Patents

Literature

51results about How to "Low content of harmful impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

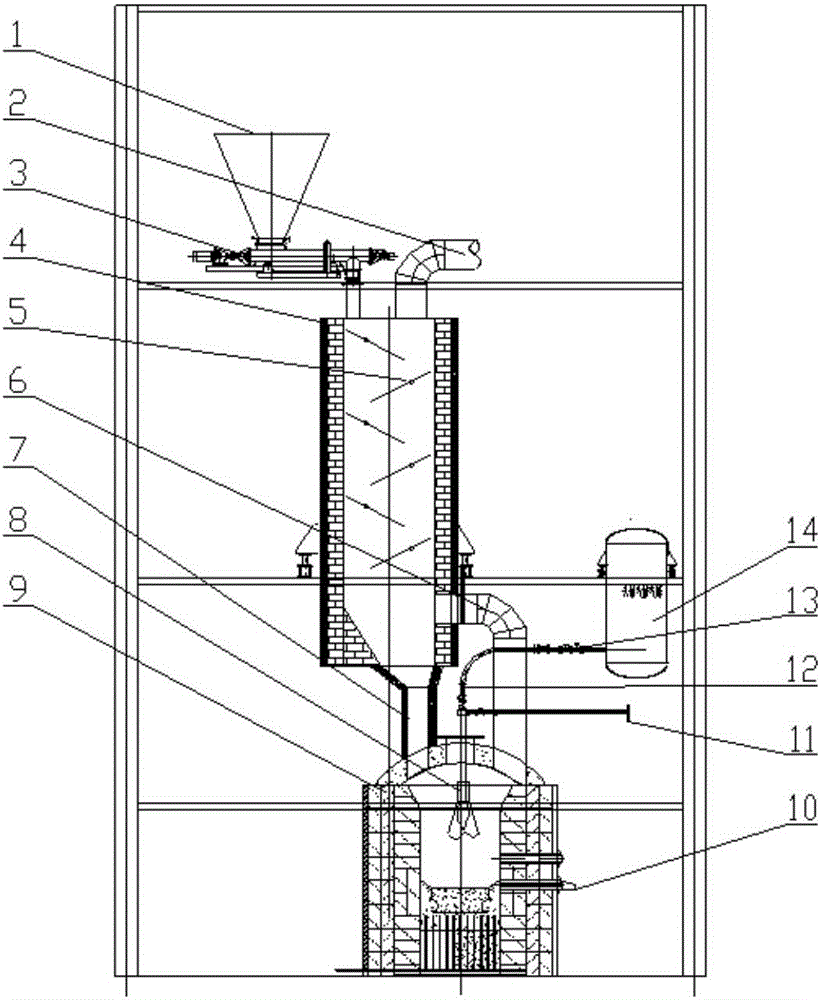

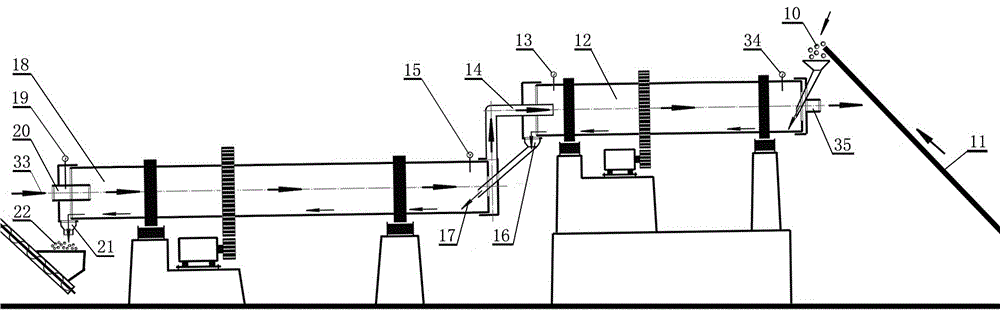

Pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement

ActiveCN105129744AImprove decomposition efficiencyIncrease concentrationSulfur compoundsClinker productionDecompositionPhosphogypsum

The invention relates to the technical field of industrial production of sulfuric acid and cement, the field of industrial solid waste comprehensive utilization, and the field of environment protection and treatment, and particularly relates to a pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement. The method includes the steps of powder grinding of raw materials, multi-stage cyclic pre-heating, high-effective decomposition and kiln gas separation and purification. The method is used for preparing a cement raw material from the phosphogypsum subjected to pre-heating decomposition with clay, sand rock, coke and such auxiliary materials in the process of producing the sulfuric acid from the phosphogypsum with co-production of the cement. The method solves the problems that a pre-heating decomposition technology in the prior art is low in decomposition ratio of phosphogypsum, is low in productivity of sulfuric acid and clinker, is liable to cause crusting and blocking in a kiln and is high in production energy consumption, can reduce the decomposition efficiency of the phosphogypsum and accelerate escape of SO2, and further increase the productivity of the sulfuric acid and cement clinker. The pre-heating decomposition method of producing the sulfuric acid from the phosphogypsum with co-production of the cement can significantly reduce sintering temperature and energy consumption of the clinker, can reduce production cost of sulfuric and cement clinker, and can further increase comprehensive utilization rate of the phosphogypsum.

Owner:湖北湖大天沭新能源材料工业研究设计院有限公司

Preparation process for high-strength high-conductivity micro copper wire

The invention discloses a preparation process for a high-strength high-conductivity micro copper wire. The preparation process comprises the following steps: S1, adding electrolytic copper into a smelting furnace, preserving heat and melting the electrolytic copper completely to obtain molten copper, introducing an inert gas, adding a composite refining agent, standing and slagging; S2, detecting that the molten copper comprises the following components in percentage by weight: 0.45 to 0.55 percent of Ti, 0.25 to 0.35 percent of Zr, 0.07 to 0.09 percent of Te, 0.07 to 0.09 percent of La, 0.03 to 0.05 percent of Y, 0.15 to 0.25 percent of Sn, less than or equal to 0.05 percent of Mg, and the balance of Cu; S3, enabling a crystallizer of a continuous casting machine to extend into the molten copper, and drawing upwards through a drawing roller mechanism to form an oxygen-free copper rod; S4, extruding the oxygen-free copper rod continuously and drawing repeatedly to obtain the high-strength high-conductivity micro copper wire. According to the copper wire which is prepared by the preparation process, the electric conductivity reaches over 95 percent IACS, and moreover, the tensile strength is also over 480 MPa.

Owner:安徽晋源铜业有限公司

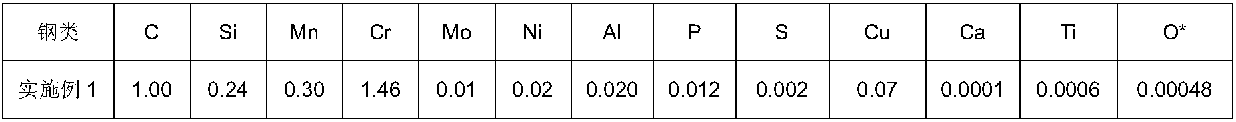

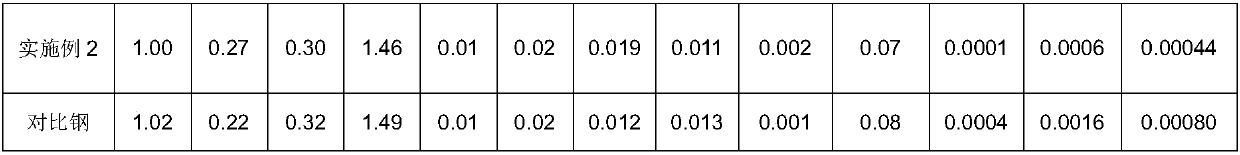

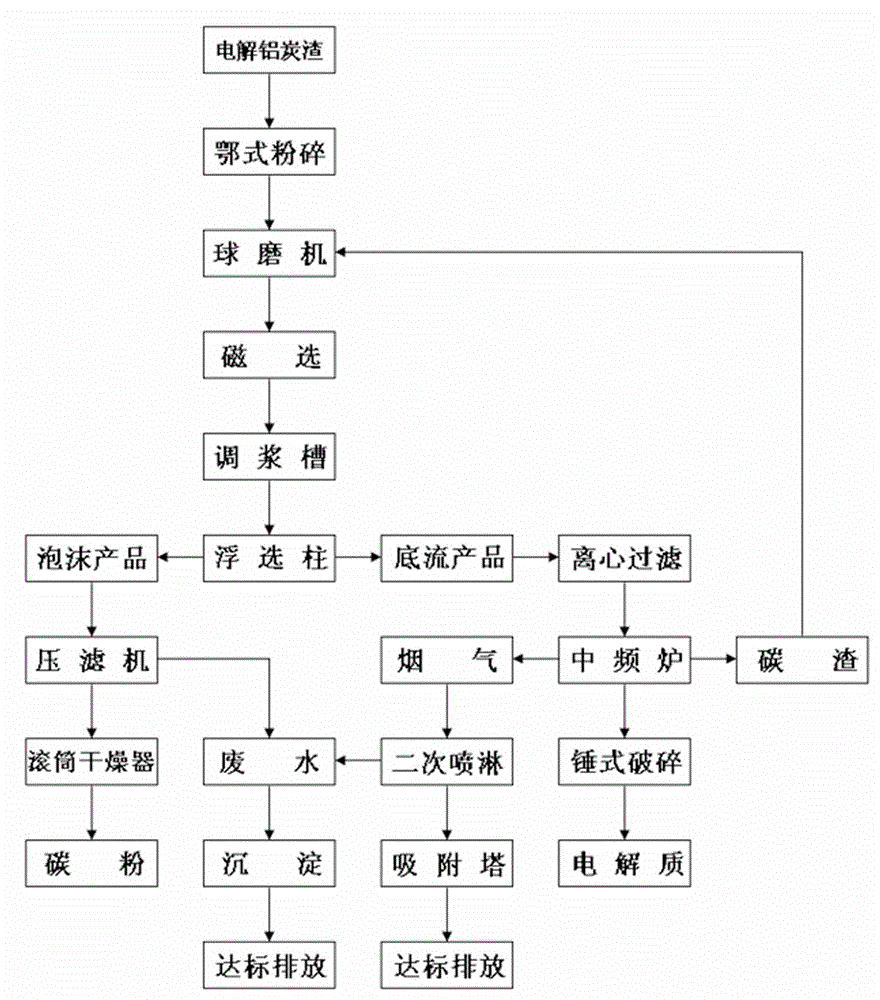

High-carbon chromium bearing steel for railway truck bearing and preparation method

The invention relates to high-carbon chromium bearing steel for a railway truck bearing. The high-carbon chromium bearing steel for the railway truck bearing is characterized in that product elementsC, Si, Mn, Cr and Al have the same requirements on technical conditions with vacuum degassed high-carbon chromium bearing steel for a traditional railway truck bearing. Hairlines longer than 0.6 mm donot exist through detection by a tower shape method; a metallographical method is adopted to detect that the B fine system of microcosmic brittle inclusions is not more than 1.5 grade, the B thick system is not more than 0.5 grade, the D fine system is not more than 0.5 grade, the D thick system is not more than 0.5 grade and the DS system is not more than 1.0 grade; the metallographical method is adopted to detect without allowing existence of microcosmic holes; the center porosity of a macrostructure is not more than 1.0 grade; the general porosity is not more than 1.0 grade; the ingot segregation is not more than 1.0 grade; and the metallographical method is adopted to detect that the carbide liquation is not more than 0 grade, the carbide strip shape is not more than 2.0 grade and thecarbide net shape is not more than 2.5 grade. The high-carbon chromium bearing steel belongs to excellent bearing steel with high purity, high structure uniformity and high compactness.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

High alumina slag ball and preparing method thereof

InactiveCN1521279AAvoid bursting phenomenonReduce inclusionsProcess efficiency improvementSlagSesquioxide

The high-aluminum slag ball used as molten steel surface heat insulating and refining agent in smelting pure steel contains metal aluminum, alunina, titania, boron sesquioxide, calcium carbonate, fluorite powder and evitable impurity. With controlled silica, carbon, sulphur and phosphorus contents, the high-aluminum slag ball is suitable for use in smelting low-carbon and low-silicon pure steel or other super-pure steel. It has low water content to avoid molten steel sputtering and content of deoxygenating and alloying elements capable of being altered in wide range to suit for steel variety change. It has excellent performance of heat insulating for the surface of molten steel, and makes the deoxygenation and refining completed simultaneously to reduce included oxide in molten steel.

