Patents

Literature

43results about How to "Stable gas flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

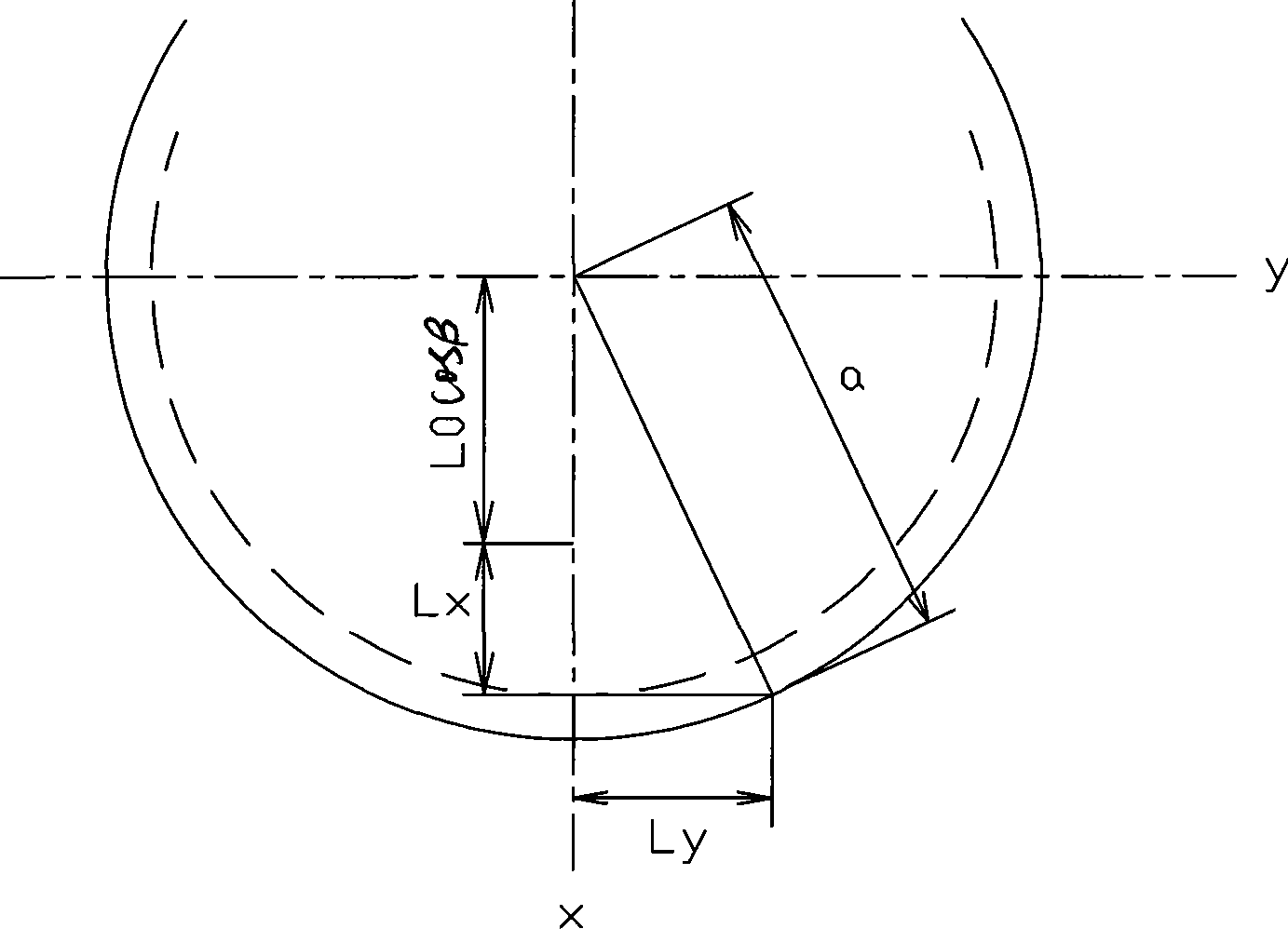

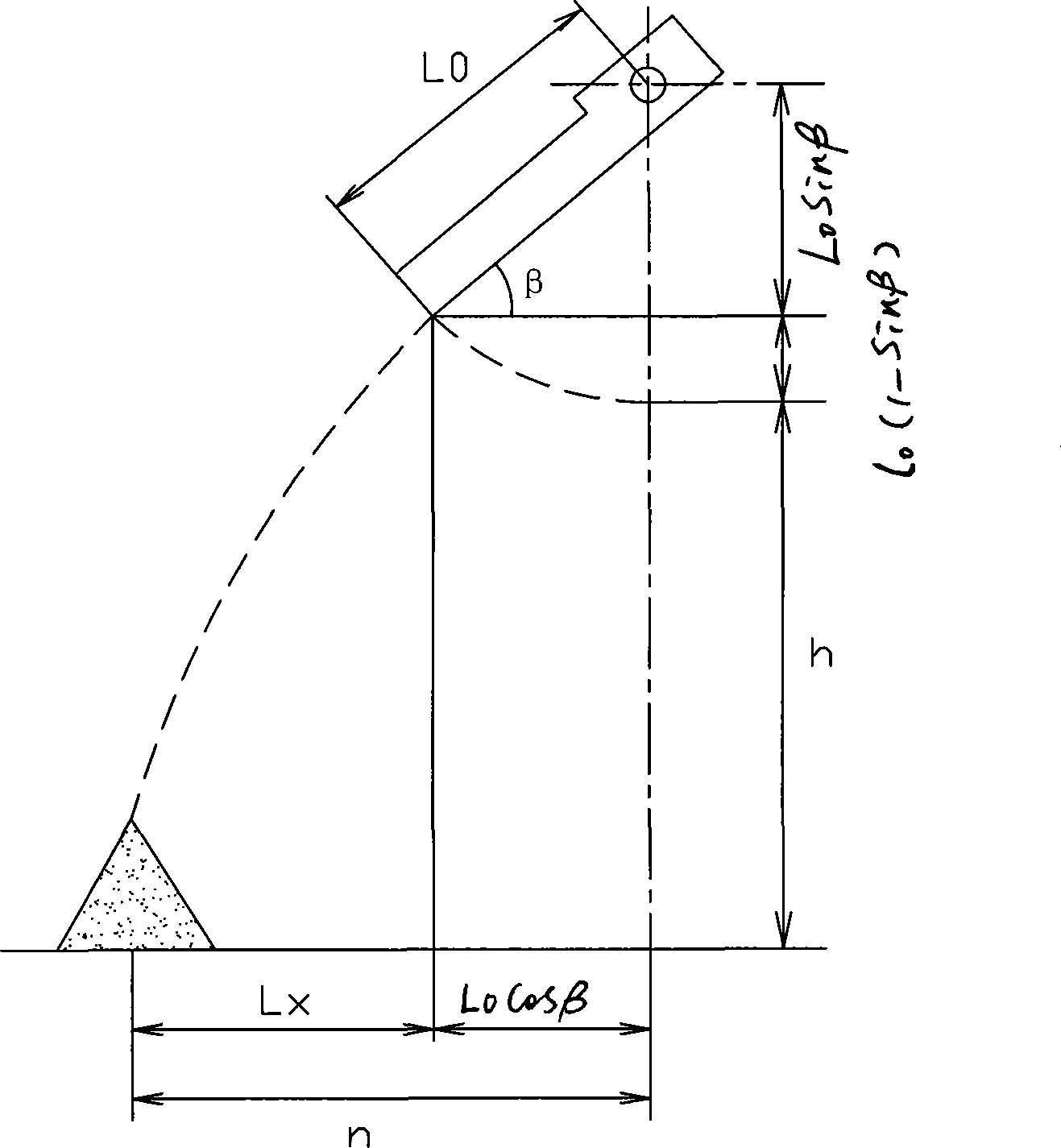

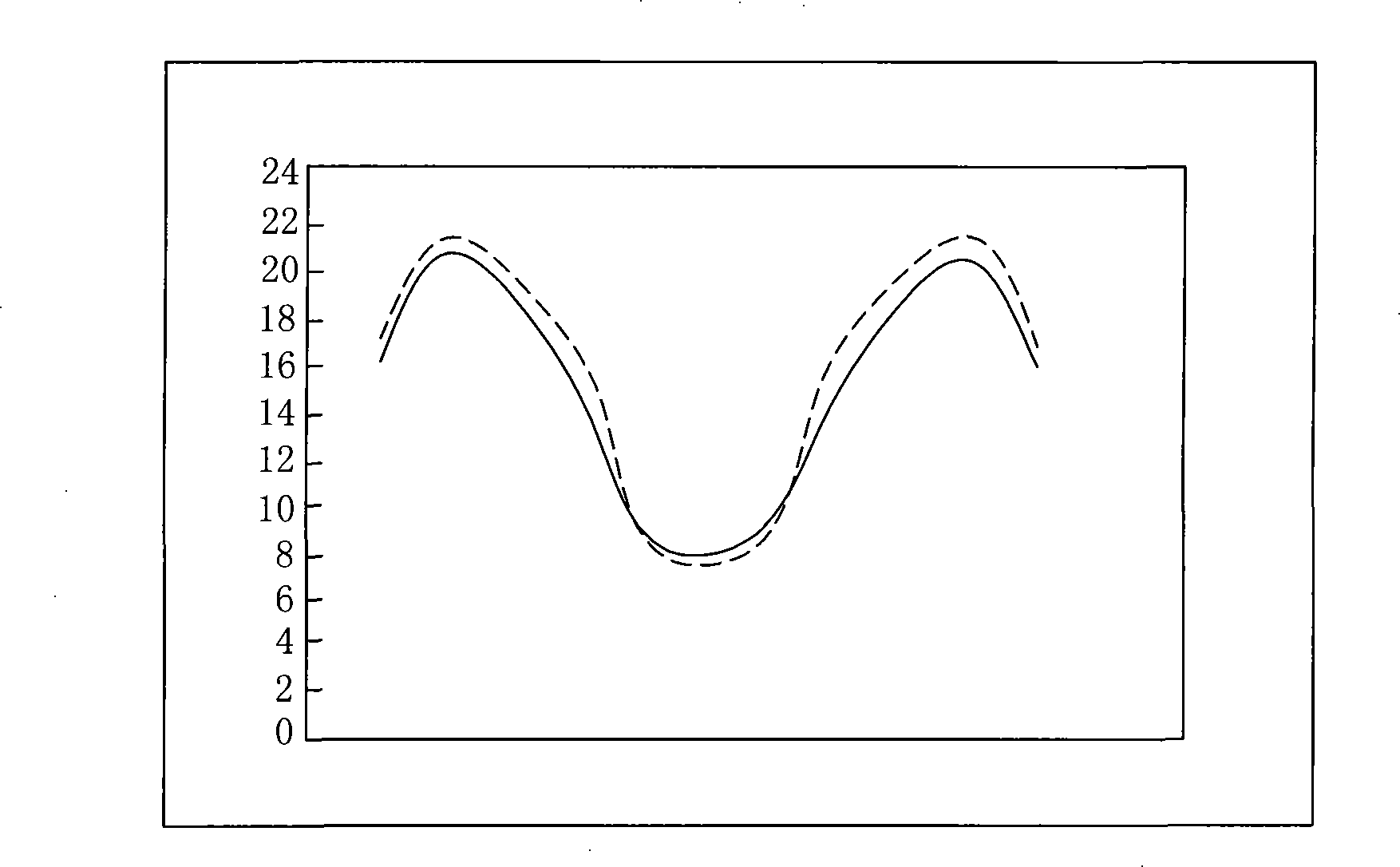

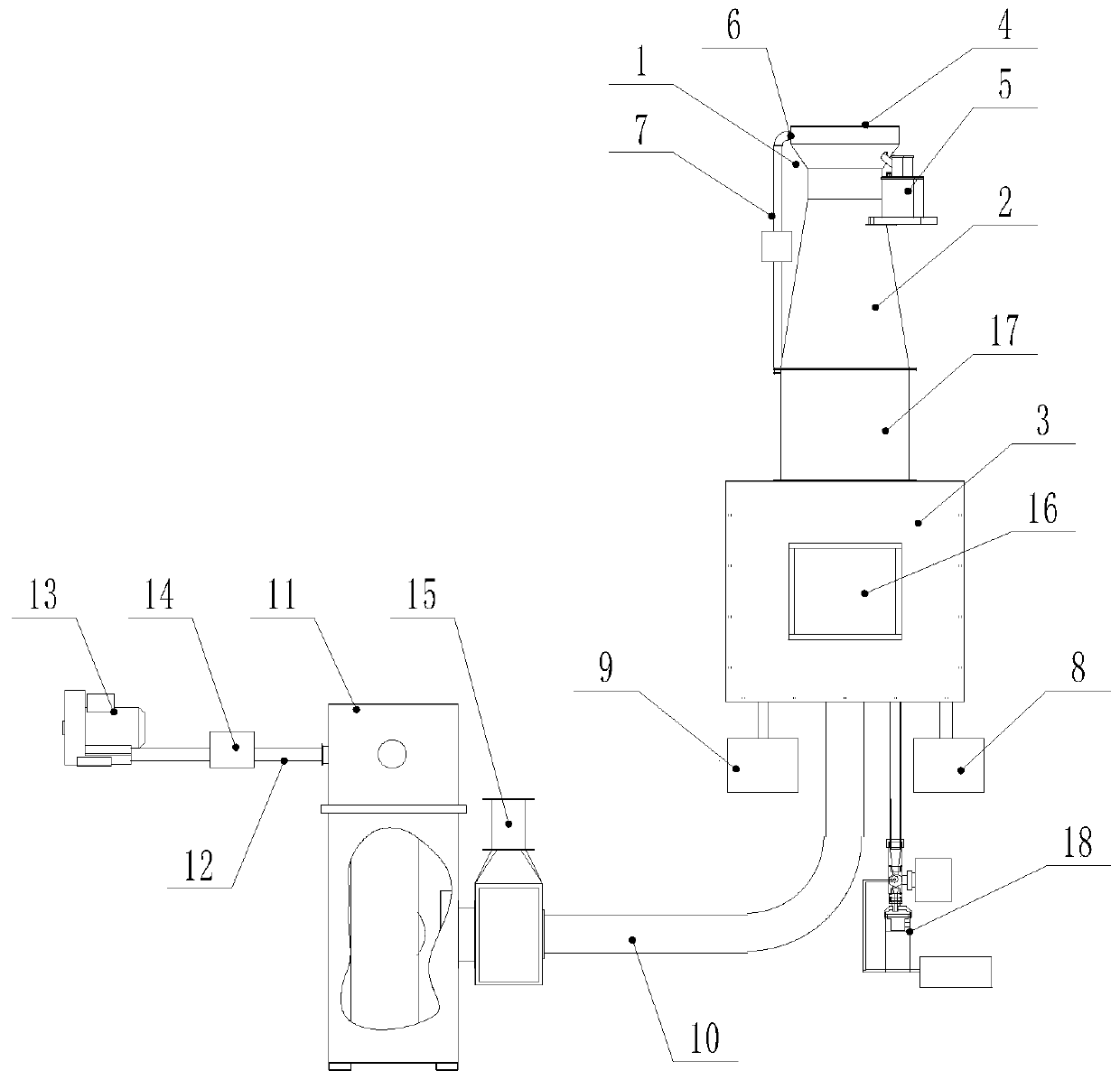

