Patents

Literature

71results about How to "Rich adjustment means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

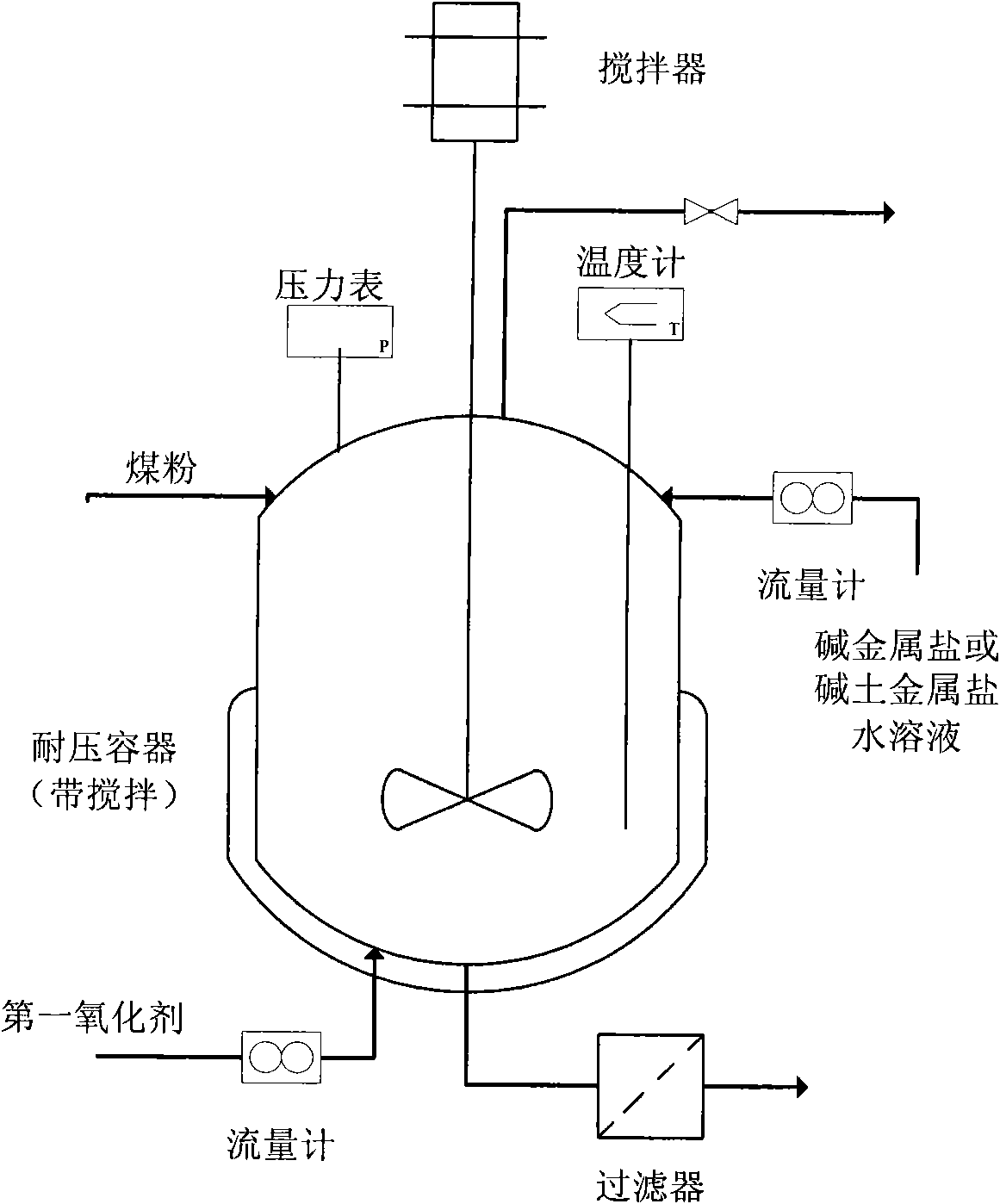

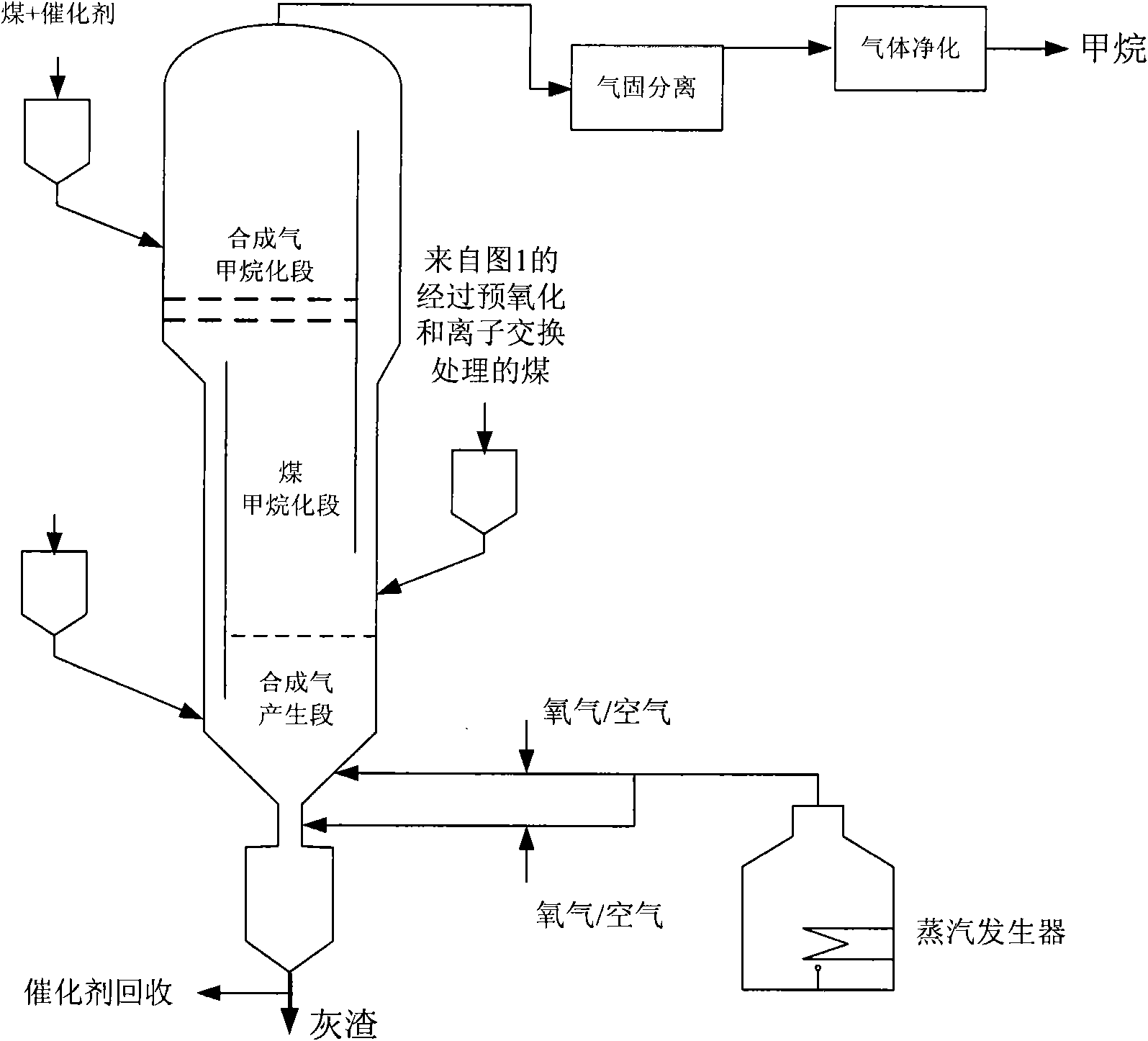

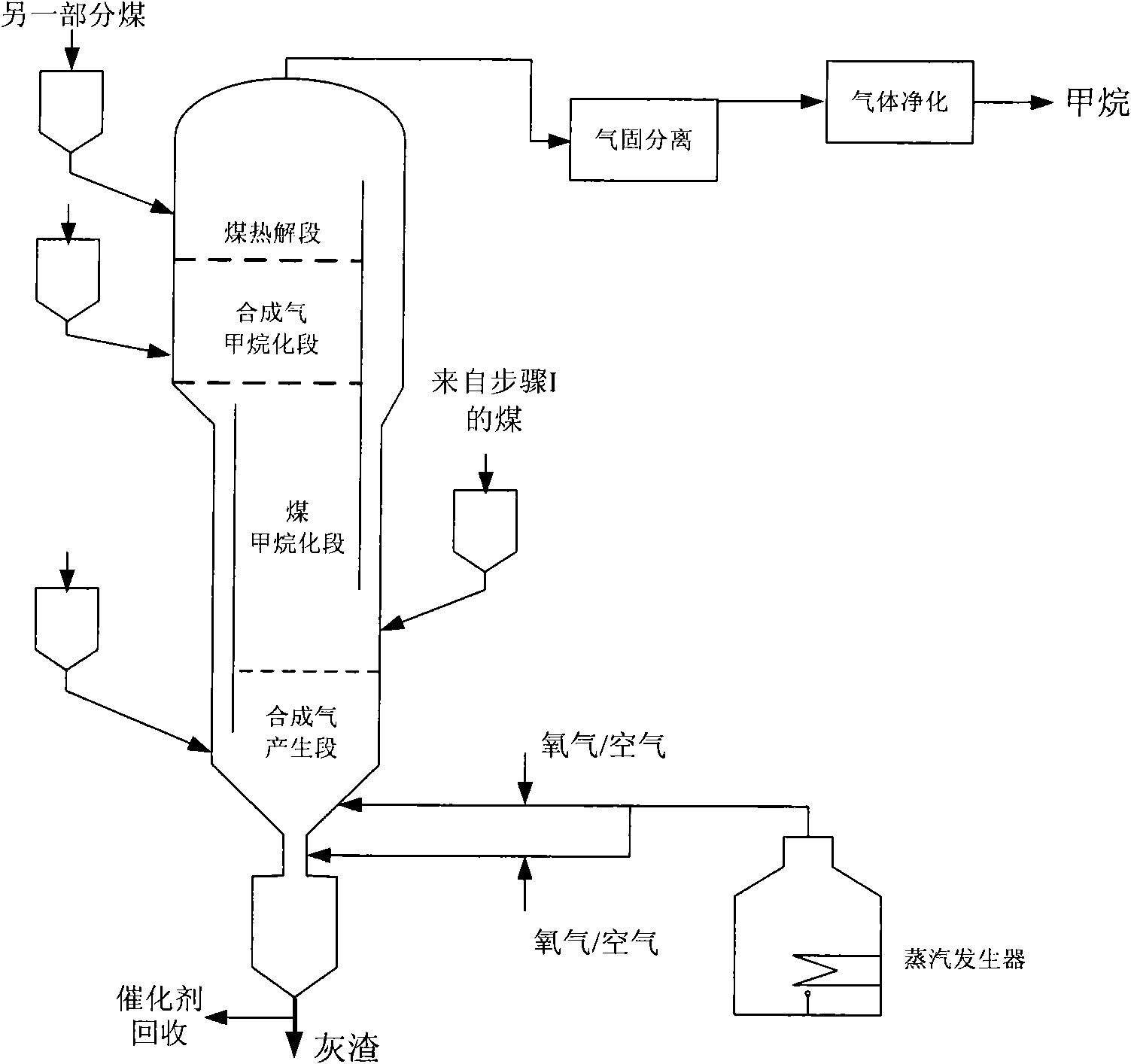

Method for preparing methane by catalyzing and gasifying coal

ActiveCN102465047AIncrease the amount of chemical bindingDoes not affect movement characteristicsHydrocarbon from carbon oxidesGaseous fuelsMethanationIon exchange

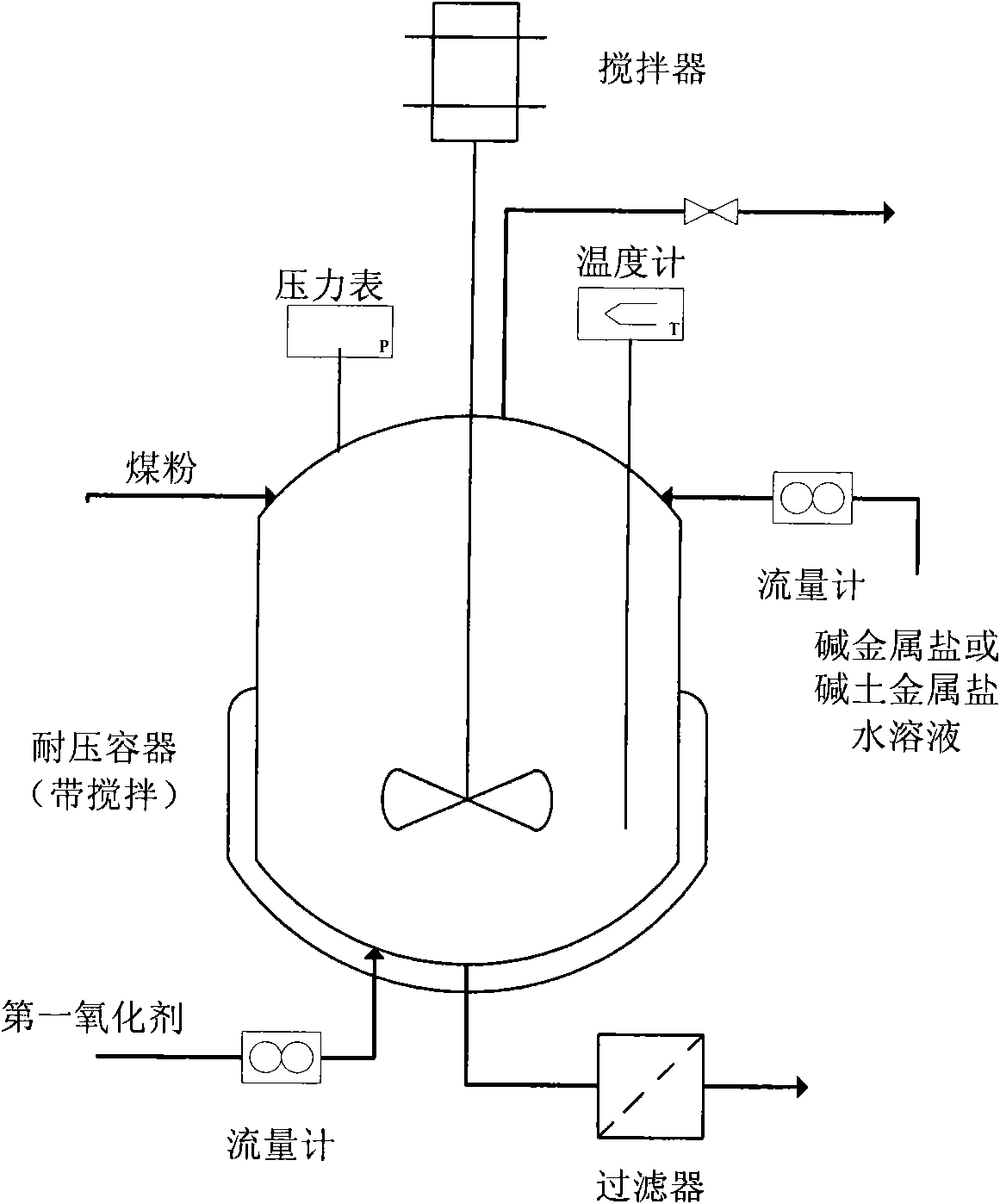

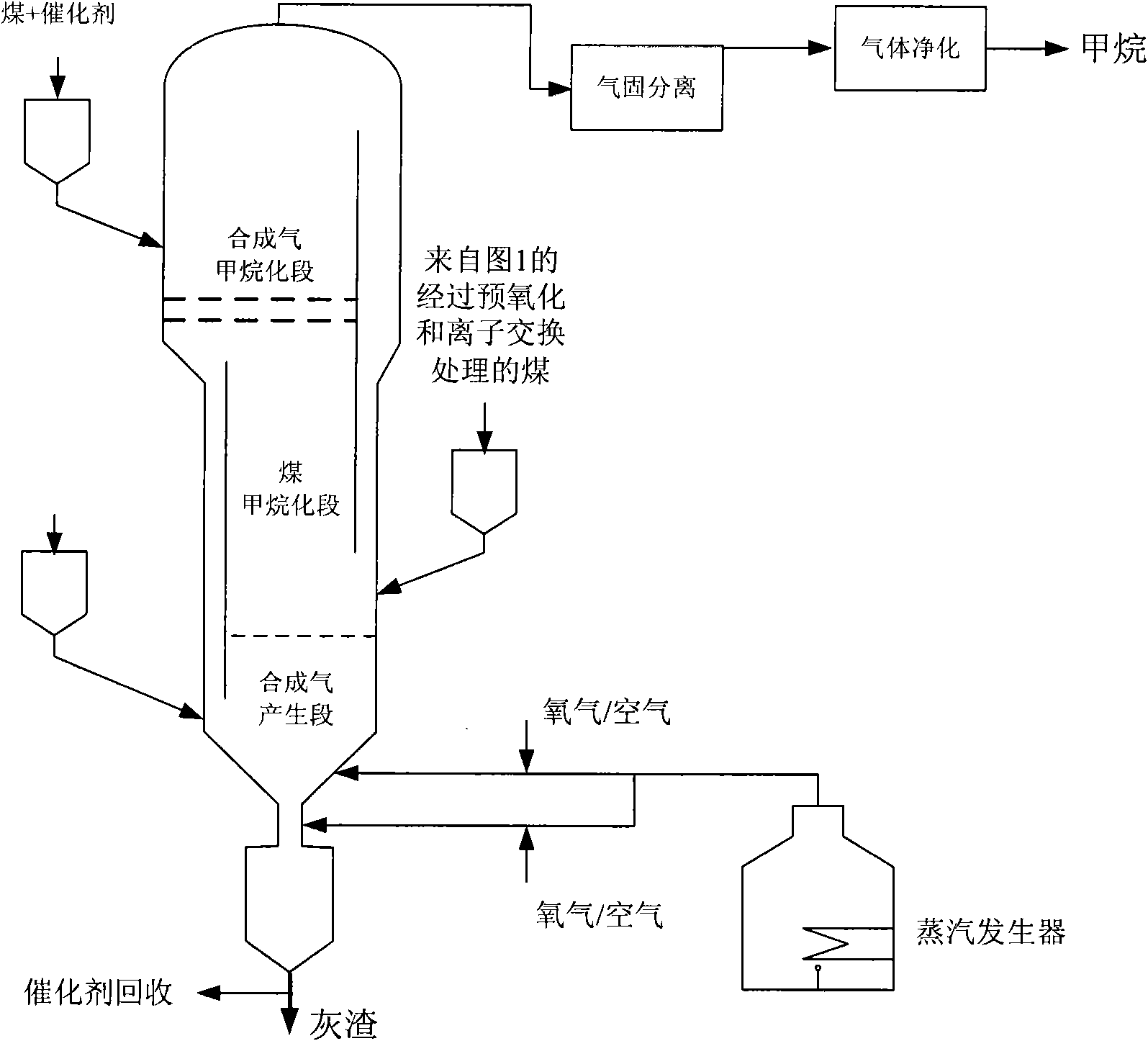

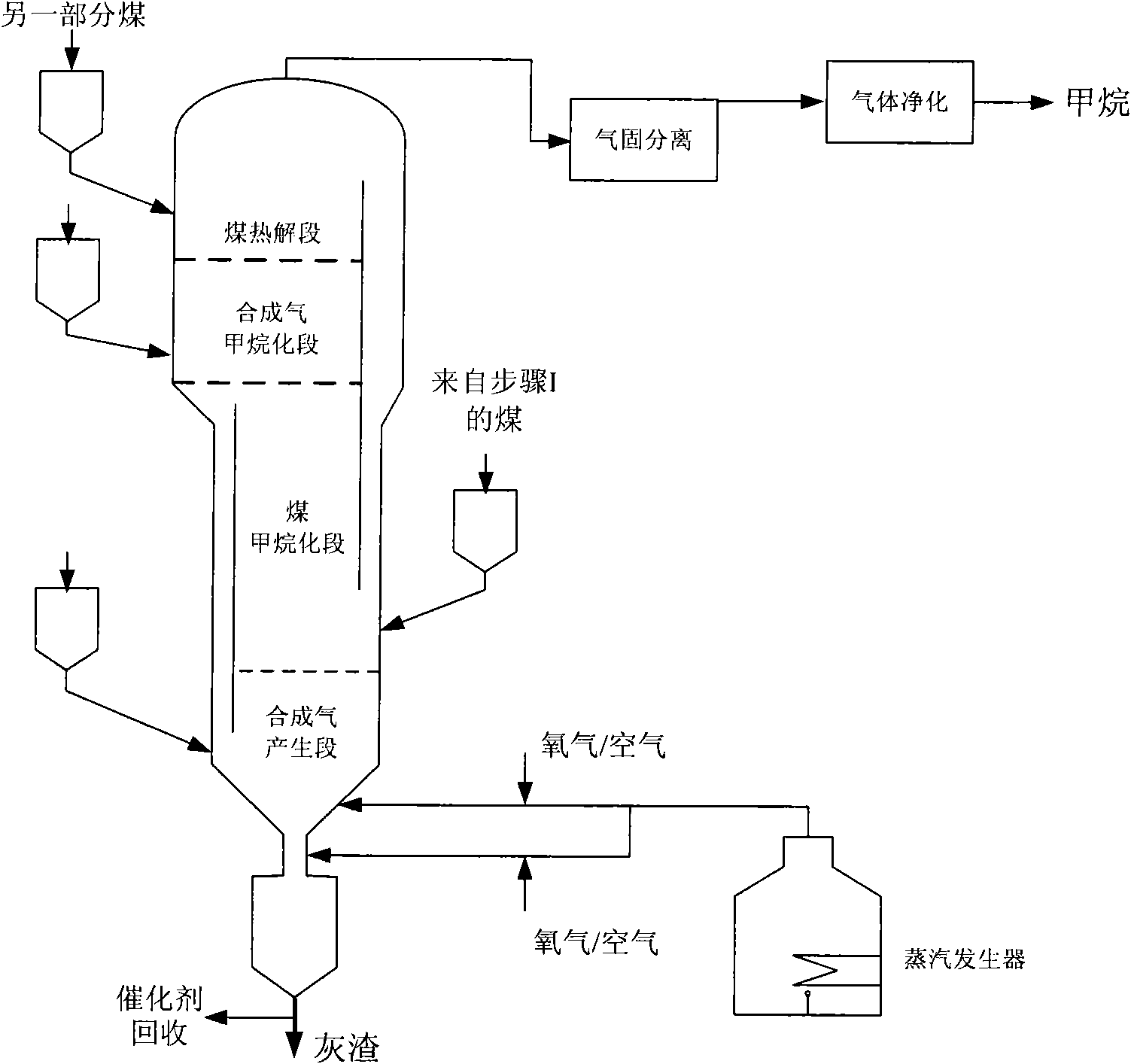

The invention relates to a method for preparing methane by catalyzing and gasifying coal. The method sequentially comprises the following two steps: 1, successively or simultaneously carrying out preoxidation and ion exchange treatment on coal in a slurry containing coal and water; and 2, gasifying the product obtained in step 1 by sending it to a gasification furnace which sequentially comprises a gas generation segment, a coal methanation segment, a synthetic gas methanation segment and an optional coal pyrolysis segment from bottom to top to obtain a gas product containing methane.

