Method for producing electrolyte for aluminium and recovering carbon through recycle of aluminum electrolysis carbon residue

A technology of electrolytic aluminum and electrolyte, which is applied in the field of waste resource recycling, can solve the problems of unutilized valuable elements, high environmental risks of landfill method, unqualified product quality of flotation method, etc., and achieve low harmful impurity content and high moisture content low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

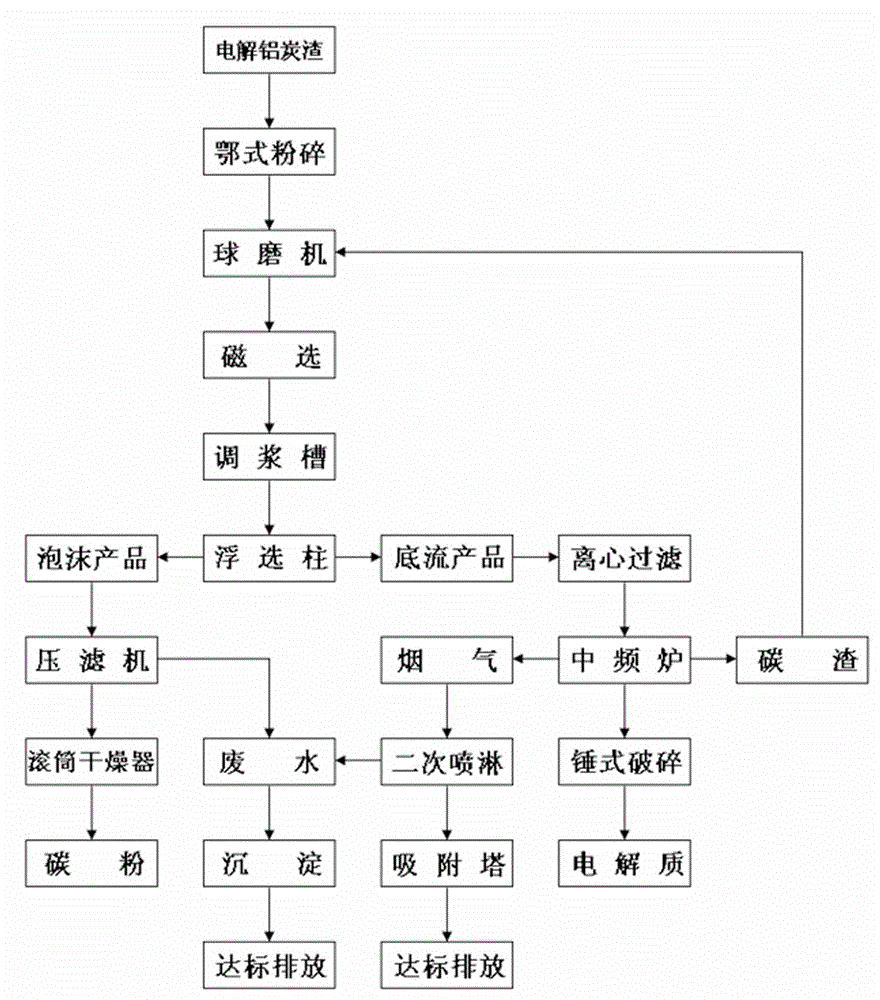

Image

Examples

Embodiment 1

[0037] Put 100Kg of electrolytic aluminum carbon slag into the jaw crusher for crushing, and then enter the ball mill to crush it through a 100-150 mesh sieve, magnetic separation to remove iron filings, add diesel 2.1Kg coal flotation GF oil 0.7Kg into the microbubble countercurrent flotation Column selection and separation to obtain 65Kg of underflow product and 35Kg of foam product. The underflow product is filtered by centrifugal and carbon is removed by an intermediate frequency furnace. The power of the intermediate frequency induction furnace is controlled at 350KW. The carbon removal time is about 8-10 minutes. The target aluminum is obtained by hammer crushing. Using 63.5Kg of electrolyte, the separated foam product was filtered and dried to obtain 34Kg of target carbon powder. The flue gas produced in the preparation process is first absorbed by the second spray absorption tower, and then discharged through the activated alumina absorption tower. The wastewater is recy...

Embodiment 2

[0040] Put 100Kg of raw material electrolytic aluminum carbon slag into the jaw crusher for crushing, then enter the ball mill to crush through 100~150 mesh screen, magnetic separation to remove iron filings, add diesel oil 2.2Kg coal flotation GF oil 0.8Kg into the microbubble countercurrent flotation Column selection and separation to obtain 62Kg of underflow product and 38Kg of foam product. After centrifugal filtration, the underflow product is used to remove carbon from an intermediate frequency furnace. The power of the intermediate frequency induction furnace is controlled at 350KW. The carbon removal time is about 8-10 minutes. The target aluminum is obtained by hammer crushing. Using 61Kg of electrolyte, the separated foam product was filtered and dried to obtain 37.5Kg of target carbon powder. The flue gas produced in the preparation process is first absorbed by the second spray absorption tower, and then discharged through the activated alumina absorption tower. The w...

Embodiment 3

[0043] Put 100Kg of electrolytic aluminum carbon slag into the jaw crusher for crushing, and then enter the ball mill to crush it through a 100-150 mesh sieve, magnetic separation to remove iron filings, add diesel 2.1Kg coal flotation GF oil 0.7Kg into the microbubble countercurrent flotation Column selection separation obtains 59Kg of underflow product and 41Kg of foam product. After centrifugal filtration, the underflow product is used to remove carbon with an intermediate frequency furnace. The power of the intermediate frequency induction furnace is controlled at 350KW. The carbon removal time is about 8-10 minutes. The target aluminum is obtained by hammer crushing. With 58Kg of electrolyte, the separated foam product is filtered and dried to obtain 40Kg of target carbon powder. The flue gas produced in the preparation process is first absorbed by the second spray absorption tower, and then discharged through the activated alumina absorption tower. The wastewater is recycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com