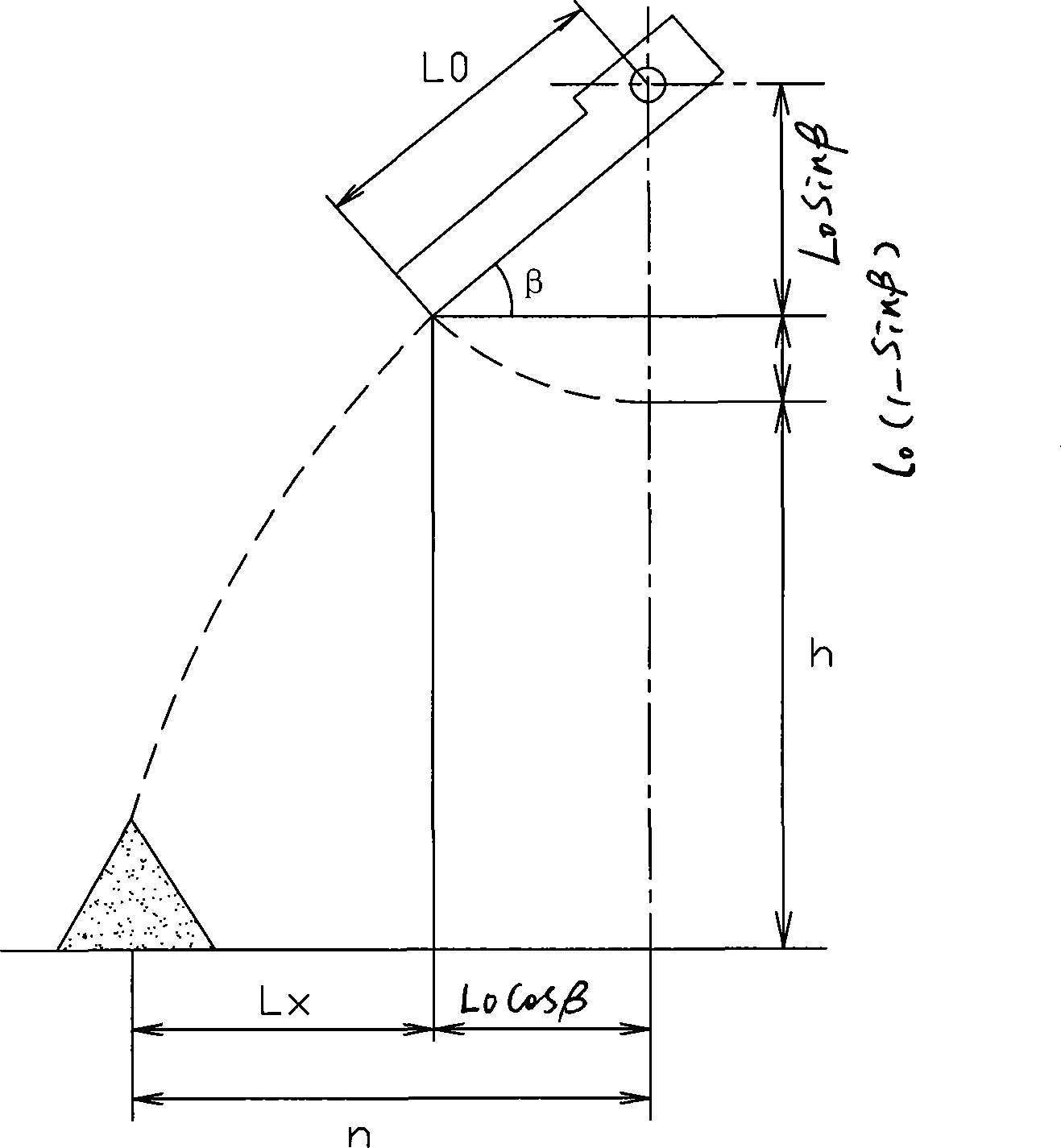

Blast furnace chute polycyclic distributing method

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

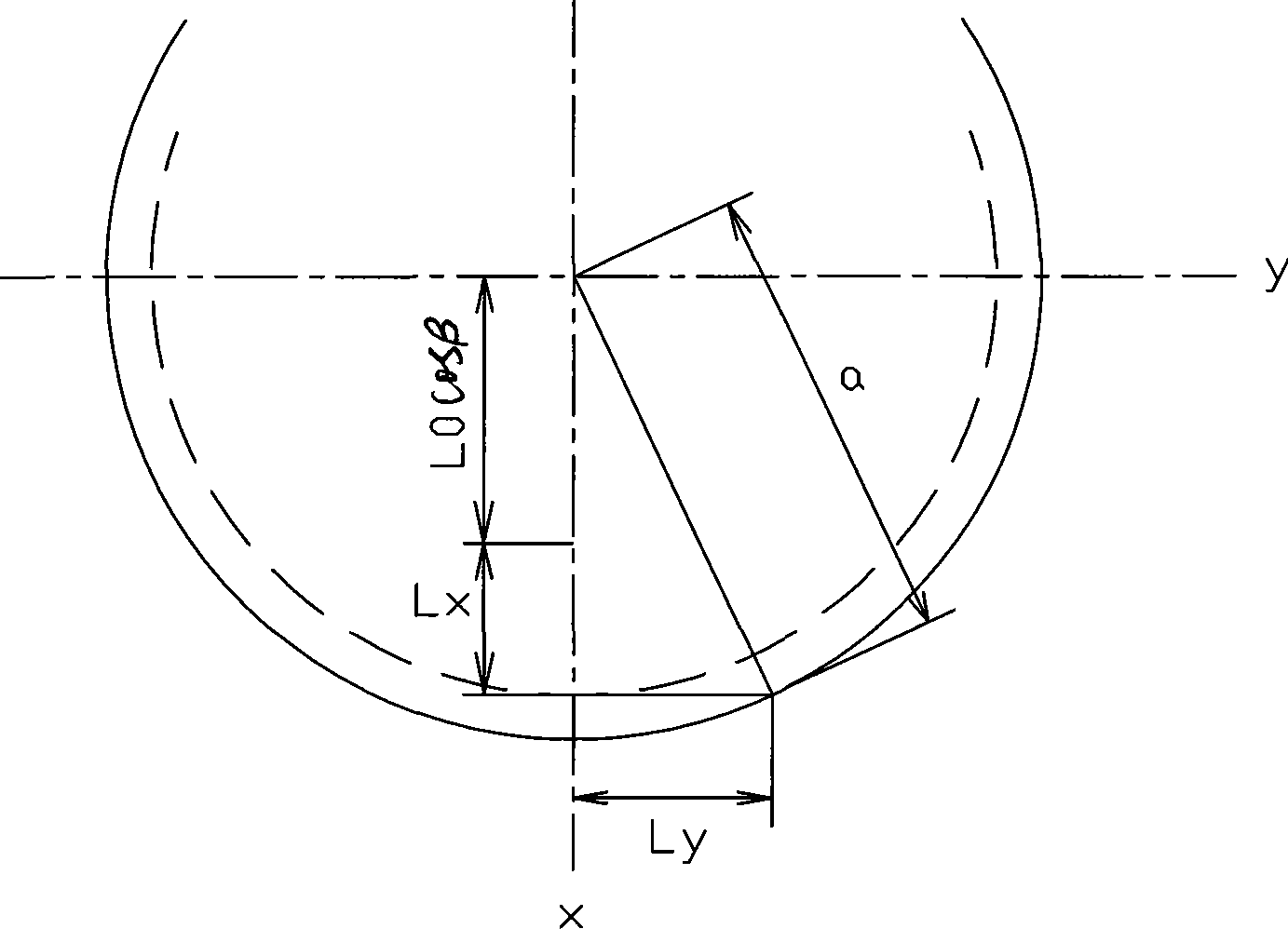

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

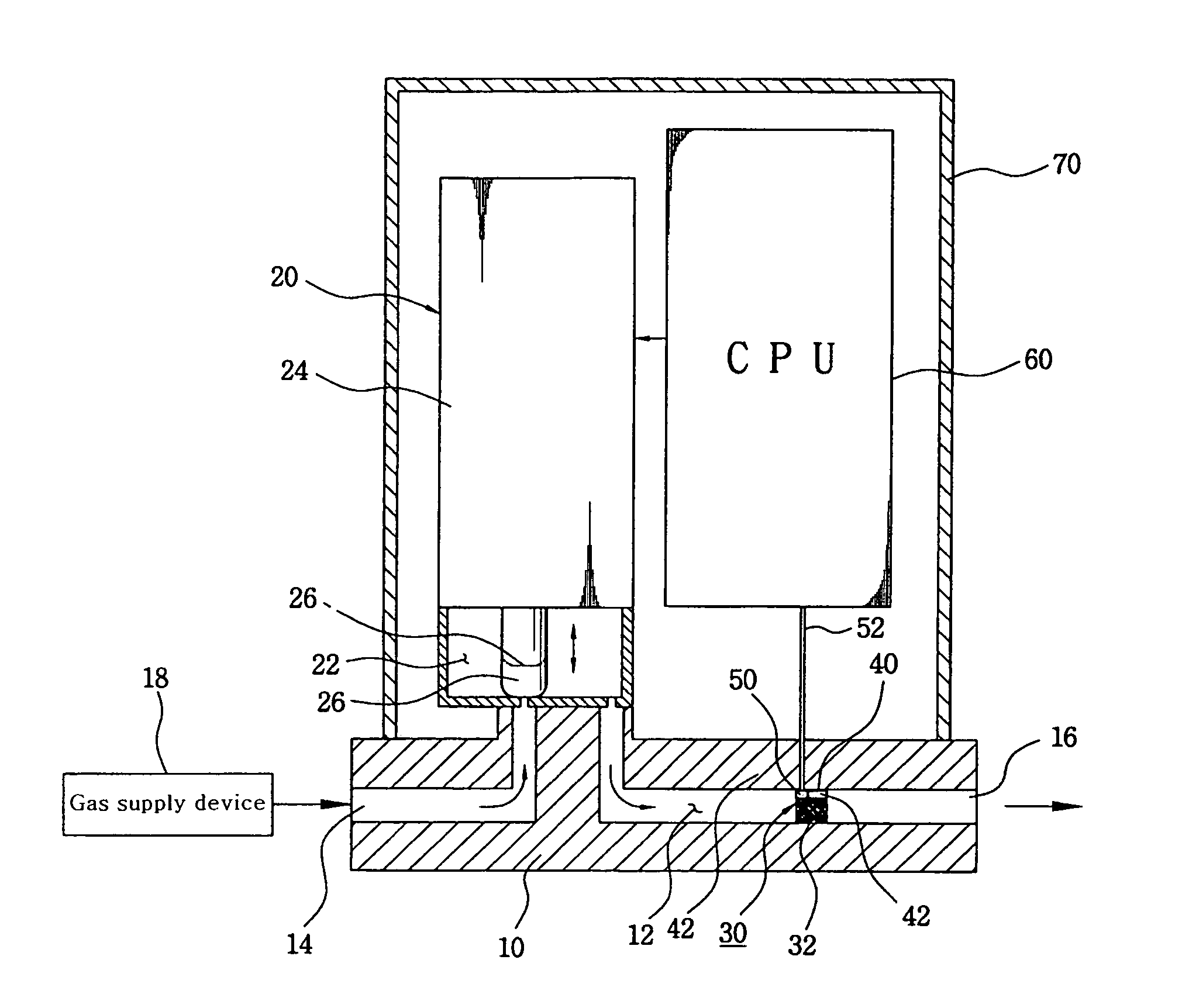

