Weathering steel welding method

A welding method and technology of weathering steel, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of poor weldability and large cold cracking tendency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

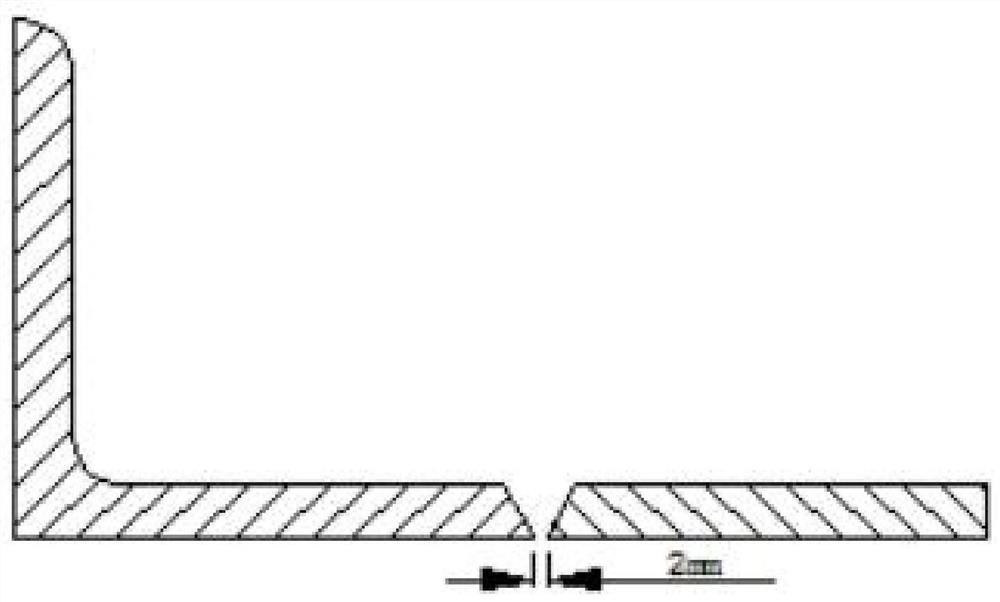

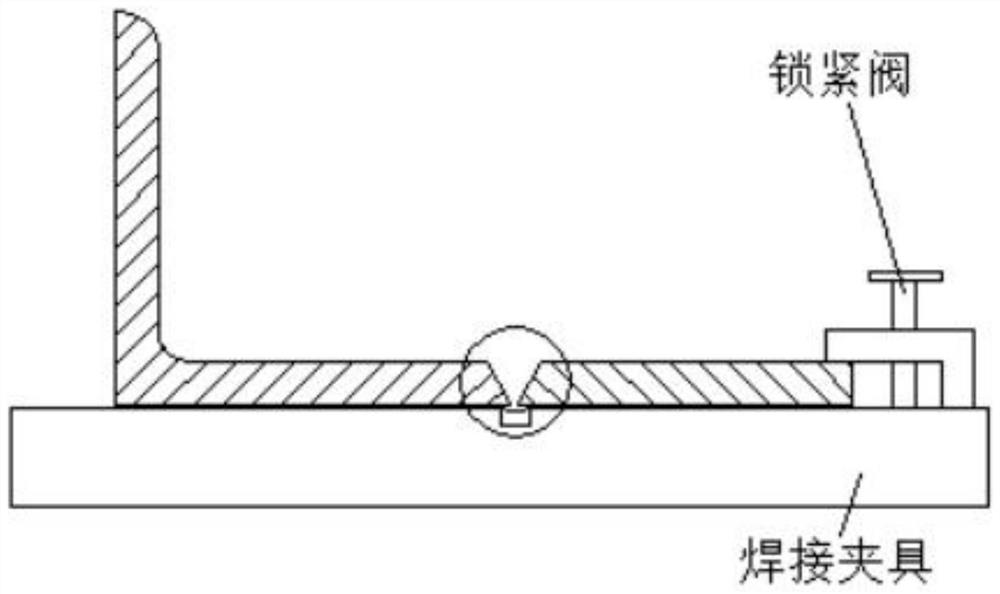

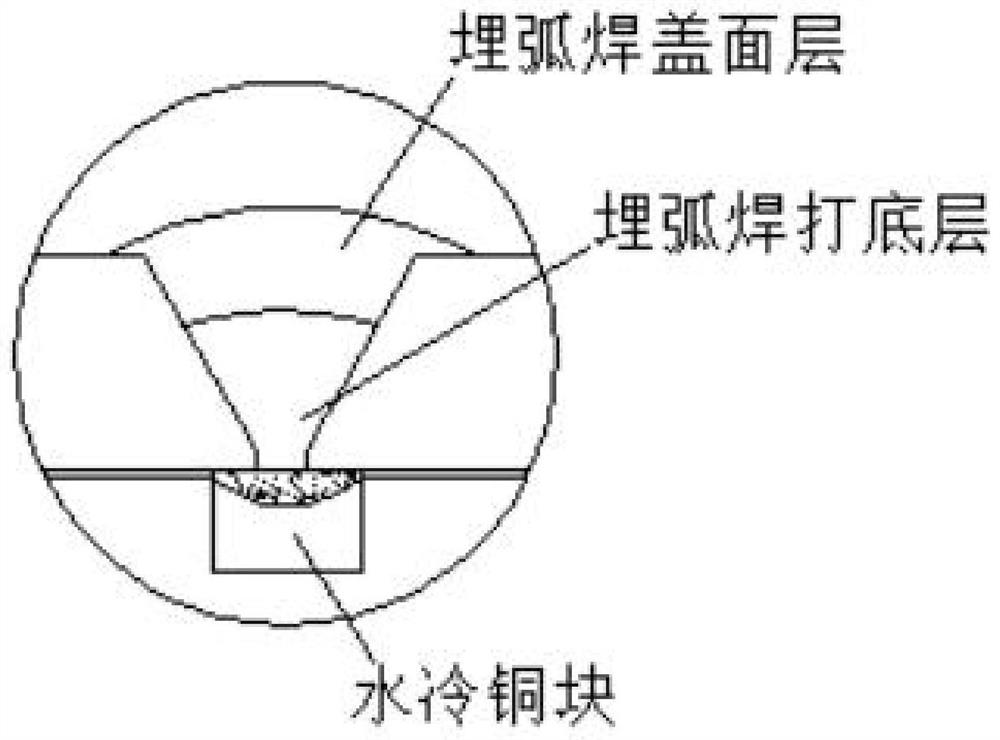

[0029] Welding preparation: Get the weather-resistant steel tower hanging plate to be welded, and the special fixture for welding the hanging plate. The fixture is equipped with copper block, water cooling system, locking valve, etc., and the copper block is embedded in the groove on the top of the fixture. The water cooling system is located on the At the bottom of the copper block, the locking valve is located on the right side of the top of the fixture. Butt and assemble the weather-resistant steel hang-on angle steel and the hang-on plate. The assembling interval is kept at 2-3mm, and the amount of misalignment is less than 1mm; Hanging plate: first lay the flux inside the groove of the copper block, then place the hanging plate on the fixture, and the assembly gap of the hanging plate should be placed in the middle above the groove of the copper block, and the right end of the hanging plate should be placed Lock the inside of the valve, and then lock and fix the hanging pl...

Embodiment 2

[0031] In embodiment one, add following operation:

[0032] In step 1, the grade of the weathering steel to be welded is Q415NH, and the joint form of the structural parts is a butt joint. The weathering steel to be welded is a high weathering steel with a yield strength of 415. The steel contains Cr, Ni and other trace elements; submerged arc welding is adopted The method can effectively reduce the content of harmful impurities such as S and P in the weld through flux protection.

[0033] Welding preparation: Get the weather-resistant steel tower hanging plate to be welded, and the special fixture for welding the hanging plate. The fixture is equipped with copper block, water cooling system, locking valve, etc., and the copper block is embedded in the groove on the top of the fixture. The water cooling system is located on the At the bottom of the copper block, the locking valve is located on the right side of the top of the fixture. Butt and assemble the weather-resistant st...

Embodiment 3

[0035] In embodiment two, add following operation:

[0036] In step 1, the water cooling system cooperates with the copper block to form a water-cooled copper block for easy cooling.

[0037] Welding preparation: Get the weather-resistant steel tower hanging plate to be welded, and the special fixture for welding the hanging plate. The fixture is equipped with copper block, water cooling system, locking valve, etc., and the copper block is embedded in the groove on the top of the fixture. The water cooling system is located on the At the bottom of the copper block, the locking valve is located on the right side of the top of the fixture. Butt and assemble the weather-resistant steel hang-on angle steel and the hang-on plate. The assembling interval is kept at 2-3mm, and the amount of misalignment is less than 1mm; Hanging plate: first lay the flux inside the groove of the copper block, then place the hanging plate on the fixture, and the assembly gap of the hanging plate shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com