Aluminum alloy conductor material and preparation method thereof

An aluminum alloy conductor and alloy technology, applied in the field of aluminum alloy, can solve the problems of decreased tensile strength, poor cable performance, low tensile strength, etc., and achieve the effect of improving strength, improving heat resistance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

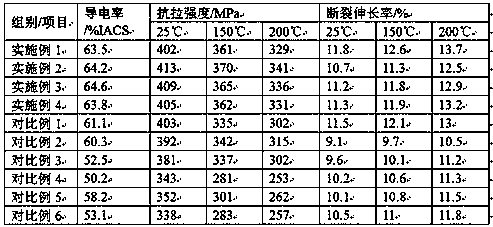

Examples

Embodiment 1

[0028] An aluminum alloy conductor material, made of the following components in mass percentage: Fe0.2%, Cu0.05%, Mg0.12%, Ca0.1%, V0.01%, Yb0.03%, the balance is Al and unavoidable impurities.

[0029] The preparation method of the aluminum alloy conductor material of this embodiment comprises the following steps:

[0030] Step S1: Carry out alloy melting according to the above composition ratio to obtain alloy melt;

[0031] Step S2: deslagging and refining the alloy melt in sequence, cooling and extruding the refined alloy melt to obtain an ingot;

[0032] Step S3: Heat the ingot to 470°C at a rate of 0.5°C / min, hold it for 9 hours, lower it to 355°C, hold it for 1 hour, then raise the temperature to 430°C for rolling, and heat the rolled alloy material to 520°C ℃, after holding for 4 hours, water quenched to room temperature;

[0033] Step S4: performing aging treatment on the water-quenched alloy material to obtain an aluminum alloy conductor material.

[0034] In th...

Embodiment 2

[0040] An aluminum alloy conductor material, made of the following components in mass percentage: Fe0.3%, Cu0.09%, Mg0.15%, Ca0.18%, V0.03%, Yb0.08%, the balance is Al and unavoidable impurities.

[0041] The preparation method of the aluminum alloy conductor material of this embodiment comprises the following steps:

[0042] Step S1: Carry out alloy melting according to the above composition ratio to obtain alloy melt;

[0043] Step S2: deslagging and refining the alloy melt in sequence, cooling and extruding the refined alloy melt to obtain an ingot;

[0044] Step S3: raise the temperature of the ingot to 475°C at a rate of 0.6°C / min, keep it warm for 10 hours, lower it to 360°C, hold it for 1 hour, then raise the temperature to 435°C for rolling, and heat the rolled alloy material to 520°C ℃, after holding for 4 hours, water quenched to room temperature;

[0045] Step S4: performing aging treatment on the water-quenched alloy material to obtain an aluminum alloy conducto...

Embodiment 3

[0051] An aluminum alloy conductor material, made of the following components in mass percentage: Fe0.42%, Cu0.15%, Mg0.31%, Ca0.25%, V0.05%, Yb0.12%, the balance is Al and unavoidable impurities.

[0052] A method for preparing an aluminum alloy conductor material, comprising the following steps:

[0053] Step S1: Carry out alloy melting according to the above composition ratio to obtain alloy melt;

[0054] Step S2: deslagging and refining the alloy melt in sequence, cooling and extruding the refined alloy melt to obtain an ingot;

[0055] Step S3: Heat the ingot to 480°C at a rate of 0.6°C / min, keep it warm for 8 hours, lower it to 365°C, hold it for 1 hour, then raise the temperature to 440°C for rolling, and heat the rolled alloy material to 520°C ℃, after holding for 4 hours, water quenched to room temperature;

[0056] Step S4: performing aging treatment on the water-quenched alloy material to obtain an aluminum alloy conductor material.

[0057] In the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com