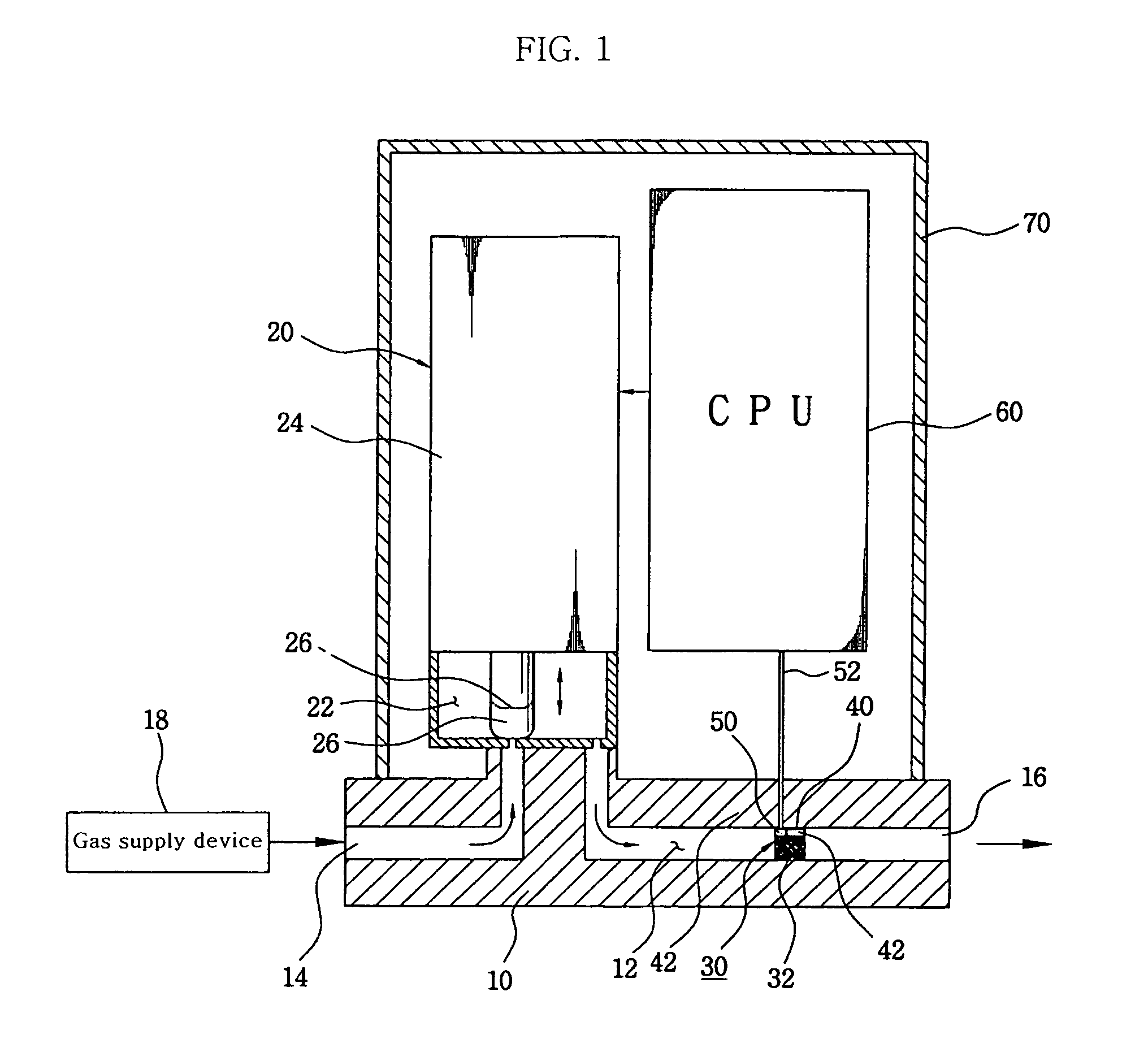

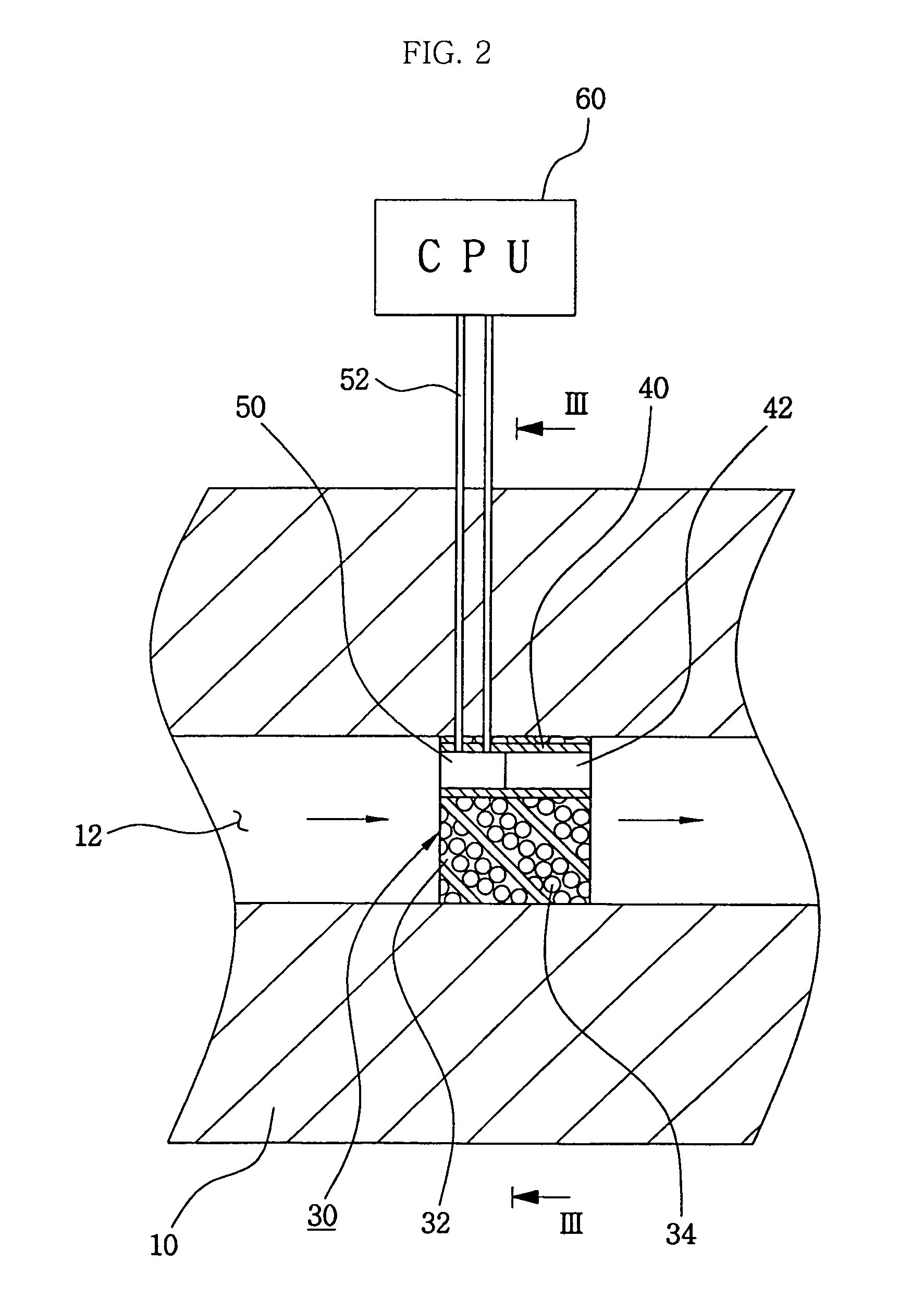

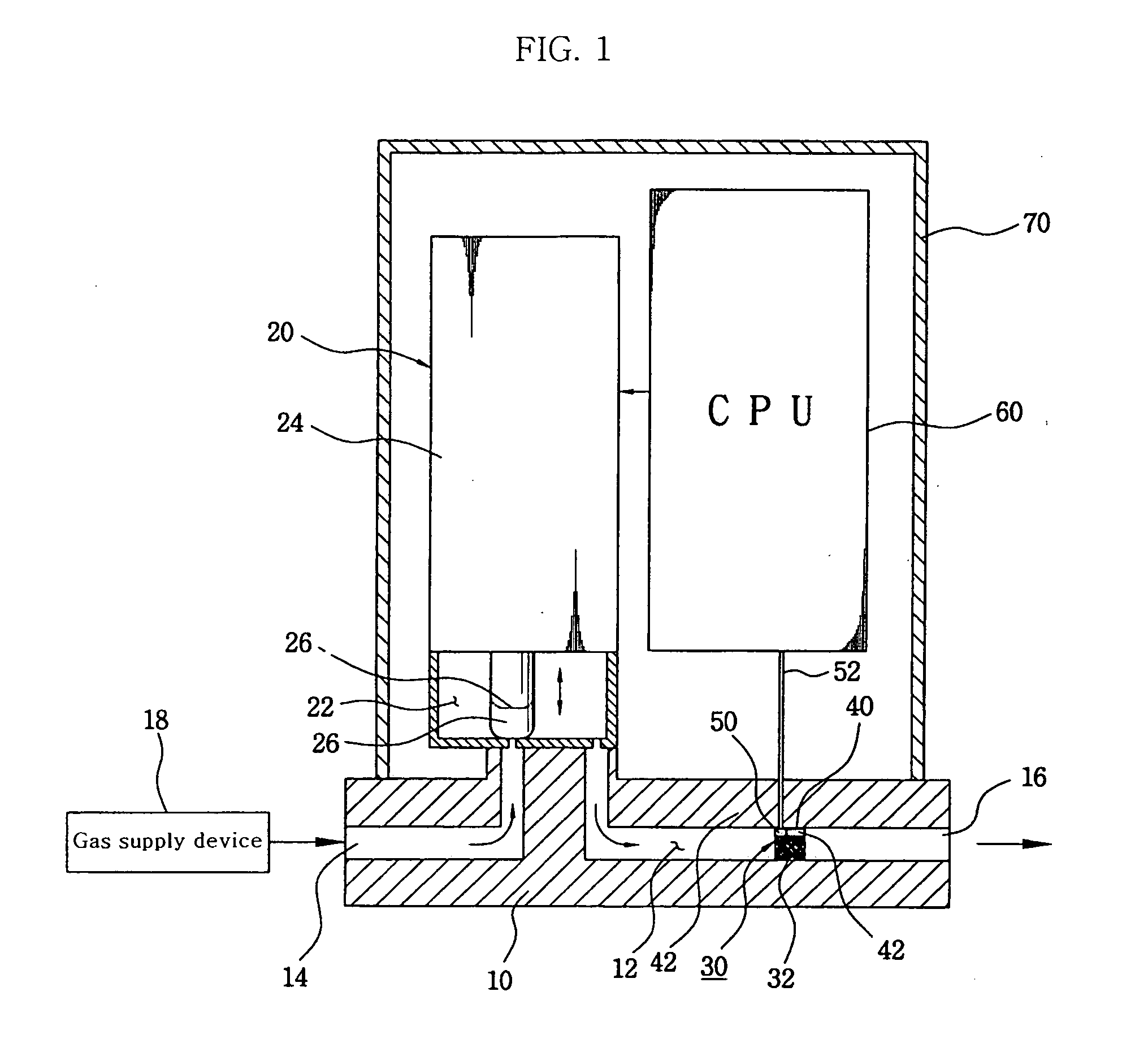

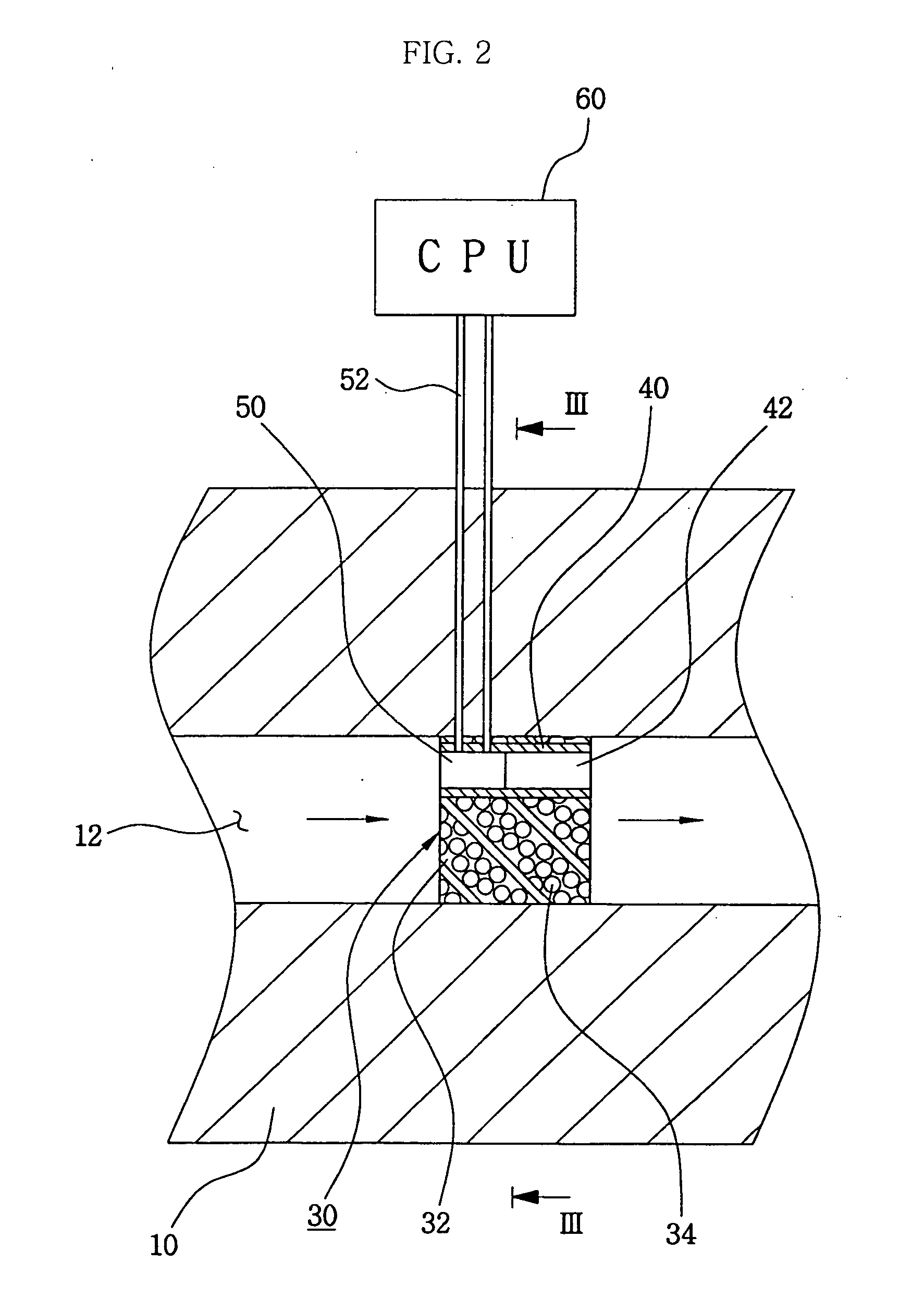

Apparatus for controlling flow rate of gases used in semiconductor device by differential pressure

InactiveUS7334602B2Improving response and reliabilityQuick responseLiquid surface applicatorsCheck valvesControl flowDifferential pressure

Provided is apparatus for controlling flow rate of gases used in semiconductor device by differential pressure by generating differential pressure in a fluid path. A differential pressure generation element generates pressure difference in the fluid path of gases used in semiconductor device fabrication, a pressure, sensor which is installed at a bypass of the fluid path detects the pressure difference, and a central processing unit (CPU) measures and controls a flow rate of the gases, thereby the present invention is capable of controlling the flow rate precisely and rapidly, and enhancing the degree of purity of the gases by the filtering function of the differential pressure generation element itself.