Owner:梅一峰

Preparation method of copper chloride hydroxide

ActiveCN101717110AHigh purityImprove protectionAnimal feeding stuffCopper chloridesResource utilizationCopper chloride

The invention discloses a preparation method of copper chloride hydroxide. The method comprises the following steps: adding copper hydroxide slurry in copper chloride solution according to a ratio of 2.5-3.5:1, reacting under the condition that the temperature is 80-160 DEG C, the pH value is 4-9 and the pressure is 0-600kPa, obtaining the reaction product after the reaction; and rinsing, centrifuging and drying the reaction product to obtain copper chloride hydroxide. The method of the invention has simple and safe operation, less waste discharge, lower production cost, more complete resource utilization and less environmental pollution.

Owner:昕嘉生物技术(长沙)有限公司

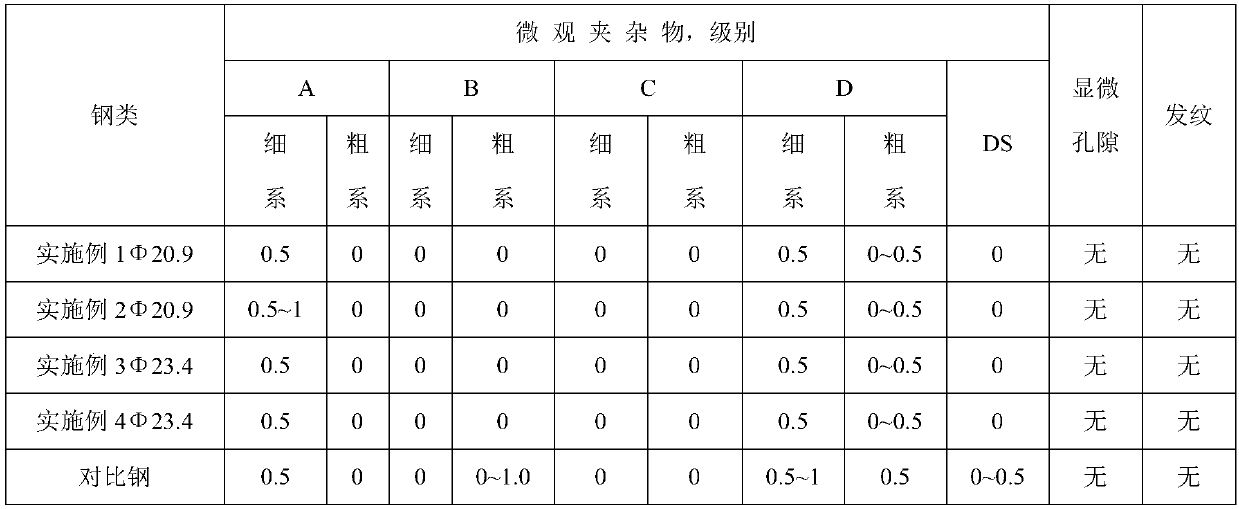

Method for producing electrolyte for aluminium and recovering carbon through recycle of aluminum electrolysis carbon residue

ActiveCN103949459ALow content of harmful impuritiesSolid waste disposalCarbon preparation/purificationFiltrationImpurity

The invention discloses a method for producing an electrolyte for aluminium and recovering carbon through recycle of aluminum electrolysis carbon residue. The method comprises steps of pretreatment, flotation separation, preparation and post-treatment, and specifically comprises: crushing electrolysis waste old carbon material, removing scrap iron through magnetic separation, performing separation on the electrolysis waste old carbon material subjected to pretreatment to obtain a bottom flow product and a foam product; performing filtering, carbon-removing and crushing on the separated bottom-flow product to obtain a target electrolyte for aluminium; performing pressing filtration and drying on the separated foam product to obtain a target carbon powder; and recovering flue gas and wastewater generated during preparation, and discharging when flue gas and wastewater reach the standards. According to the method, waste materials badly needing processing are taken as the raw material, various resources are completely recycled, waste gas is completely recovered and subjected to purification processing, also the produced electrolyte for aluminium is low in water content and less in harmful impurities, and is an ideal raw material for aluminium electrolysis production, and the carbon powder obtained through flotation can be used as a dye during production of aluminium electrolysis bottom pastes or bottom carbon blocks or metallurgy production.

Owner:云南蓝天铝业环保科技有限公司

Preparation method of basic zinc chloride

The invention discloses a preparation method of basic zinc chloride, comprising the following steps of: adding sodium hydroxide or ammonia water into zinc chloride solution with the mol ratio of the sodium hydroxide or ammonia water to zinc chloride solution of 7.5-8.5:5, reacting under the condition that the temperature is 60-105 DEG C and the pH value is 5-9, and obtaining reaction products after the reaction is finished; and washing with water, centrifuging and drying reaction products to obtain the basic zinc chloride. The preparation method is simple and safe in operation, and has the advantages of little waste emission, low production cost and excellent product quality.

Owner:XINGJIA BIO ENG CO LTD

Diatomite-based silicon fertilizer and preparation method thereof

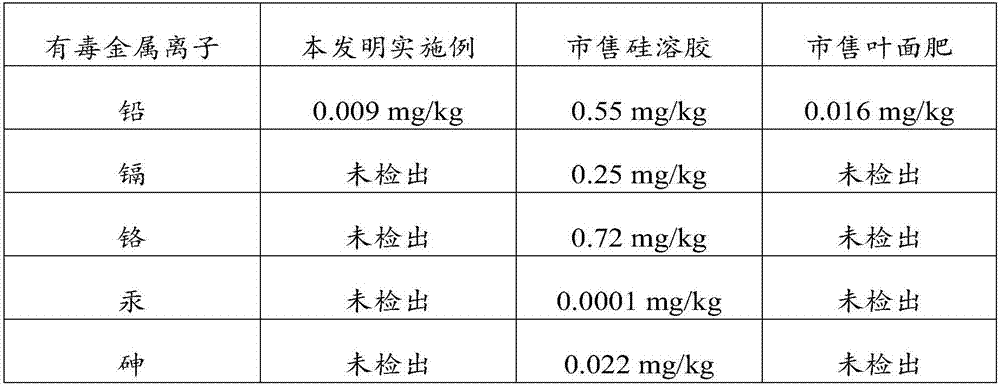

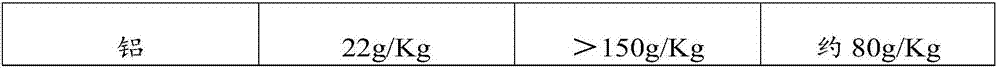

ActiveCN107245011AReduce heavy metal contentIncrease acidityLiquid fertilisersFertilizer mixturesSiliconMetal

The invention relates to the field of a fertilizer and provides a preparation method of a diatomite-based silicon fertilizer. The preparation method of the diatomite-based silicon fertilizer comprises the following steps: putting diatomite into an alkaline solution to form turbid liquid, performing heating and heat preservation on the turbid liquid, cooling, performing solid-liquid separation, and taking separating liquid; and adding an acidic solution into the separating liquid, adjusting the pH value of the separating liquid to be 8 to 10, heating and stirring completely, and then cooling. According to the preparation method, harmful metal can be separated effectively, the aim of reducing the content of the heavy metal in the diatomite is fulfilled, the diatomite-based silicon fertilizer is alkaline, and the acidity of the soil is improved, so that the soil is improved; and the preparation method has the advantages of being simple, low in cost, easy to popularize and the like. In addition, the invention futher provides the diatomite-based silicon fertilizer. The diatomite-based silicon fertilizer is prepared with the preparation method of the diatomite-based silicon fertilizer. The diatomite-based silicon fertilizer has high silicon content, is easy to absorb by crops, can greatly increase the yield of the crops during small-amount application; application modes are diversified, and diatomite-based silicon fertilizer can be used for root fertilization and also can serve as a foliage fertilizer to be applied.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI +1

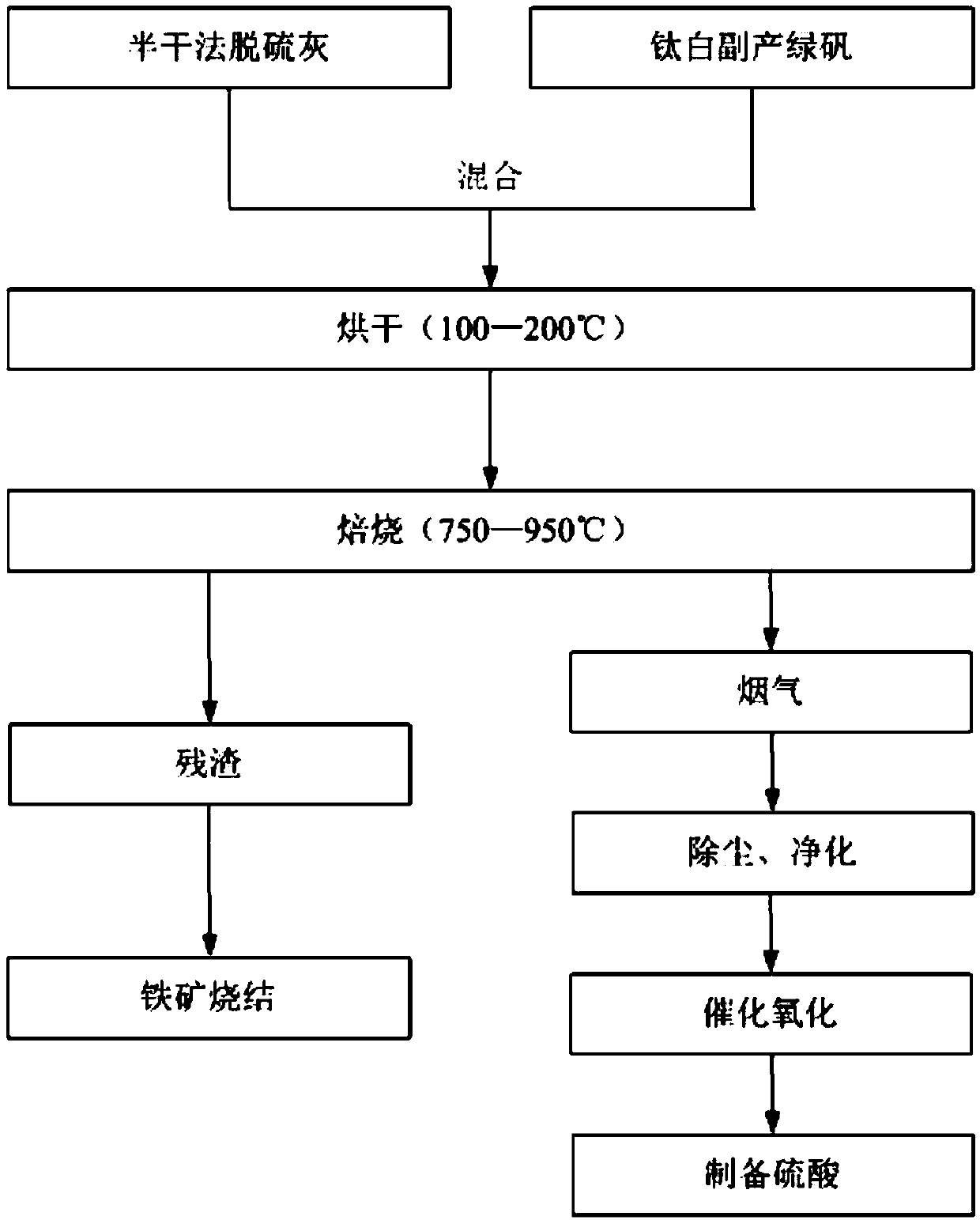

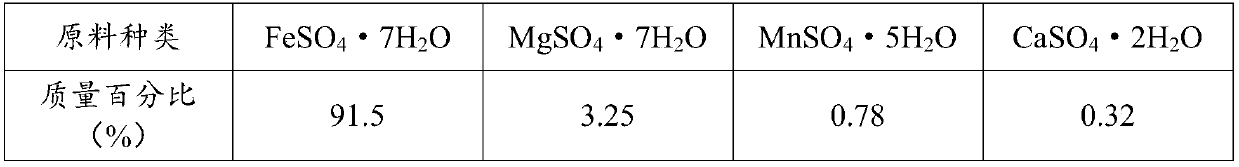

Method for realizing collaborative resource utilization of semi-dry desulfurization ash and titanium dioxide byproduct copperas