Owner:ENN SCI & TECH DEV

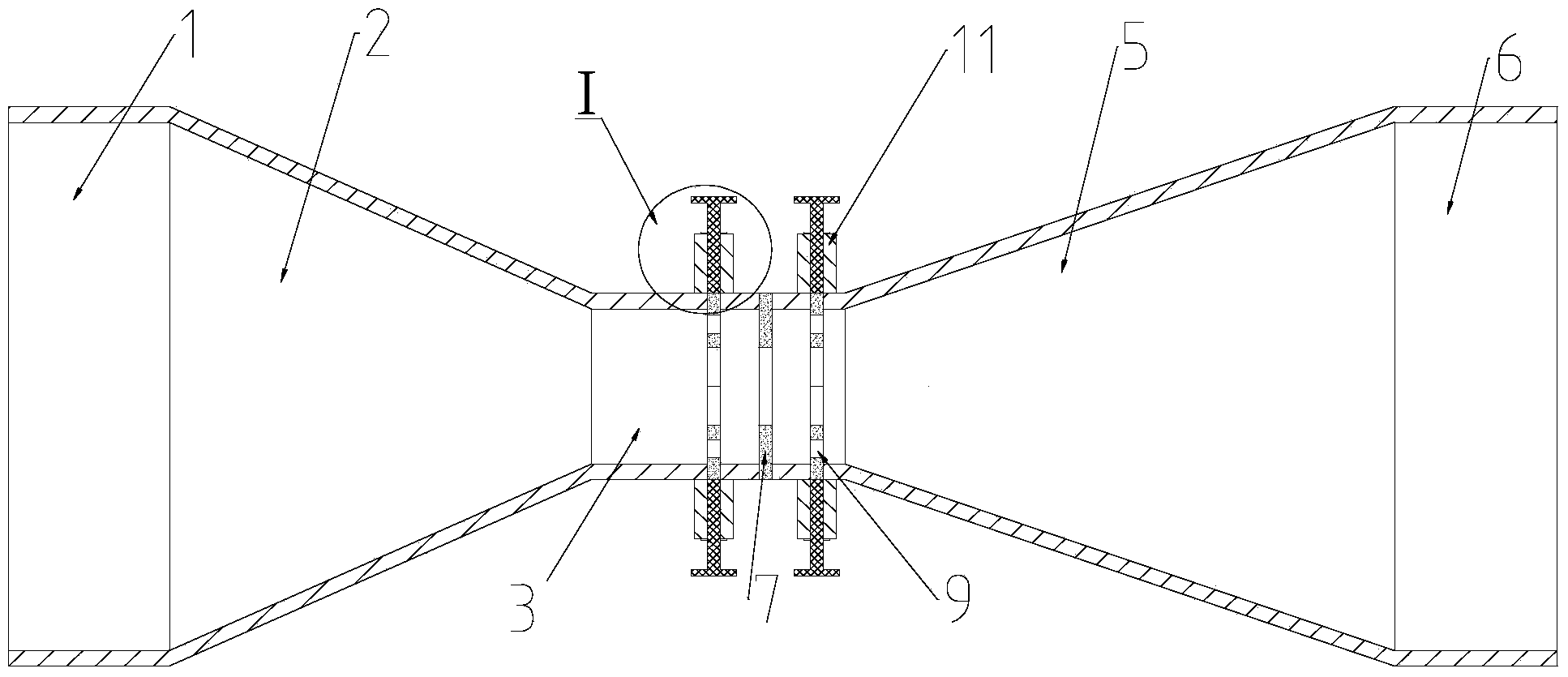

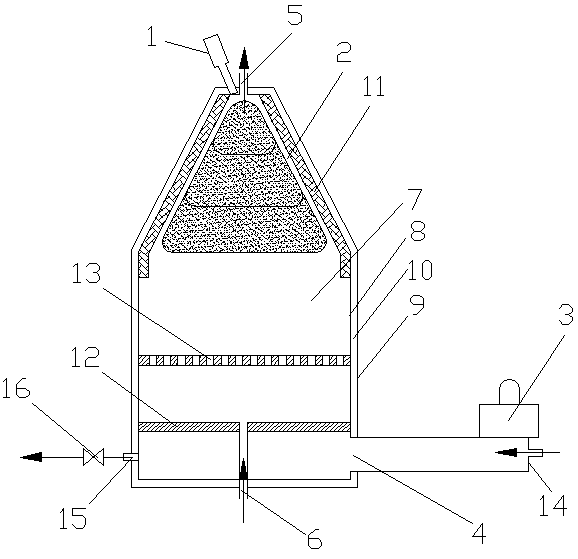

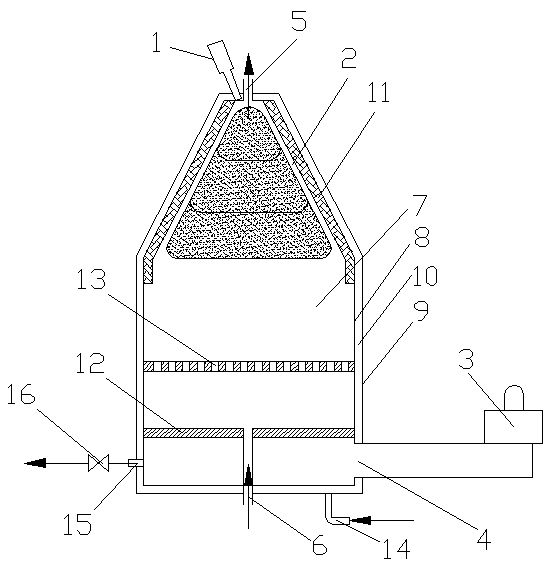

Blast furnace chute polycyclic distributing method

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

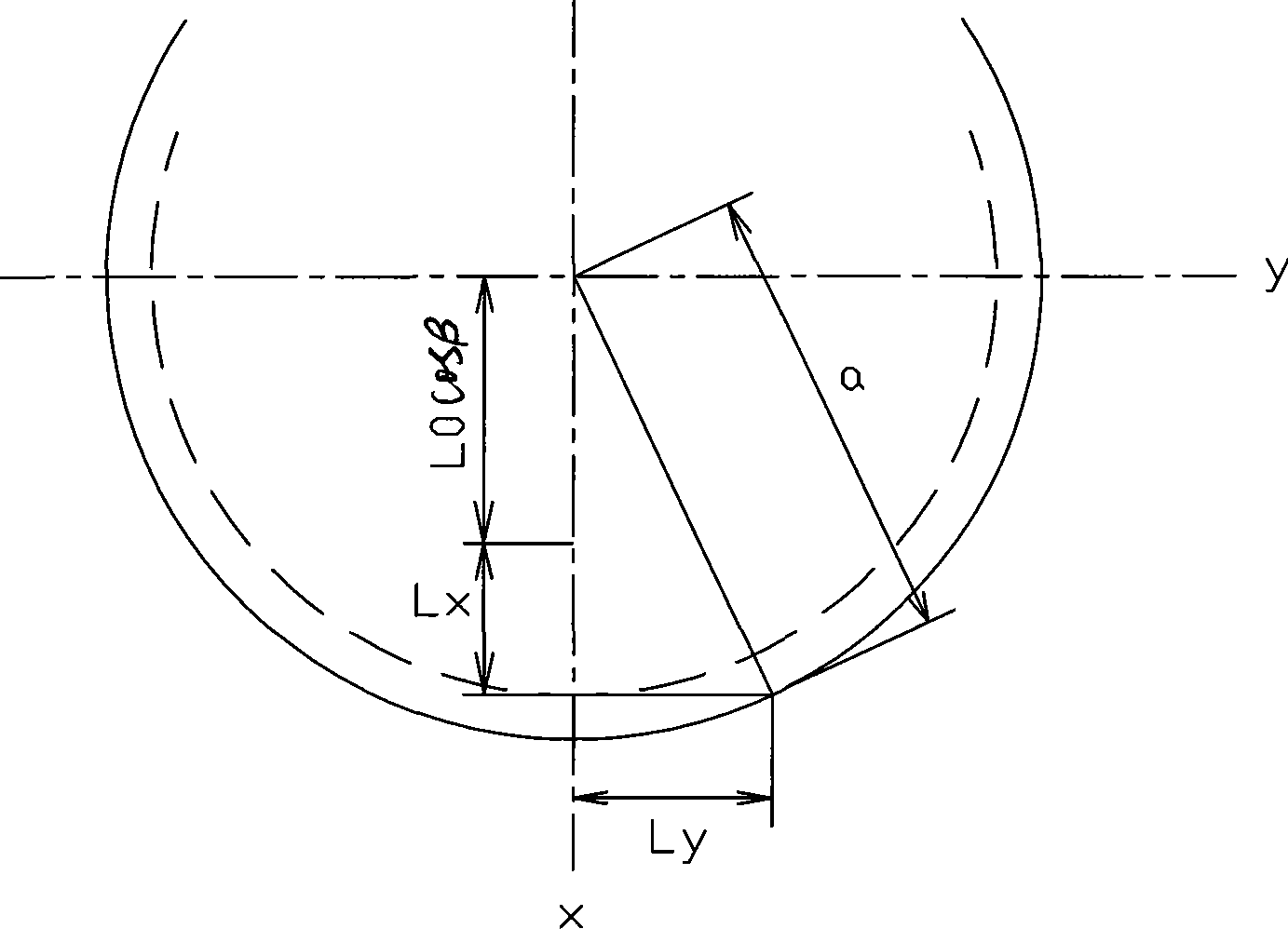

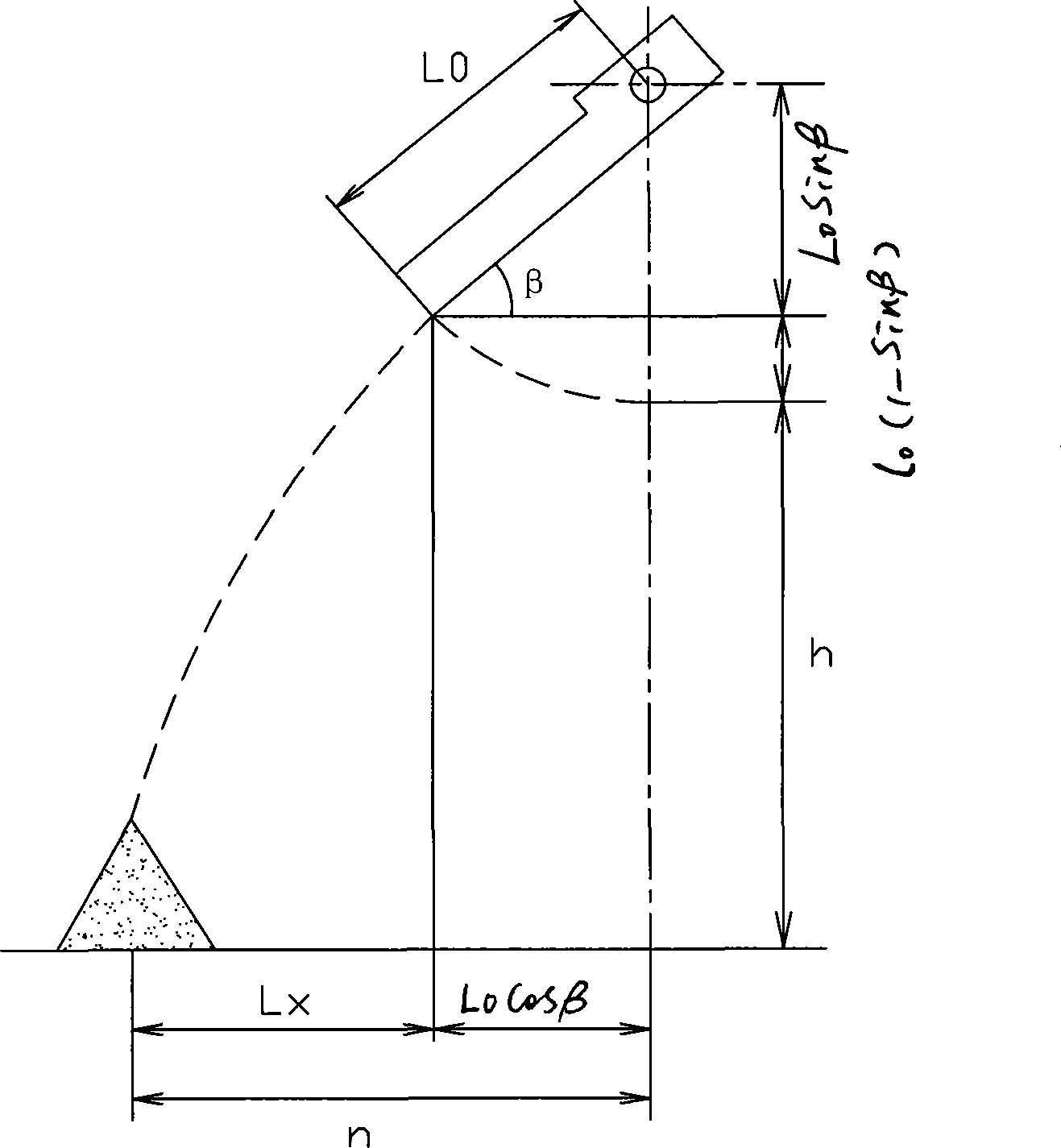

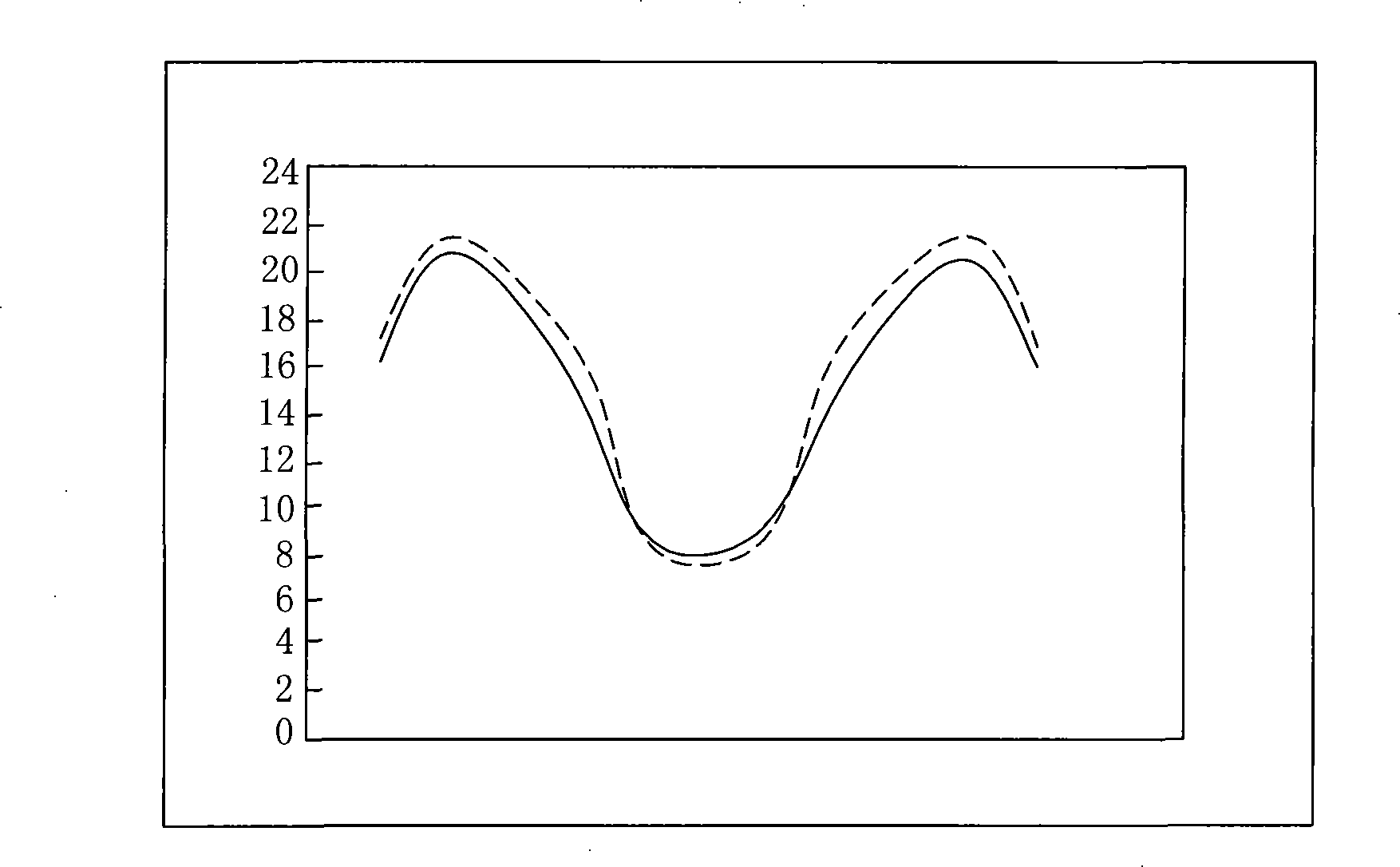

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

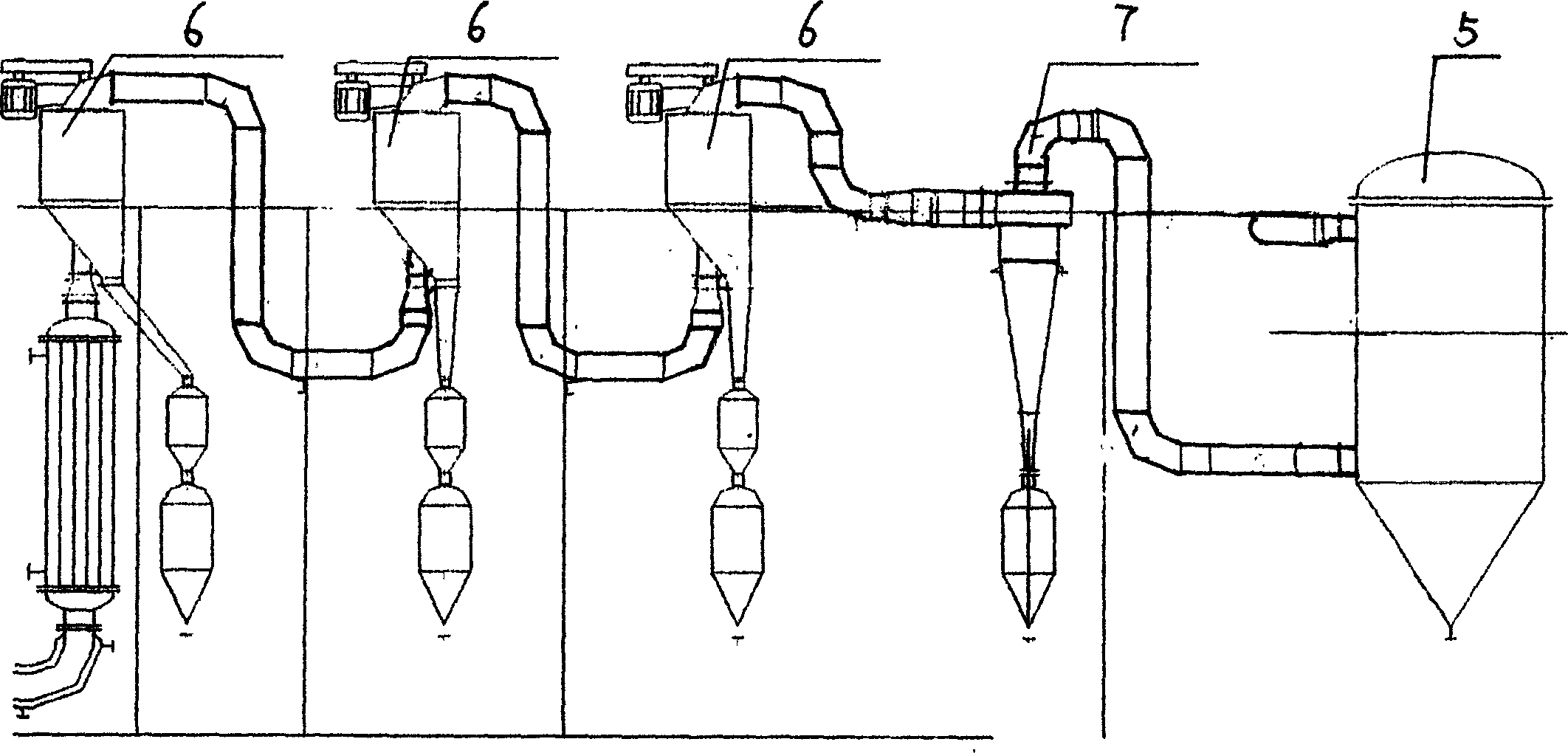

Production technology of two-nozzle atomization aluminium powder

The double nozzle atomizing aluminum powder production process includes the following steps: smelting aluminum ingot in aluminum smelting furnace with two heating silicon carbon rods, atomizing the liquid aluminum in double nozzle atomizing chamber, blowing high temperature and high pressure nitrogen with air compressor into the atomizing chamber to cooling liquid aluminum into aluminum grains, grading in a grading system comprising three stages centrifugal grading machine and one cyclonic collector, and circulating through a circulating system comprising double balance tank and double blower. The present invention has greatly raised production capacity, saving in investment and low production cost.

Owner:鞍钢实业微细铝粉有限公司

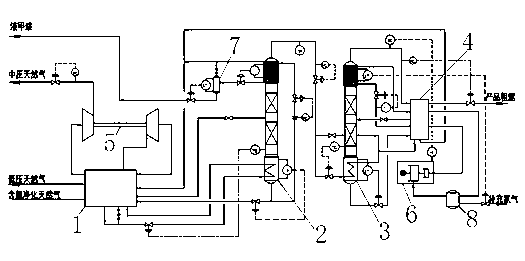

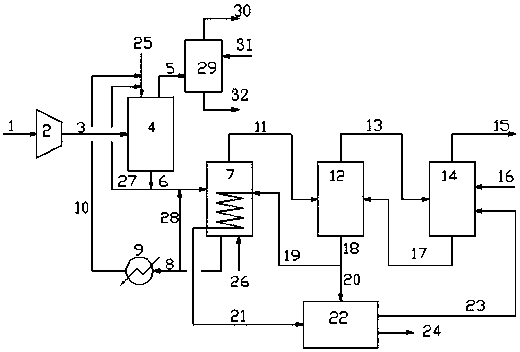

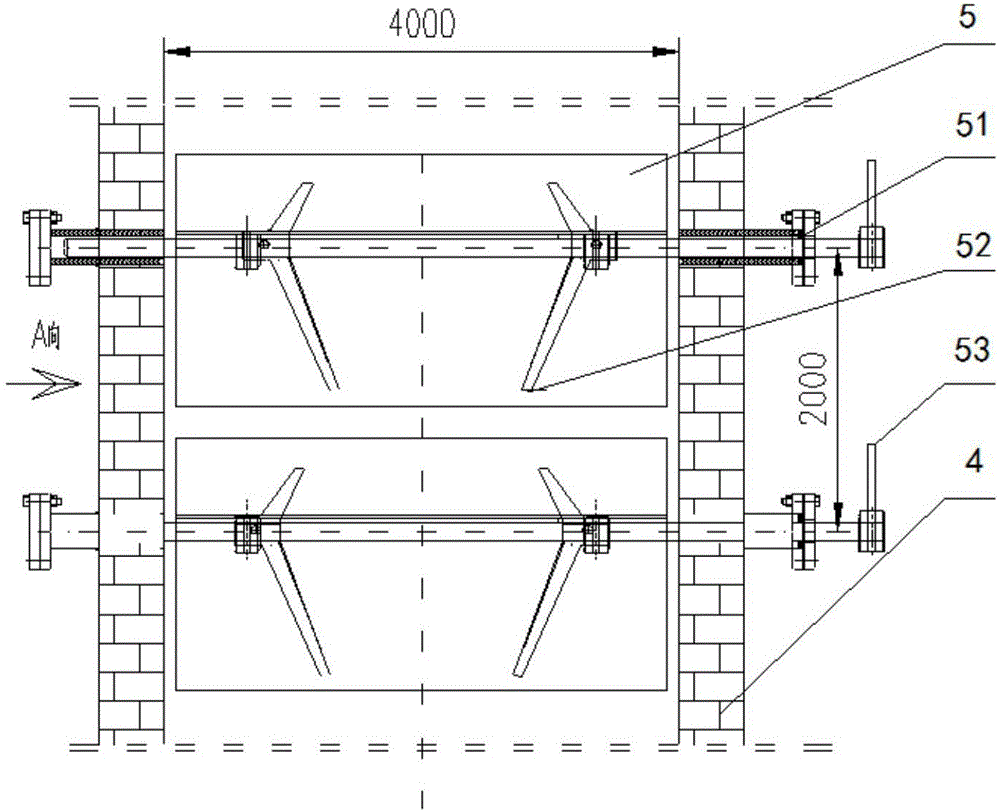

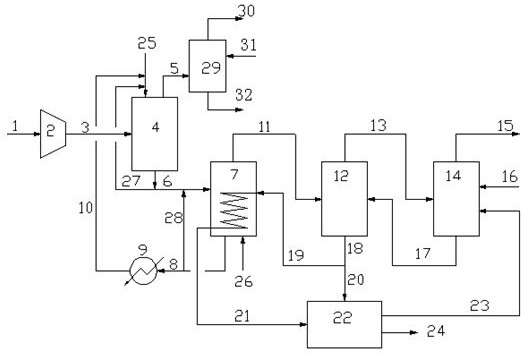

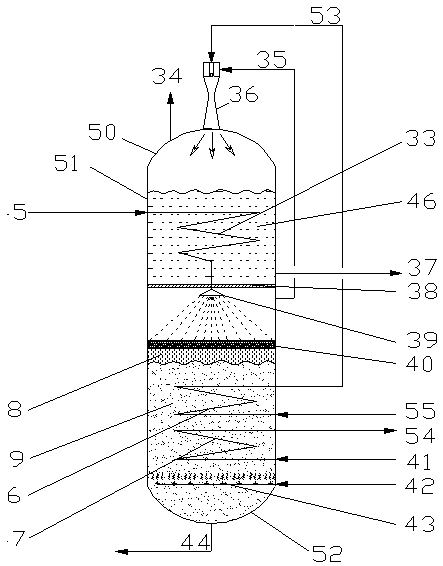

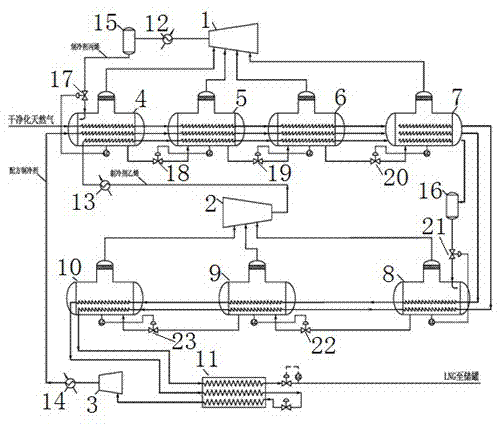

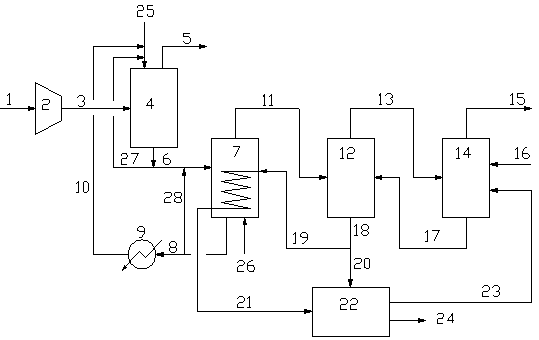

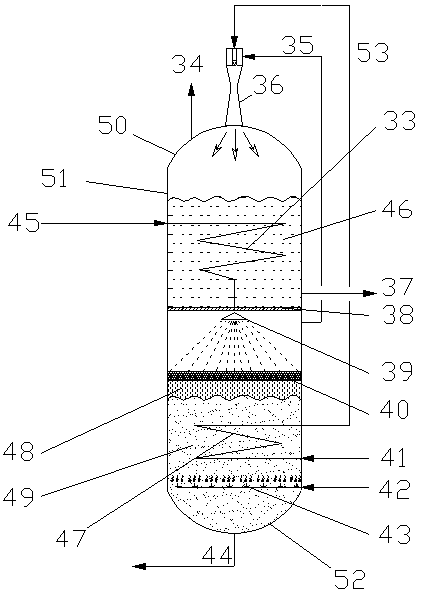

Natural-gas low-temperature helium extracting system and method

ActiveCN102937369ARich adjustment meansReduce energy consumptionSolidificationLiquefactionHigh concentrationEngineering