Owner:HYUNDAI CALIBRATION & CERTIFICATION TECH CO LTD +1

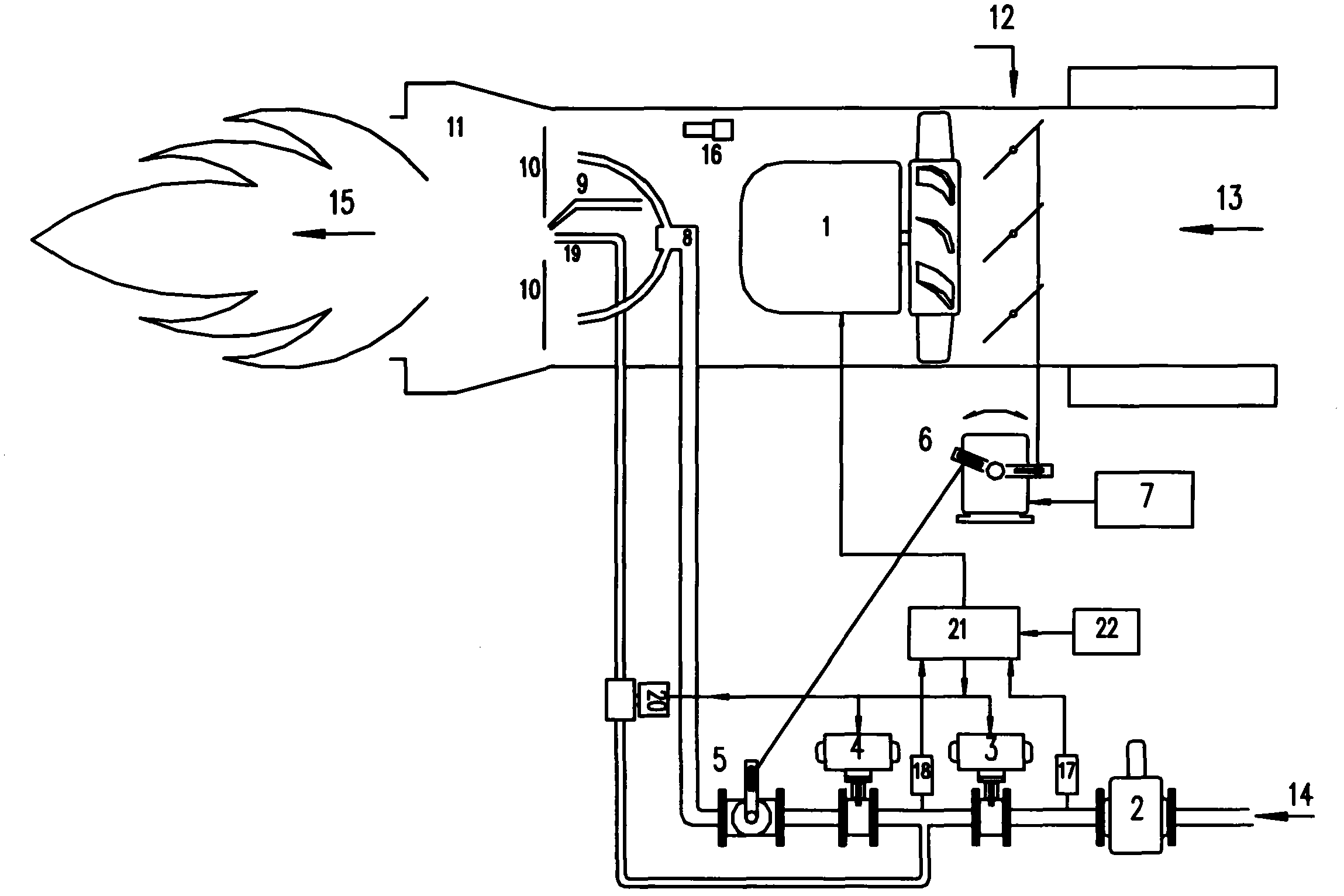

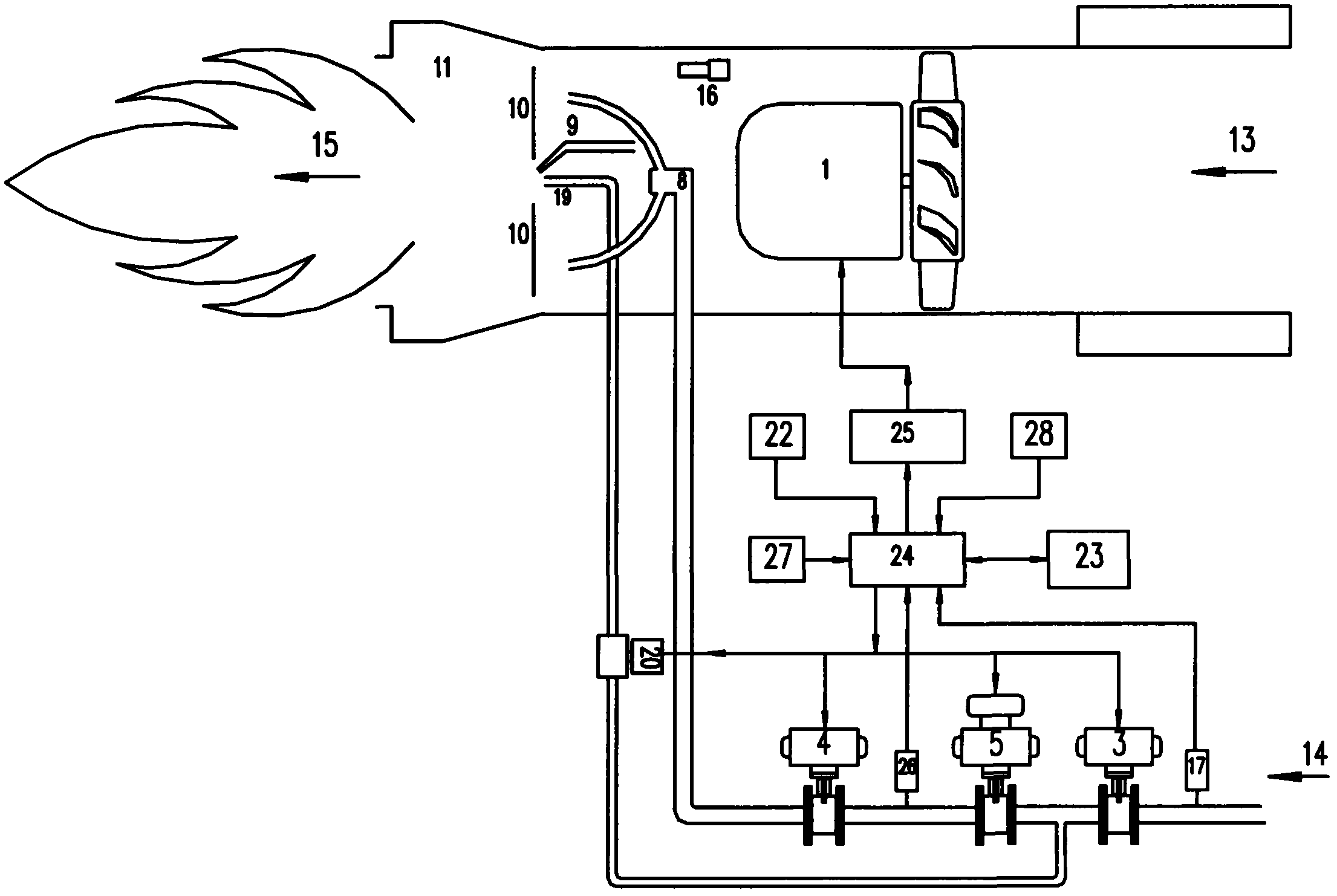

Numerical control gas burner

ActiveCN102519041AStable gas flowOvercoming poor stabilityGaseous fuel burnerAutomatic controlGas burner

The invention discloses a numerical control gas burner, which comprises a gas valve set, a gas metering unit, a blower, an igniter, a flame detector and a highly intelligent numerical control system. When the numerical control gas burner is operated, the highly intelligent numerical control system presets flame openness of the burner to control the gas valve set to output gas flow adapting to the flame openness according to manual instructions and feedback signals such as temperature, pressure or the like; and the highly intelligent numerical control system calculates and adjusts rotation speed of the blower to ensure constant output of best air distribution of the blower in large-range flame adjustment according to gas flow and air-fuel ratio provided by the gas metering unit. The highly intelligent numerical control system is completely different from special controllers for conventional gas burners, and is capable of monitoring and recording the whole combustion process and important parameters of a controlled object at any time, capable of sending acoustic, optic and text warnings in case of failure, and capable of automatically controlling the burner to take corresponding measures to ensure absolute security of personnel and equipment according to severity of the failure.