ActiveCN109593953ALow costReduce consumptionSulfur compoundsProcess efficiency improvementFlue gasResource utilization

The invention discloses a method for realizing collaborative resource utilization of semi-dry desulfurization ash and titanium dioxide byproduct copperas. The method sequentially comprises the following steps of S1, mixing the semi-dry desulfurization ash and the titanium dioxide byproduct copperas according to a certain ratio and then drying; S2, feeding the dried materials into a high-temperature furnace for roasting; S3, carrying out dust removal, purifying, catalytic oxidation and absorption the preparation sulfuric acid on the flue gas generated in the step S2; S4, feeding the residue generated in the step S2 into the iron ore sintering mixture to replace part of the iron-containing raw material and the flux. The method has the advantages that the sintering semi-dry desulfurization ash and the titanium dioxide byproduct copperas are simultaneously processed, so that the problem of environmental protection is solved, and treating waste by using waste is achieved.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +2

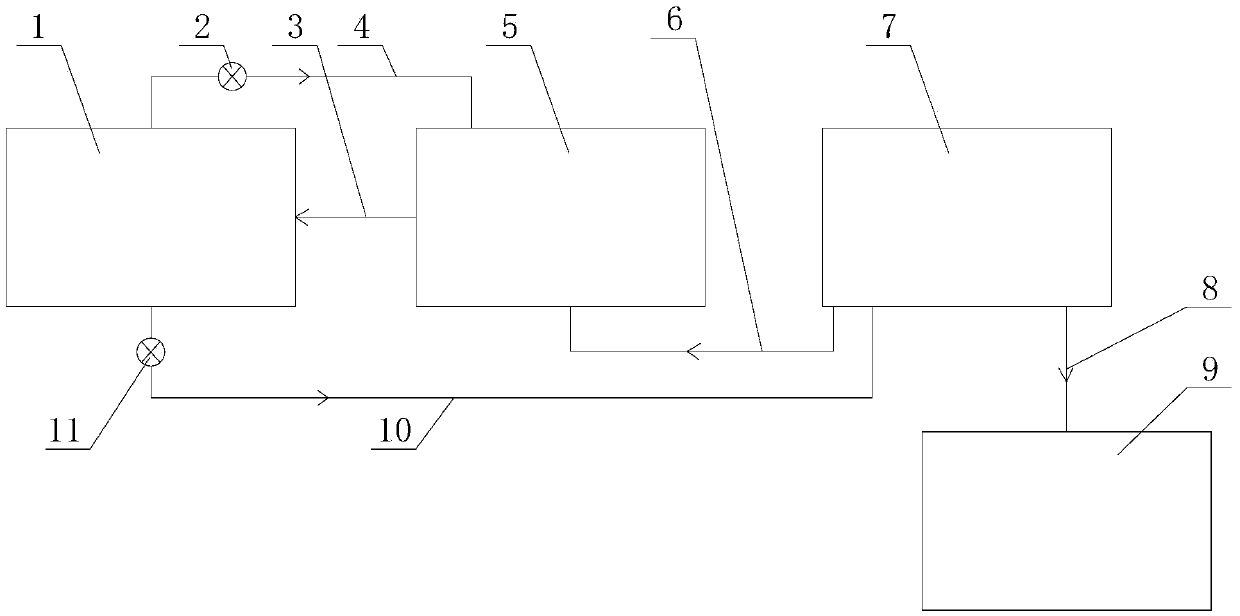

Magnetite concentrate quality-improving and impurity-reducing technology and device

InactiveCN105498929ARaise the gradeLow content of harmful impuritiesMagnetic separationGrain treatmentsMagnetiteClosed loop

The invention discloses a magnetite concentrate quality-improving and impurity-reducing technology and device. The technology comprises the following specific steps that firstly, a vertical spiral stirring ore grinding machine is used for carrying out wet grinding on coarse concentrate particles with the grade lower than or equal to 60%, and primary ore pulp is obtained after grinding is carried out for a period of time; secondly, the primary ore pulp is discharged into an ore pulp pool and pumped into a hydrocyclone through a slurry pump, the primary ore pulp is classified through the hydrocyclone, the classified settled sand (at a coarse fraction) is subjected to the second step again, and secondary ore pulp (at a fine fraction) overflows; thirdly, the secondary ore pulp enters a cylindrical magnetic extractor, and iron ore concentrate with the iron-containing grade higher than 63.5% is obtained. According to the magnetite concentrate quality-improving and impurity reducing technology, the steps are orderly linked, the existing low-grade coarse concentrate is ground, subjected to closed-loop classification and magnetic sorting, the iron-containing grade of the magnetite concentrate is increased to 63.5% or above from 60% or lower, and the content of silicon and aluminum impurities is effectively reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD

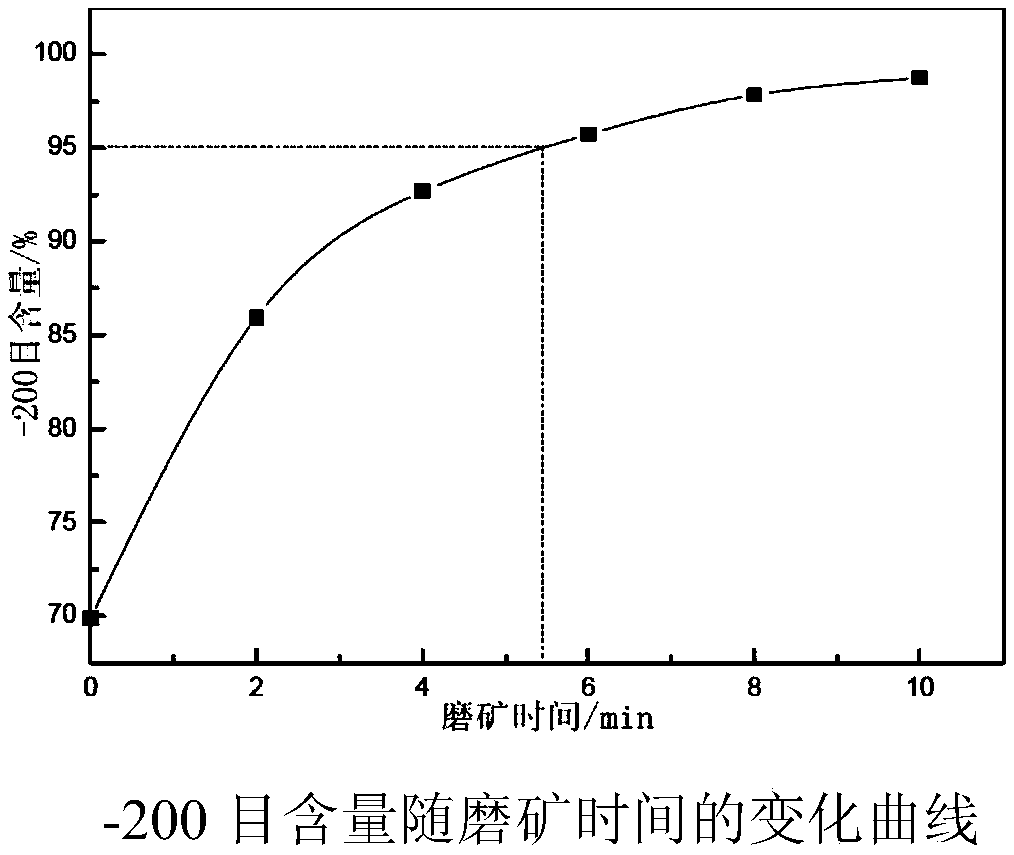

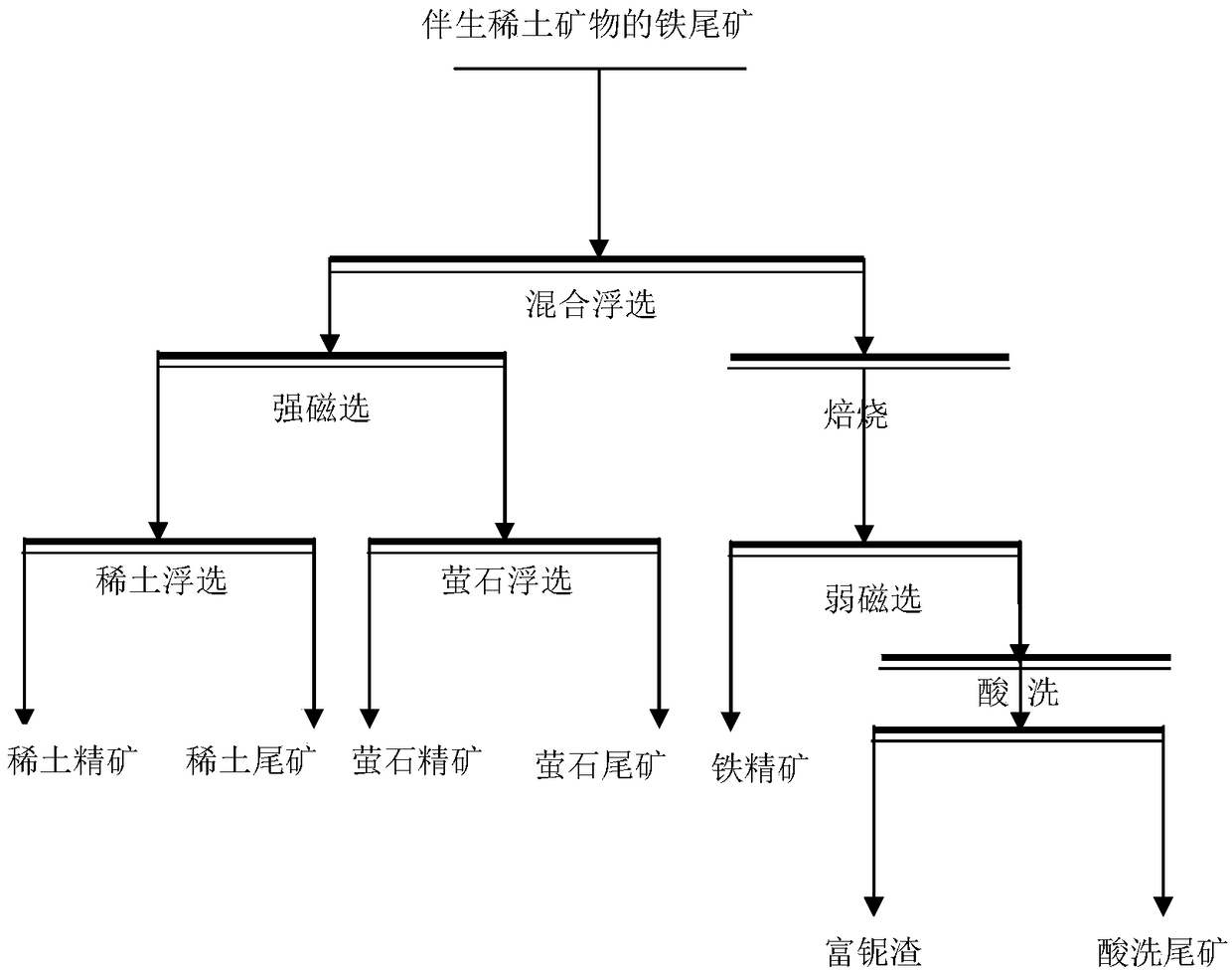

Multi-component recovery and ore dressing method for iron tailings of associated rare earth minerals