The invention discloses a natural-gas flow-temperature helium extracting system and a natural-gas flow-temperature helium extracting method. According to the system and the method, the post-expansion and nitrogen circulating refrigerating two-column separating technology is carried out for fully recovering the cooling capacity of the device in order to pre-cool the natural gas which serves as the raw material, and thereby the system can be applied to the natural gas which has an extremely low content of helium, and has the characteristics of being low in energy consumption, high in helium recovery rate, small in investment, flexible in operation, and high in adaptability to variable working conditions. The system and the method have the positive effects that little helium in the helium-containing natural gas can be extracted by a pre-cooling system and a low-temperature rectifying system, an independent nitrogen circulating refrigerating system is adopted and used for supplying an ultralow-temperature cold source required in helium concentration, and the independent system is rich in adjusting means and cannot be influenced by upstream operations; and a post-expansion refrigerating system is adopted, so that the natural-gas low-temperature helium extracting system has the operation pressure higher than that in conventional technology, and higher concentration of the helium can also be obtained at the same refrigerating temperature.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

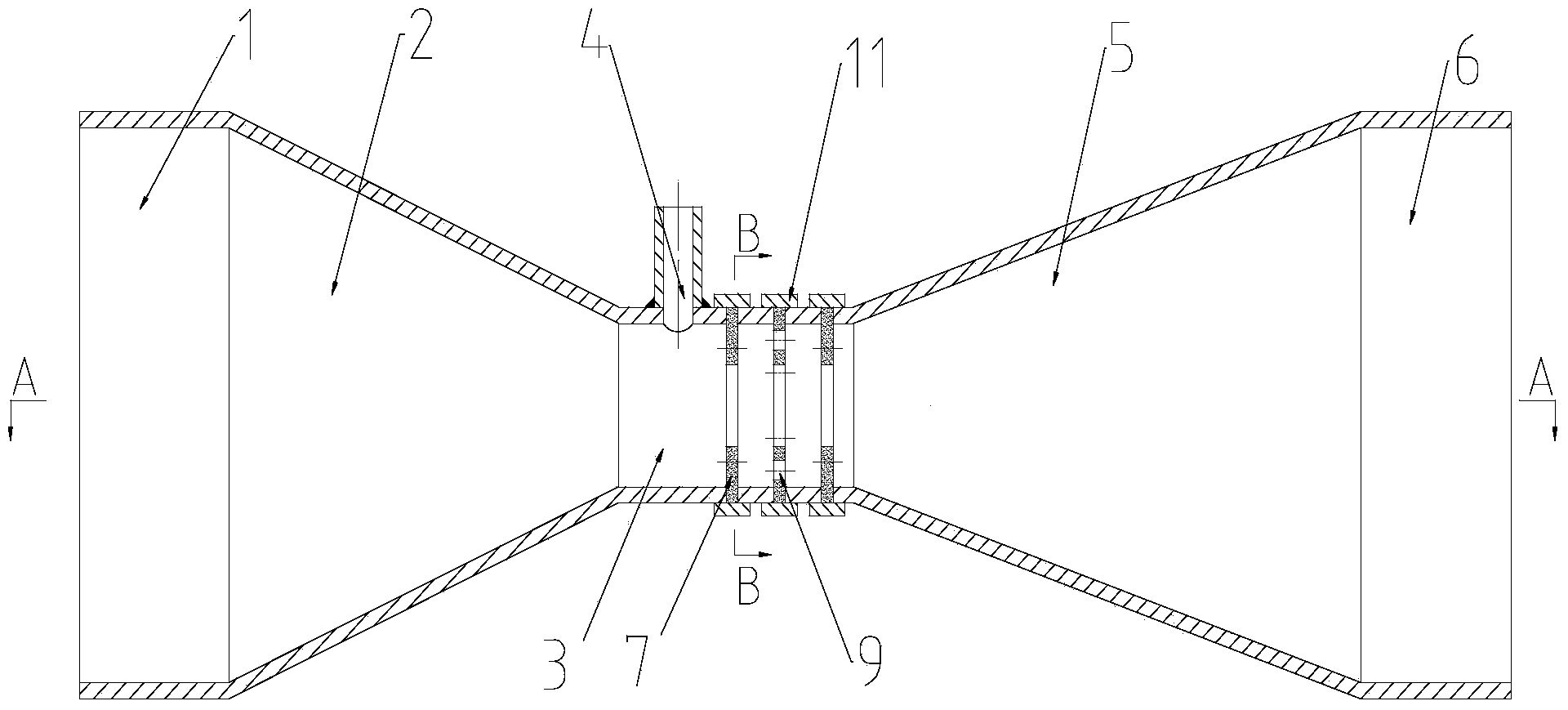

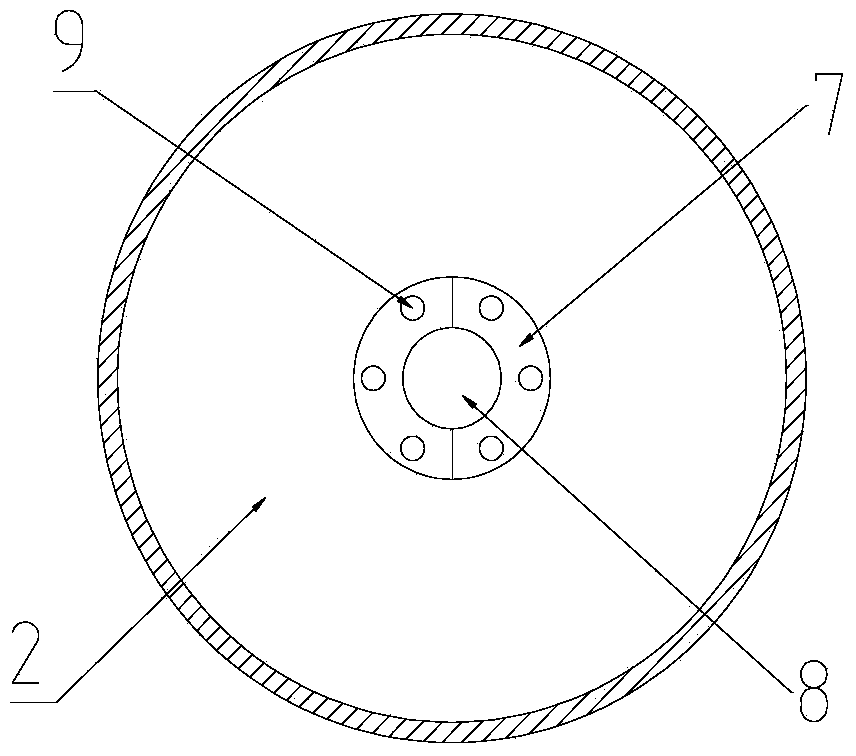

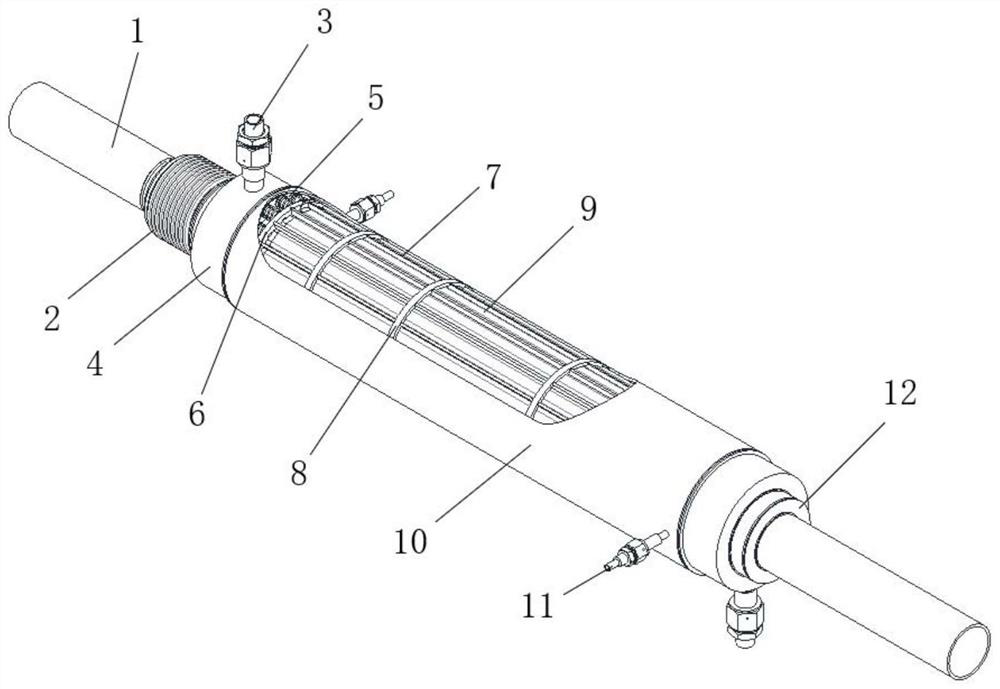

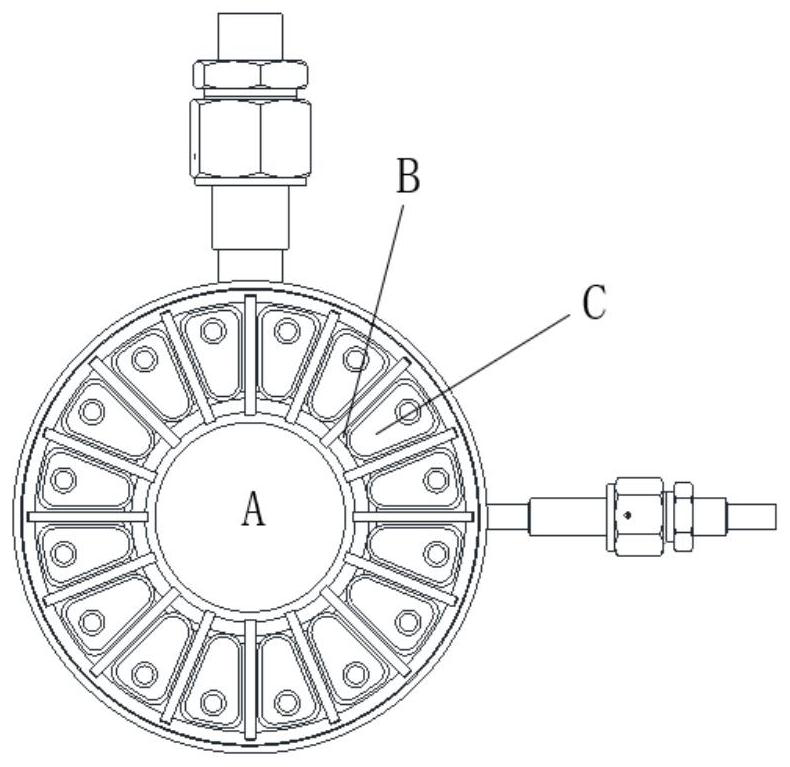

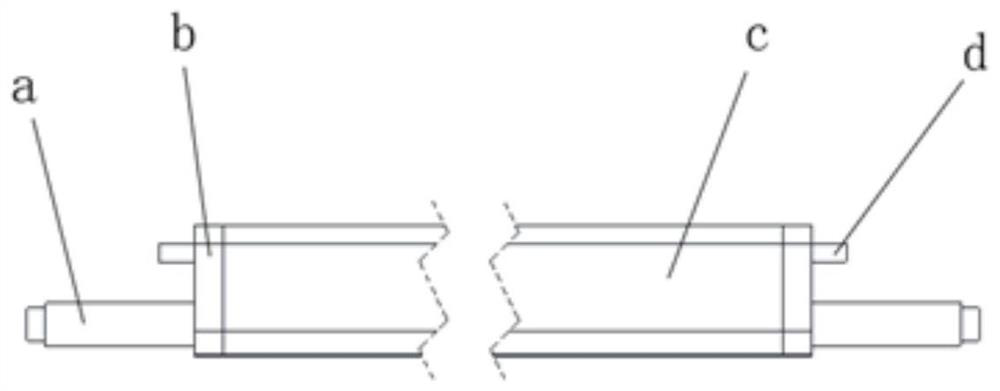

Venturi mixer with adjustable shrinkage hole on throat

The invention discloses a venturi mixer with an adjustable shrinkage hole on the throat. The venturi mixer comprises a mainstream venturi tube inflow pipeline, a mainstream venturi tube reducing section, a mainstream venturi tube throat, a mainstream venturi tube diffusion section and a mainstream venturi tube outflow pipeline, wherein an opening through which fluid is introduced to flow in is formed in a side face of the mainstream venturi tube throat. The venturi mixer also comprises multiple shrinkage holes formed in the downstream of the opening in the mainstream venturi tube throat and a matched shrinkage hole adjusting device, wherein the shrinkage holes consist of two semicircular core plates; the core plates can be designed into different thicknesses according to the needs; multiple through holes are formed in each core plate; the two core plates in the same shrinkage hole reciprocate inwards and outwards in the throat through an adjusting rod, so that a flow area of the mixed liquid at the shrinkage holes is changed; the shapes and sizes of three shrinkage holes are completely the same; during installation, a staggered mounting angle of 30 degrees is formed between the second shrinkage hole and the first shrinkage hole. By adopting the venturi mixer, disturbance of the mixed fluid in the venturi mixer can be effectively enhanced, the mixing efficiency of the venturi mixer is effectively improved, and a phenomenon that the mixing is non-uniform is avoided.

Owner:度测(上海)科技服务中心

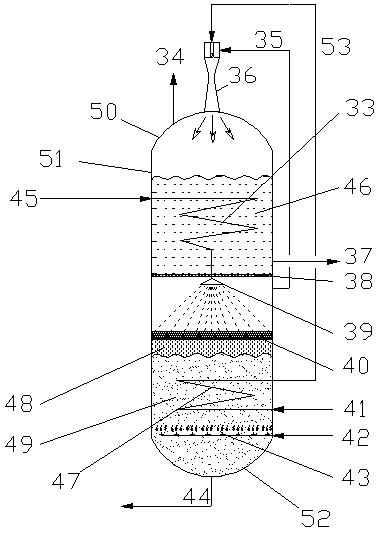

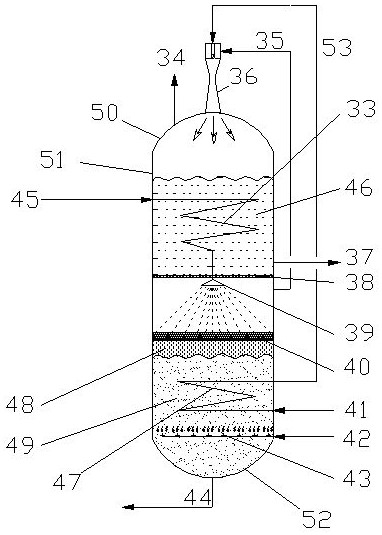

Treating method and device for carbon dioxide and hydrogen sulfide containing gas

ActiveCN108722148AReasonable useReduce energy consumptionGas treatmentDispersed particle separationProduct gasChemical products

The invention discloses a treating method and device for carbon dioxide and hydrogen sulfide containing gas. The device comprises a hydration reactor, a hydrate decomposing device, an exhaust gas treating device, a first-stage absorbing reactor, a second-stage absorbing reactor and a product tank. The invention further provides a method for treating the carbon dioxide and hydrogen sulfide containing gas through the abovementioned device. With the adoption of the device and the method, NaHS products meeting national quality standard can be produced while acidic gas standardized discharging is realized; the environment treatment and the production process of chemical products are integrated. Compared with the prior art, the method has the advantages that the carbon dioxide and hydrogen sulfide containing gas can be economically and efficiently pretreated; the energy in the technical process can be reasonably utilized, so that the energy consumption is extremely decreased; the whole treatment process is environmentally friendly, reliable, and free of three wastes.

Owner:CHINA PETROLEUM & CHEM CORP +1

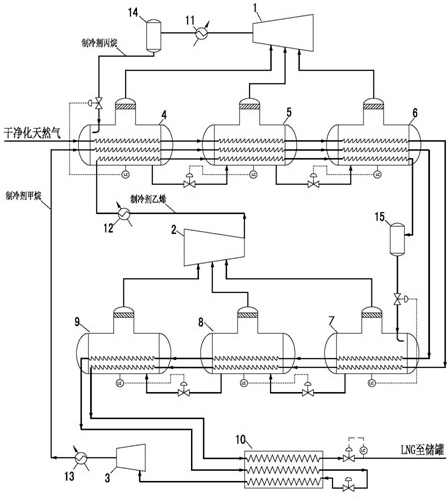

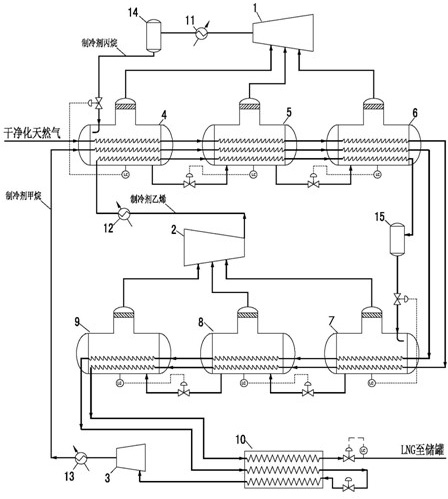

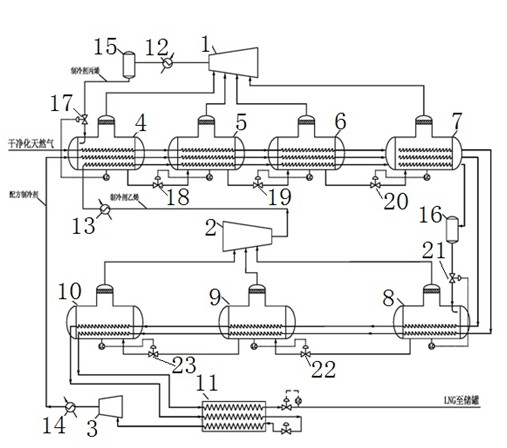

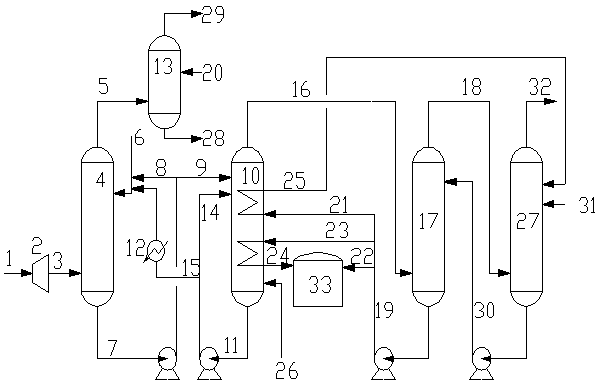

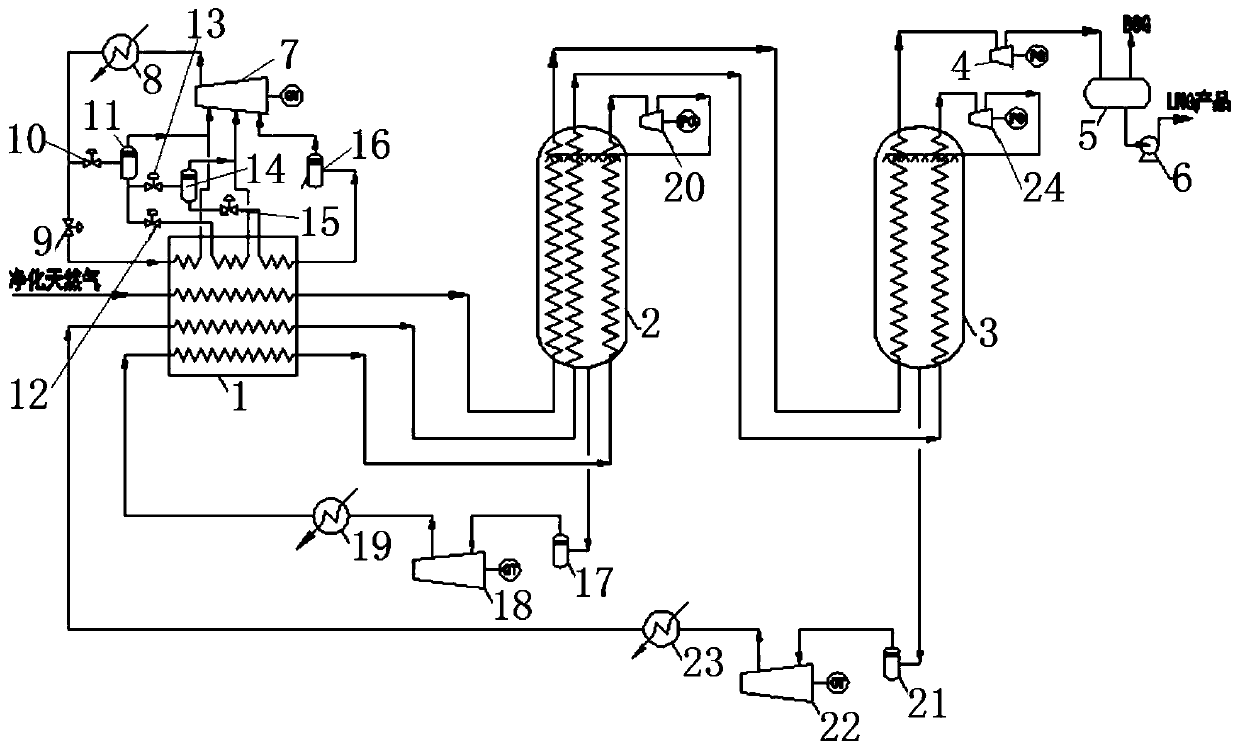

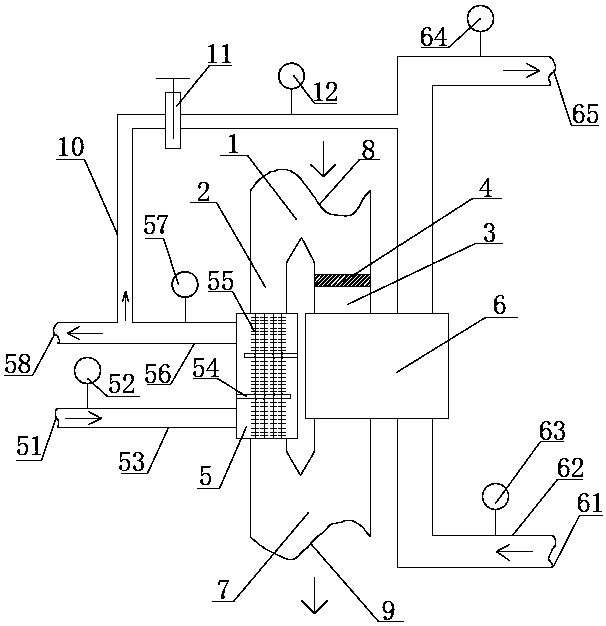

Multi-level single-component refrigeration natural gas liquefaction system and multi-level single-component refrigeration natural gas liquefaction method

