Method for preparing alpha high-strength gypsum from freezing method nitrophosphate byproduct calcium nitrate tetrahydrate

A technology of calcium nitrate tetrahydrate and nitrophosphate fertilizer, applied in chemical instruments and methods, calcium/strontium/barium nitrate, calcium/strontium/barium compounds, etc., can solve long process, difficulty in freezing and separating calcium nitrate, complicated operation, etc. problems, to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

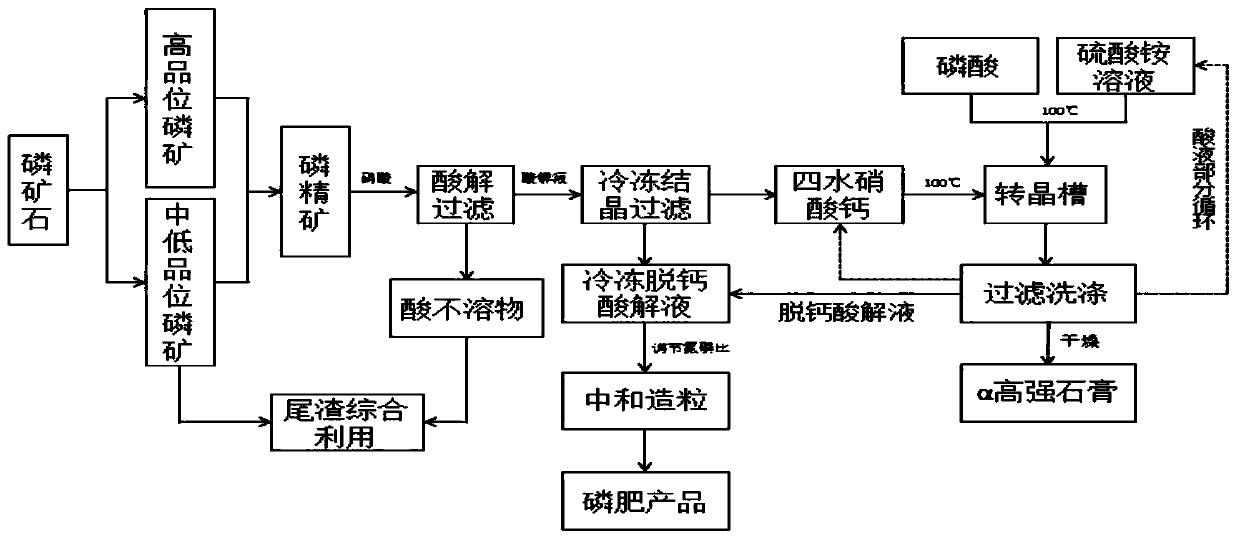

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, implementation raw materials: 1, phosphate concentrate powder: P205 content is 31.12%, CaO is 46.23%; 2, nitric acid; 3, ammonium sulfate solution; 4, phosphoric acid.

[0042] A method for making α high-strength gypsum by-product calcium nitrate tetrahydrate by freezing nitrophosphate fertilizer, comprising the following steps:

[0043] (1) Acid hydrolysis: acidolysis reaction is carried out with nitric acid after the phosphate concentrate powder is added water, and the mass concentration of nitric acid is 60%; The acid-mineral ratio of nitric acid and phosphate concentrate is 1.25:1, and the acid excess coefficient of nitric acid is 120%; The temperature of the acidolysis reaction is 60°C, and the time of the acidolysis reaction is 3 hours to obtain a crude acidolysis solution;

[0044] (2) Filtration: the crude acid solution of step (1) is filtered to remove acid insolubles and organic matter, to obtain the acid solution;

[0045] (3) freezing and crys...

Embodiment 2

[0050] Embodiment 2, implementation raw materials: 1, phosphate concentrate powder: P205 content is 31.12%, CaO is 46.23%; 2, nitric acid; 3, ammonium sulfate; 4, phosphoric acid.

[0051] A method for making α high-strength gypsum by-product calcium nitrate tetrahydrate by freezing nitrophosphate fertilizer, comprising the following steps:

[0052] (1) Acid hydrolysis: acid hydrolysis reaction is carried out with nitric acid after the phosphate concentrate powder is added water, and the mass concentration of nitric acid is 50%; The acid-mineral ratio of nitric acid and phosphate concentrate is 1.3:1, and the acid excess coefficient of nitric acid is 115%; The temperature of the acidolysis reaction is 50°C, and the time of the acidolysis reaction is 2 hours to obtain a crude acidolysis solution;

[0053] (2) Filtration: the crude acid solution of step (1) is filtered to remove acid insolubles and organic matter, to obtain the acid solution;

[0054] (3) freeze crystallization...

Embodiment 3

[0059] Embodiment 3, implementation raw materials: 1, phosphate concentrate powder: P205 content is 31.12%, CaO is 46.23%; 2, nitric acid; 3, ammonium sulfate; 4, phosphoric acid.

[0060] A method for making α high-strength gypsum by-product calcium nitrate tetrahydrate by freezing nitrophosphate fertilizer, comprising the following steps:

[0061] (1) Acid hydrolysis: acid hydrolysis reaction is carried out with nitric acid after the phosphate concentrate powder is added water, and the mass concentration of nitric acid is 50%; The acid-mineral ratio of nitric acid and phosphate concentrate is 1.2:1, and the acid excess coefficient of nitric acid is 105%; The temperature of the acidolysis reaction is 40°C, and the time of the acidolysis reaction is 1 hour to obtain a crude acidolysis solution;

[0062] (2) Filtration: the crude acid solution of step (1) is filtered to remove acid insolubles and organic matter, to obtain the acid solution;

[0063] (3) freezing and crystalliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com