ActiveCN108580023AReduce the content of fluorine and other harmful elementsLow content of harmful impuritiesWet separationSlagMaterials science

The invention relates to a multi-component recovery and ore dressing method for iron tailings of associated rare earth minerals, and belongs to the field of mineral machining engineering and comprehensive recovery and utilization of resources. The method comprises the steps that the iron tailings of the associated rare earth minerals are subjected to bulk flotation of rare earth minerals and fluorite minerals to obtain bulk flotation concentrates and bulk flotation tailings; the bulk flotation concentrates are subjected to high-intensity magnetic separation at magnetic field strength of 0.4-1.0T to obtain high-intensity magnetic separation concentrates and high-intensity magnetic separation tailings; the high-intensity magnetic separation concentrates are subjected to rare earth flotationto obtain rare earth flotation concentrates and rare earth flotation tailings, high-intensity magnetic separation tailings are subjected to fluorite flotation to obtain fluorite flotation concentratesand fluorite flotation tailings; and the bulk flotation tailings after being dewatered and dried are roasted in reducing atmosphere, the minerals obtained after roasting are subjected to low-intensity magnetic separation at 0.1-0.3T to obtain low-intensity magnetic concentrates and low-intensity magnetic tailings. Three concentrates, that is, rare earth concentrates, fluorite concentrates and iron concentrates and niobium-rich slag are finally obtained so as to improve the comprehensive utilization ratio of the iron tailings of the associated rare earth minerals.

Owner:NORTHEASTERN UNIV

Preparation process of flaky pure copper powder catalyst

ActiveCN102935369AHigh purityLow content of harmful impuritiesMetal/metal-oxides/metal-hydroxide catalystsLow activityFluidized bed

The invention relates to a preparation process of a flaky pure copper powder catalyst. The preparation process comprises the steps of: preparing copper cuttings, grinding the copper cuttings, and grading flaky copper to prepare the flaky pure copper powder catalyst. As any element harmful to an environment is not introduced to the whole process course, the harmful impurity content is low, and the stability of product quality is good; the catalytic characteristic is obviously better than that of common composite copper powder, so that the effect of synthesizing a metal catalytic system by an organosilicone monomer is improved, organosilicone monomer synthesis and the space time yield of fluidized beds are increased, the synthetic reaction period is prolonged, the preparation efficiency of dimethyldichlorosilance is improved, the cost is reduced, and the benefits are created; and promoters, such as Zn, Sn and P are used so that the synthetic reaction of the organosilicone monomer can be flexibly regulated according to impurity conditions in the fluidized beds and contact compositional variation, and the problems of low activity and selectivity of the composite copper powder and deteriorated catalytic performances as reaction goes on are solved.

Owner:湖南省天心博力科技有限公司

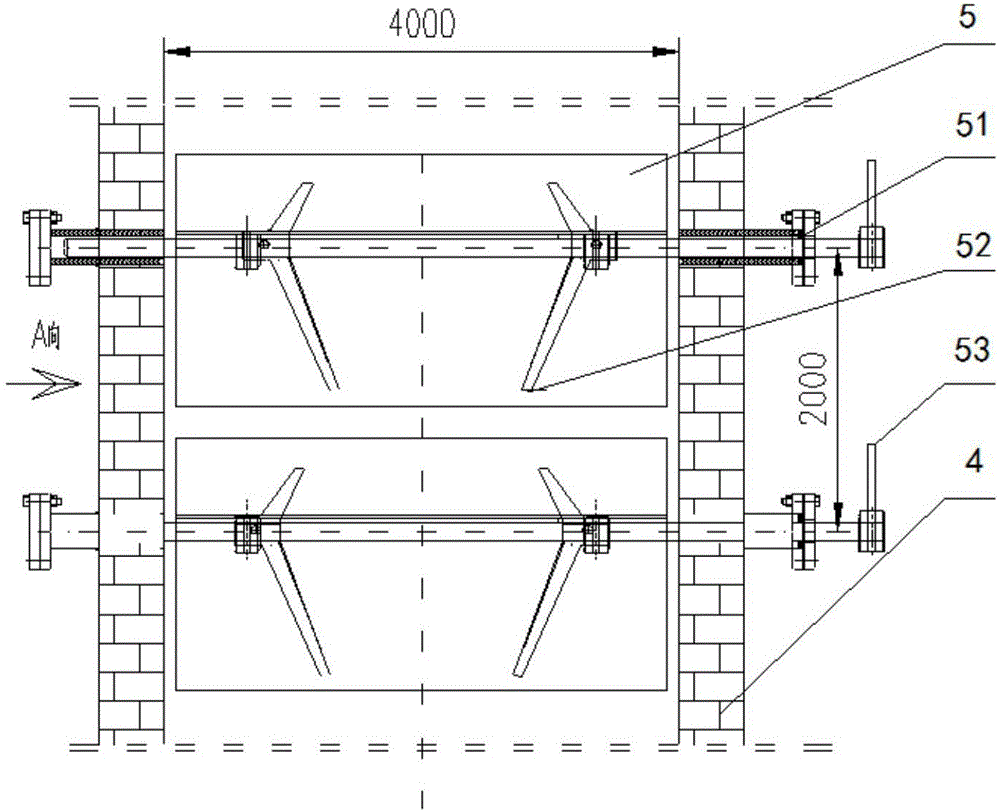

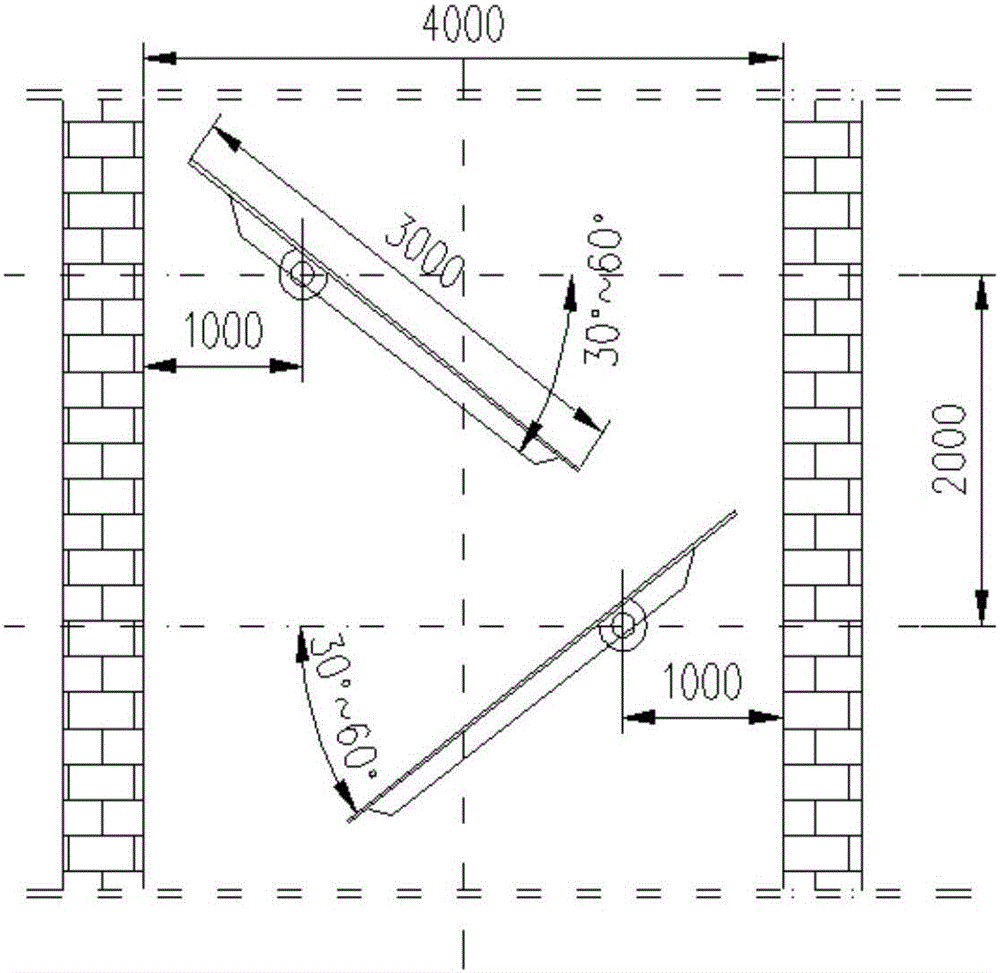

Smelting separation furnace reduction system and method based on natural gas-oxygen heating

PendingCN106148627AComplete restorationReduce usageShaft furnaceGas emission reductionFlue gasOxygen

The invention relates to a smelting separation furnace reduction system and method based on natural gas-oxygen heating. The system comprises a reduction shaft furnace, a smelting separation furnace and a natural gas-oxygen gun, wherein the reduction shaft furnace comprises a mineral powder-flux feeding port, a dropping port and a flue gas inlet; inclination-adjustable baffle plates are arranged in the hearth of the reduction shaft furnace; the smelting separation furnace comprises a feeding port, a flue gas outlet and a discharging port; the feeding port communicates with the dropping port of the reduction shaft furnace; the flue gas outlet communicates with the flue gas inlet of the reduction shaft furnace; a spray gun head of the natural gas-oxygen gun is arranged in the smelting separation furnace; and the natural gas-oxygen gun extends into the smelting separation furnace from the furnace top of the smelting separation furnace. According to the system and the method provide by the invention, the mineral powder dropping speed and residence time can be controlled through arrangement of the inclination-adjustable baffle plates in the reduction shaft furnace, thereby guaranteeing the mineral powder reduction effect.

