Magnetite concentrate quality-improving and impurity-reducing technology and device

A technology for magnetite concentrate and quality degradation, applied in the fields of magnetic separation, solid separation, grain processing, etc., can solve the problems of complicated operation, environmental pollution, equipment and infrastructure investment, etc. The effect of grinding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention takes the coarse and concentrated ore produced by the company's mine as an example, and further describes the present invention in detail in combination with examples.

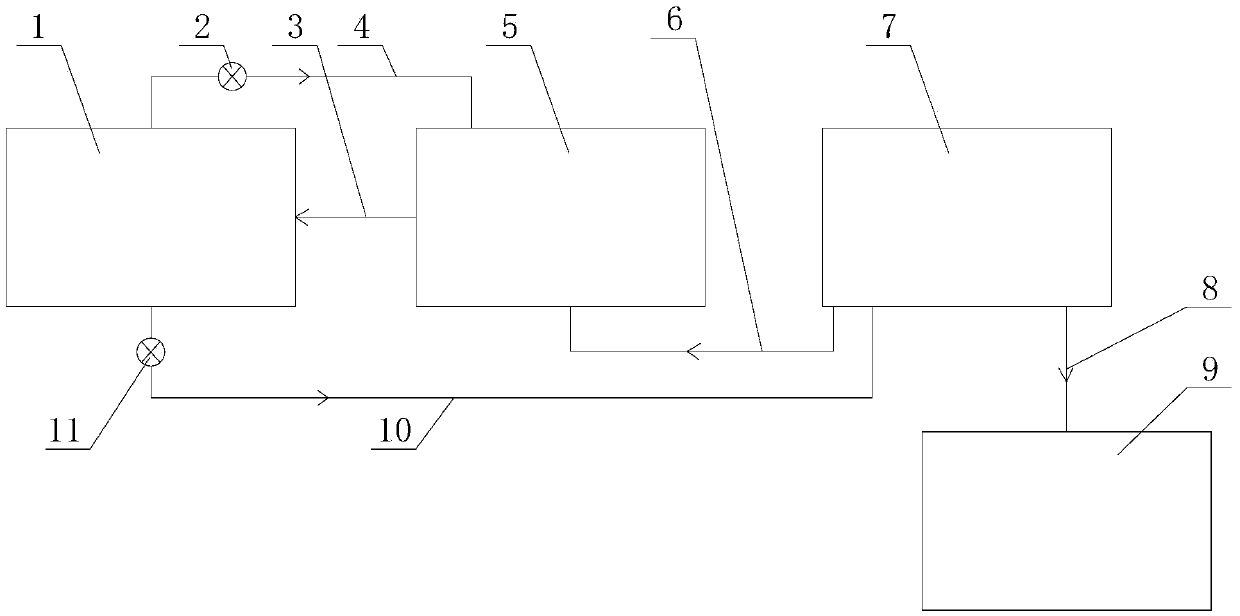

[0023] Such as figure 1 As shown, the present invention provides a magnetite concentrate quality improvement and impurity reduction device, which includes a vertical spiral grinding mixer 5, a slurry pool 1, a hydrocyclone 7, a drum magnetic separator 9, a primary slurry output pipe 3, and a second A conveying pipe 10, a sand return pipe 6, an overflow pipe 8 and a slurry pump 11. The vertical spiral grinding mixer has an inlet, an outlet and a water inlet; the hydrocyclone has an inlet Slurry port, return port and overflow port; the two ends of the primary slurry output pipe are respectively connected with the discharge port of the vertical spiral grinding mixer and the middle of the slurry pool; the slurry pump is installed on the first delivery pipe , The two ends of the first con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com