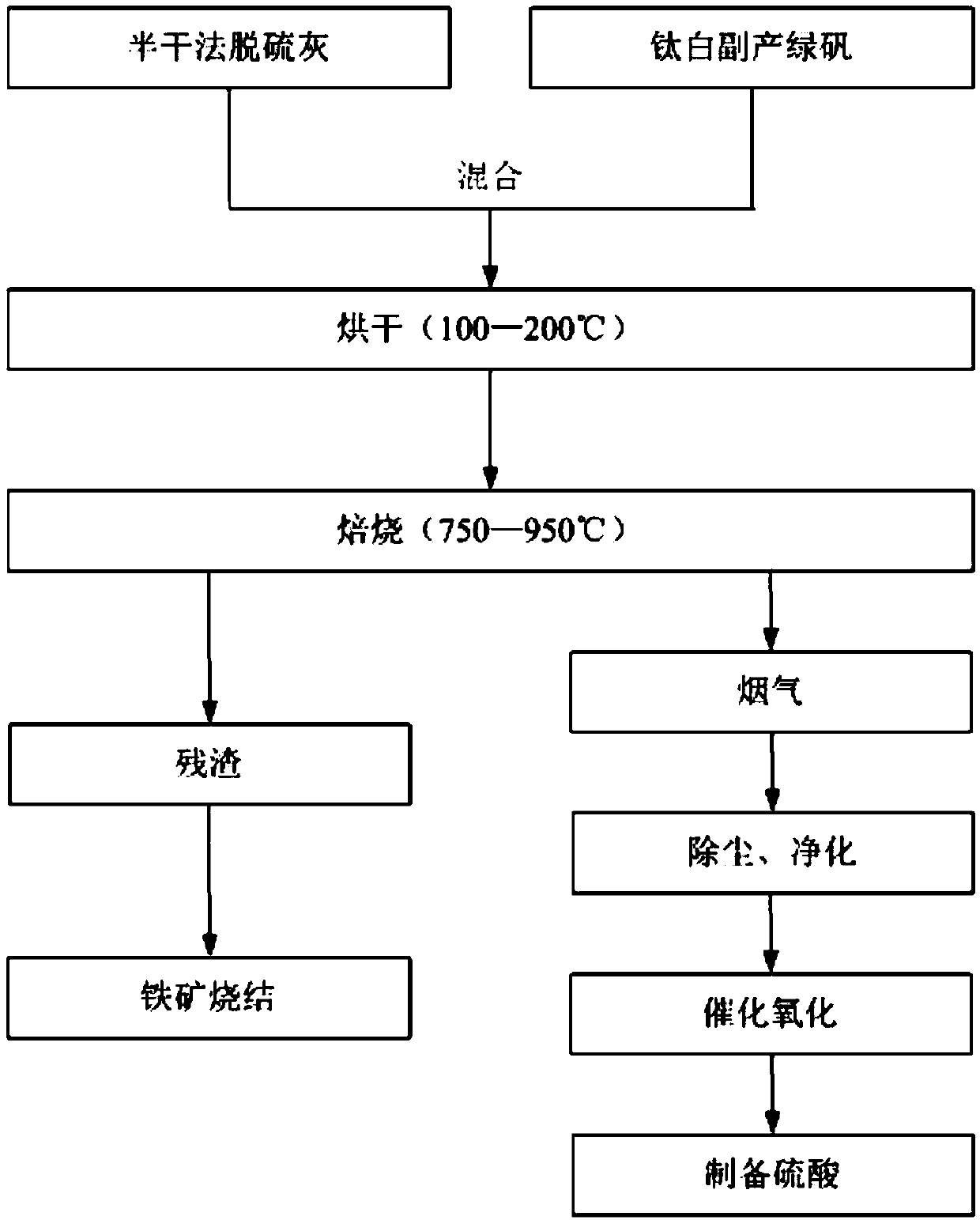

Method for realizing collaborative resource utilization of semi-dry desulfurization ash and titanium dioxide byproduct copperas

A semi-dry desulfurization and titanium dioxide technology, which is applied in the field of comprehensive utilization of resources, can solve the problems of small dosage, and achieve the effects of low content of harmful impurities, significant economic and environmental benefits, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

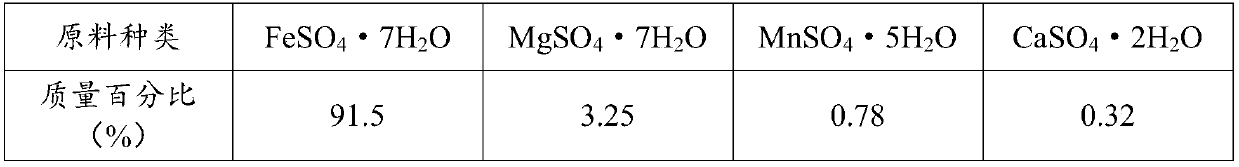

[0036] Using the above raw materials, fully mix the semi-dry desulfurization ash and titanium dioxide by-product green vitriol in a mass ratio of 3:7, dry at a temperature of 120°C, and send the dried mixture into a high-temperature furnace for roasting. The roasting temperature is 750°C, the roasting time is 100min, and the roasting atmosphere is a weakly reducing atmosphere; the sulfuric acid concentration of the flue gas produced during the roasting process is 93% after dust removal, purification, catalytic oxidation, absorption and other processes; the residue produced after roasting is all The iron content is 41.2%, and the calcium oxide content is 45.7%. The proportion of 2% is mixed with iron ore for sintering to replace part of iron concentrate powder and limestone, and has no negative impact on sintering.

Embodiment 2

[0038] Using the above raw materials, fully mix the semi-dry desulfurization ash and titanium dioxide by-product green vitriol in a mass ratio of 7:3, dry at 180°C, and send the dried mixture into a high-temperature furnace for roasting. The roasting temperature is 950°C, the roasting time is 40min, and the roasting atmosphere is a weakly reducing atmosphere; the sulfuric acid concentration of the flue gas produced during the roasting process is 98% after dust removal, purification, catalytic oxidation, absorption and other processes; the residue produced after roasting is all The iron content is 15.7%, and the calcium oxide content is 81.5%. The proportion of 0.5% is mixed with iron ore for sintering to replace part of iron concentrate powder and limestone, and has no negative impact on sintering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com