Owner:SHENWU TECH GRP CO LTD

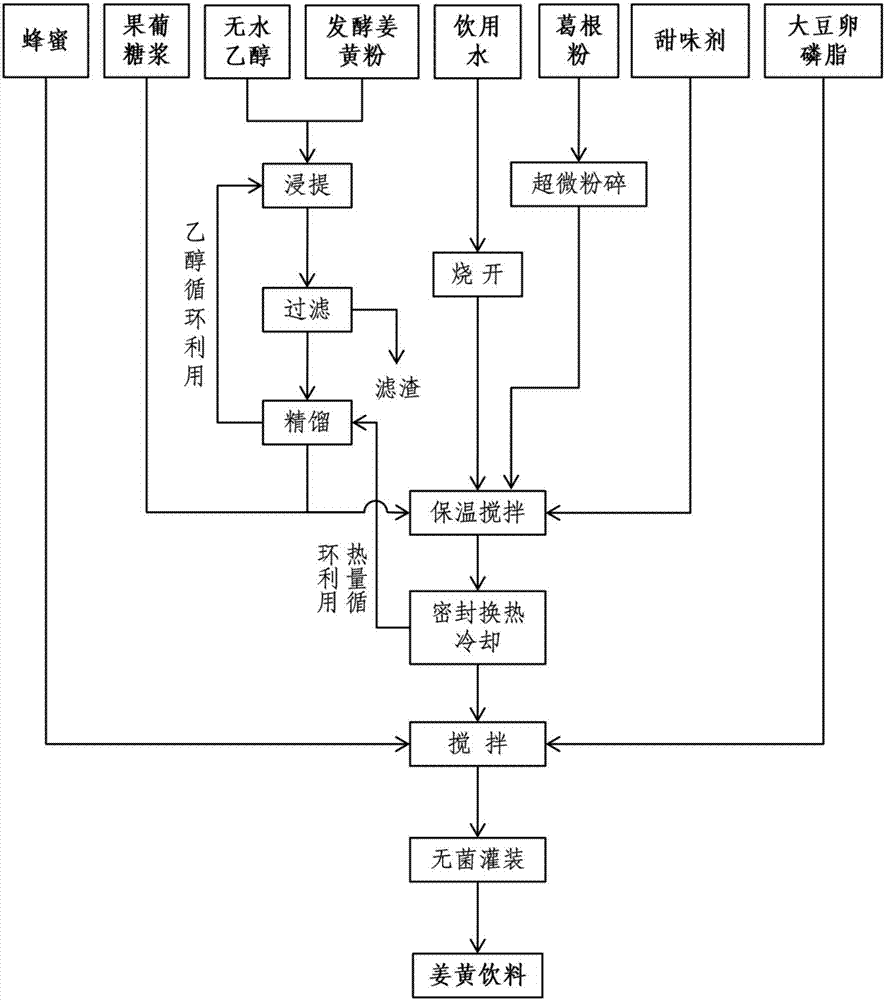

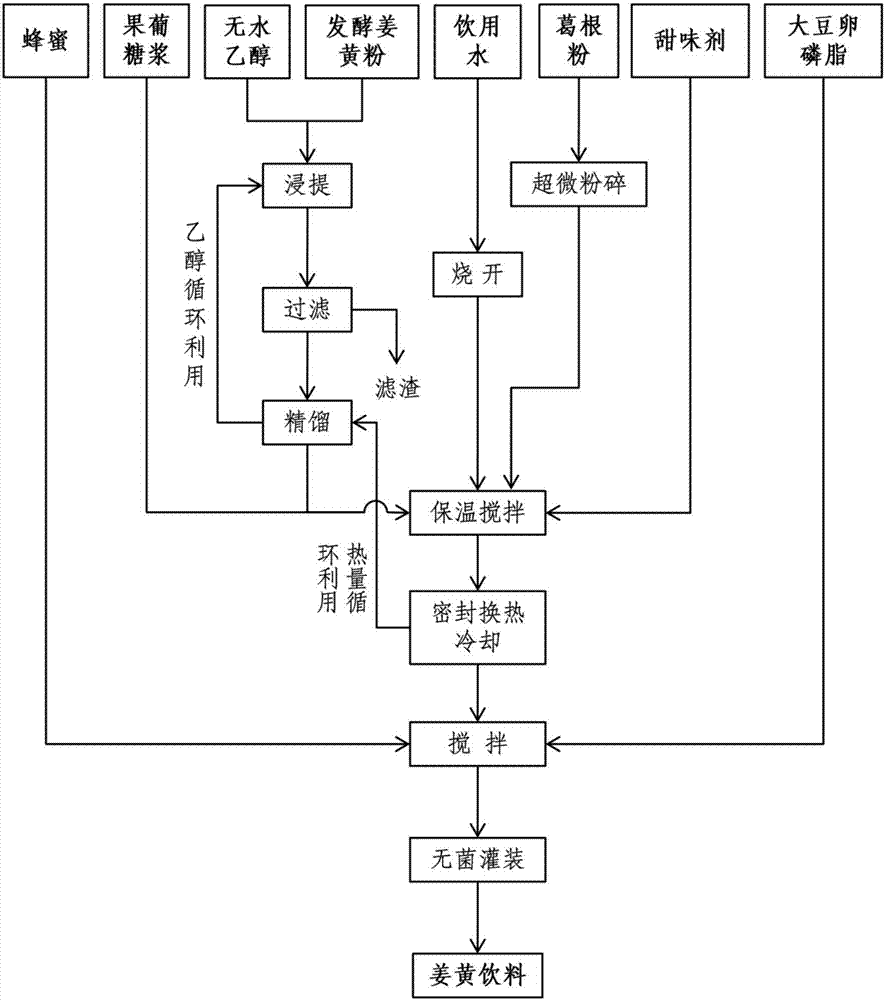

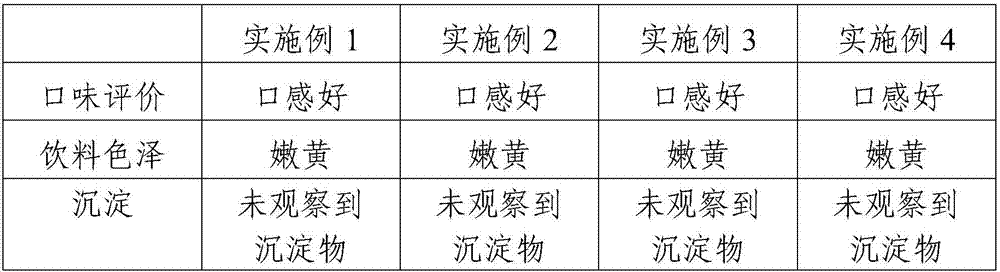

Curcuma beverage and making method thereof

ActiveCN107996932AHigh dissolution rateLow content of harmful impuritiesNatural extract food ingredientsFood ingredient functionsOrganic solventSoybean Lecithin

The invention relates to a curcuma beverage and a making method thereof. The making method comprises the following steps of (1) extracting a curcuma extract from fermented curcuma powder with an organic solvent, so as to obtain an extracting solution containing the curcuma extract; (2) performing rectification on the obtained extracting solution, so as to obtain a curcuma extract; (3) adding the obtained curcuma extract, radix puerariae powder and syrup to boiling water, and performing stirring, so as to obtain a gelatinized mixture; and (4) cooling the gelatinized mixture, and adding honey and soybean lecithin under an aseptic condition, so as to obtain the curcuma beverage. According to the curcuma beverage disclosed by the invention, curcumin is extracted with fermented curcuma powder,so that the extraction rate is increased; the curcuma extract, the radix puerariae powder, the syrup, the honey and the soybean lecithin powder are combined, and through combination of a specific production technology, the problems that the curcumin is low in absorptivity by human bodies, insoluble in water, easy to precipitate and easy to delaminate, are solved; the efficacy of neutralizing the effect of alcoholic drinks, protecting the liver, resisting oxidation and resisting mutation of the curcuma beverage is strengthened; and a new way is developed for the utilization of the curcuma.

Owner:四川新磷环保技术有限公司

Method for preparing trace element additive basic zinc chloride

The invention discloses a preparing process for a trace element addition agent of basic zinc chloride, which is characterized in that adding basic zinc carbonate in hydrochloric acid, wherein the mole ratio of usage of the basic zinc carbonate to content of hydrogen chloride of the hydrochloric acid is 2 : 4, the reaction product can be obtained under the temperature of 60-95 DEGC in 5-8 pH value, then washing, centrifugal separating and drying the reaction product, thereby obtaining the basic zinc carbonate. The reaction solution from centrifugal separation can be used as a mother solution of the other preparing process, which can further react with zinc oxide to form the basic zinc carbonate, thereby realizing recycling of secondary product. The preparing process has the advantages of simple process, low cost, reliable quality without impurity, little environmental pollution and the like.

Owner:XINGJIA BIO ENG CO LTD

Magnesite dolomite dry ramming mix for medium-frequency induction furnace lining and preparation method of magnesite dolomite dry ramming mix

InactiveCN110183212AImprove high temperature structural strengthImprove thermal shock resistanceNon-metallic inclusionsMedium frequency

The invention relates to a magnesite dolomite dry ramming mix for a medium-frequency induction furnace lining. The product is a loose, dry and uniform aggregate, and components comprise calcined dolomite sand particles, fused magnesite and desiliconized fused zirconia. The product comprises the following components in parts by weight: 1-19 parts of dolomite sand having a particle size of more than3mm and less than or equal to 6mm, 20-30 parts of dolomite sand having a particle size of more than 1mm and less than or equal to 3mm, 0-13 parts of dolomite sand having a particle size of more than0.3mm and less than or equal to 1mm, 20-40 parts of fused magnesite having a particle size of more than 0mm and less than or equal to 1mm, 15-23 parts of fused magnesite having a particle size of morethan 0.074mm and less than or equal to 0.045mm, and 2-6.5 parts of 325-mesh desiliconized fused zirconia. The dry ramming mix disclosed by the invention has a desulfurization effect; nonmetallic inclusions in molten steel are removed, and the molten steel is purified; high-temperature performance is excellent; the thermal shock resistance is improved; and the refractoriness is high.

Owner:裘伟 +1

Stanniferous catalyst promoter

InactiveCN104138760AEvenly combinedWell mixedMetal/metal-oxides/metal-hydroxide catalystsFluidized bedCopper

Provided is a stanniferous catalyst promoter. The stanniferous catalyst promoter is used for an organosilicone monomer synthetic reaction and preferentially selected as a catalyst promoter in a dimethyl dichlorosilane synthetic reaction copper base catalysis system. Tin is evenly distributed and combined with a carrier, so that on one hand, uniform mixing of tin, silicon and the like in a fluidized bed is facilitated, and reaction efficiency is improved; on the other hand, unnecessary losses of tin in the industrial production are lowered. Compared with the method that tin is added to a fluidized bed reaction system in a granular metal tin powder manner in the prior art, the stanniferous catalyst promoter has the advantages that the content of harmful impurities of tin components is low, purity is high, the tin-assisted catalyst components can be evenly added to a synthetic reaction system when the stanniferous catalyst promoter is used for organosilicone monomer synthesis, the utilization efficiency of tin is improved, oxidation films on silica powder and surfaces of contacts can be well eliminated, activity of the synthetic reaction can be improved, the space time yield of the fluidized bed is increased, cost of industrial production is reduced, and remarkable economical benefits are obtained.

Owner:湖南省天心博力科技有限公司

Method for preparing trace element additive basic zinc chloride

The invention discloses a preparing process for a trace element addition agent of basic zinc chloride, which is characterized in that adding basic zinc carbonate in hydrochloric acid, wherein the mole ratio of usage of the basic zinc carbonate to content of hydrogen chloride of the hydrochloric acid is 2 : 4, the reaction product can be obtained under the temperature of 60-95 DEGC in 5-8 pH value, then washing, centrifugal separating and drying the reaction product, thereby obtaining the basic zinc carbonate. The reaction solution from centrifugal separation can be used as a mother solution of the other preparing process, which can further react with zinc oxide to form the basic zinc carbonate, thereby realizing recycling of secondary product. The preparing process has the advantages of simple process, low cost, reliable quality without impurity, little environmental pollution and the like.

