Smelting separation furnace reduction system and method based on natural gas-oxygen heating

A technology of natural gas and melting furnaces, applied in furnaces, shaft furnaces, furnace types, etc., can solve problems affecting iron quality, complex structure, etc., and achieve the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

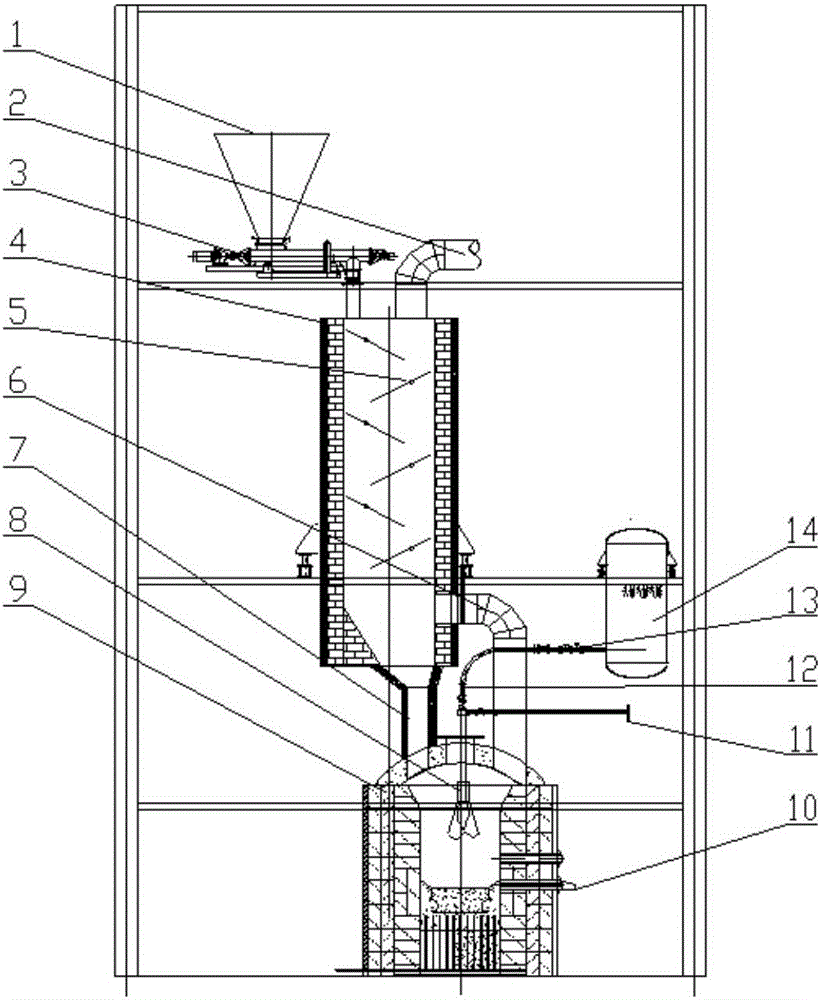

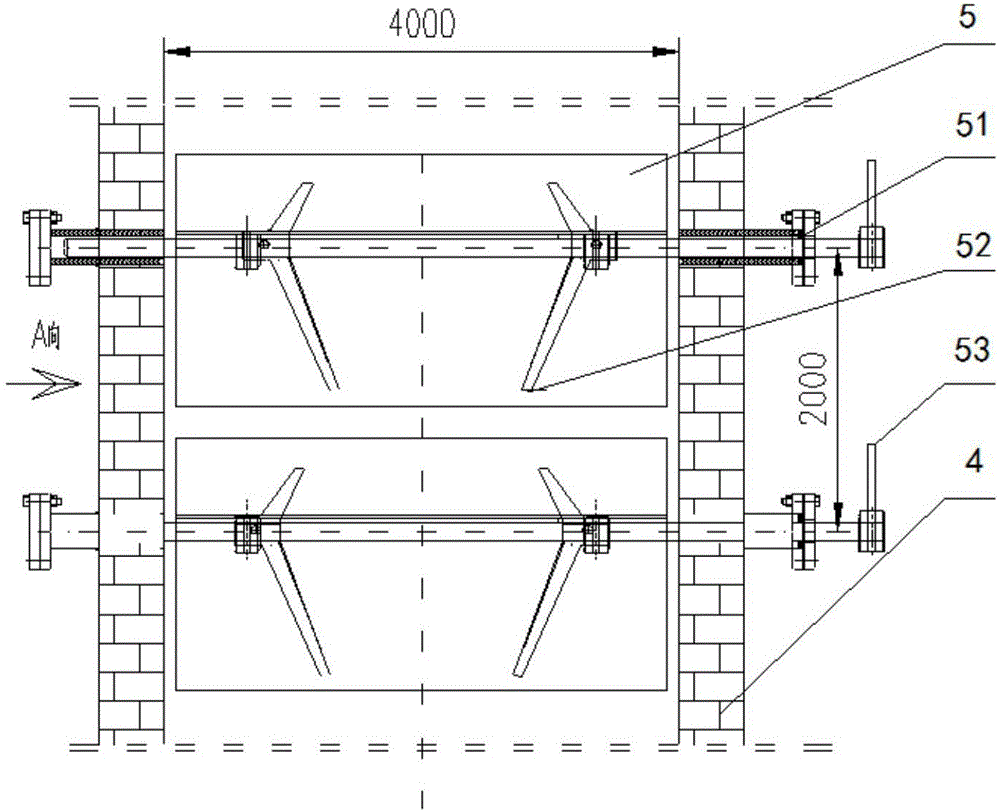

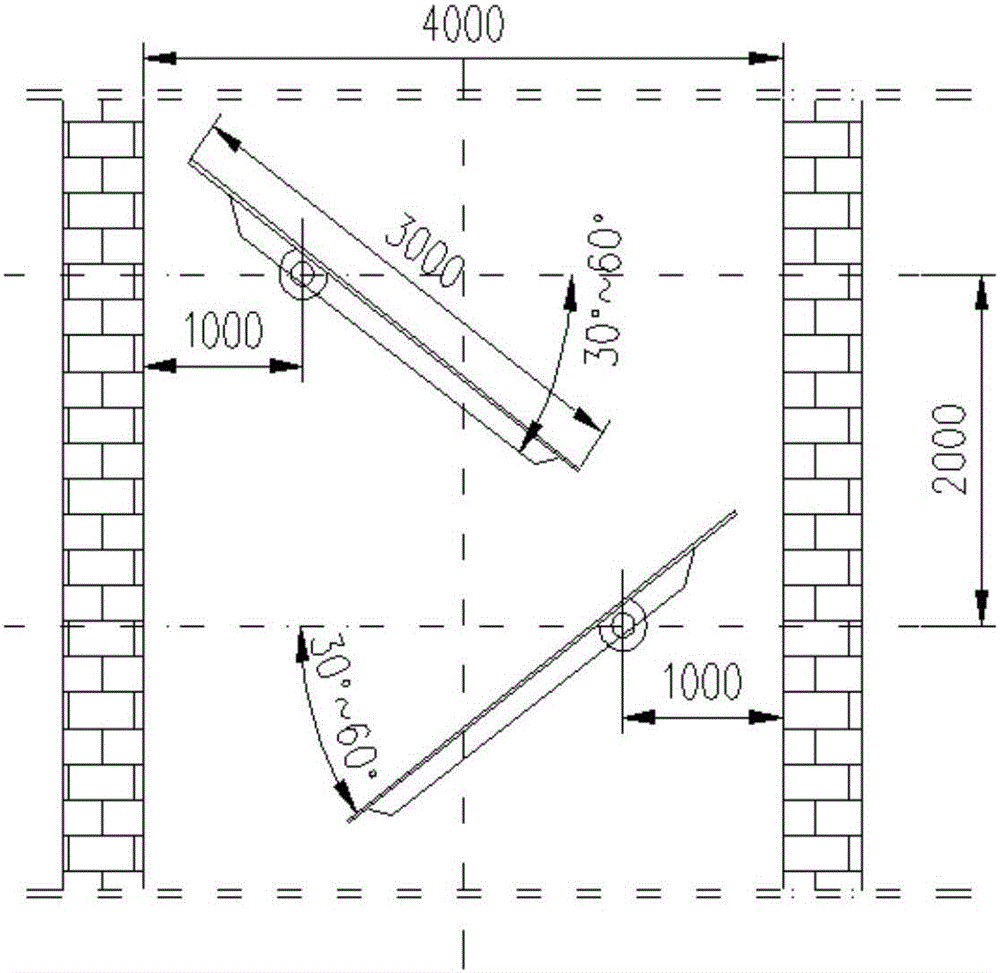

[0050] Mineral powder and a small amount of flux lime powder are put into the raw material hopper 1, and are fed into the direct reduction shaft furnace 4 through the speed-regulating feeder 2 at the lower part of the raw material hopper 1. The mineral powder falls on the inclined baffle plate 5 and slides down gradually. The high-temperature CO gas coming out of the melting furnace 9 enters the direct reduction shaft furnace 4 through the high-temperature flue gas pipeline 6 . The high-temperature CO gas reacts with the ore powder, and the ore powder generates direct reduced iron powder, and the iron powder enters the melting furnace 9 through the feeding port 7 . Natural gas comes out from the natural gas storage tank 14, enters the spray gun through the natural gas pipeline 12, and its flow is controlled by the regulating valve 13 on the pipeline. The combustion of natural gas and oxygen in the furnace provides heat and the temperature required for the reaction. The natura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com