Diatomite-based silicon fertilizer and preparation method thereof

A diatomite and silicon-based technology, applied in liquid fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of difficult popularization and application, difficult preparation process, complicated preparation steps, etc., and achieves diversified application methods, easy crop absorption, Ease of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] A preparation method of diatomite-based silicon fertilizer, comprising:

[0015] S100: Prepare raw materials.

[0016] In this embodiment, diatomaceous earth is used as the raw material. The mass percentage of diatom shells of the selected diatomite is greater than 60%.

[0017] Diatomite is a natural aggregate of porous silicon minerals, mainly composed of diatom opal (porous silica) and a very small amount of clay minerals, quartz and other minerals. The amount of diatom-containing opal is generally greater than 65%, and even higher than 90% in some samples. In addition, diatom opal has an amorphous structure with very low crystallinity. Compared with other silicon-containing minerals or solid wastes, it has higher solubility and is easier for crops to absorb. Therefore, diatomaceous earth is a naturally available silicon fertilizer.

[0018] Studies have found that direct application of diatomaceous earth can increase the yield of rice. However, it must be point...

Embodiment 1

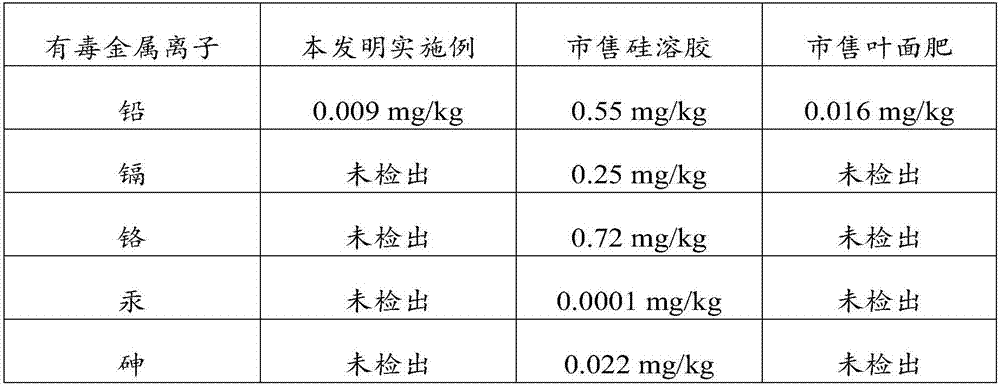

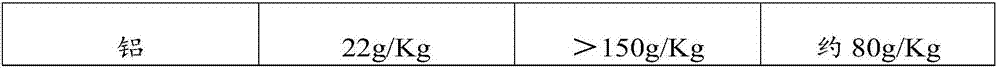

[0043] Put 100kg of diatomite (Guangdong Puchang diatomite, diatom opal content is about 75%) in 2000L of 0.1mol / L sodium hydroxide solution to form a suspension, after fully stirring, heat to boiling under normal pressure, keep After 12 hours, solid-liquid separation was carried out after cooling, and the separation liquid was taken. Add 2kg of activated carbon powder to the separation liquid, after fully stirring, use 0.1mol / L hydrochloric acid solution to adjust the pH value to 8, heat to 50°C and fully stir, and then cool to room temperature to obtain sol-like diatomite-based Silicon fertilizer. The obtained diatomite-based silicon fertilizer is evaluated by a transmission electron microscope and a particle size analyzer, and the particle size distribution of a single particle is 10-25 nm.

[0044] Through the actual rice culture comparison, it was found that 20 kg of sol-like diatomite-based silicon fertilizer (effective SiO 2 content of about 14.6 kg), through foliar f...

Embodiment 2

[0046] Put 100kg of diatomite (Guangdong Buchang diatomite, diatom opal content about 75%) in 1000L of 1mol / L sodium hydroxide solution to form a suspension. hours, solid-liquid separation was carried out after cooling, and the separation liquid was taken. Add 1 kg of activated carbon powder to the separation liquid, after fully stirring, use 0.1mol / L sulfuric acid solution to adjust the pH value to 10, heat to 60°C and fully stir, and then cool to room temperature to obtain a sol-like diatomite-based Silicon fertilizer. The obtained diatomite-based silicon fertilizer is evaluated by a transmission electron microscope and a particle size analyzer, and the particle size distribution of a single particle is 8-22 nm.

[0047] Through the actual rice culture control, it was found that 20 kg of high-efficiency soluble silicon fertilizer (effective SiO 2 content of about 15.5 kg), through foliar fertilization can make 1000m 2 18.2% increase in rice yield (while direct application...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com