Owner:XINGJIA BIO ENG CO LTD

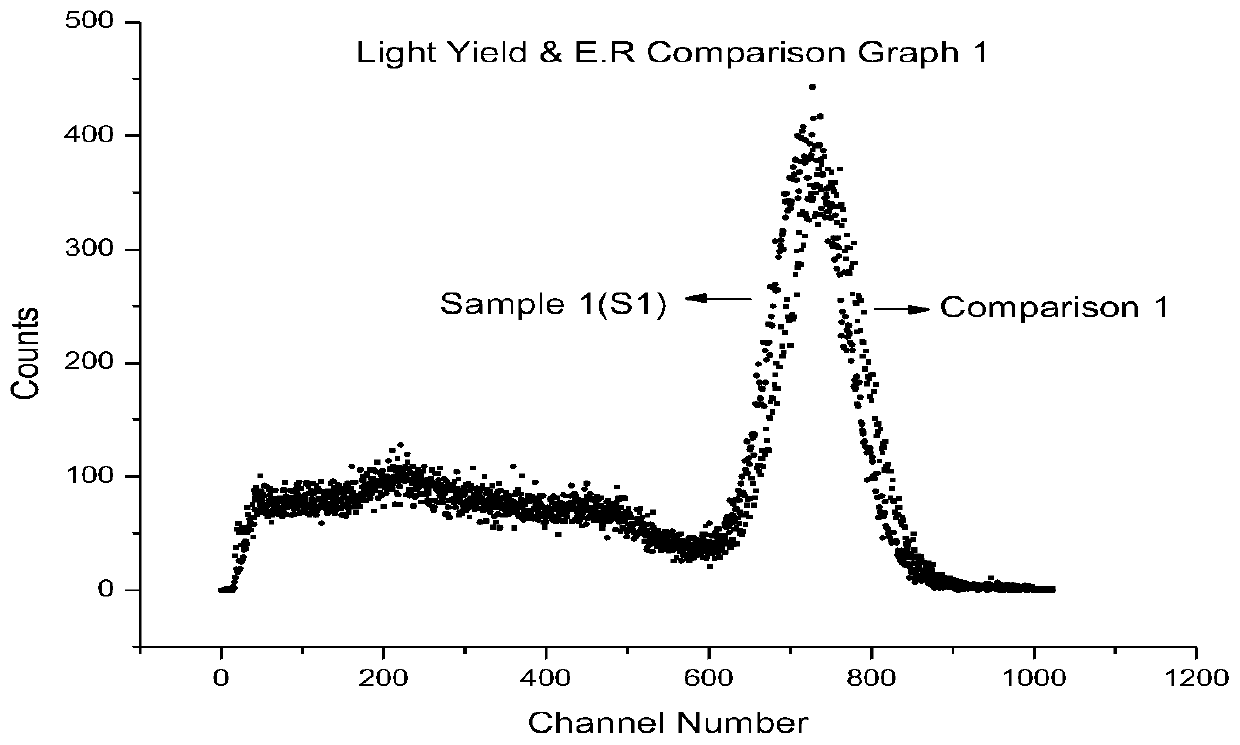

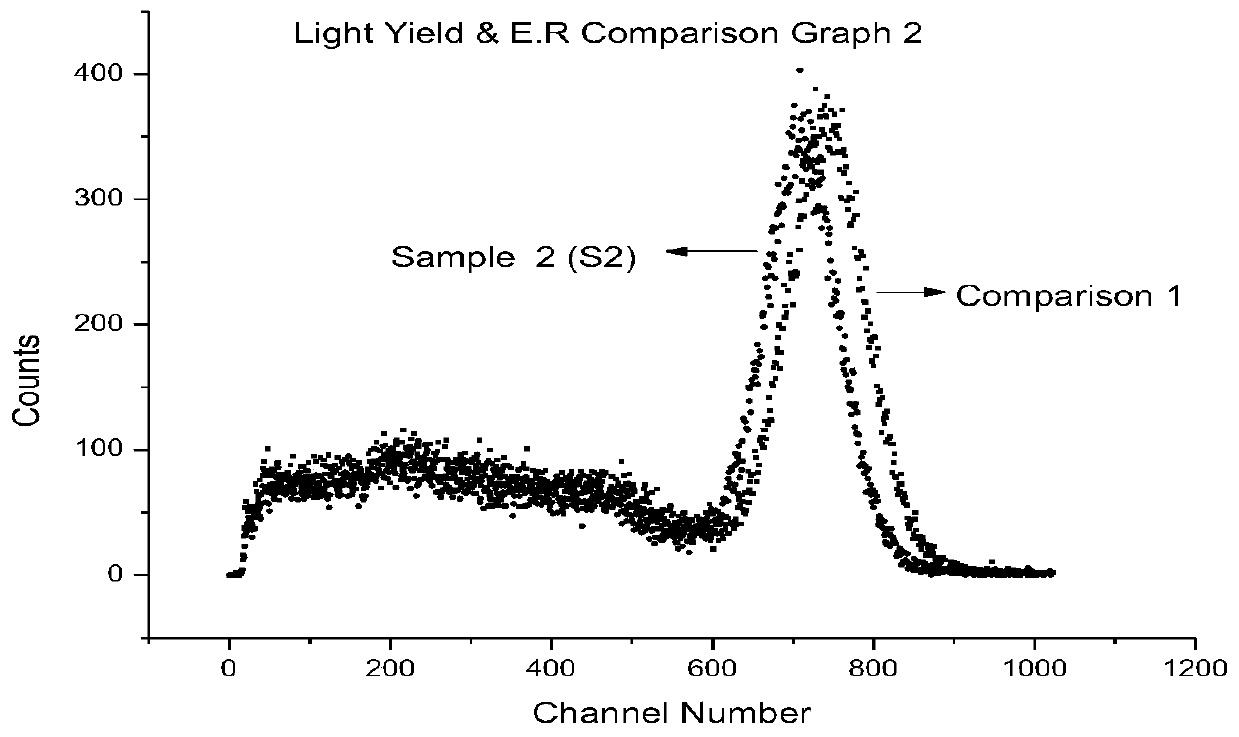

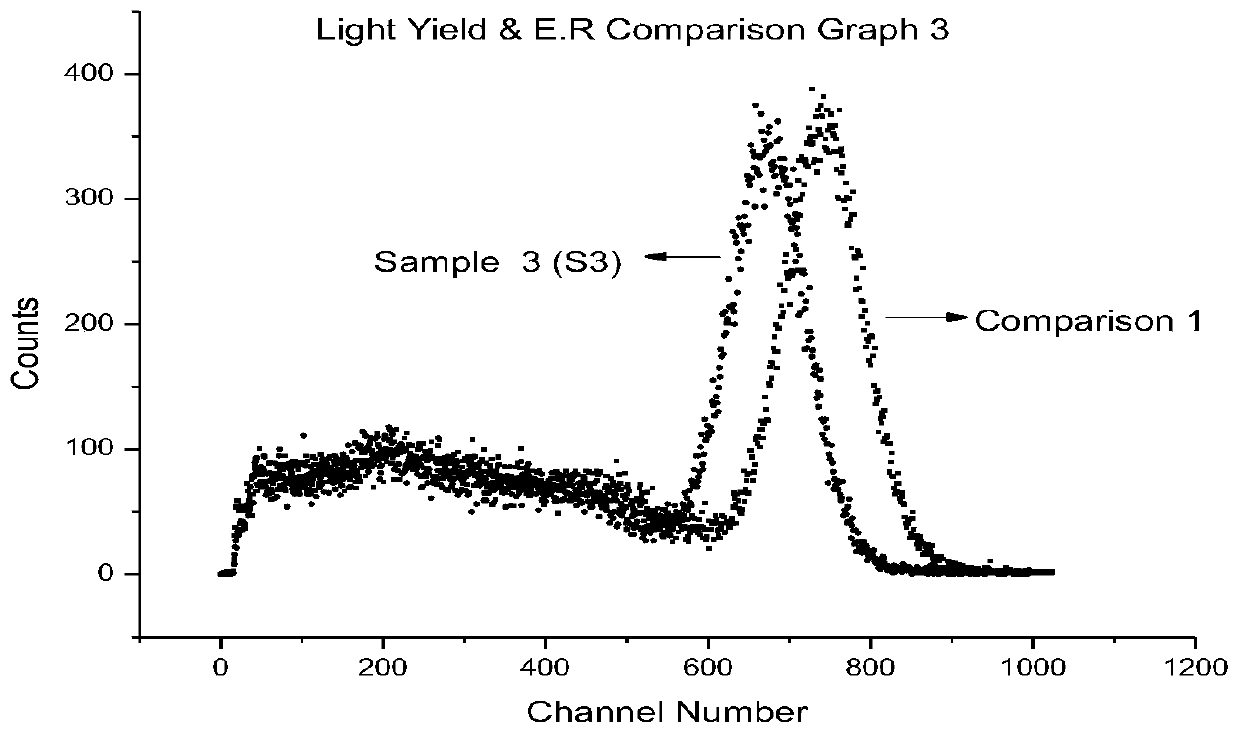

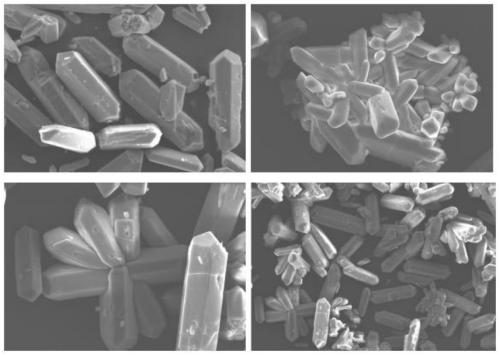

Scintillation crystal, and preparation method and application thereof

InactiveCN111593405AHigh purityLow content of harmful impuritiesPolycrystalline material growthFrom frozen solutionsScintillation crystalsCesium iodide

The invention relates to the technical field of artificial scintillation crystals, and concretely relates to a scintillation crystal, and a preparation method and application thereof. The chemical formula of the scintillation crystal is CsI:T1(x):Cu(y), wherein x is more than or equal to 0.05 and less than or equal to 0.1; and y is more than or equal to 0.01 and less than or equal to 0.1. The cesium iodide crystal prepared by adopting a co-doping formula and an improved descending method not only can keep the original light yield, but also can effectively reduce the afterglow, particularly, the afterglow in the first 50 ms time period after irradiation rays are turned off is remarkably improved, and the requirement of high-speed ray imaging detection can be met.

Owner:上海御光新材料科技股份有限公司

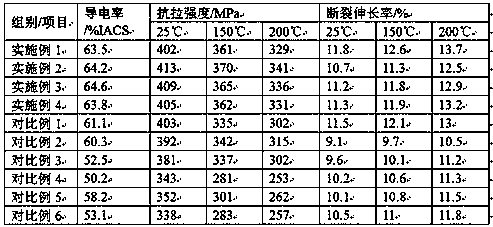

Aluminum alloy conductor material and preparation method thereof

ActiveCN110042279AImprove conductivityGood mechanical propertiesConductive materialMetal/alloy conductorsElectrical conductorMechanical property

The invention provides an aluminum alloy conductor material, and belongs to the technical field of coating components. The aluminum alloy conductor material is prepared from the following components of, by mass, 0.2-0.7% of Fe, 0.05-0.2% of Cu, 0.12-0.35% of Mg, 0.1-0.3% of Ca, 0.01-0.07% of V, 0.03-0.15% of Yb and the balance Al and unavoidable impurities. By optimizing the aluminum alloy components and a preparation process, and the obtained aluminum alloy conductor material can be used as aluminum alloy cable cores, has high electric conductivity and good mechanical properties.

Owner:国网河南省电力公司方城县供电公司

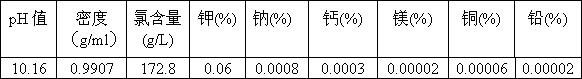

Method for preparing alkaline etching liquid by using constant boiling hydrochloric acid

ActiveCN103224796AReduce manufacturing costReduce pollutionSurface treatment compositionsDipotassium hydrogen phosphatePotassium nitrate

The invention discloses a method for preparing an alkaline etching liquid by using constant boiling hydrochloric acid. The method comprises that: constant boiling hydrochloric acid is adjusted with water to obtain an acid liquid with a Cl<-> content of 185-195 g / L, the acid liquid absorbs ammonia gas to form an ammonium chloride solution, the ammonium chloride solution is added with a hydrogen peroxide aqueous solution and active carbon, stirring and filtration are sequentially performed, the filtrate is added with potassium nitrate and dipotassium hydrogen phosphate, and the obtained filtrate absorbs ammonia gas to obtain the alkaline etching liquid so as to change dilute waste hydrochloric acid into treasure.

Owner:XILONG SCI CO LTD

High alumina slag ball and preparing method thereof

InactiveCN1238533CAvoid bursting phenomenonReduce inclusionsProcess efficiency improvementSlagSesquioxide

The high-aluminum slag ball used as molten steel surface heat insulating and refining agent in smelting pure steel contains metal aluminum, alunina, titania, boron sesquioxide, calcium carbonate, fluorite powder and evitable impurity. With controlled silica, carbon, sulphur and phosphorus contents, the high-aluminum slag ball is suitable for use in smelting low-carbon and low-silicon pure steel or other super-pure steel. It has low water content to avoid molten steel sputtering and content of deoxygenating and alloying elements capable of being altered in wide range to suit for steel variety change. It has excellent performance of heat insulating for the surface of molten steel, and makes the deoxygenation and refining completed simultaneously to reduce included oxide in molten steel.

