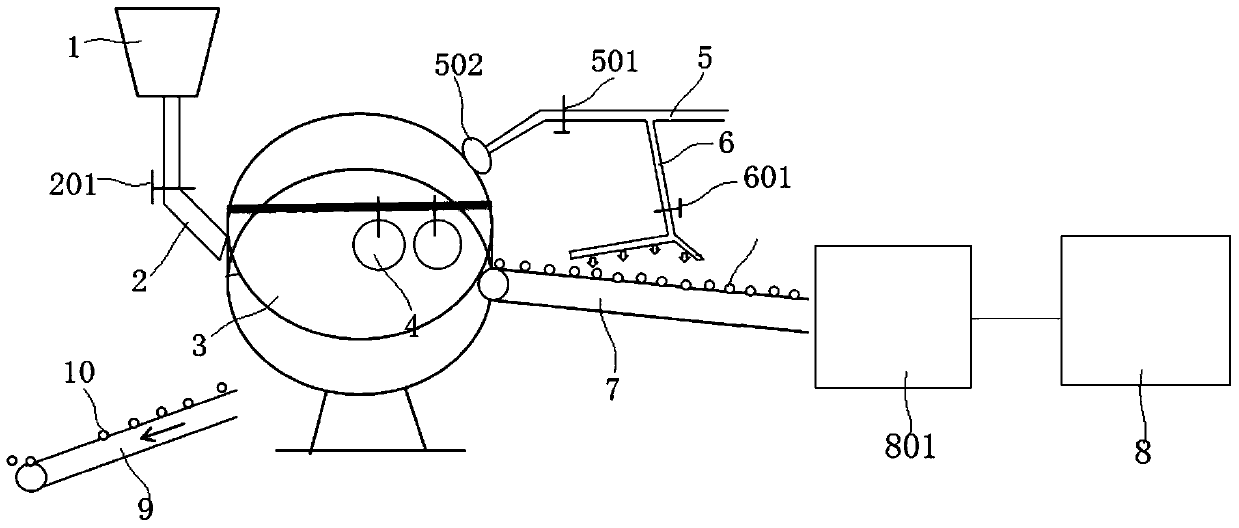

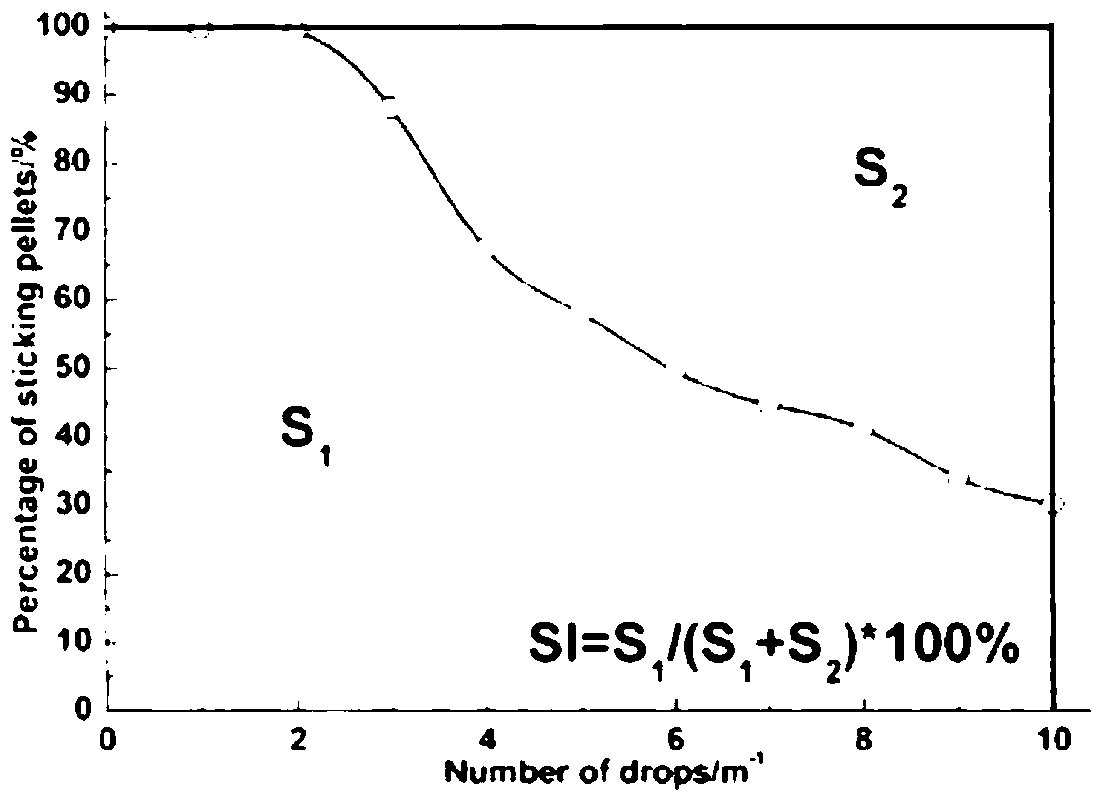

A method of suppressing pellet sticking in corex shaft furnace

The invention discloses a method for inhibiting bonding of pellets in a COREX shaft furnace and belongs to the technical field of melt reduction ironmaking. The method comprises (1) roasting green pellets to obtain finished products of oxidized pellets, (2) placing the roasted oxidized pellets into a disc pelletizer, spraying water to wet the pellets, carrying out rotation of the pelletizer along with addition of solid inhibitor powder and spraying of a certain amount of water so that the pellets are uniformly coated with solid inhibitor layers and coated pellets are prepared, and (3) drying the coated pellets, adding the coated pellets into a load reduction furnace and carrying out reduction at a reduction gas temperature of 800-950 DEG C. The method can effectively improve the problem of the agglomeration of the pellets in the COREX shaft furnace process, is beneficial to smooth production of the pre-reduction furnace, improves utilization efficiency of the COREX shaft furnace, and reduces a direct reduction iron production cost. The reduced pellets have a bonding index less than 25%.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A production method and system for magnesium alloy continuous extrusion temperature control continuous rolling

ActiveCN108787779BQuality improvementGood for going straightTemperature control deviceRollsTemperature controlContinuous rolling

The invention discloses a magnesium alloy continuous extrusion and temperature controlled continuous rolling production method. The method includes the following steps: (1) extruding magnesium alloy billet into magnesium alloy plates and strips; (2) measuring initial temperature and initial thickness of the magnesium alloy plates and strips, and obtaining and inputting a preset scheme according tothe measured initial temperature and initial thickness, wherein the scheme at least includes a preheating scheme and a rolling scheme for rolling passes and the rolling scheme at least includes the rolling passes and pre-press quantity of the rolling passes; (3) rolling; and (4) completing the rolling. The magnesium alloy continuous extrusion and temperature controlled continuous rolling production method adopts a rolling method of combining the continuous extrusion and on-line temperature controlled rolling, realizes the efficient continuous operation of the continuous extrusion and temperature controlled rolling process of the magnesium alloy billet through adaptive control of the extrusion and rolling process of the magnesium alloy billet, and matches real-time state of the plates andstrips, which is beneficial to improve the smoothness of the rolling process and the stability of the product quality.

Owner:CHINA BAOWU STEEL GRP CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com