Blast furnace chute polycyclic distributing method

A multi-ring cloth and chute technology, applied in blast furnace, blast furnace details, blast furnace parts, etc., can solve the problems of cloth segregation and pile tip that cannot be solved, it is difficult to ensure normal feeding line operation, and the central coke distribution is uneven. Achieve the effect of improving the utilization rate of gas, increasing the anti-fluctuation ability, and reducing the comprehensive coke ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

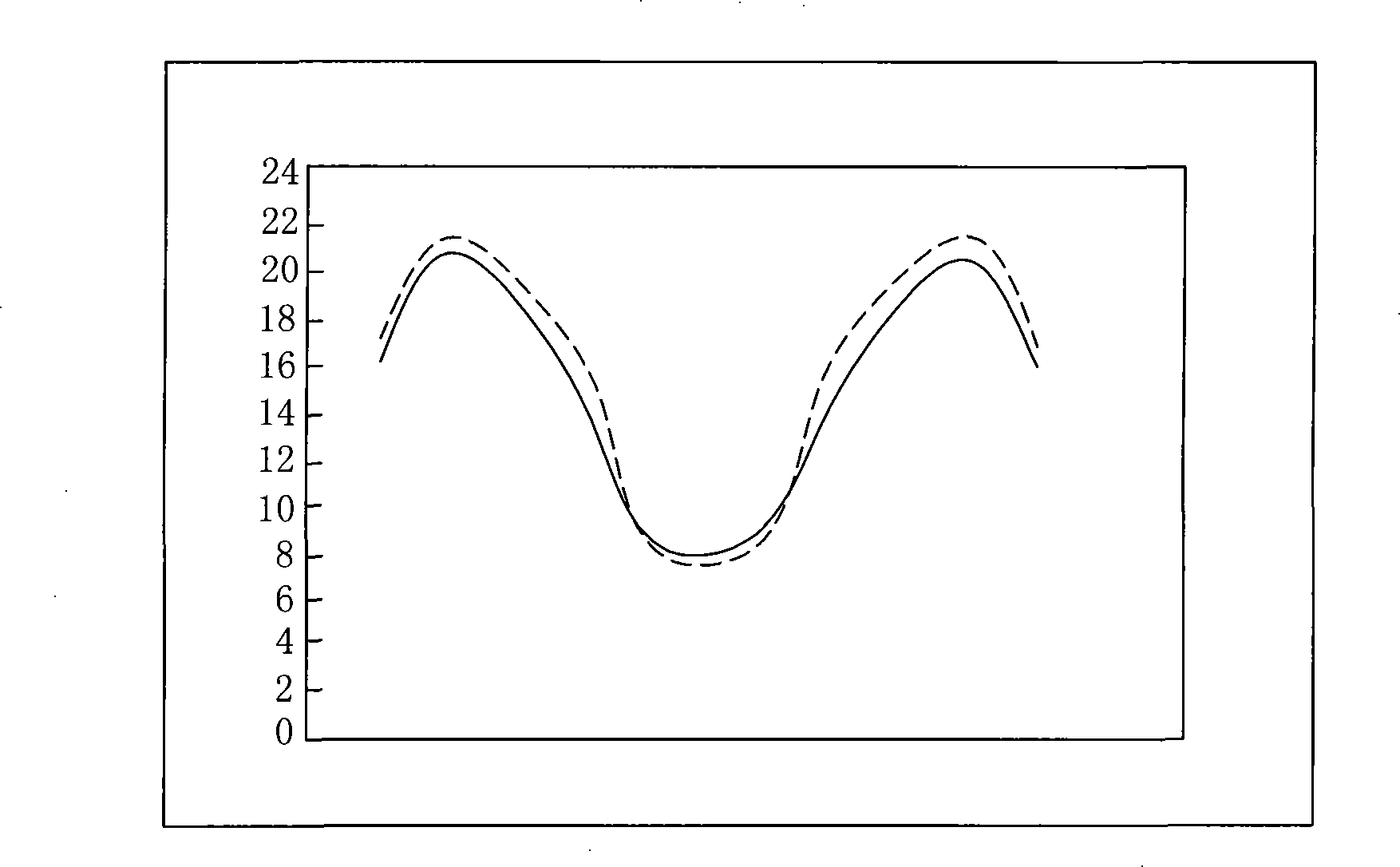

[0055] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

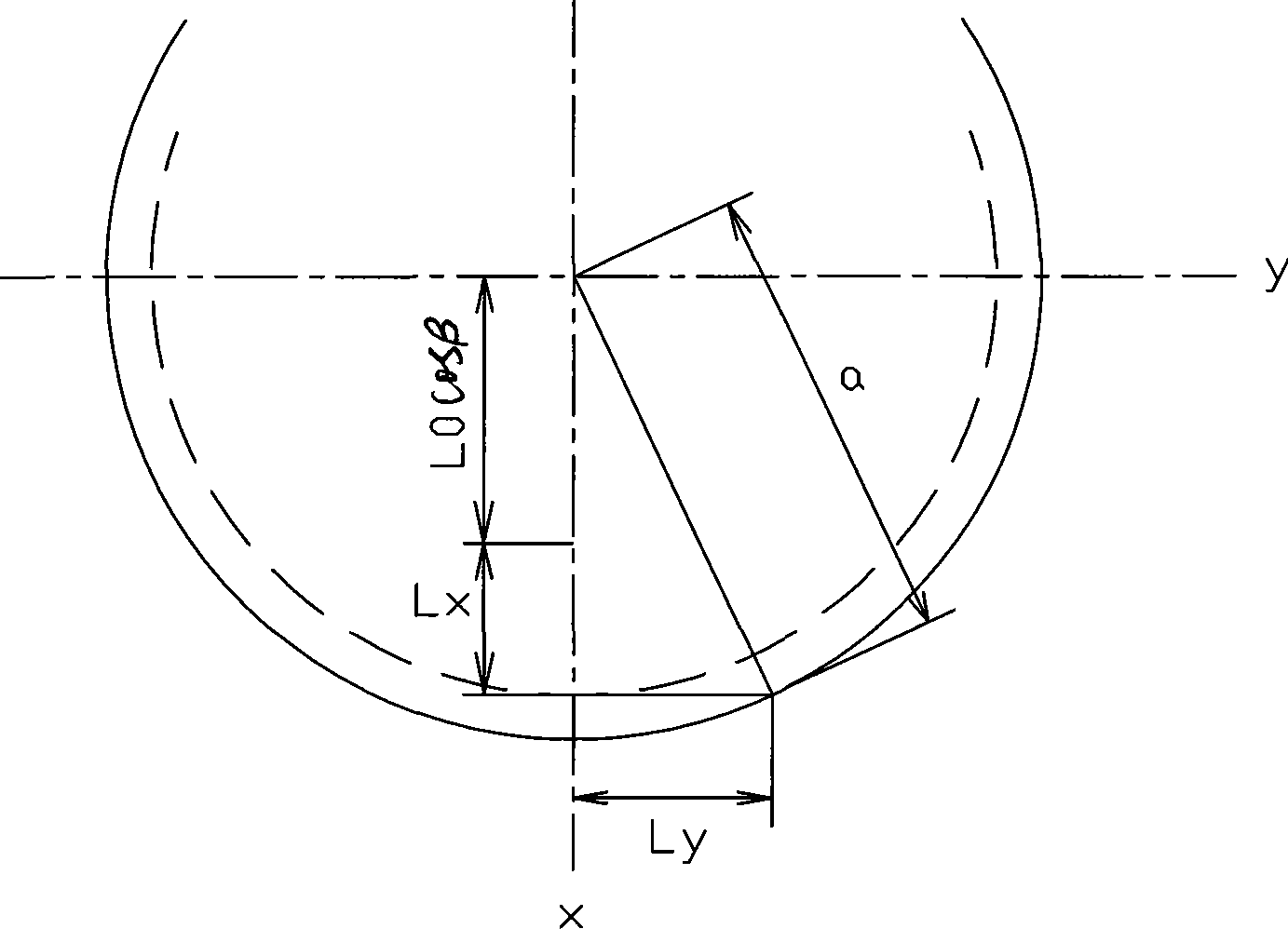

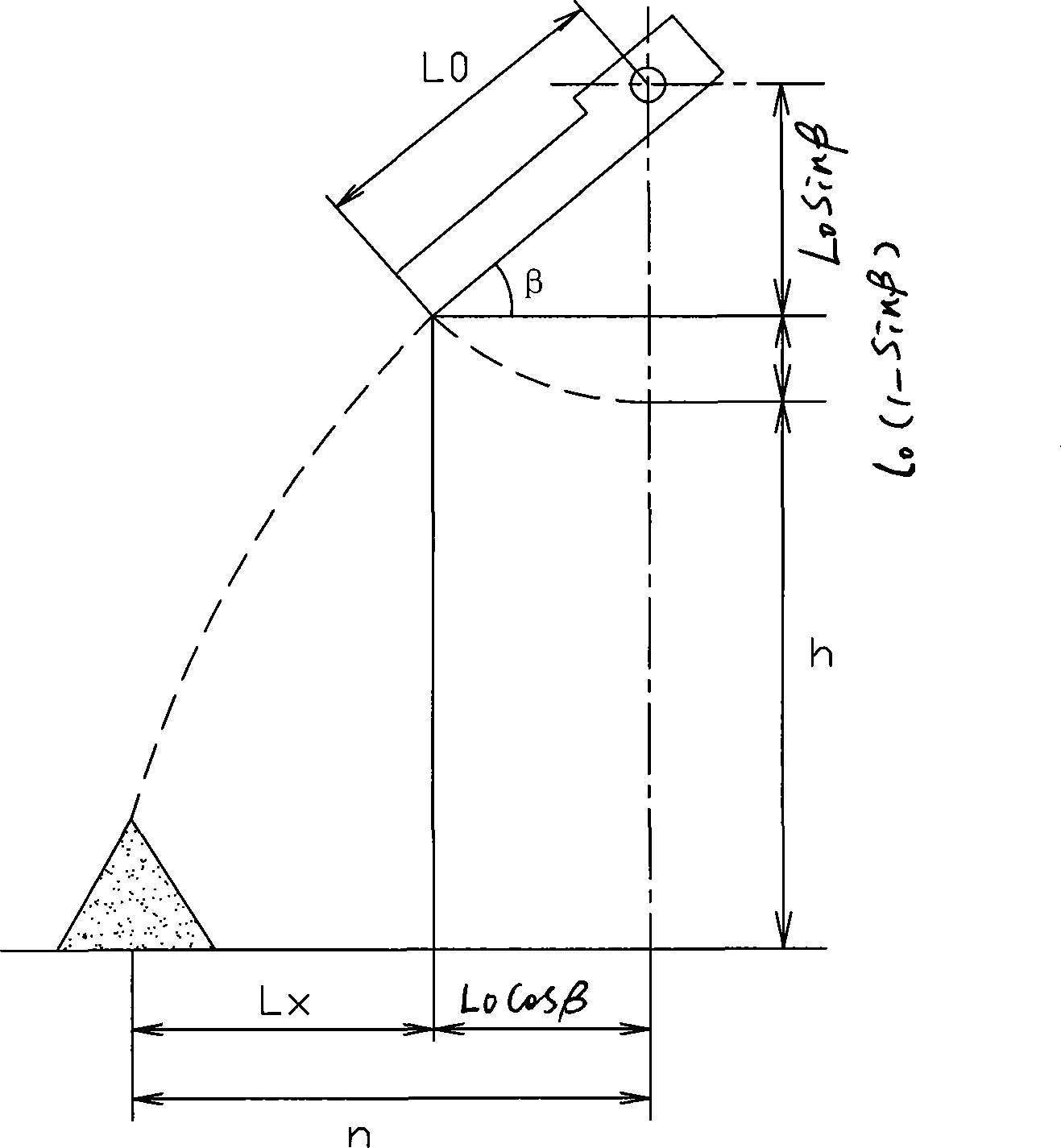

[0056] Some specific parameters that may be involved in the blast furnace of this embodiment: furnace throat diameter d1=5.5m, chute length l 0 =2.25m, charge friction coefficient u=0.42, chute speed ω=0.2 circle / second, e value chute tilting distance 0.622m, material line 1.0m.

[0057] The specific steps of the blast furnace chute multi-ring distributing method are as follows:

[0058] (1) Deriving the unified cloth equation

[0059] (1) Calculate the initial velocity C before the charge falls into the chute 0 '

[0060] C 0 ′ = λ · 3.2 gr r = D ′ - b ′ 4 = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com