ActiveCN102538391AEmbody adaptabilityRich adjustment meansSolidificationLiquefactionPlate fin heat exchangerMethane

The invention discloses a multi-level single-component refrigeration natural gas liquefaction system and a multi-level single-component refrigeration natural gas liquefaction method. Purified natural gas is cooled gradually in six heat exchangers (evaporators) and a plate fin type heat exchanger (natural gas subcooler) until being liquefied. Cold energy required by the liquefying process is provided by a propane system, an ethylene system and a methane system. The system is rich in adjusting means, the cold energy matched with the natural gas liquefying process can be provided for the naturalgas liquefying process, and thereby operational flexibility and adaptability to raw materials of the method are embodied. The system and the method have the advantages that the natural gas liquefyingprocess is low in energy consumption; refrigerant compressors are all single-component compressors, so that design is easier, purchase is more convenient, the compressors are more stable in operation, domestic equipment can be used, and construction investment of liquefaction factories can be effectively reduced; and the liquefying process is wide in heat exchanger selection range, and a cold boxstructure and a tube-shell structure can be used simultaneously or alternatively.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for preparing methane by catalyzing and gasifying coal

ActiveCN102465047BIncrease the amount of chemical bindingDoes not affect movement characteristicsHydrocarbon from carbon oxidesGaseous fuelsMethanationIon exchange

Owner:ENN SCI & TECH DEV

Ternary-cycle cascade refrigeration natural gas liquefaction system and method thereof

ActiveCN102628634ARich system adjustment meansSmall heat transfer temperature differenceSolidificationLiquefactionProcess engineeringNatural gas

The invention discloses a ternary-cycle cascade refrigeration natural gas liquefaction system and a method thereof. Heat is transferred from a relatively low temperature level cycle to an adjacent relatively high temperature level cycle: a first stage propylene refrigeration cycle provides cold energy for natural gas, refrigerant ethene, and formulated refrigerant; a second stage ethene refrigeration cycle provides cold energy for the natural gas and the formulated refrigerant; and a third stage formulated refrigerant refrigeration cycle provides cold energy for the natural gas and the formulated refrigerant itself. Through the cooling by seven heat exchangers and one plate-fin heat exchanger, temperature of the natural gas is reduced gradually till the natural gas is liquefied. In the invention, temperature of purified natural gas is reduced gradually in seven heat exchangers and one plate-fin heat exchanger till the purified natural gas is liquefied. The cold energy needed in a liquefaction process is provided by the three systems of propylene refrigerant, ethene refrigerant, and formulated refrigerant. The systems have abundant adjusting means, and can provide matching cold energy for the natural gas liquefaction process, thereby showing operation flexibility and adaptability to raw materials of the method.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

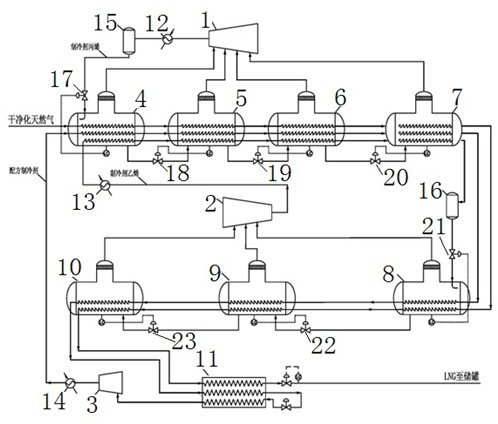

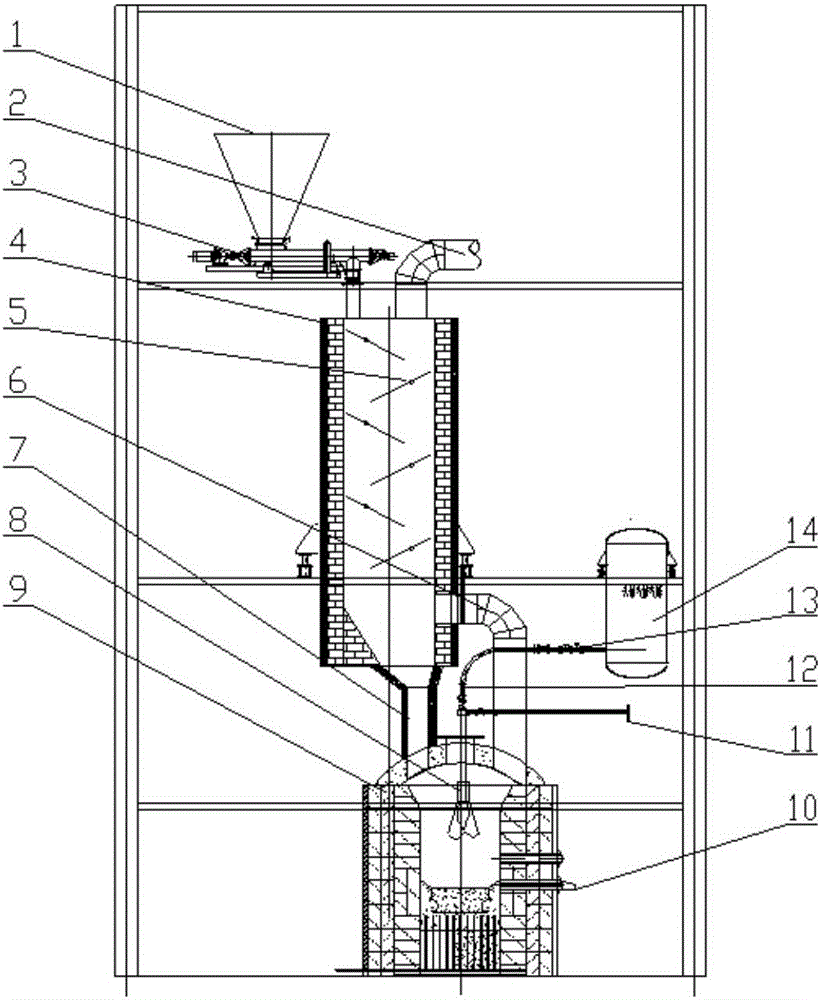

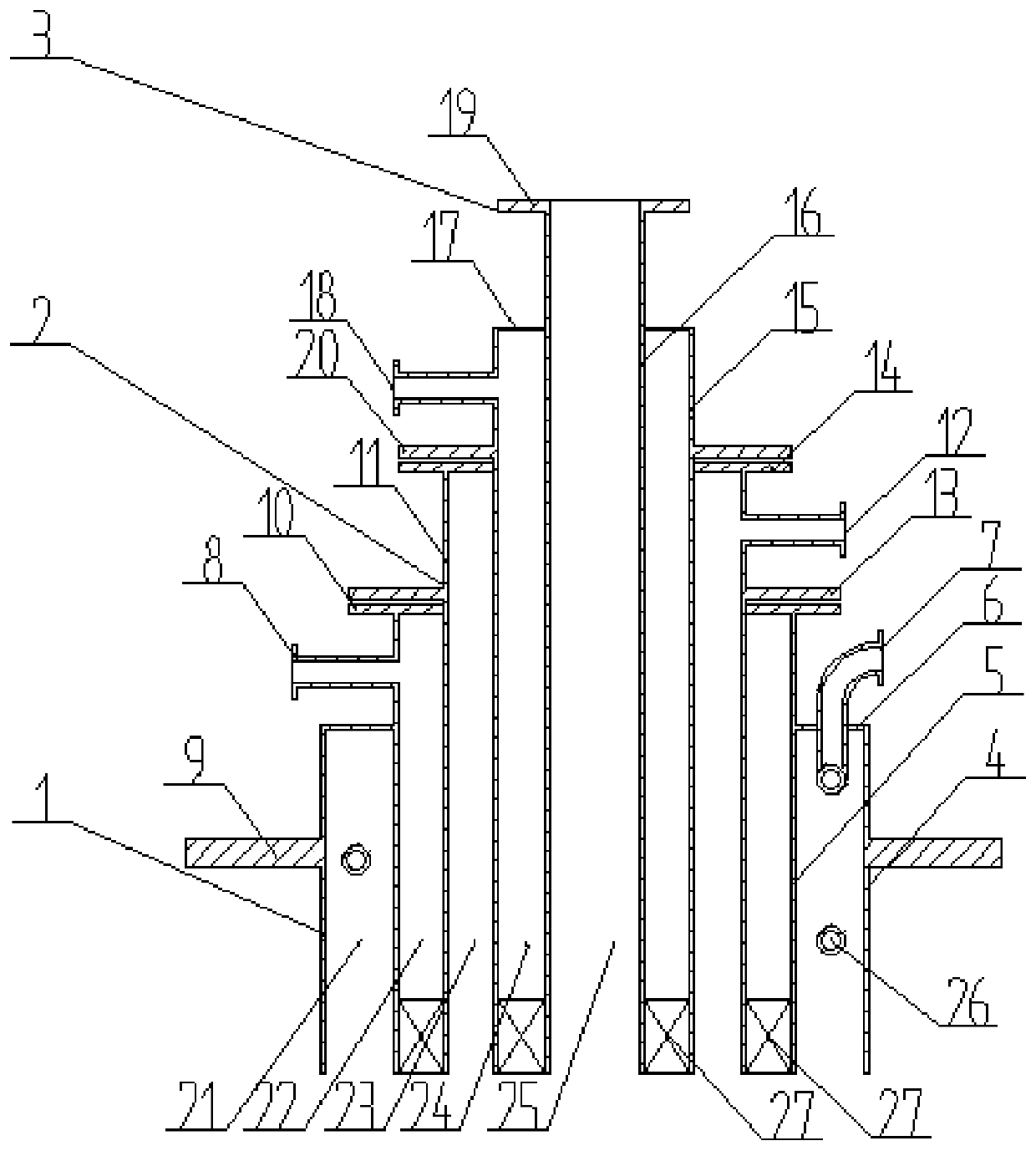

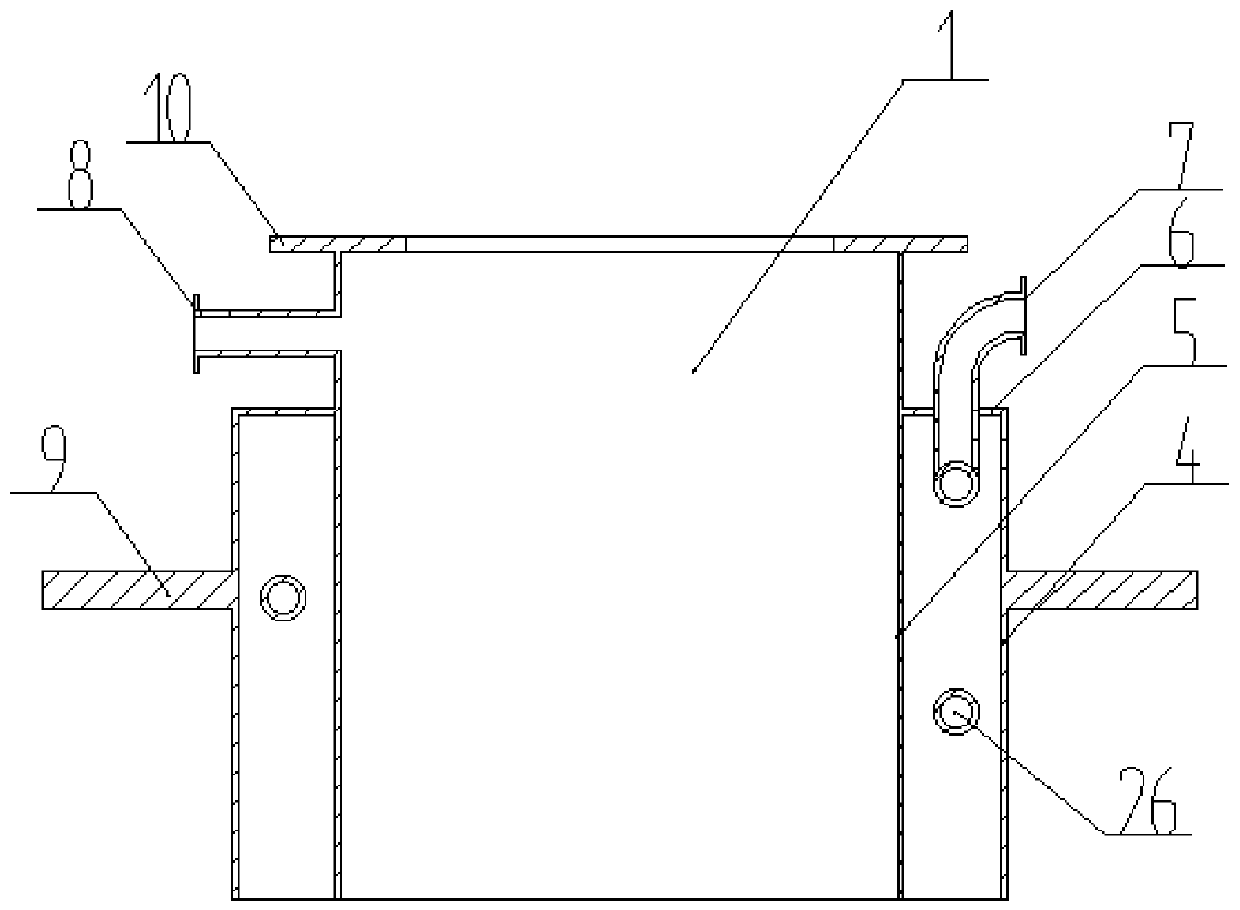

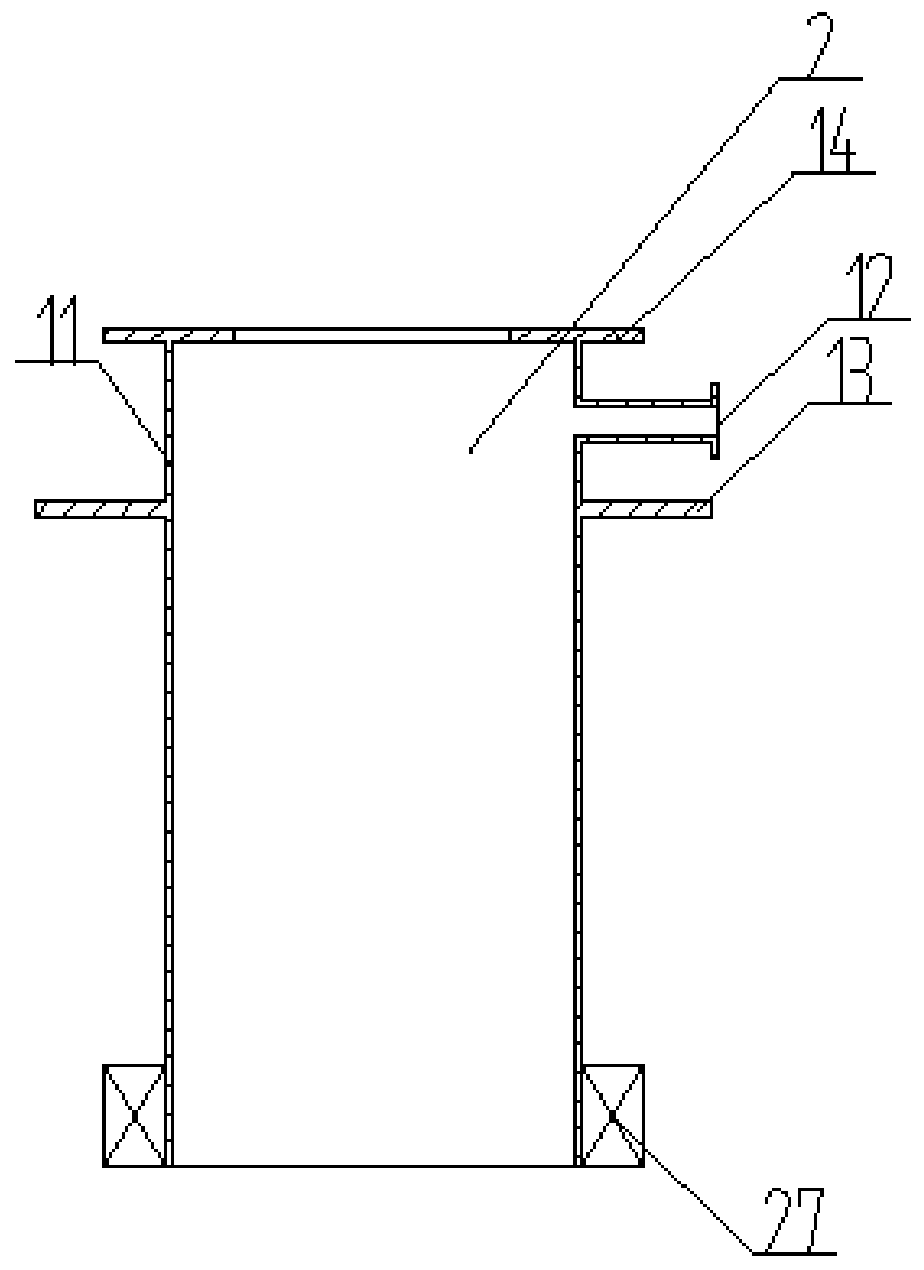

Smelting separation furnace reduction system and method based on natural gas-oxygen heating

PendingCN106148627AComplete restorationReduce usageShaft furnaceGas emission reductionFlue gasOxygen

The invention relates to a smelting separation furnace reduction system and method based on natural gas-oxygen heating. The system comprises a reduction shaft furnace, a smelting separation furnace and a natural gas-oxygen gun, wherein the reduction shaft furnace comprises a mineral powder-flux feeding port, a dropping port and a flue gas inlet; inclination-adjustable baffle plates are arranged in the hearth of the reduction shaft furnace; the smelting separation furnace comprises a feeding port, a flue gas outlet and a discharging port; the feeding port communicates with the dropping port of the reduction shaft furnace; the flue gas outlet communicates with the flue gas inlet of the reduction shaft furnace; a spray gun head of the natural gas-oxygen gun is arranged in the smelting separation furnace; and the natural gas-oxygen gun extends into the smelting separation furnace from the furnace top of the smelting separation furnace. According to the system and the method provide by the invention, the mineral powder dropping speed and residence time can be controlled through arrangement of the inclination-adjustable baffle plates in the reduction shaft furnace, thereby guaranteeing the mineral powder reduction effect.