Owner:梅一峰

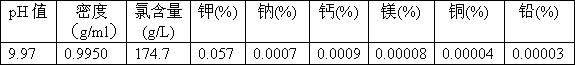

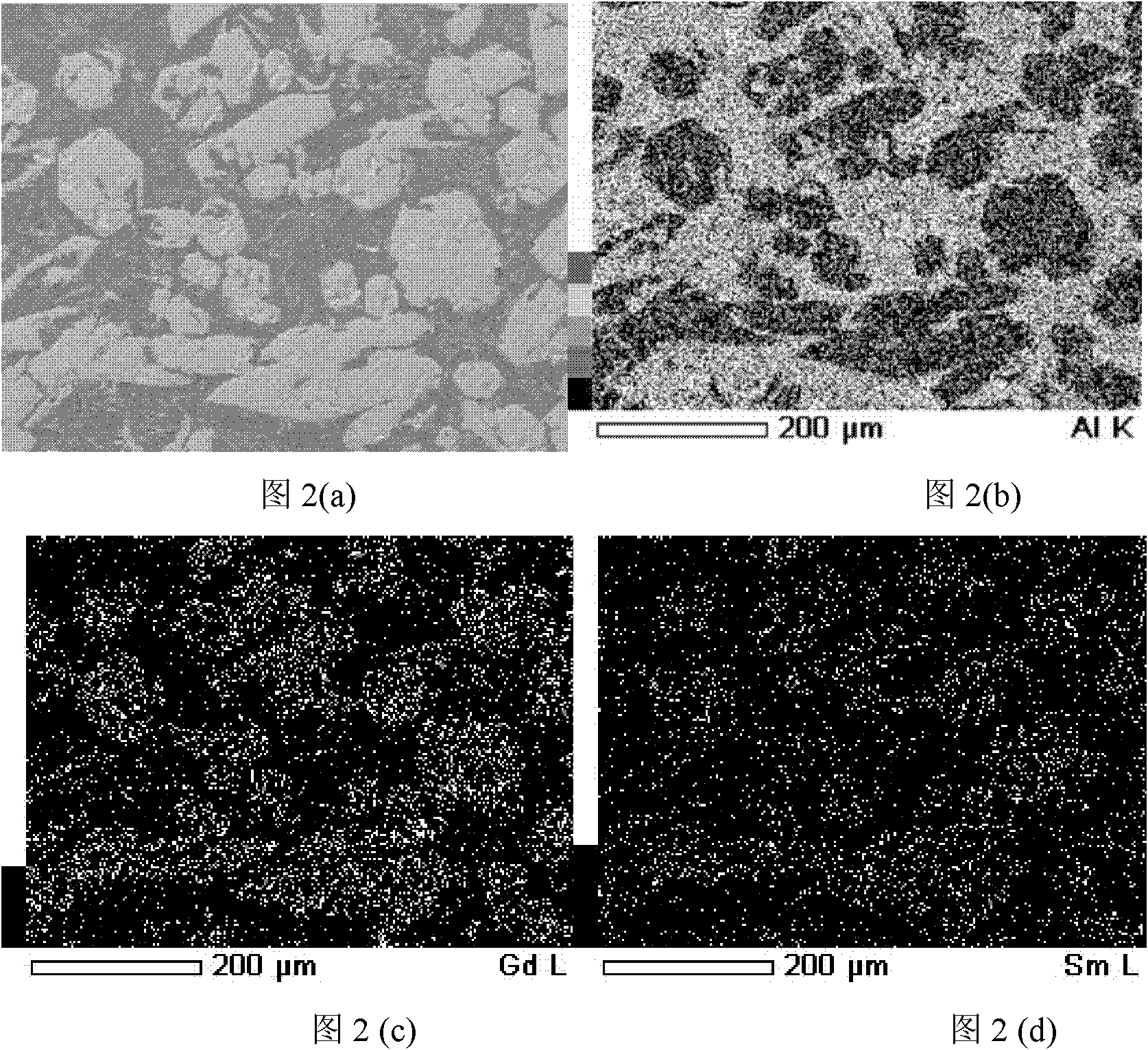

Method for preparing aluminum gadolinium samarium intermediate alloy from gadolinium carbonate and samaric carbonate through molten salt electrolysis

The invention provides a method for preparing aluminum gadolinium samarium intermediate alloy from gadolinium carbonate and samaric carbonate through molten salt electrolysis. AlF3-NaCl-KCl is used as an electrolyte system, and a mixture of the gadolinium carbonate and samaric carbonate is added into the electrolyte system; inert metal of tungsten is used as a cathode, graphite is used as an anode, the electrolytic temperature is 750 to 840 DEG C, a cathode sinking method is adopted, the electrode distance is 4cm, the cathode current density is 6.2 to 10 A / cm<2>, the anode current density is 0.5 A / cm<2>, the groove voltage is 4.5 to 7.2V, the electrolysis is carried out for 2 to 5h, and the Al-Gd-Sm alloy is deposited nearby the cathode of a molten salt electrolytic bath. The production process of the method is simple, and the efficiency is high. Compared with a heat reducing method, the method has the advantages that the smelting burning loss is little, and the defects of high smelting cost and large-scale production are overcome. In addition, the creep deformation performance, the mechanical intensity and the corrosion resistant performance of the aluminum gadolinium alloy are changed through adding rare earth elements of gadolinium and samarium.

Owner:HARBIN ENG UNIV

Method for producing multi-functional plum blossom-shaped papermaking sludge lightweight through-hole ceramsite

InactiveCN106478143AWith renewableSmall granularityCeramic materials productionCeramicwareSludgeThermal insulation

The invention discloses a method for producing a multi-functional plum blossom-shaped papermaking sludge lightweight through-hole ceramsite. The method comprises ingredient stirring, extrusion granulation, drying, roasting, thermal insulation, screening and sealed packaging. The ingredients comprise papermaking sludge, high viscosity attapulgite clay, zeolite, activated carclazyte residues, activated alumina, nanometer zinc oxide, light magnesium oxide, light calcium carbonate, hollow microbeads, expanded perlite and sodium dodecyl sulfate. The ceramsite has the advantages of good adsorption performance, high effective specific surface area, high porosity, low bulk density, light weight, high strength and integration of micropores and macropores and is suitable for a variety of greening projects such as water purification and filtration, soil repair, landscaping, roof greening and desert management. The method is suitable for production of multi-functional lightweight plum blossom-shaped papermaking sludge through-hole ceramsites in plum blossom-type shape, cylinder shape and ball shape.

Owner:甘肃华晨生态治理有限公司

Aluminum-containing cocatalyst

InactiveCN104190420AEvenly combinedReduce lossGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsMetallic aluminumFluidized bed

The invention discloses an aluminum-containing cocatalyst which is used as a cocatalyst in a copper-based catalyst system in synthesis reaction of organic silicon monomers, preferably synthesis reaction of dimethyldichlorosilance. The aluminum is uniformly distributed and combined in a carrier, so that the aluminum-containing cocatalyst has the advantages that uniform mixing of the aluminum and silicon in a fluidized bed is facilitated; oxidation films on the surfaces of silicon powder and contacts are removed and the reaction activities of the silicon powder and the contacts are improved; the unnecessary loss of the aluminum in industrial production is reduced. Compared with a method in the prior art for adding the aluminum into a fluidized bed reaction system by using particle metallic aluminum powder, the aluminum-containing cocatalyst also has the advantages that aluminum components are low in contents of harmful impurities and high in purity; the aluminum-assisted catalytic components can be uniformly added into a synthesis reaction system during synthesis of the organic silicon monomers; the utilization efficiency of the aluminum can be improved; the oxidization films on the surfaces of the silicon powder and the contacts can be well removed; the improvement of the activity of the synthesis reaction is facilitated; the space time yield of the fluidized bed is improved; the cost of the industrial production is reduced; the aluminum-containing cocatalyst has remarkable economical benefits.

Owner:湖南省天心博力科技有限公司

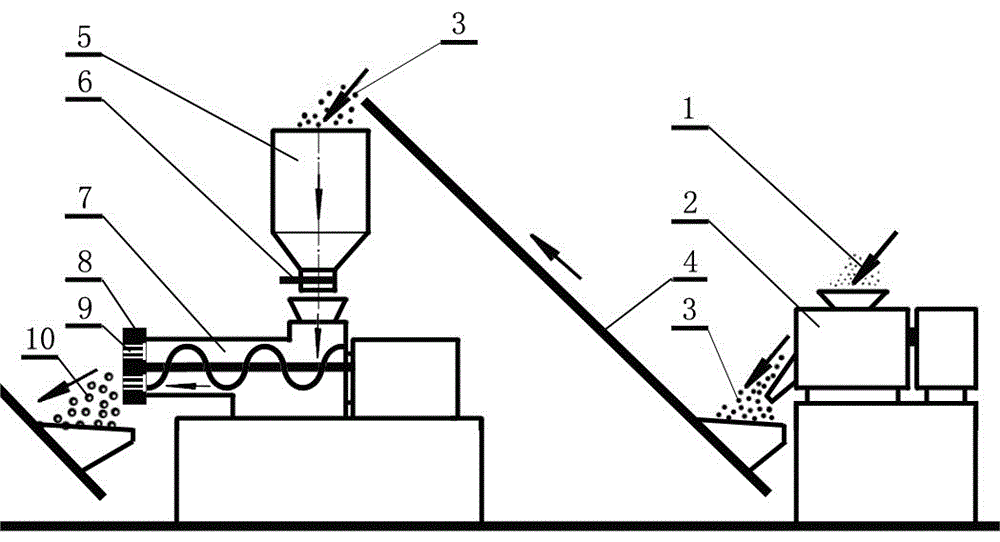

Process for smelting ferronickel in tunnel kiln

InactiveCN101892413AImprovement ingredientsLess investmentFluidised-bed furnacesTunnel kilnAnthracite

The invention discloses a process for smelting ferronickel in a tunnel kiln. The process comprises the following steps of: preparing burnt charcoal into charcoal particles with required particle sizes, feeding gas produced in a charcoal preparing process into the tunnel kiln and taking the gas as reducing atmosphere gas and fuel gas; and mixing laterite-nickel ore, charcoal, limestone and a smelting additive according to a certain proportion in a batching room, loading the mixture, feeding the loaded mixture into the tunnel kiln, preheating, drying, reducing and cooling the mixture in the tunnel kiln, discharging the treated mixture out of the kiln, quenching the discharged mixture and grinding and sorting the quenched mixture. Because the charcoal is taken as a reducing agent, charcoal resource is rich, the components of the charcoal are superior to those of coke and anthracite, harmful impurity content is low and obtained ferronickel has few impurities. The process has the characteristics of solving the problem of fuel gas for industrial production, taking fuel gas produced in a charcoal burning process as reducing gas and fuel gas for production, making full use of energy sources and optimizing energy utilization along with easy implementation and low energy consumption.

