Method for preparing alkaline etching liquid by using constant boiling hydrochloric acid

A technology of etching solution and hydrochloric acid, which is applied in the field of preparing alkaline etching solution from dilute waste hydrochloric acid, can solve the problems of low HCl recovery rate and high energy consumption, and achieve the effects of reducing environmental pollution, reducing manufacturing costs, and high etching efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Acid preparation: pump 16 tons of industrial azeotropic hydrochloric acid (HCl weight content 21%) into a 20 cubic meter acid storage tank, adjust the acid concentration to Cl - The content is 190g / L.

[0016] Neutralization: The acid liquid passes through the absorption tower in the spray state, and ammonia gas is passed into the absorption tower to form an ammonium chloride solution with pH=6.5.

[0017] Impurity removal: Add 2 liters of 30% hydrogen peroxide aqueous solution and 1 kg of activated carbon to the above ammonium chloride solution, pump and circulate for 30 minutes, and then filter into the quantitative tank with a plate and frame machine.

[0018] Synthesis: Add 14 kg of potassium nitrate and 12 kg of dipotassium hydrogen phosphate to the filtrate, continue to spray and absorb ammonia gas until the pH of the solution is 10±0.2, and filter the solution to obtain about 20 tons of alkaline etching solution.

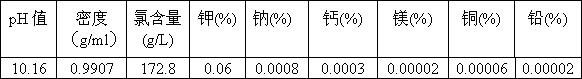

[0019] The product inspection results are as fo...

Embodiment 2

[0022] Acid preparation: pump 16.37 tons of industrial azeotropic hydrochloric acid with a HCl weight content of 20.3% into a 20 cubic meter acid liquid storage tank, and adjust the acid liquid to Cl - The content is 188 g / L.

[0023] Neutralization: The acid solution passes through the absorption tower in the spray state, and ammonia gas is passed into the absorption tower to form an ammonium chloride solution with pH=6.7.

[0024] Impurity removal: Add 2 liters of 30% hydrogen peroxide aqueous solution and 1 kg of activated carbon to the ammonium chloride solution, pump and circulate for 30 minutes, and then filter it into the quantitative tank with a plate and frame machine.

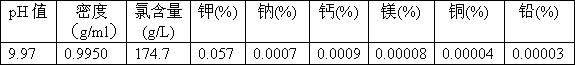

[0025] Synthesis: Add 14 kg of potassium nitrate and 12 kg of dipotassium hydrogen phosphate to the filtrate, then continue spraying and absorbing ammonia through the absorption tower until the pH of the solution is 10±0.2, and filter the solution to obtain about 20 tons of alkaline etching solution. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com