Owner:SHENWU TECH GRP CO LTD

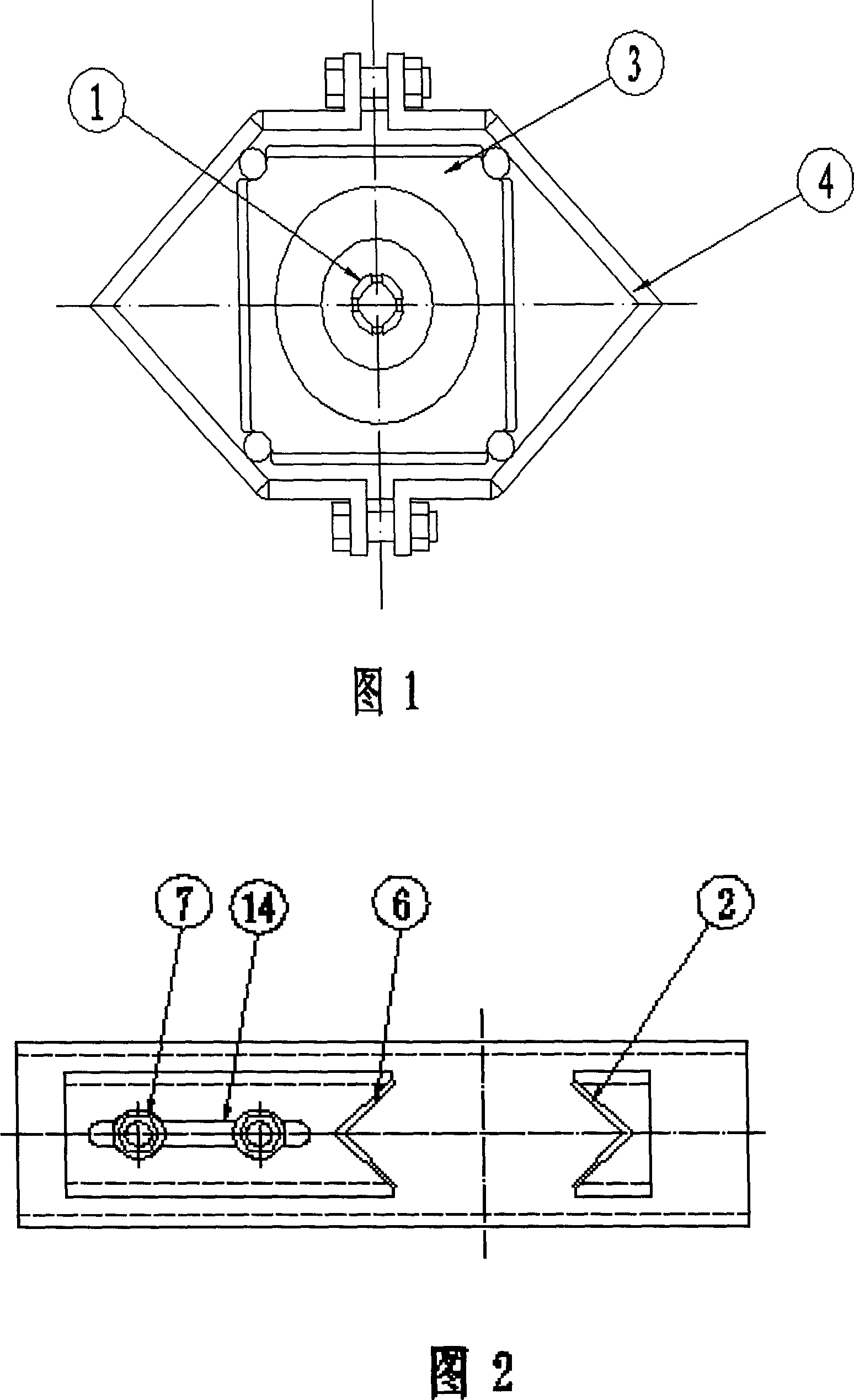

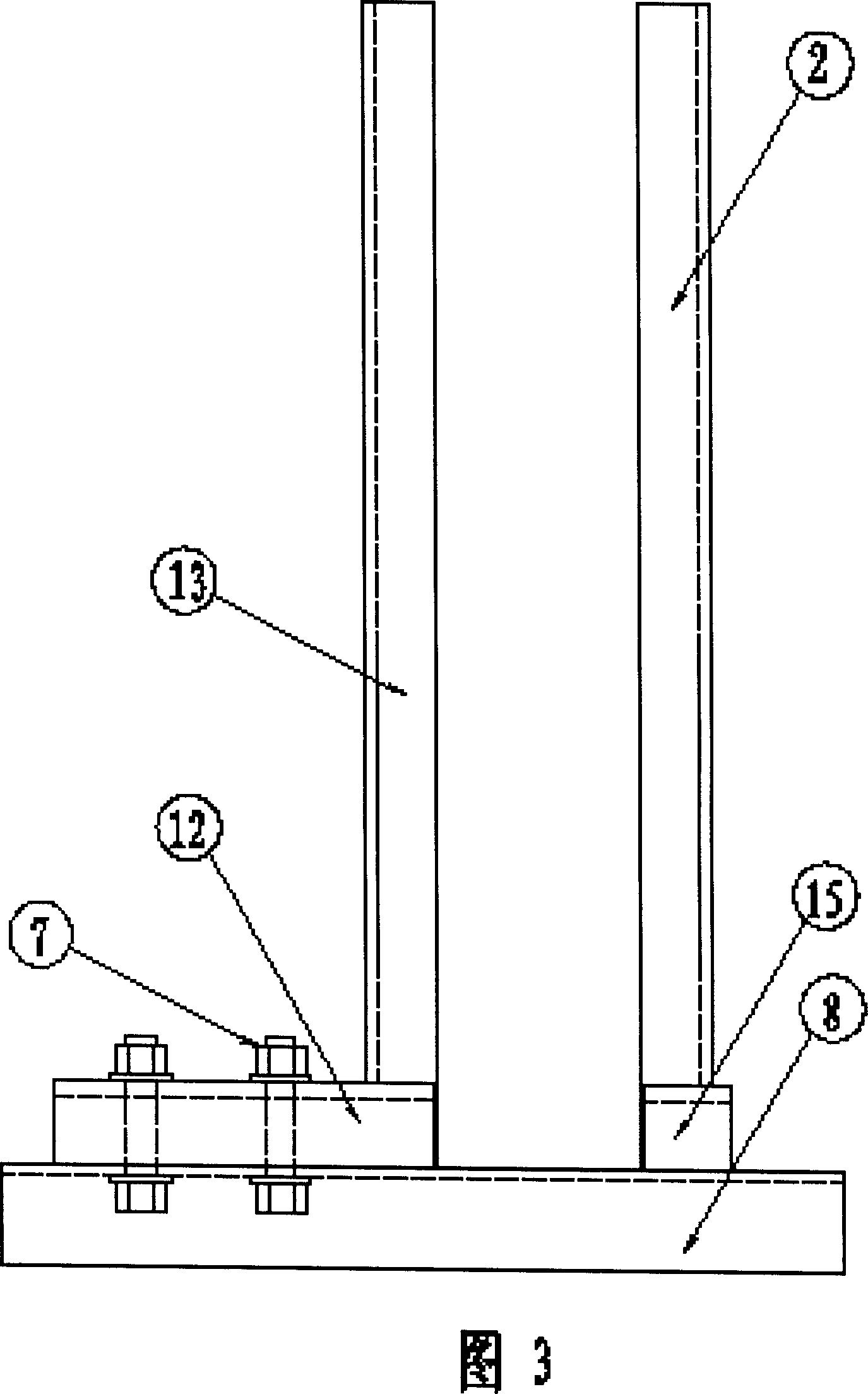

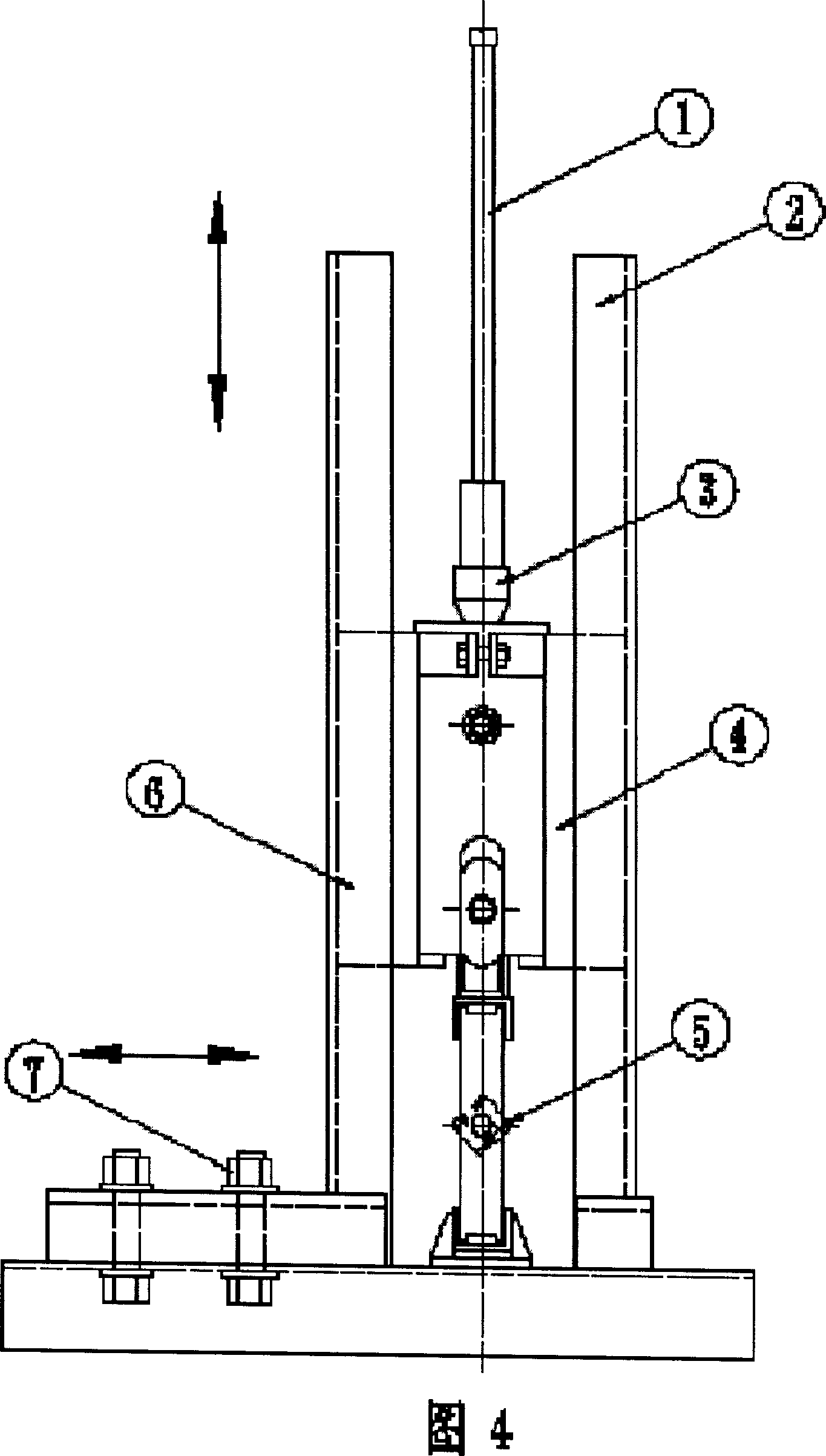

Method for drilling refractory materials in thermal state, and drilling equipment in thermal state

InactiveCN101092048ARich adjustment meansLarge amount of informationStone-like material working toolsThermal stateRefractory

The invention relates to a thermal state drilling method applied on fireproof material. It includes the following steps: installing a working platform under drilling section; installing a vertical guiding rail clamping device on the platform; installing jack screw that could make the water cooling air drill move along rail; connecting compressed air and cooling water of water cooling air drill and realizing feed by rocking jack screw; taking thermal state drilling operation on fireproof material. The invention could enhance tank furnace adjusting method, improve product quality and increase working efficiency.

Owner:HENAN ANCAI HI-TECH

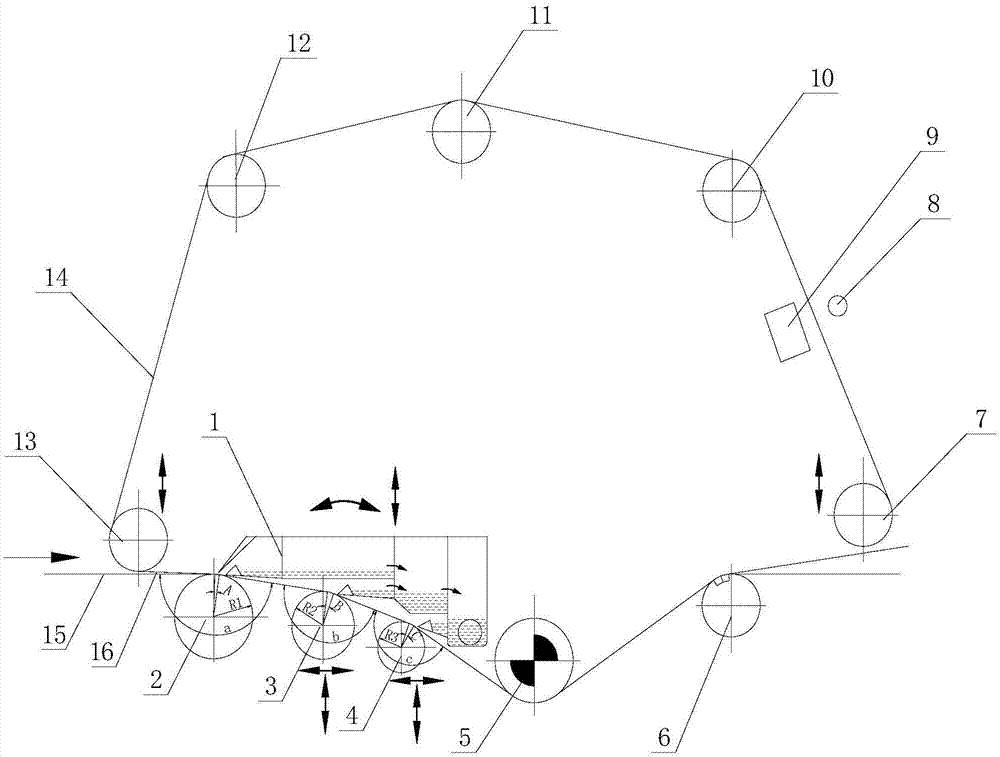

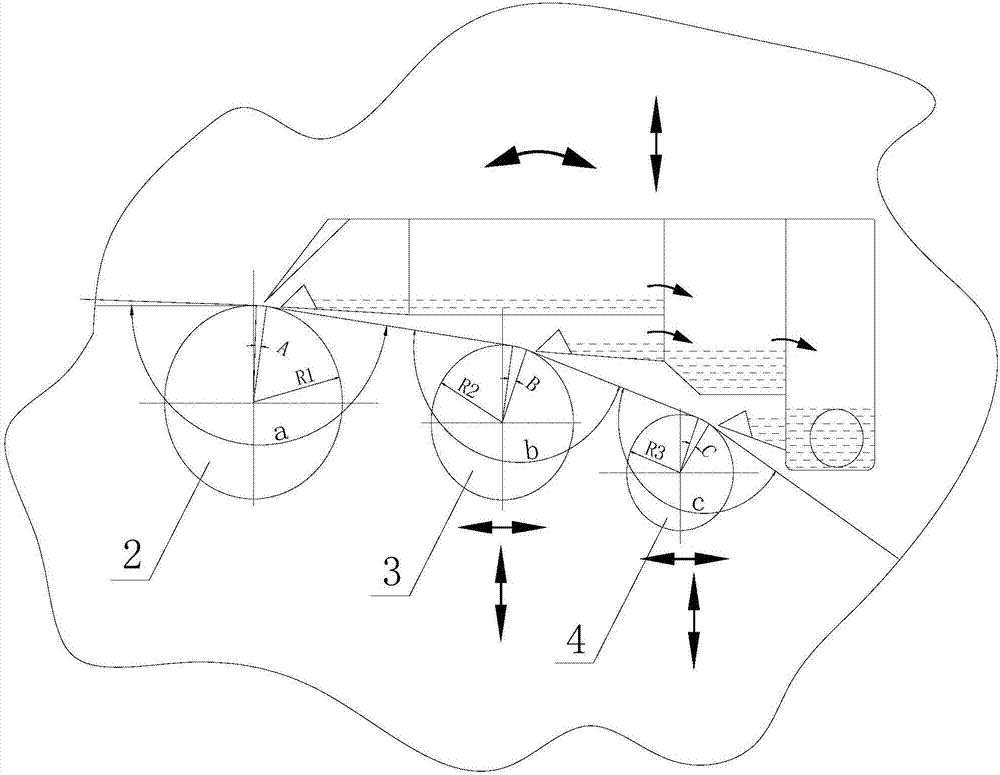

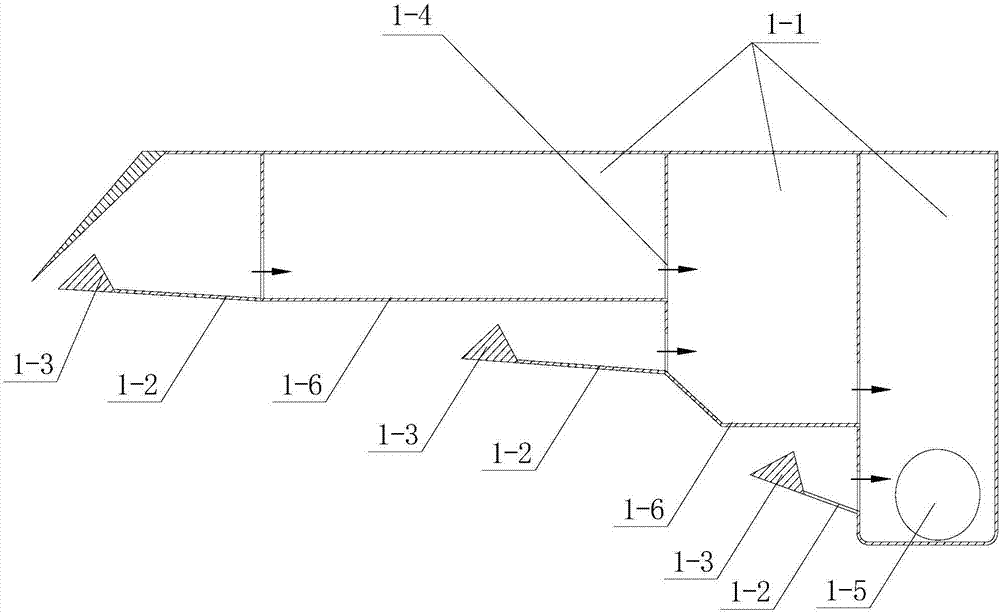

Roller type top-net forming device and its dewatering method

ActiveCN107419584ALarge wrapping angleReduce the impact of formingMachine wet endPaper sheetGeotechnical engineering

The invention discloses a roller type top-net forming device and its dewatering method. The top-net forming device includes a top net, a main forming roller and several pre-forming rollers, in the conveying direction of wet paper sheets, the pre-forming rollers and the main forming roller are arranged in sequence, the pre-forming rollers are arranged below a bottom net, and the main forming roller is arranged above the top net; a suction box is arranged above the portion, corresponding to the pre-forming rollers, of the top net, the suction box is provided with a plurality of scrapers, each scraper corresponds to one pre-forming roller, and each scraper makes contact with the surface of the top net. The dewatering method includes the following steps that after the wet paper sheets enter a wet paper sheet conveying channel, the pre-forming rollers are used for multistage pre-dewatering, water generated by dewatering is brought out through the suction box, and the wet paper sheets are then fed into the main forming roller for dewatering along with the rotation of the top net and brought out through the bottom net after dewatering. According to the forming device and the method, extrusion force of wet paper sheets entering the interlayer region of the two nets and the bend degree of a conveying route are increased gradually, and thus the forming device can adapt to a wide quantitative range and a wide speed range.

Owner:SOUTH CHINA UNIV OF TECH

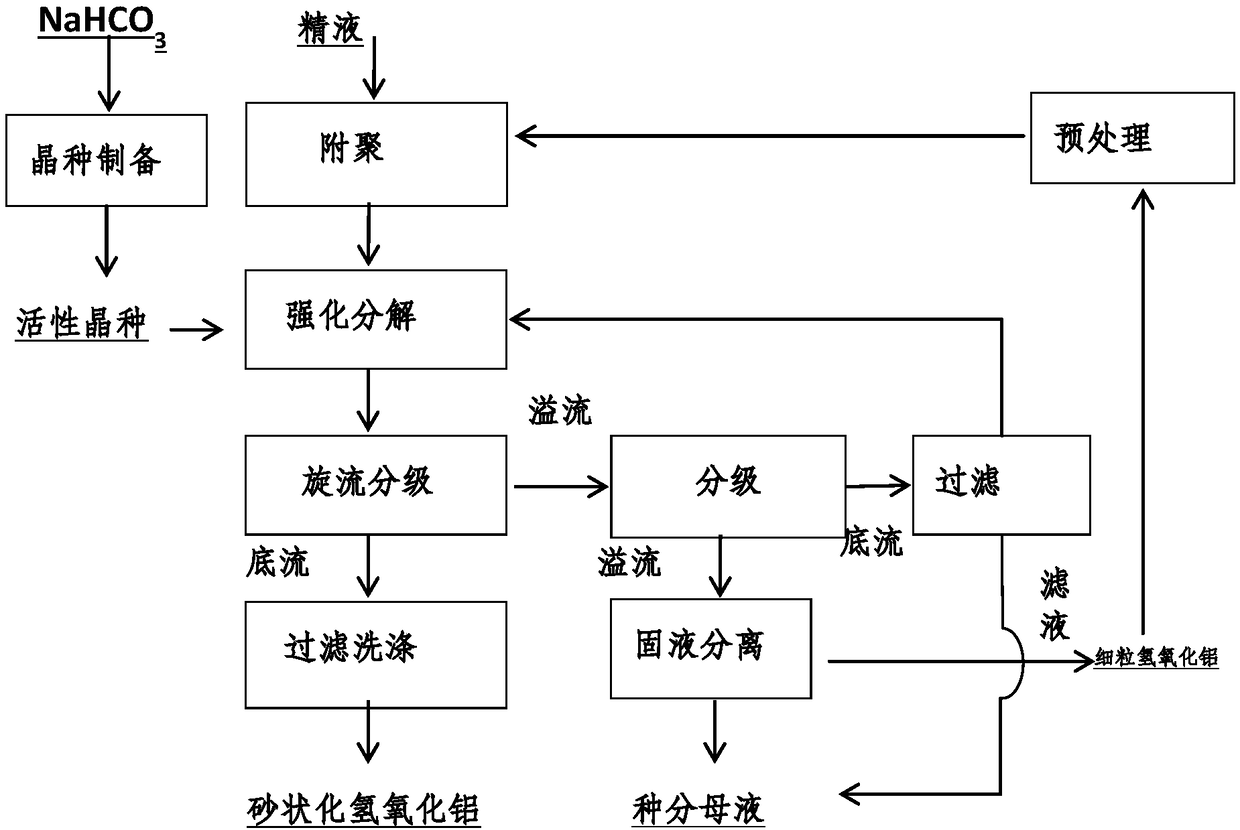

Method of cooperatively regulating and improving crystal seed decomposition of sodium aluminate solution

InactiveCN108585007ARich adjustment meansImprove decomposition rateAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDecompositionSodium aluminate

A method of cooperatively regulating and improving crystal seed decomposition of sodium aluminate solution includes the steps of preparing high-activity crystal seed slurry, reinforcing seed precipitation, pretreating and agglomerating fine particles. In the method, solution decomposition and crystallization processes are regulated through multiple means, thus solving a contradictory problem of increasing decomposition rate and guaranteeing production quality. By means of the method, solution decomposition rate can reach more than 57%. The product has a sandy appearance and can satisfy first grade in national standard. The method is high in decomposition rate, can form the sandy product, has simple process and low investment, and has extensive application prospect.

Owner:CENT SOUTH UNIV

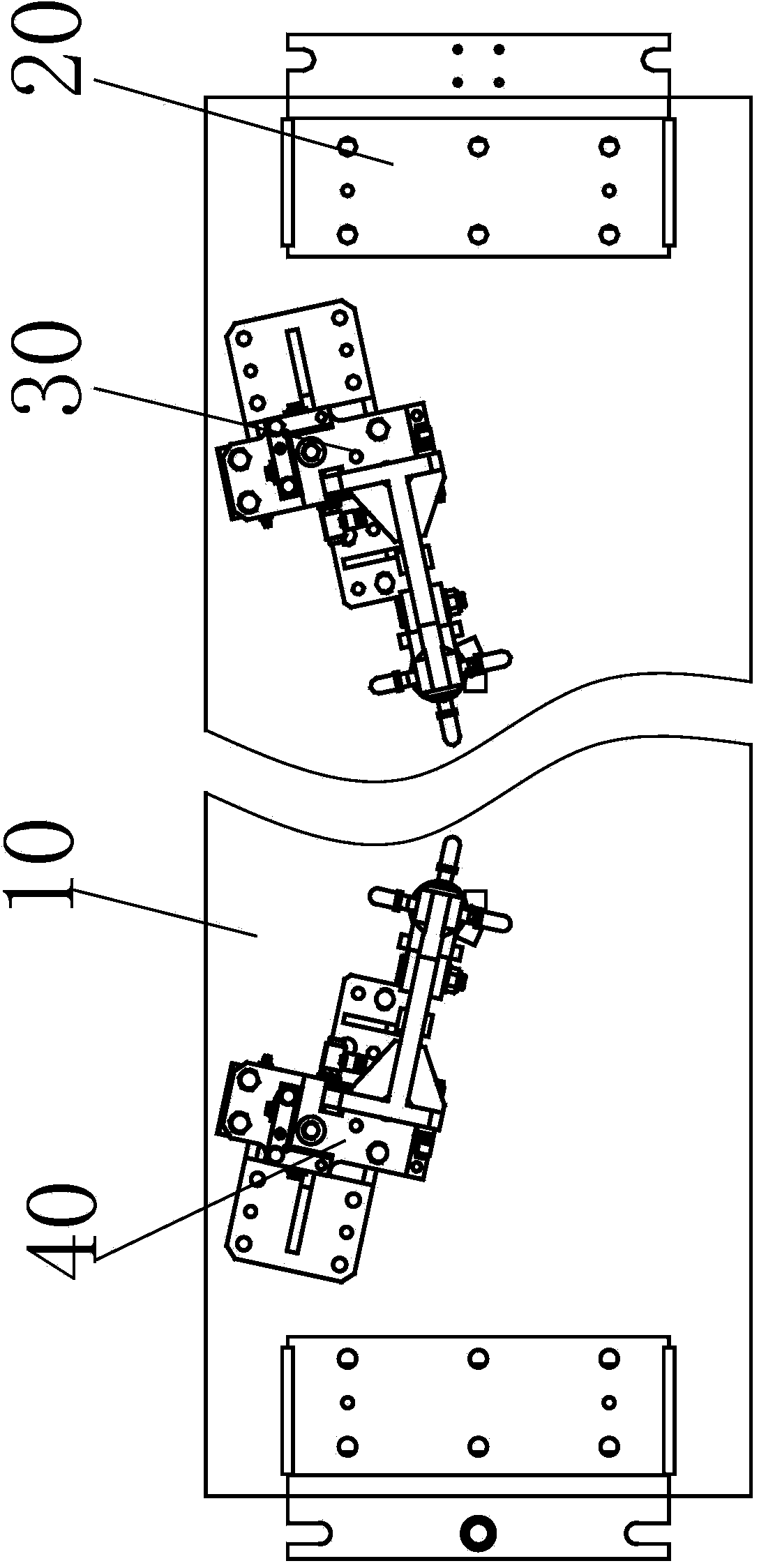

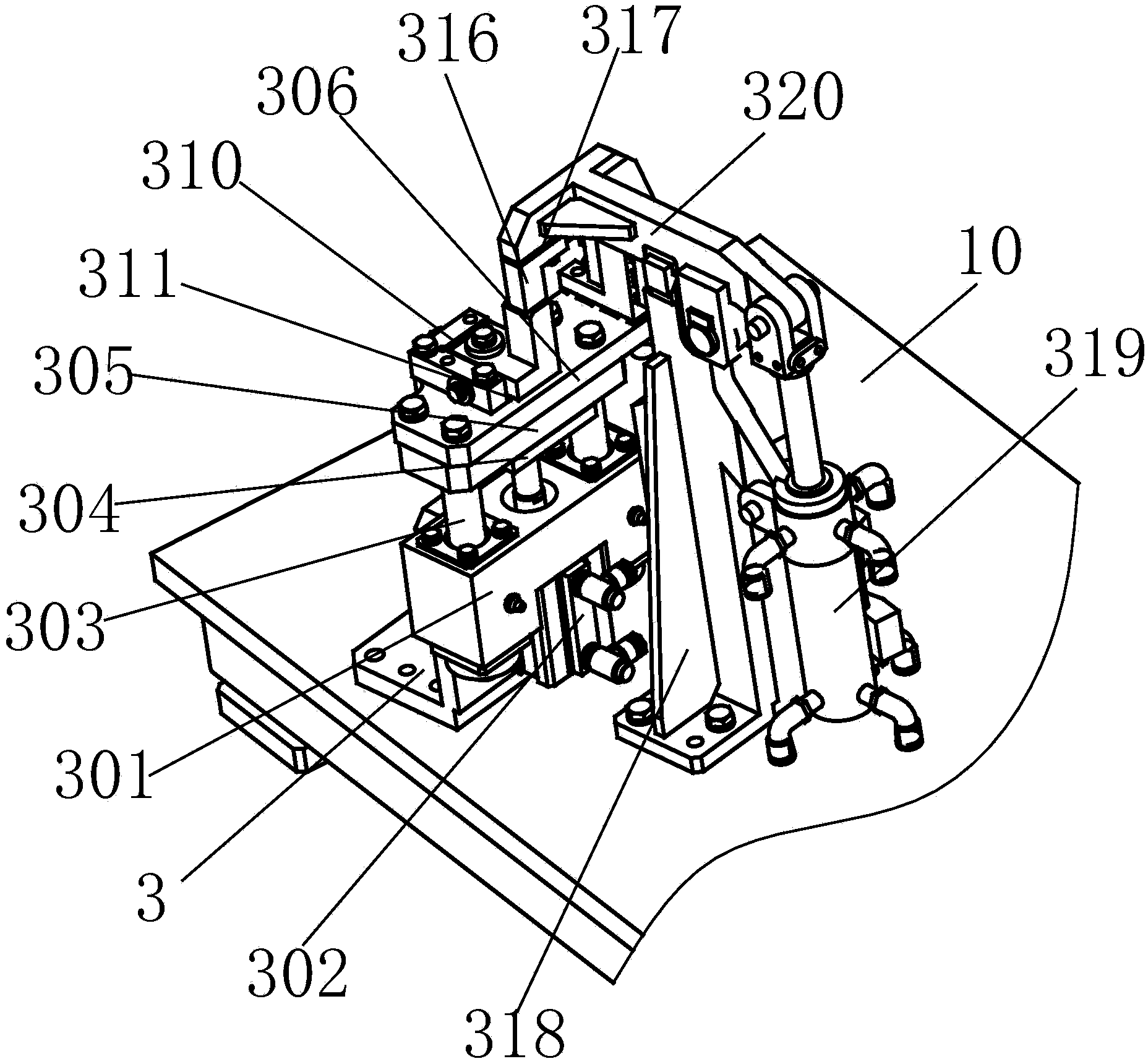

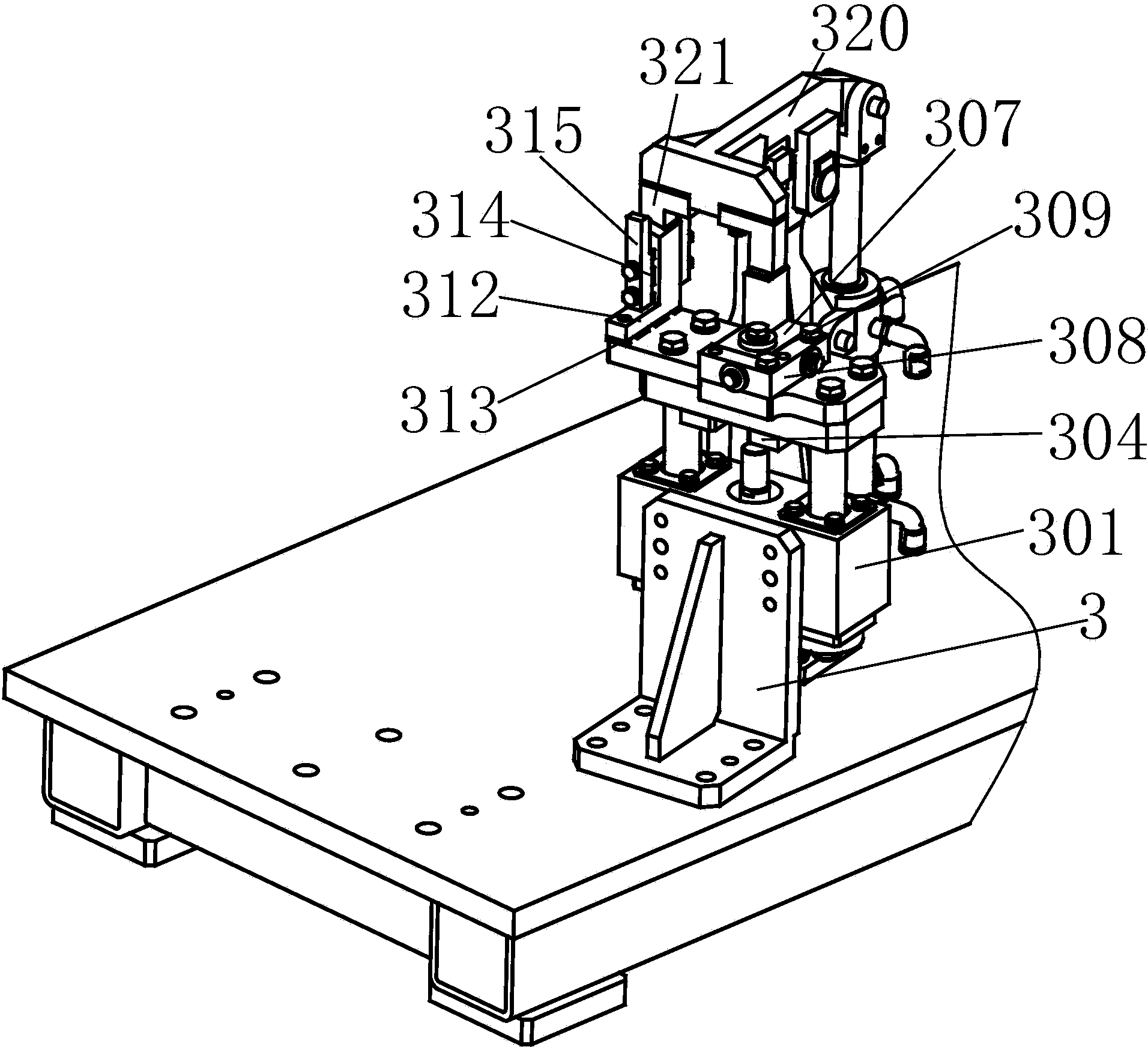

Assembly welding jig for IP body end plate fixing support of automobile instrument board