Owner:SHANDONG TAISHAN STEEL GROUP

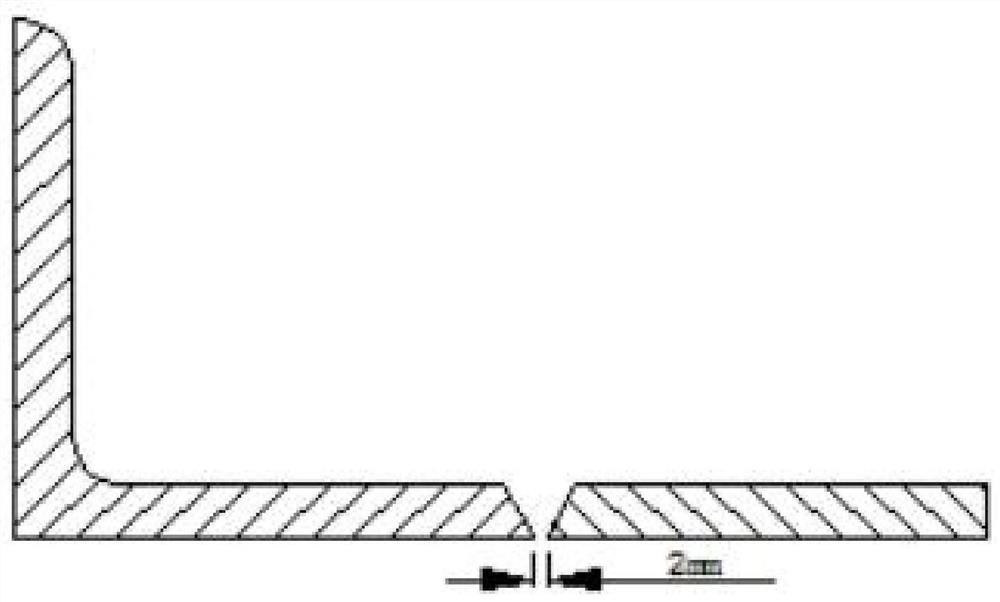

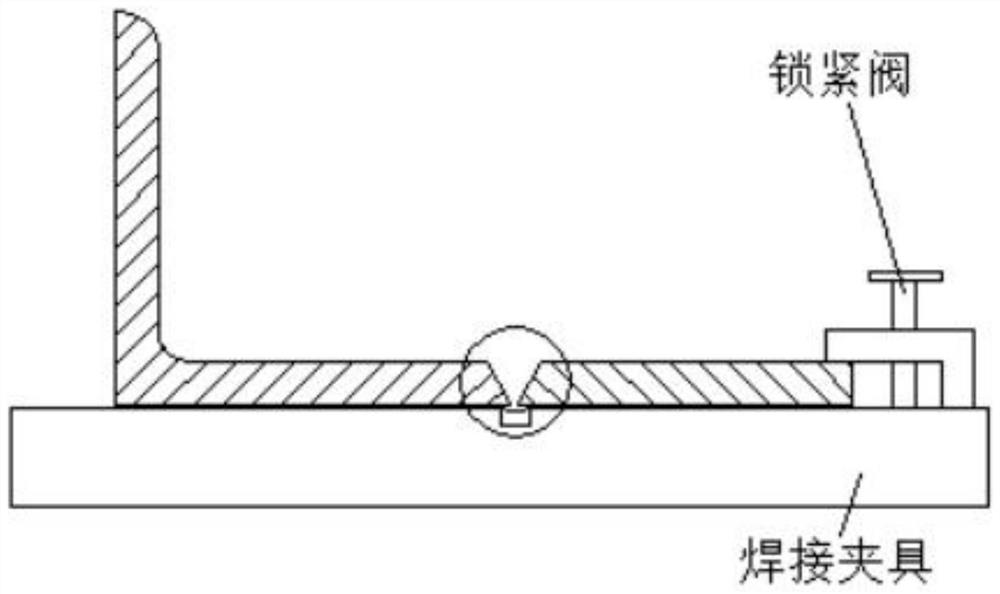

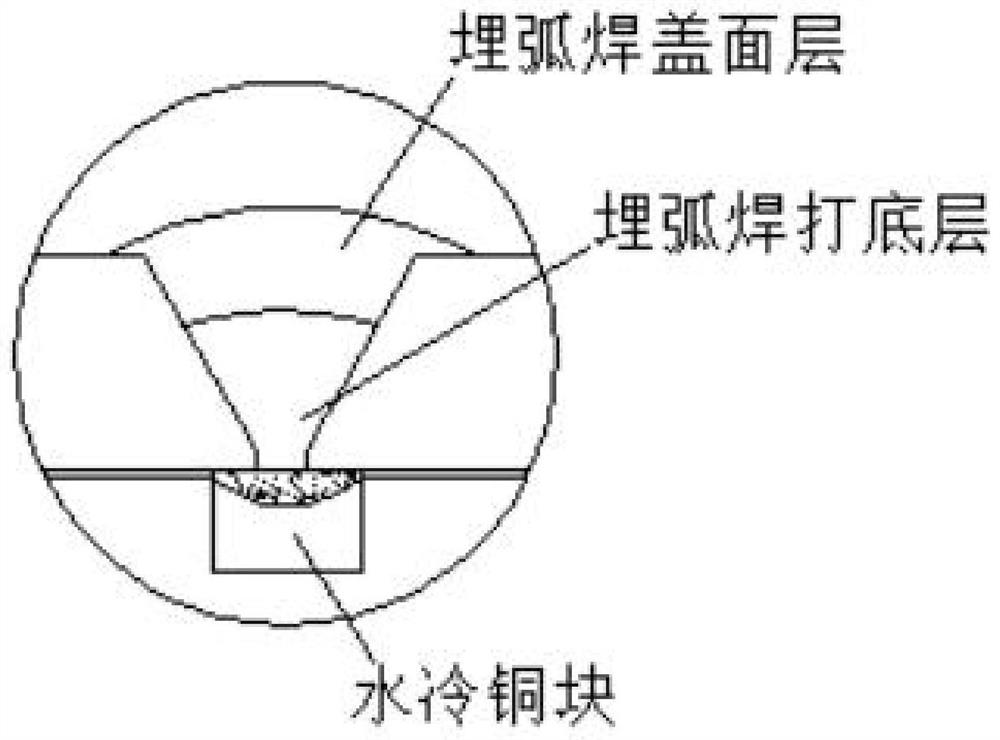

Weathering steel welding method

The invention relates to the technical field of welding, in particular to a weathering steel welding method. The method comprises the following steps of welding preparation, wherein a to-be-welded weathering steel tower wire hanging plate and a fixture special for wire hanging plate welding are obtained, a copper block, a water cooling system, a locking valve and the like are assembled on the fixture, the copper block is embedded into a groove in the top of the fixture, the water cooling system is located at the bottom of the copper block, the locking valve is located on the right side of thetop of the fixture, to-be-welded weathering steel wire hanging angle steel and the wire hanging plate are spliced in a butt joint manner, the splicing interval is kept at 2-3 mm, and the splicing misalignment amount is smaller than 1 mm; and wire hanging plate locking, wherein welding flux is firstly laid in a groove of the copper block, and then the wire hanging plate is placed on the fixture. Bymeans of the method, the fixture special for welding is additionally arranged, deformation during welding can be avoided, the fixture is provided with the water-cooled copper block, the welding fluxis laid in the groove of the copper block, the phenomenon of weld joint breakdown during backing welding of submerged-arc welding can be effectively controlled, and the welding flux laid on the back face can force back face weld joint forming, so that the root back chipping procedure is omitted.

Owner:GUANGZHOU ZENGLI STEEL STRUCTURE

Sound insulation coating and production method thereof

The invention belongs to the technical field of materials, and specifically relates to a sound-insulating coating, which includes the following components: styrene-butadiene rubber, rosin, propyl epoxy resin, ethyl cellulose, polyurethane, desulfurized gypsum and mortar. The invention provides a A sound-insulating material mainly having a sound-insulating effect and a production method thereof.

Owner:YANCHENG TIANSHUN MACHINERY TECH CO LTD

Vitamin D3 purification method

The invention discloses a vitamin D3 purification method which comprises the following steps: a1, mixing organic amine, a first organic solvent, vitamin D3 oil and aryl chloride to react, and then adding water to stop the reaction; a2, washing the product obtained in the step a1 with water, performing drying and filtering, carrying out reduced pressure distillation, performing dissolving, carryingout secondary reduced pressure distillation, carrying out cooling and crystallizing; b1, dissolving vitamin D3 methyl benzoate in methanol, and dropwise adding a strong alkaline solution to perform reacting; b2, carrying out reduced pressure distillation on the substance obtained in the step b1, then carrying out liquid separation, washing an organic phase with water, and carrying out drying, filtering, carrying out secondary reduced pressure distillation, dissolving, cooling and recrystallizing; c1, dissolving the vitamin D3 crude product in a third organic solvent, and then performing stirring for decolorization; and c2, filtering the product obtained in the step c1, carrying out reduced pressure distillation on the filtrate, and carrying out dissolving, cooling, recrystallizing, filtering, and drying to obtain the vitamin D3. The vitamin D3 purified by the purification method disclosed by the invention has the advantages of higher purity, lower harmful impurity content and higher stability.

Owner:弘健制药(上海)有限公司

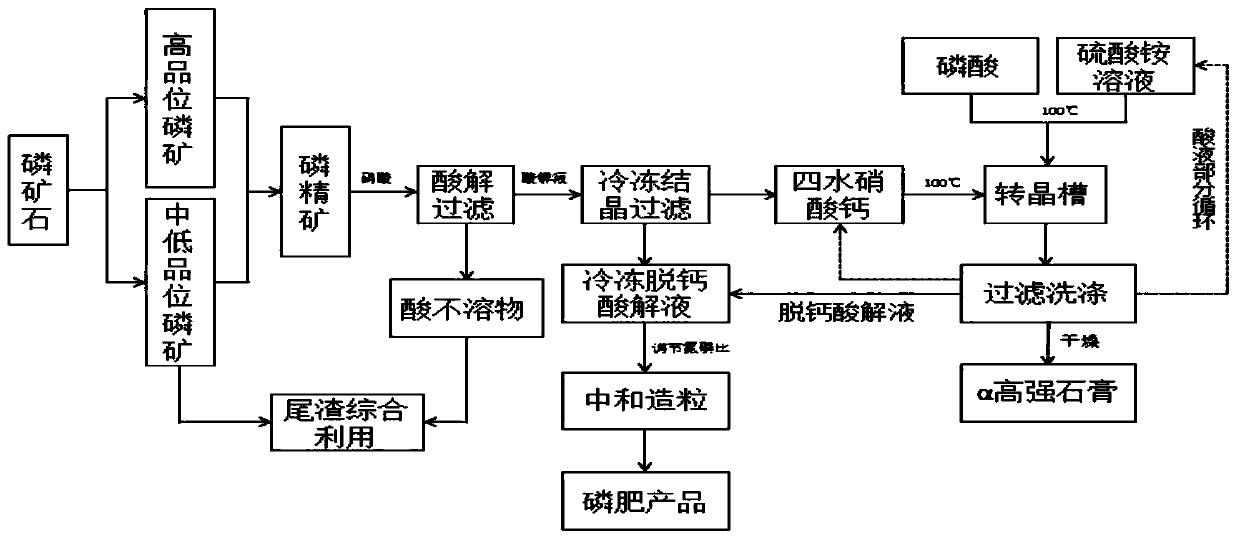

Method for preparing alpha high-strength gypsum from freezing method nitrophosphate byproduct calcium nitrate tetrahydrate

PendingCN111498892AReduce manufacturing costIncrease useCalcium/strontium/barium sulfatesCalcium/strontium/barium nitratesCalcium nitrate tetrahydrateO-Phosphoric Acid

The invention discloses a method for preparing alpha high-strength gypsum from a freezing method nitrophosphate byproduct calcium nitrate tetrahydrate. The method comprises the following steps: decomposing phosphorite by utilizing nitric acid; filtering out acid-insoluble substances, carrying out freezing crystallization on an acidolysis solution, filtering out calcium nitrate tetrahydrate, regulating the concentration of calcium ions in a calcium nitrate solution, respectively preheating the calcium nitrate solution, phosphoric acid and ammonium sulfate mixed solution to 95-110 DEG C, mixingin a crystallization tank, and carrying out constant-temperature reaction for 8-12 hours to directly obtain the alpha-type high-strength gypsum product; the mass percent of the decalcifying acid solution for preparing the mixed solution of phosphoric acid and ammonium sulfate in the step (5) is less than or equal to 35%, and the mass percent of the decalcifying acid solution for preparing the calcium nitrate solution in the step (4) is less than or equal to 50%. The method disclosed by the invention has the beneficial effects that the high-purity and high-quality alpha high-strength gypsum isproduced by utilizing the byproduct calcium nitrate tetrahydrate of the existing freezing method nitrophosphate fertilizer process flow, the new application of the calcium nitrate tetrahydrate is increased, the operation is simple, and the cost is low.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com