ActiveCN103949834ARich adjustment meansStable clampingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to an assembly welding jig for an IP body end plate fixing support of an automobile instrument board. The assembly welding jig comprises a clamping table, wherein fixed ends are respectively arranged at the two ends of the clamping table; a left IP body end plate fixing support assembly clamping frame and a right IP body end plate fixing support assembly clamping frame are respectively and correspondingly arranged at the left rear part and the right rear part of the clamping table; the left IP body end plate fixing support assembly clamping frame and the right IP body end plate fixing support assembly clamping frame are symmetrical about the central axial line of the clamping table. The assembly welding jig is reasonable in structural design, simple to adjust, various for adjusting means of jig position and stable in clamping, and the clamping stability and precision of the jig are improved through positioning column head holes and positioning column heads, so that the improvement on the welding quality of clamped components and parts is facilitated, various types of gaskets are convenient for adjusting the jig position, the production efficiency is improved, different cylinders in all positions are used for replacing manpower for clamping, the clamping efficiency is improved, and the benefits of enterprises are improved.

Owner:ANHUI DACHANG TECH

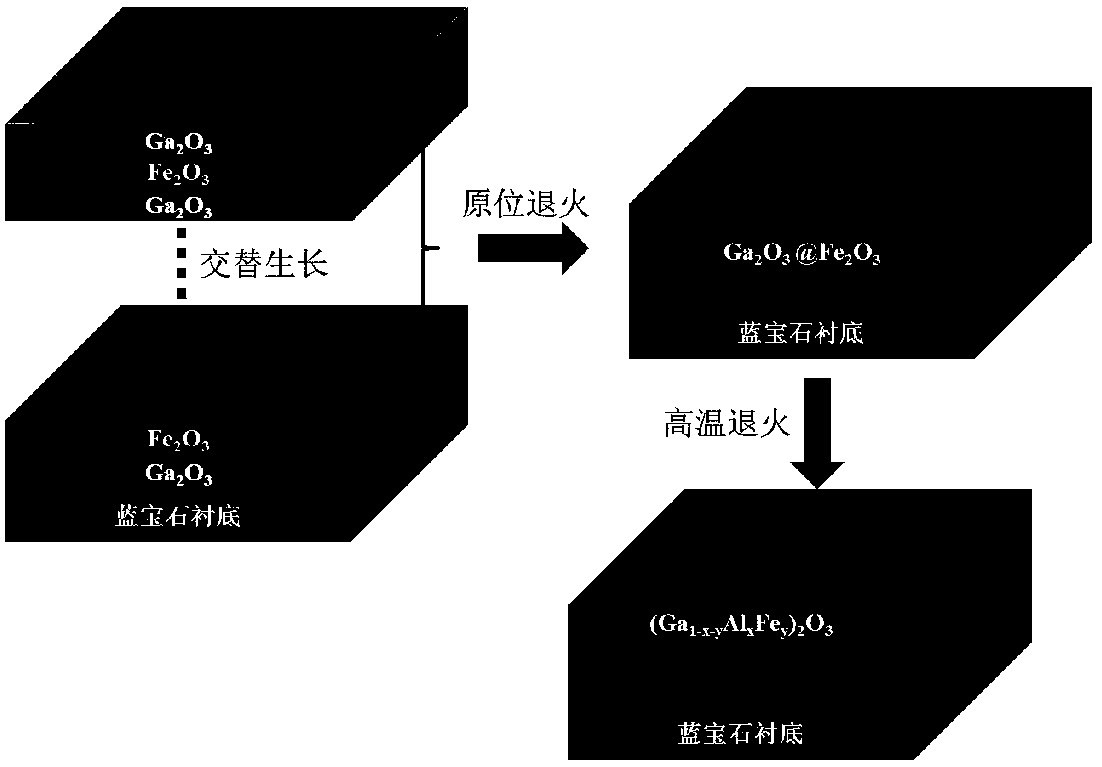

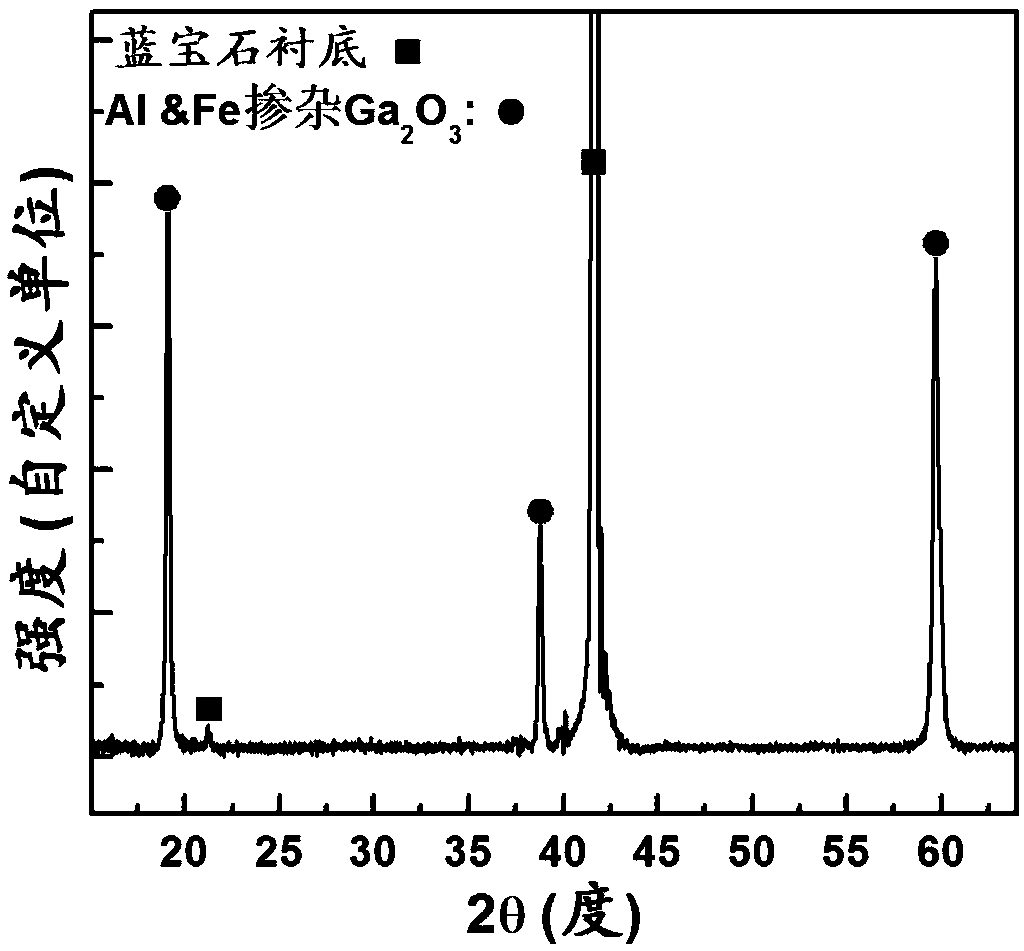

Preparation method of bandgap longitudinal gradient distributed Ga2O3 thin film co-doped with Al and Fe

The invention relates to a preparation method of a bandgap longitudinal gradient distributed Ga2O3 thin film co-doped with Al and Fe. According to the preparation method, the Ga2O3 thin film is prepared by taking Alpha-Al2O3 single crystal as a substrate, alternatively depositing Ga2O3 and Fe2O3 superthin layers by laser molecular beam epitaxy and then performing annealing. The preparation methodis simple in process, high in process controllability and good in repeatability and is easy to prepare, and large-area preparation can be achieved; and Al constituent in the prepared thin film is distributed in a longitudinal and gradient way, and the thin film is good in crystallinity and uniform in surface and is compact.

Owner:北京镓和半导体有限公司

Method and device for treating gas containing carbon dioxide and hydrogen sulfide

ActiveCN108722148BGreat operating flexibilityMild operating conditionsGas treatmentDispersed particle separationHydration reactionChemical products

The invention discloses a treatment method and device for gas containing carbon dioxide and hydrogen sulfide. The device includes a hydration reactor, a hydrate decomposer, a gas exhaust processor, a primary absorption reactor, a secondary absorption reactor and a product tank . Also provided is a method for treating gas containing carbon dioxide and hydrogen sulfide by using the above device. It can produce NaHS products that meet the national quality standards while achieving acid gas discharge standards, and organically combine environmental governance with the production process of chemical products into an integrated process. Compared with the prior art, the method of the present invention can economically and efficiently pretreat the gas containing carbon dioxide and hydrogen sulfide, rationally utilize the energy in the process, and greatly reduce energy consumption; the whole process is environmentally friendly, reliable, No "three wastes" are generated.

Owner:CHINA PETROLEUM & CHEM CORP +1

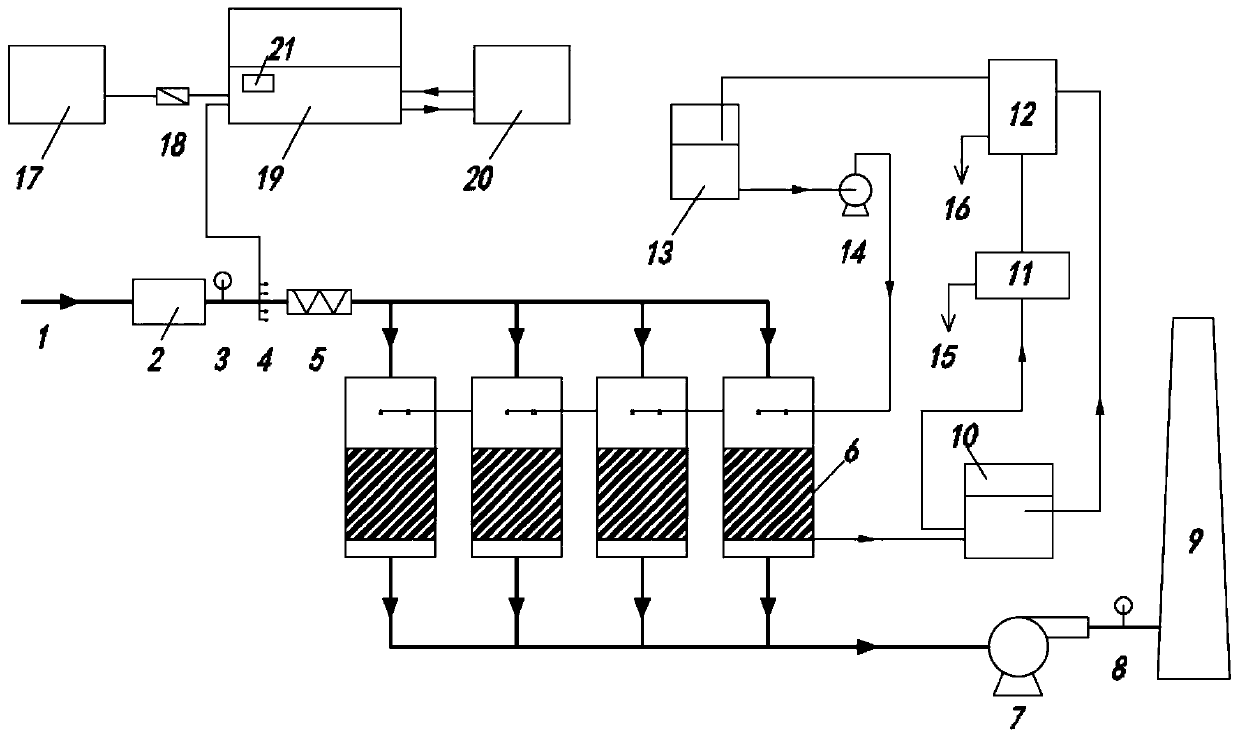

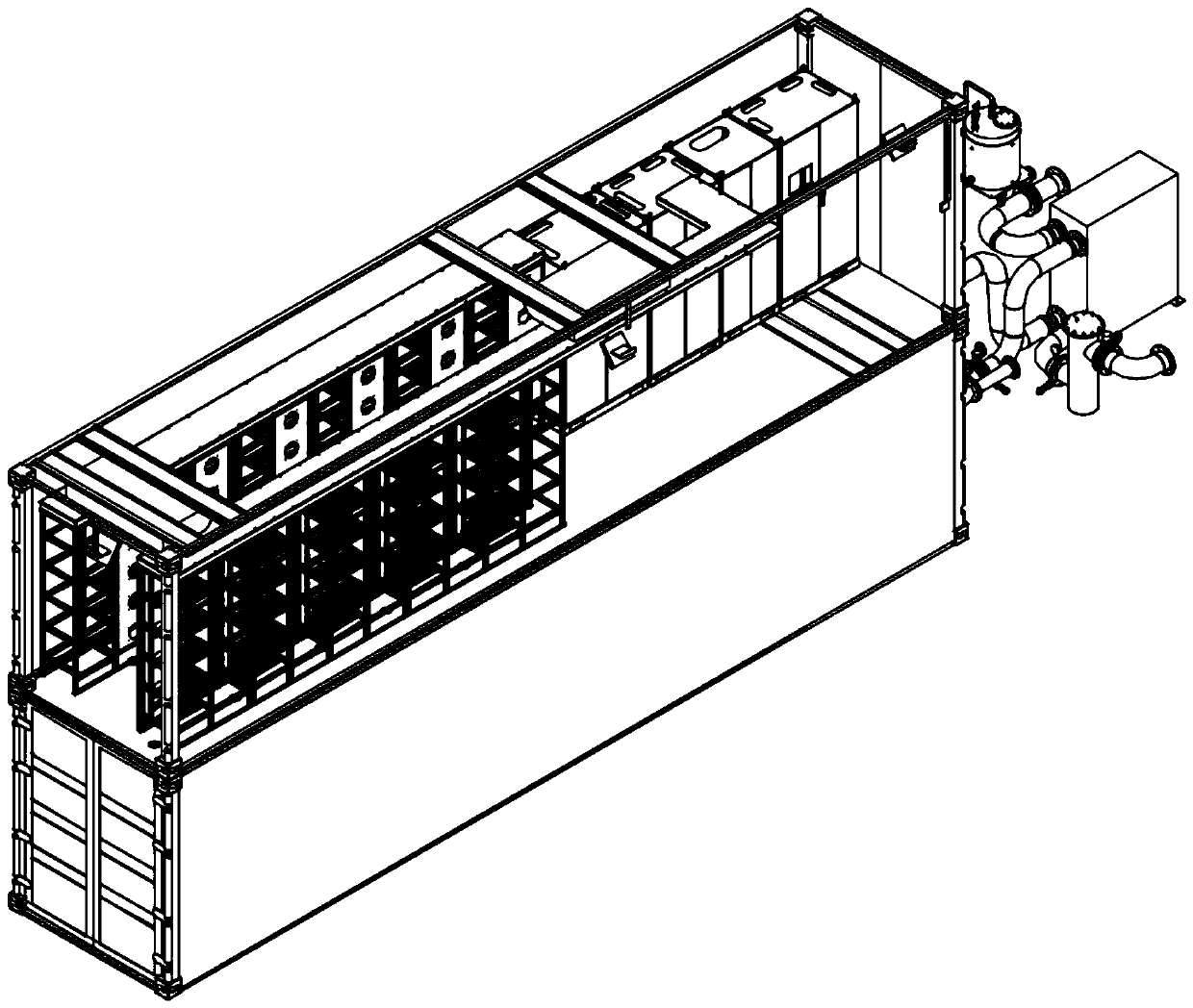

Ion exchange desulfurization and denitrification integrated process and equipment

PendingCN111495147AImprove reliabilityRich adjustment meansGas treatmentLighting and heating apparatusIon exchangeSulfur dioxide

The invention discloses an ion exchange desulfurization and denitrification integrated process and equipment; sulfur dioxide and nitrogen oxide in flue gas are oxidized by ozone, and then oxidation products are absorbed by an ion exchange material to achieve the purpose of synchronous denitrification. According to the technical scheme, compared with a wet method or semi-dry method desulfurizationand denitrification process and an ion exchange desulfurization and denitrification process, the desulfurization and denitrification efficiency is higher, the ozone consumption is lower, produced waste liquid is recycled, the disposal amount of waste is greatly reduced, the problem of yellow smoke emission is solved, and better economic benefits and environmental benefits are achieved. Meanwhile,a container type modular ozone generation system is adopted in the process scheme, hoisting arrangement is flexible, the problem of field space arrangement can be solved, the ozone yield can be automatically adjusted, accurate ozone adding is achieved, and the device adapts to NOx load fluctuation of flue gas.

Owner:BEIJING JINGDAWANXIANG ENVIRONMENTAL PROTECTION CO LTD +1

Variable-heat-conductivity-coefficient vacuum environment liquid metal cooler

ActiveCN113309684AMeet performance test requirementsWide operating temperature rangePump testingPositive displacement pump componentsLiquid stateWater flow

The invention relates to a variable-heat-conductivity-coefficient vacuum environment liquid metal cooler. The variable-heat-conductivity-coefficient vacuum environment liquid metal cooler comprises a liquid metal pipeline, a heat conduction gas cavity and a cooling water assembly. The heat conduction gas cavity wraps at least one part of the liquid metal pipeline so as to adjust heat dissipation of the liquid metal pipeline through change of the heat conductivity coefficient of the heat conduction gas cavity. A cooling water flow channel of the cooling water assembly is arranged in the heat conduction gas cavity so as to adjust the background temperature. The variable-heat-conductivity-coefficient vacuum environment liquid metal cooler has the beneficial effects that the variable-heat-conductivity-coefficient vacuum environment liquid metal cooler effectively and fully utilizes three heat exchange means of heat conduction, radiation and convection, so that the working temperature range of the cooler is very wide, the cooler can work within the range of dozens of DEG C to 600 DEG C under the condition that the flow of cooling water is enough, and the performance test requirements of a thermal vacuum electromagnetic pump in a vacuum environment are met. The variable-heat-conductivity-coefficient vacuum environment liquid metal cooler is good in adjustability and multiple in adjusting means, and the heat exchange capacity can be changed by adjusting the water temperature and the flow speed of the secondary cooling water inlet and the existence and components of gas in the gas cavity.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Combined treatment process and system for acid gas

ActiveCN108722135AGreat operating flexibilityMild operating conditionsGas treatmentDispersed particle separationProduct gasChemical products

The invention discloses a combined treatment process and a system for acid gas. According to the combined treatment process and the system, NaHS products meeting national quality standards can be produced while up-to-standard discharge of the acid gas is realized; environmental improvement is organically combined with the production process of a chemical product. Compared with the prior art, the process and the system disclosed by the invention have the advantages that the acid gases containing CO2 and hydrogen sulfide can be economically and efficiently pretreated, energy in the technologicalprocess is reasonably utilized and energy consumption is greatly reduced; the whole treatment process is environmentally friendly and reliable and no three wastes are produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Three-cycle natural gas liquefaction device and method suitable for ultra-large scale

PendingCN110186251AReduce in quantityImprove adaptabilitySolidificationLiquefactionProcess equipmentProcess engineering

The invention discloses a three-cycle natural gas liquefaction device and method suitable for ultra-large scale. The device comprises a natural gas liquefaction pipeline, a propane precooling circulation system, a WMR refrigeration circulation system and a CMR refrigeration circulation system. Compared with the prior art, the device has the positive effects that on the basis of three cycles, eachstage of refrigeration load is shared, natural gas is sequentially cooled through one plate-fin heat exchanger and two coiled tube heat exchangers until liquefaction and supercooling, the number of process equipment is small, and the scale of a natural gas liquefaction device can reach 6-8 million tons per year; and the refrigeration required by the liquefaction process is provided by three systems of propane, WMR mixed refrigerant and CMR mixed refrigerant, the system adjustment means are rich, the matched refrigeration can be provided for the natural gas liquefaction process, the operation is flexible, and the adaptability to raw materials is good.

Owner:CHINA PETROLEUM ENG CORP LTD +2

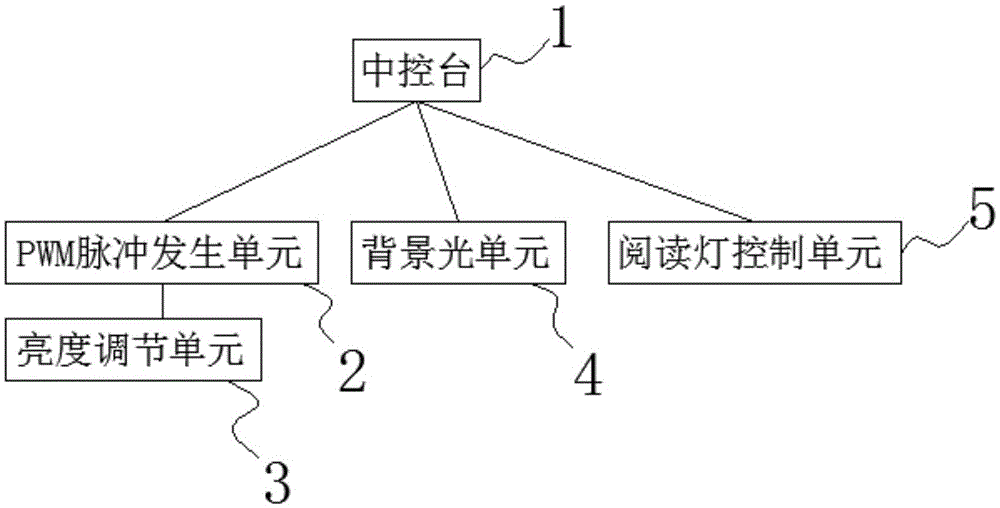

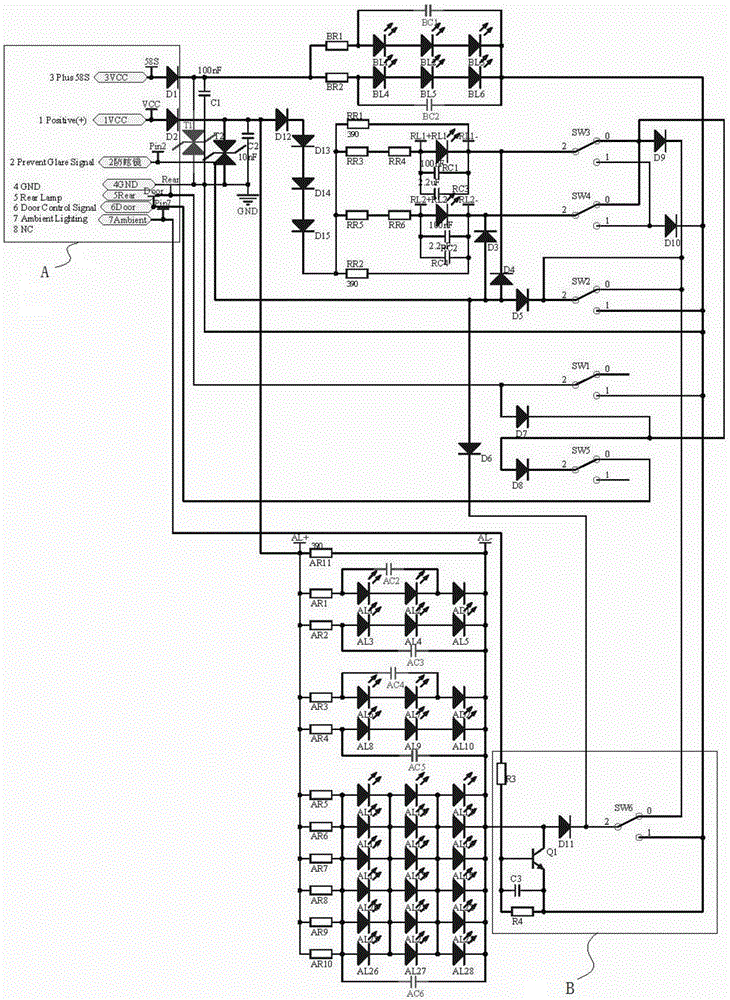

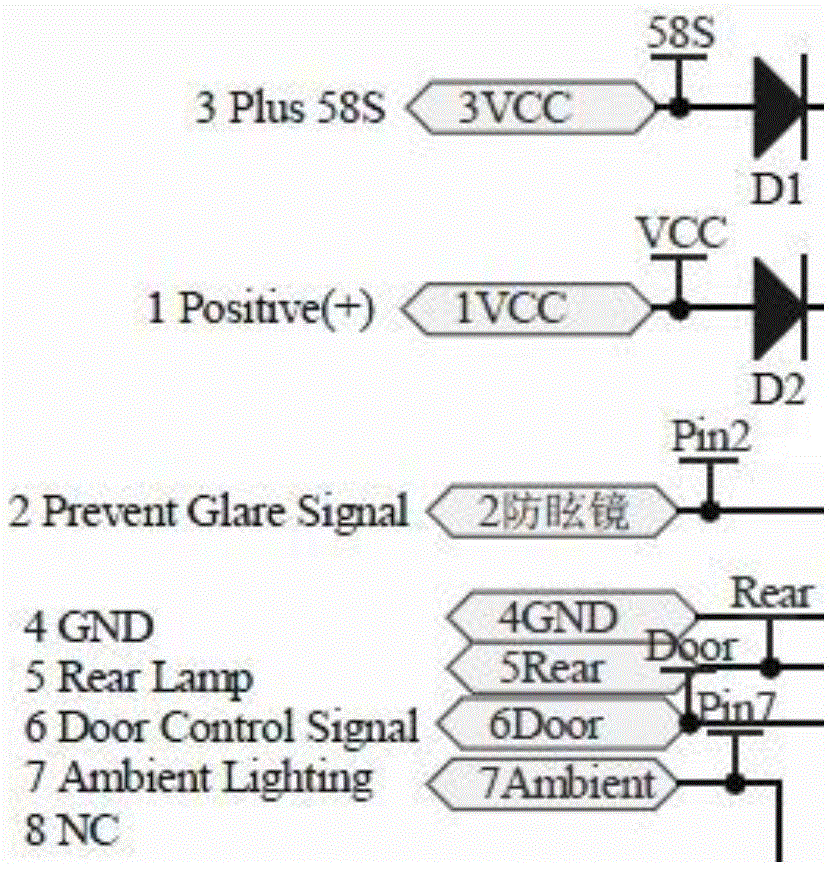

Automobile indoor atmosphere lamp light modulation circuit

ActiveCN105491729ABrightness real-time controlTo achieve the function of adjusting the atmosphere in the carElectrical apparatusElectroluminescent light sourcesOptoelectronicsBrightness perception

The invention relates to technical field of automobile indoor lamp light modulation and especially relates to an automobile indoor atmosphere lamp light modulation circuit. The automobile indoor atmosphere lamp light modulation circuit comprises a PWM pulse generation unit and a brightness adjusting unit. The PWM pulse generation unit is connected with a central console. The central console is used for adjusting the duty ratio of the PWM pulse generation unit. The PWM pulse generation unit generates corresponding PWM brightness adjusting pulses according to the duty ratio. The brightness adjusting unit adjusts the brightness of an atmosphere lamp by means of the PWM brightness adjusting pulses. According to the invention, a user can control the brightness of the atmosphere lamp to change in a certain range in real time through central console touch screen software when using the automobile indoor atmosphere lamp light modulation circuit, and the function of indoor atmosphere adjustment is realized.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST

Non-jet normal-pressure thermal plasma generator

PendingCN111491435AGuaranteed temperature conditionsAggregation is not limitedPlasma techniqueMicrowavePlasma generator

The invention discloses a non-jet normal-pressure thermal plasma generator, and belongs to the technical field of microwave plasmas. The non-jet normal-pressure thermal plasma generator comprises an igniter and a microwave source, and is characterized by further comprising a reaction cavity; a gas channel I and a gas channel II are formed in the reaction cavity; the reaction cavity comprises a cylindrical cavity and a conical cavity located above the cylindrical cavity, wherein the conical cavity is communicated with the cylindrical cavity; a microwave feed port is formed in the cylindrical cavity; the microwave source is connected with the microwave feed port; and the igniter is connected to the conical cavity. According to the invention, large and uniform thermal plasmas can be formed, so that the gas to be treated is fully and uniformly heated, and the reaction efficiency is improved; uniform distribution in a set space range is realized, destructive breakdown discharge can be effectively prevented, and heat dissipation balance is easy to control; and reasonable temperature, stable structure and long-term operation stability of the whole generator are ensured under the conditionof reducing heat dissipation as much as possible.

Owner:SICHUAN HOT PULSE MICROWAVE SCI & TECH CO LTD

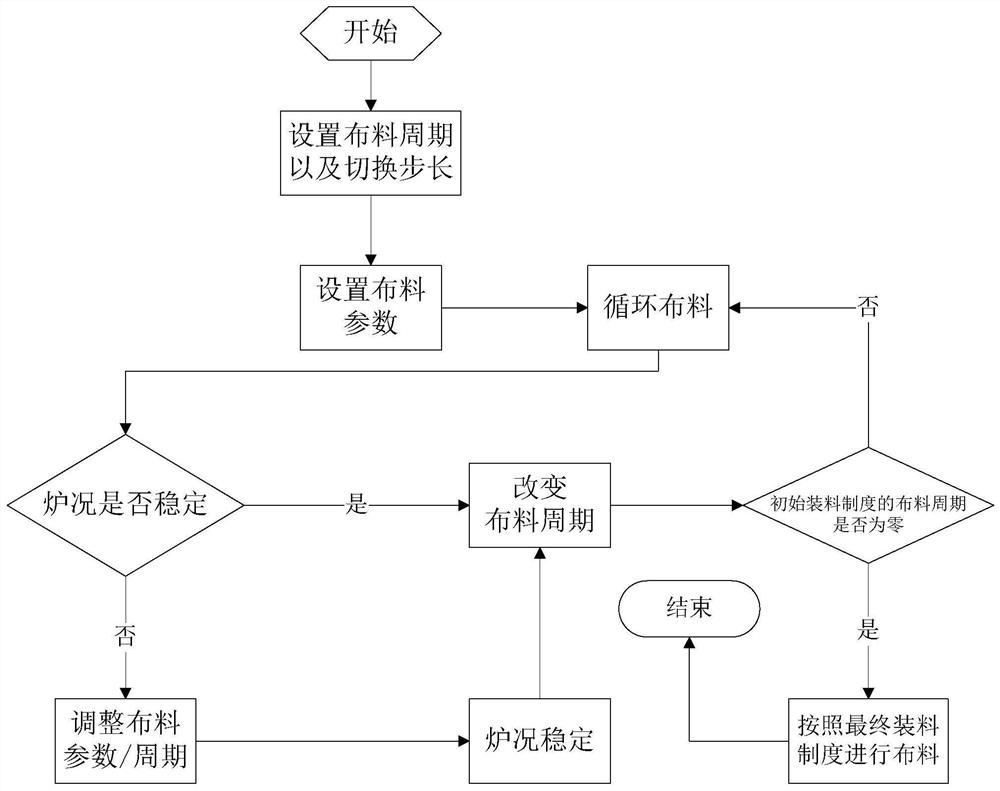

Control method for blast furnace top material distribution

ActiveCN114015826ASteady and straightAchieve fine-tuningBlast furnace detailsTotal factory controlProcess engineeringMaterial distribution

A control method for blast furnace top material distribution comprises the following steps that 1) the material distribution period of an initial charging system and the material distribution period of a final charging system are set, and the switching step length of the material distribution periods is set; 2) material distribution parameters of an initial charging system and a final charging system are set; 3) the blast furnace conducts circulating material distribution according to the initial charging system and the final charging system in sequence, and the furnace condition of the blast furnace is judged, specifically, if the furnace condition is not stable, material distribution parameters or material distribution periods of all the charging systems are adjusted; and if the furnace condition is stable, the material distribution period of the initial charging system is reduced once according to the switching step length of the material distribution period, and the material distribution period of the final charging system is increased once according to the switching step length of the material distribution period; and 4) the step 3) is repeated until the material distribution period of the initial charging system is zero.

Owner:CHONGQING IRON & STEEL GRP ELECTRONIC CO LTD

Combined gasification burner and use method thereof

PendingCN110093190AIncrease contact areaFully blendedGranular/pulverulent flues gasificationEngineeringResidence time

The invention relates to a combined gasification burner and a use method thereof. The burner comprises a first component, a second component and a third component, wherein the first component, the second component and the third component are coaxially and sequentially sleeved from outside to inside, the first component, the second component and the third component are independent of each other, and are integrally connected by fasteners, and the first component and the third component respectively have a separate fuel channel and an oxidant channel. Compared with the gasification burner only having the single-path fuel and the single-path oxidant, the combined gasification burner of the embodiments of the present invention increases the numbers of the fuel channels and the oxidant channels,increases the contact area between the fuel and the oxidant, ensures the rapid, complete and uniform doping of the fuel and the oxidant, and improves the fuel conversion rate and the burner performance in the case of the same total feeding amount, the same gasification chamber reaction space and the same residence time.

Owner:BEIJING AEROSPACE MWAY TECH CO LTD

Novel air preheater system for coal-fired power plant and work method thereof

PendingCN110107912AReduce the impact of air leakage rateReduce power consumptionIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterCold air

The invention discloses a novel air preheater system for a coal-fired power plant and a work method thereof. An inlet main flue communicates with a branch flue A and a branch flue B which are parallel. The branch flue A is provided with a tubular air preheater. The branch flue B penetrates through a rotary type air preheater and is internally provided with an adjusting baffle. A primary air inletpipeline and a primary air outlet pipeline are both connected with the tubular air preheater. A secondary air pipeline penetrates through the rotary type air preheater. The inlet end of a primary airbypass is connected with the primary air outlet pipeline. The outlet end of the primary air bypass is connected with an outlet of the secondary air pipeline. The tubular air preheater and the second branch bin rotary type air preheater are combined in parallel, a primary air system and smoke are isolated, the influence of high-pressure primary air on the air leakage rate of the air preheaters, thetwo means of the primary air bypass and the adjusting baffle are adopted, the air temperature of hot primary air can be adjusted, and the zero mixing amount of cold air is achieved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Ternary-cycle cascade refrigeration natural gas liquefaction system and method thereof

ActiveCN102628634BEmbody adaptabilityRich adjustment meansSolidificationLiquefactionRefrigerationPlate fin heat exchanger

The invention discloses a ternary-cycle cascade refrigeration natural gas liquefaction system and a method thereof. Heat is transferred from a relatively low temperature level cycle to an adjacent relatively high temperature level cycle: a first stage propylene refrigeration cycle provides cold energy for natural gas, refrigerant ethene, and formulated refrigerant; a second stage ethene refrigeration cycle provides cold energy for the natural gas and the formulated refrigerant; and a third stage formulated refrigerant refrigeration cycle provides cold energy for the natural gas and the formulated refrigerant itself. Through the cooling by seven heat exchangers and one plate-fin heat exchanger, temperature of the natural gas is reduced gradually till the natural gas is liquefied. In the invention, temperature of purified natural gas is reduced gradually in seven heat exchangers and one plate-fin heat exchanger till the purified natural gas is liquefied. The cold energy needed in a liquefaction process is provided by the three systems of propylene refrigerant, ethene refrigerant, and formulated refrigerant. The systems have abundant adjusting means, and can provide matching cold energy for the natural gas liquefaction process, thereby showing operation flexibility and adaptability to raw materials of the method.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

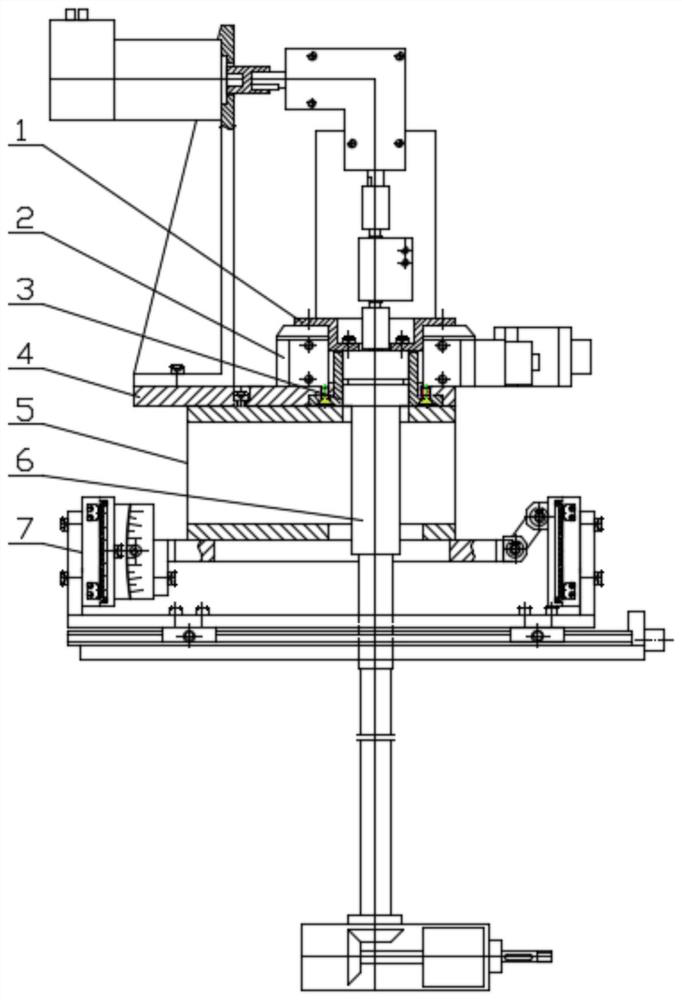

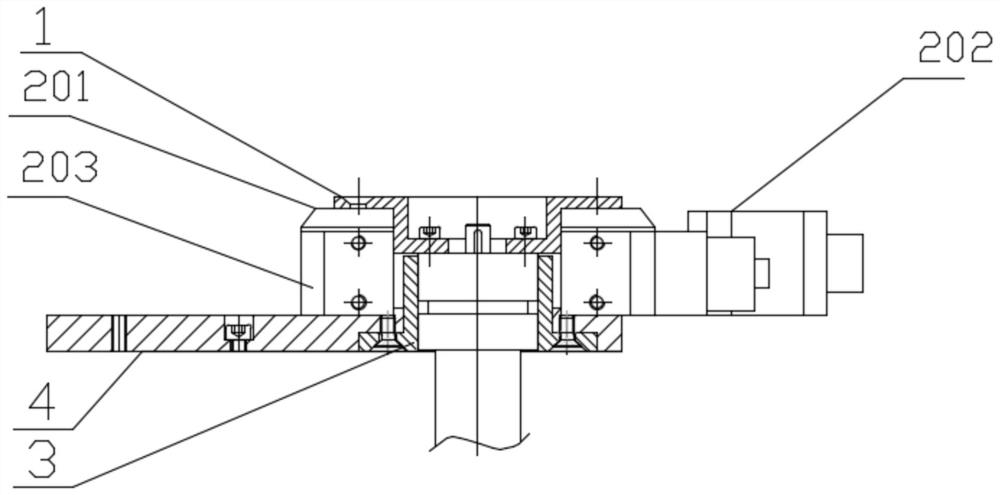

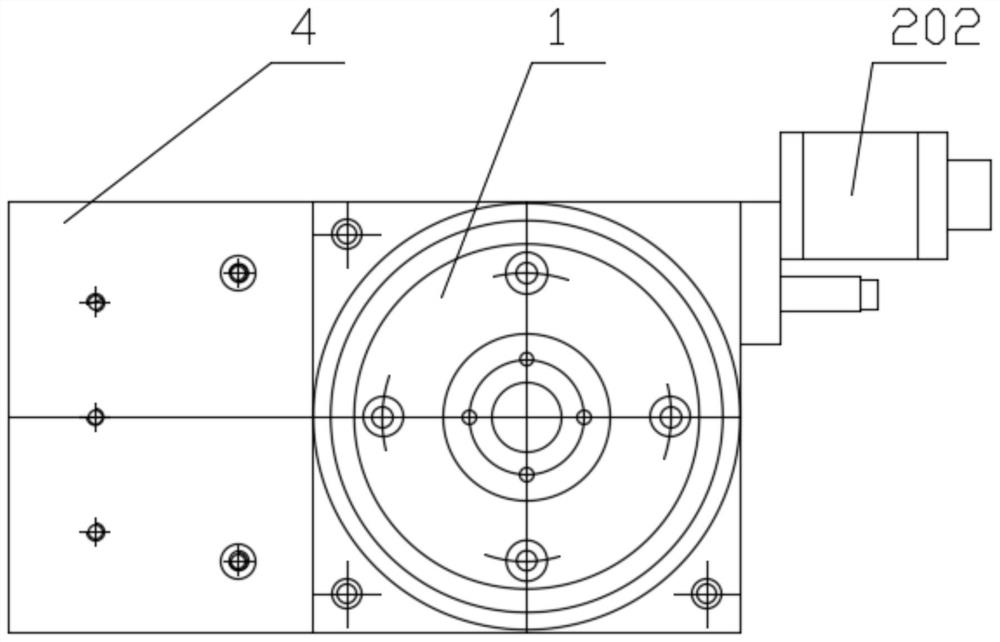

Posture adjusting mechanism for pod dynamometer

ActiveCN113581435ARealize fine adjustmentCompact structurePropulsion power plantsOutboard propulsion unitsCouplingDynamometer

The invention discloses a posture adjusting mechanism for a pod dynamometer. The mechanism comprises a flange, a rotation posture adjusting mechanism is installed at the bottom of the flange, a through hole is formed in the middle of the rotation posture adjusting mechanism, a supporting rod inner shaft of the pod dynamometer is installed concentric with the through hole, a transition plate is fixed to the bottom of the rotation posture adjusting mechanism through a fastener, a six-component balance is installed at the bottom of the transition plate, a trim posture adjusting mechanism is installed at the bottom of the six-component balance, and an inner shaft of a supporting rod of the pod dynamometer penetrates through the middle of the six-component balance and the middle of the trim posture adjusting mechanism at the same time. Through cooperative work of the trim posture adjusting mechanism and the rotation postureadjusting mechanism, comprehensive adjusting means and high adjusting precision can be achieved, the yaw angle of the pod dynamometer can be automatically adjusted, the adjusting precision is extremely high, fine adjustment of the trim angle of the pod dynamometer is achieved, adjustment of each degree of freedom is simple and convenient, and mutual coupling is avoided.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Large-capacity efficient ultra-supercritical tower-type baffle temperature-adjusting brown coal boiler matched with fan mill

PendingCN108518664AReach the design valueRich adjustment meansSteam generation using pressureCombustion processSuperheaterEngineering

The invention discloses a large-capacity efficient ultra-supercritical tower-type baffle temperature-adjusting brown coal boiler matched with a fan mill and relates to a boiler, in particular to a tower-type boiler subjected to temperature adjusting through a baffle. The problem that a reheater cannot reach the design value through the steam temperature adjusting means of an original boiler is solved. The large-capacity efficient ultra-supercritical tower-type baffle temperature-adjusting brown coal boiler matched with the fan mill comprises a boiler body. A coal economizer system, a superheater system and a reheater system are arranged in a hearth of the boiler body. Arrangement of the coal economizer system is superior to that of a traditional primary coal economizer in the aspects thatfull-load denitration of the boiler can be ensured and the efficiency of a whole boiler unit is improved. A secondary superheater is arranged on the front face of a middle partition wall, the smoke proportion between the superheater and the reheater is adjusted through a smoke adjusting baffle to achieve the purpose of steam temperature adjusting finally, and it can be better ensured that the reheater reaches the design value.

Owner:HARBIN BOILER

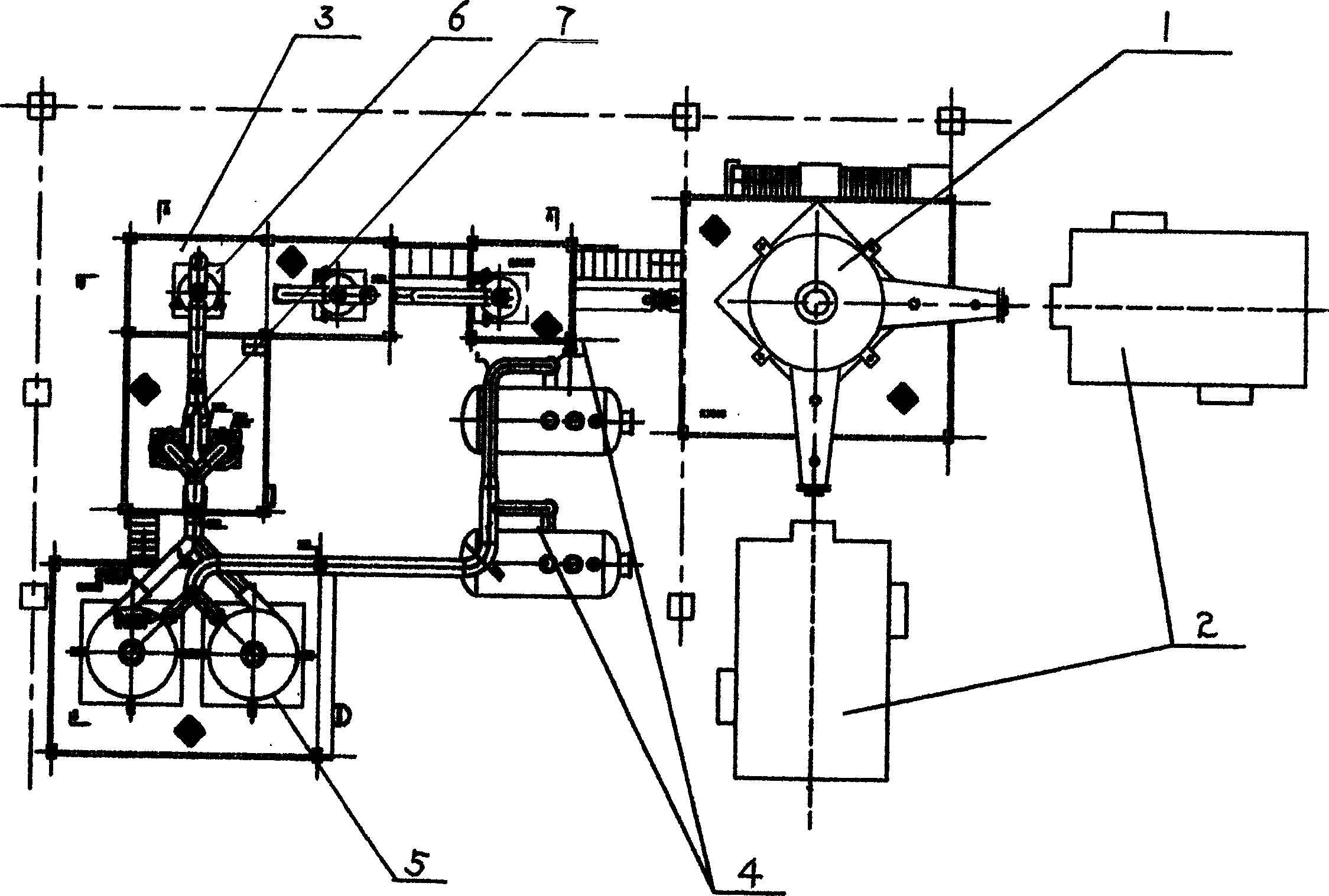

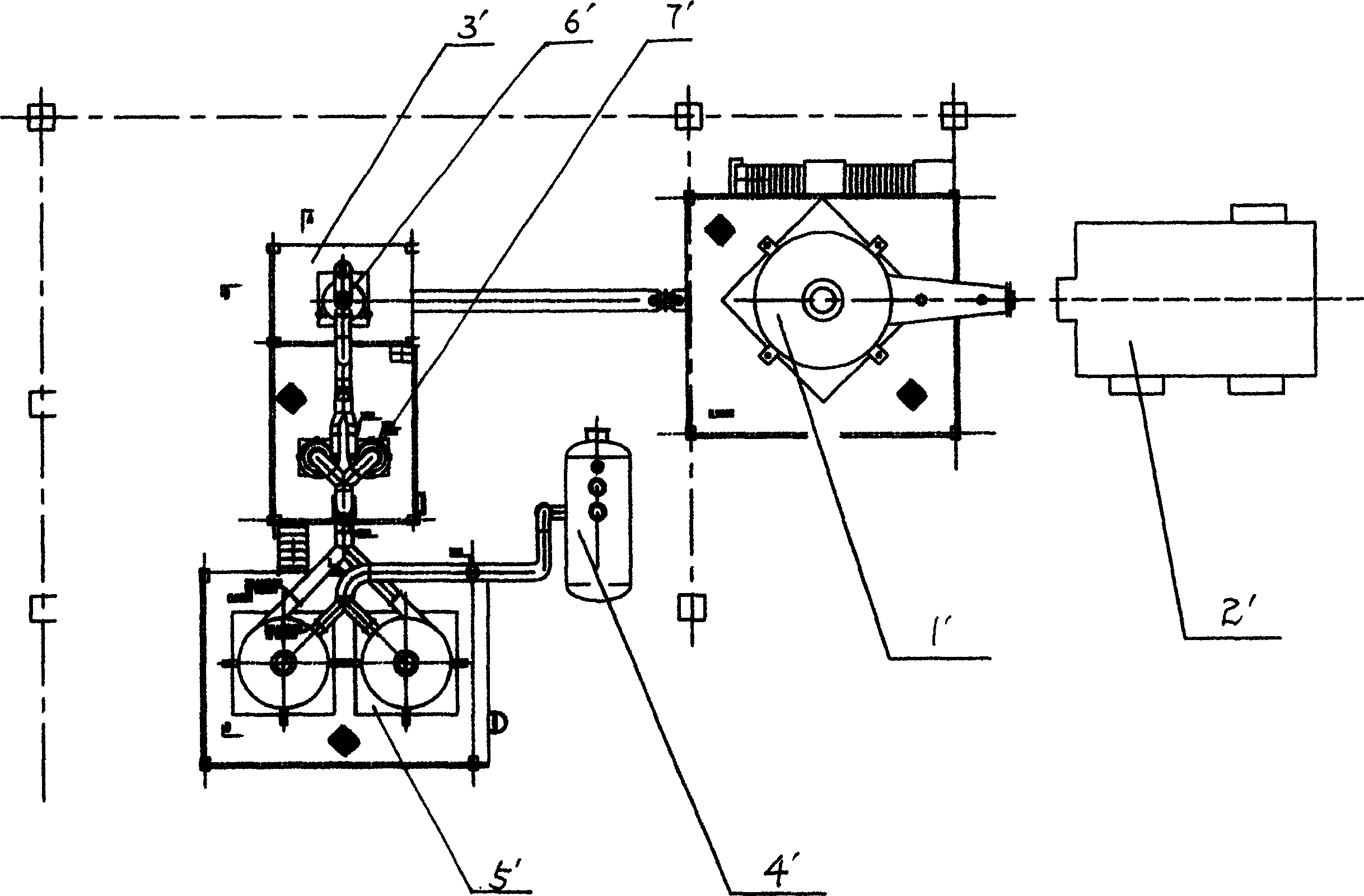

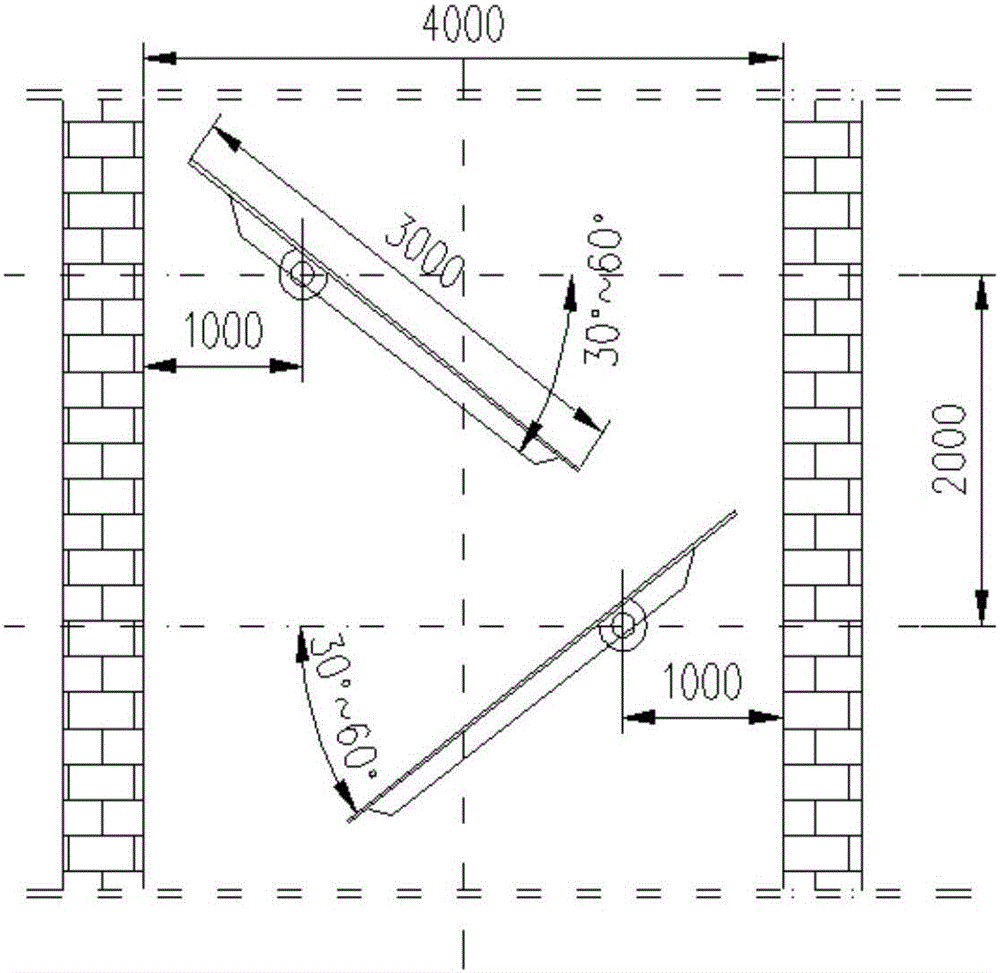

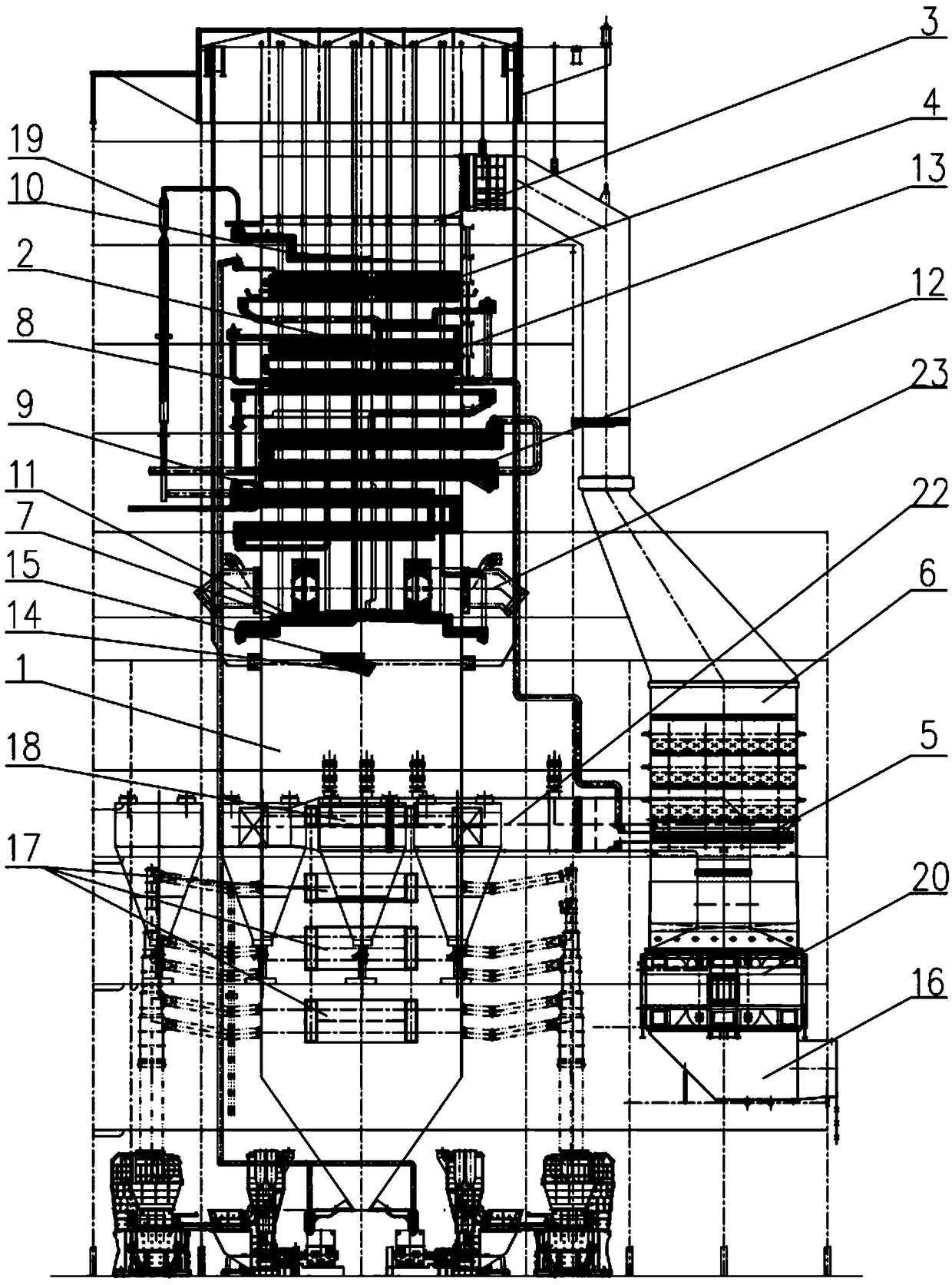

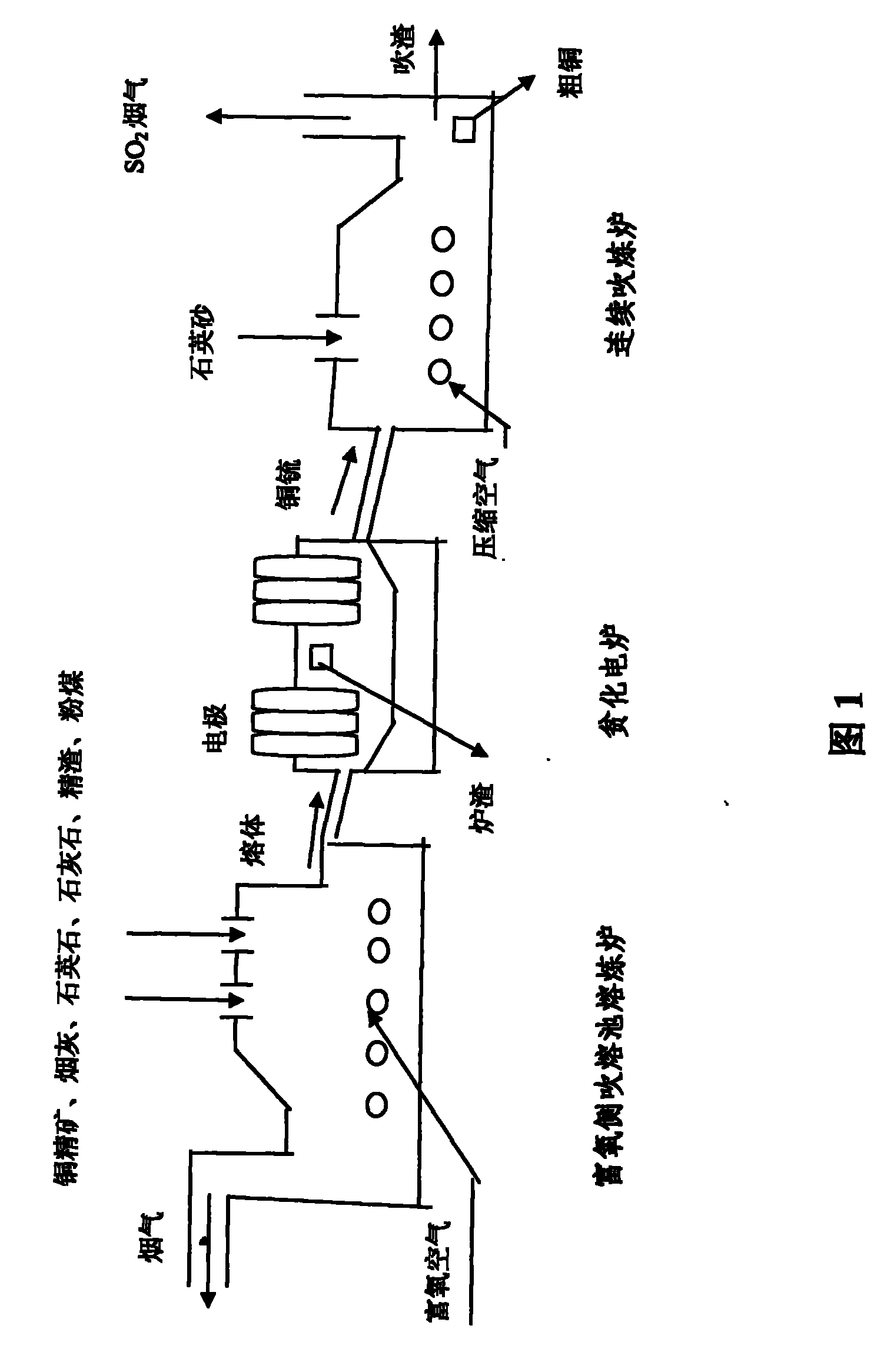

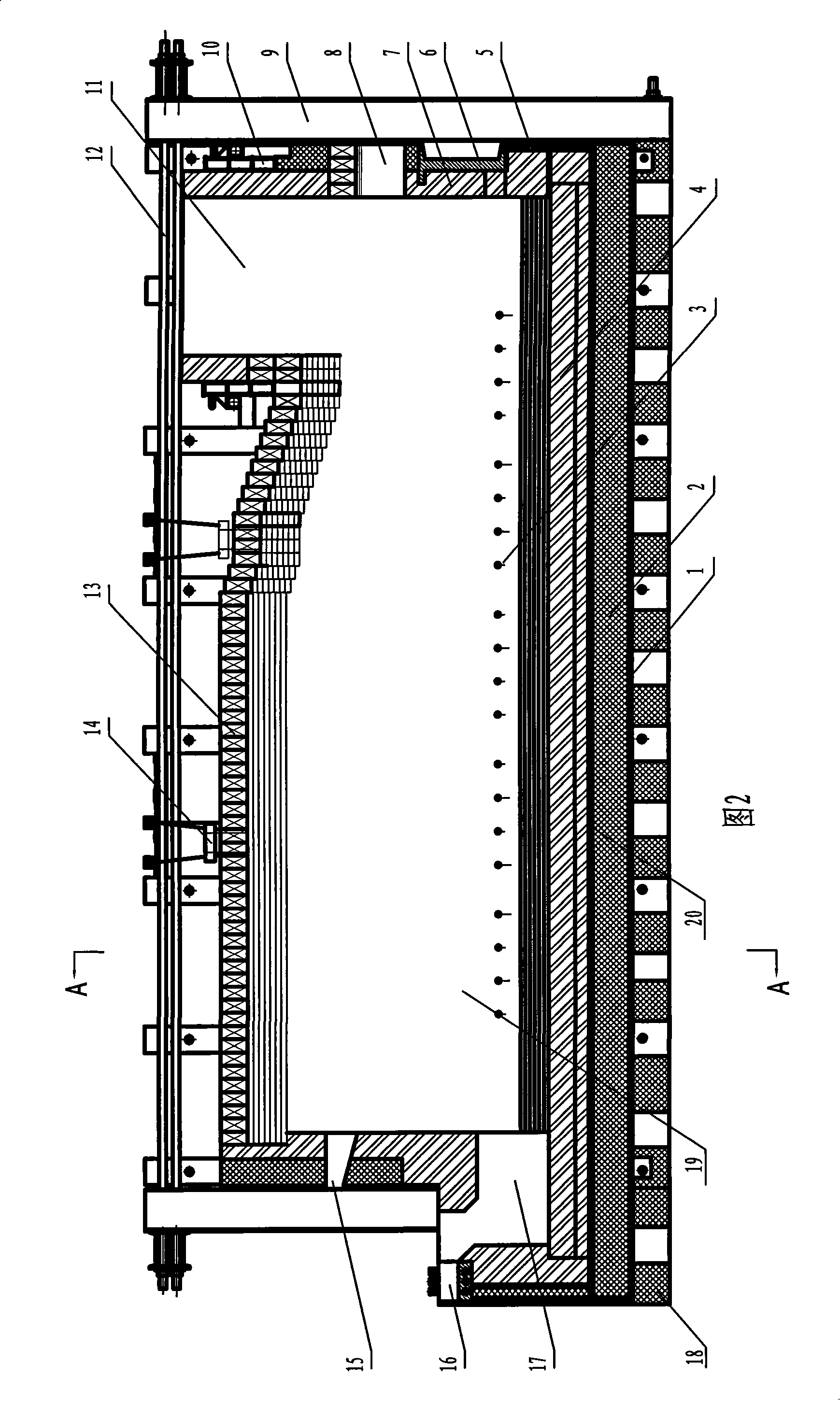

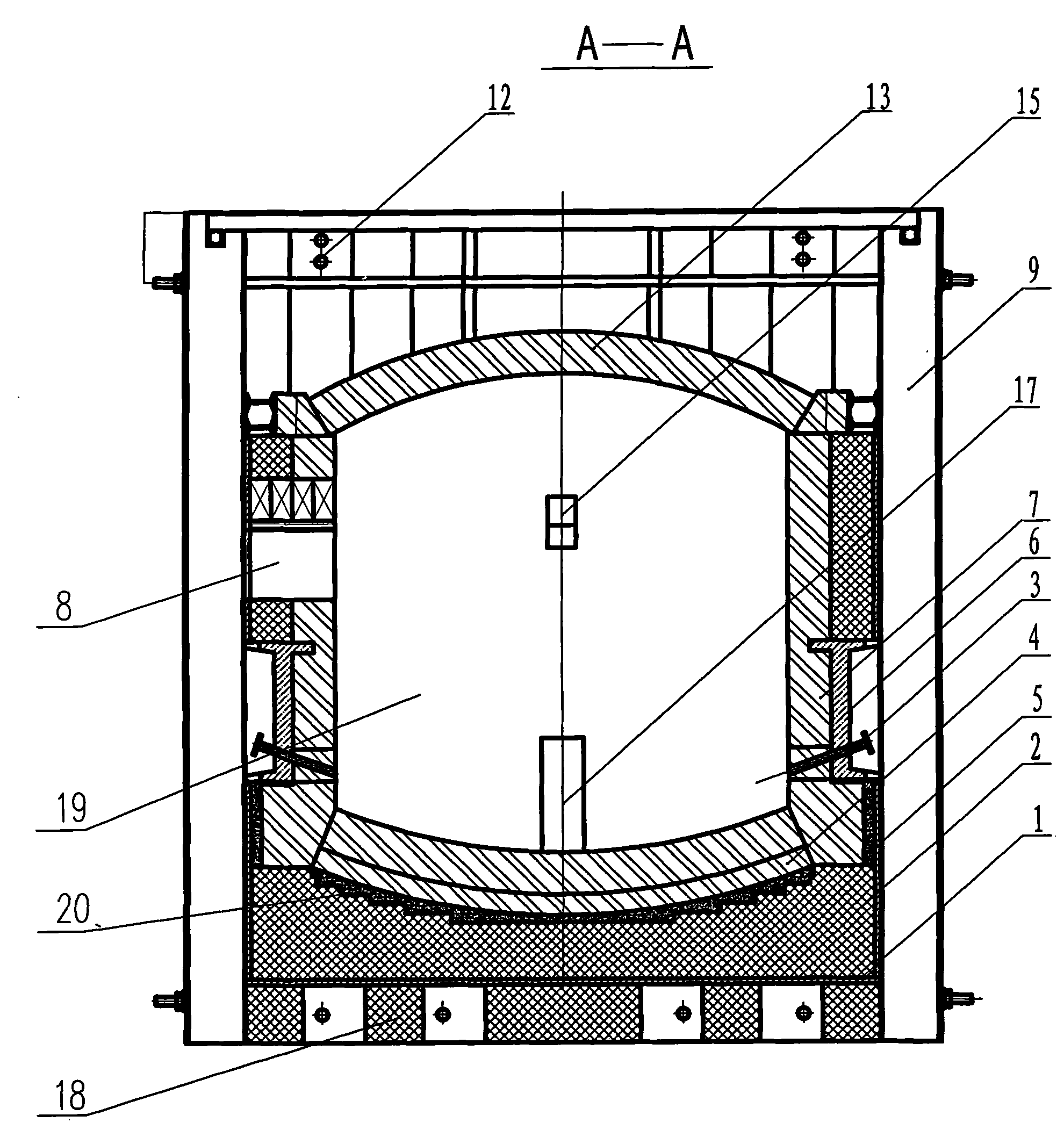

Manufacturing technique for oxygen-enriched side blowing molten pool raw copper smelting and special equipment thereof

InactiveCN101275185BLess investmentReduce energy consumptionRotary drum furnacesCrucible furnacesMelting tankHigh pressure

The invention disclose a production process for melting blister copper in a bath by side-blowing of oxygen enrichment and special apparatuses thereof, the process comprises the steps of melting concentrate of copper, diluting the slug and air refining copper matte, which is to say, adding the material comprising copper, quartz, limestone and fine coal into the furnace of bath and blowing the highpressure oxygen enrichment air into the furnace, the formed copper matte, slug are ceaselessly flowed into a diluting electric furnace, manufacturing acid after recycling waste heat by smoke gas at high temperature; overheating the slug through an electrode and separating the slug from copper matte to obtain the diluted slug and copper matte which is fed into the continuously-air-refining furnacethrough a chute slipway; reacting the copper matte with arenaceous quartz under the effect of compressed air to obtain the blister copper, performing mineral dressing to the air-refined slug, manufacturing the acid with SO<2>; the invention has less process investment, high heat utilization rate, low energy consumption, good effect of environmental protection, compact apparatus structure, small occupied area, great processing ability, light sticking in air flue, simple operations, diverse measures in adjusting the condition of furnace which is easy to control, high level of mechanization and low labor intensity.

Owner:YANTAI PENGHUI COPPER IND

Treatment method and device for acid gas

ActiveCN108722149AReasonable useReduce energy consumptionDispersed particle separationSulfur compoundsChemistryPre treatment

The invention discloses a treatment method and a device for acid gas. The device comprises a hydration reactor, a hydrate neutralizing device, a first-stage absorption reactor, a second-stage absorption reactor and a product tank. The invention also provides a method for treating the acid gas by adopting the device. According to the treatment method and the device, NaHS products meeting national quality standards can be produced while up-to-standard discharge of the acid gas is realized; environmental improvement is organically combined with the production process of a chemical product. Compared with the prior art, the method disclosed by the invention has the advantages that the acid gases containing CO2 and hydrogen sulfide can be economically and efficiently pretreated, energy in the technological process is reasonably utilized and energy consumption is greatly reduced; the whole treatment process is environmentally friendly and reliable and no three wastes are produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com