Owner:北京蒂吉博纳科技有限公司

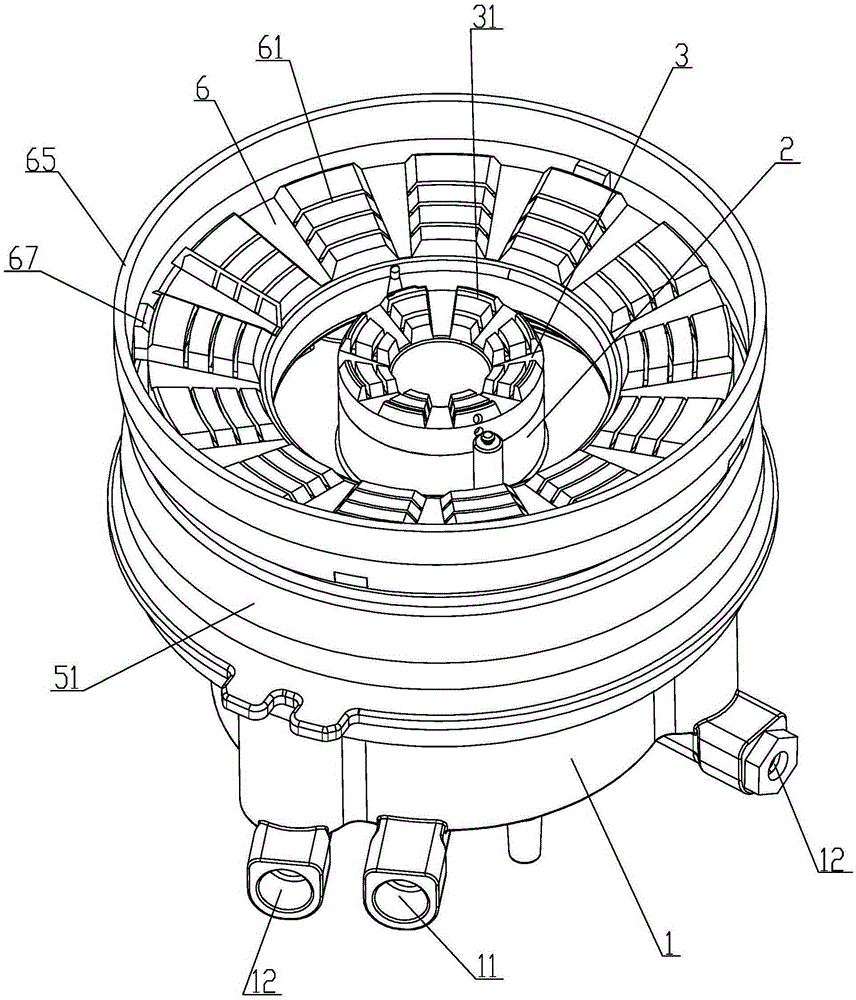

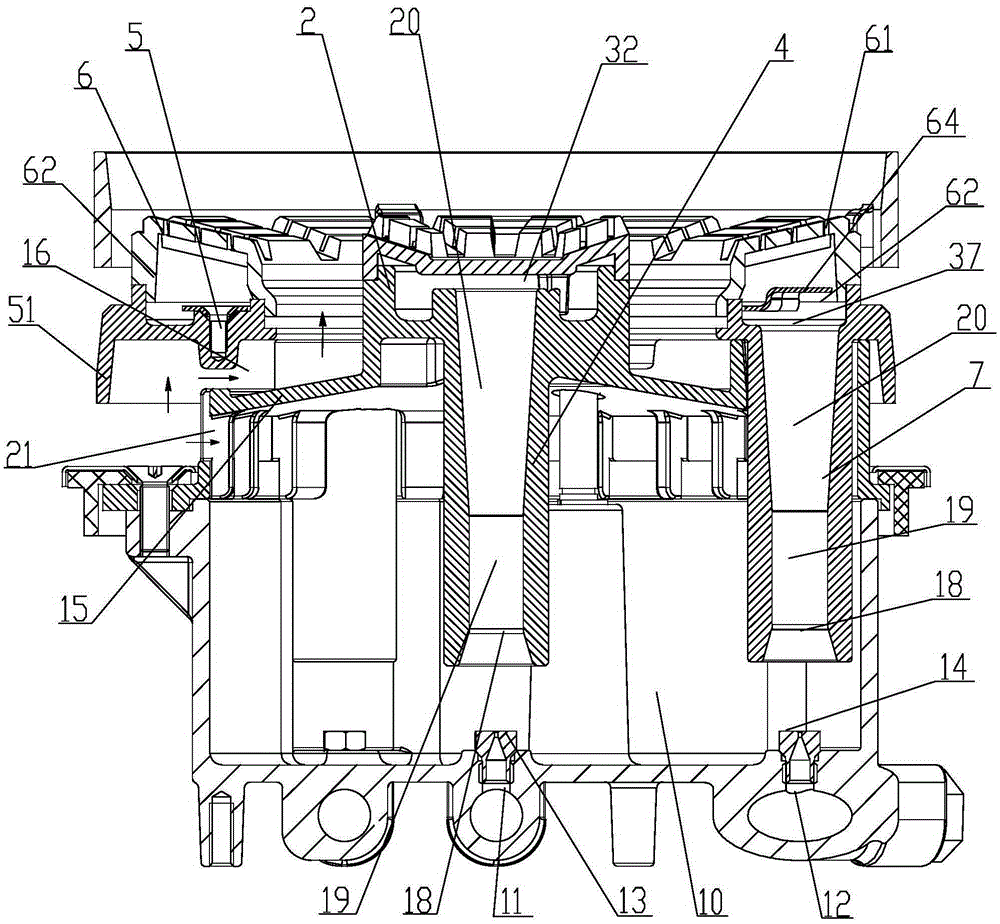

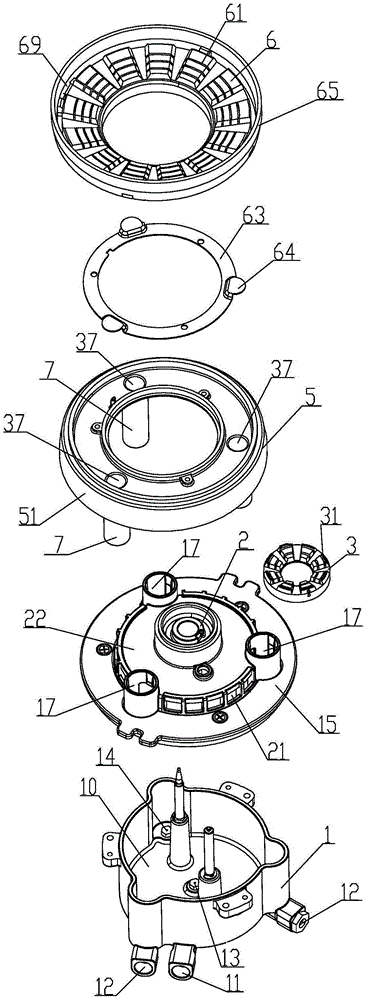

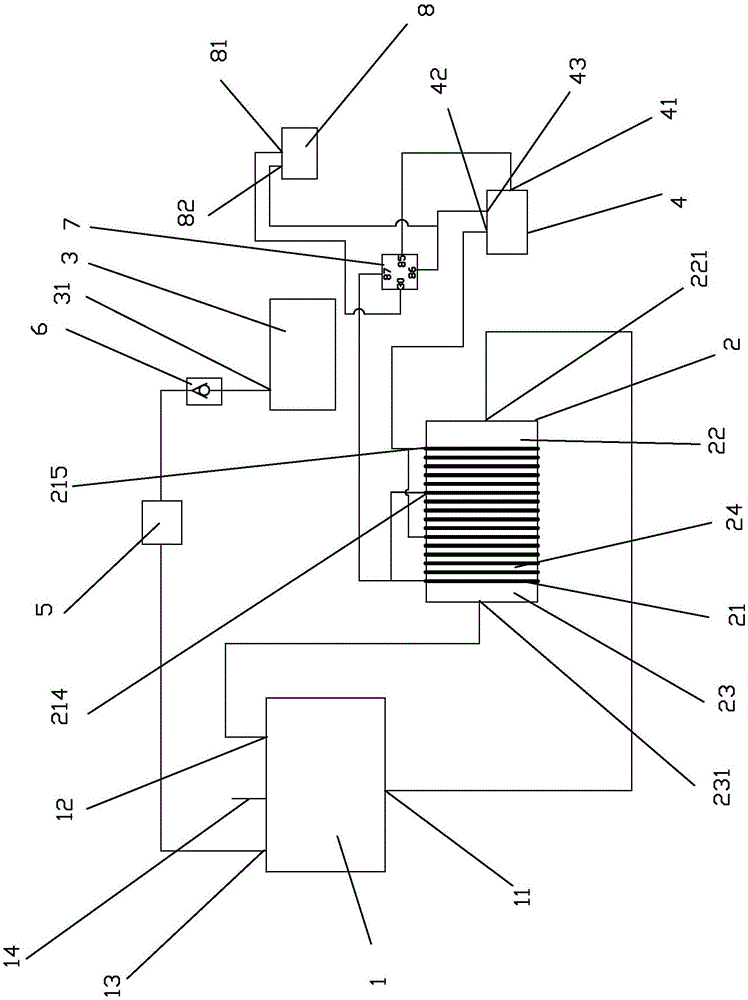

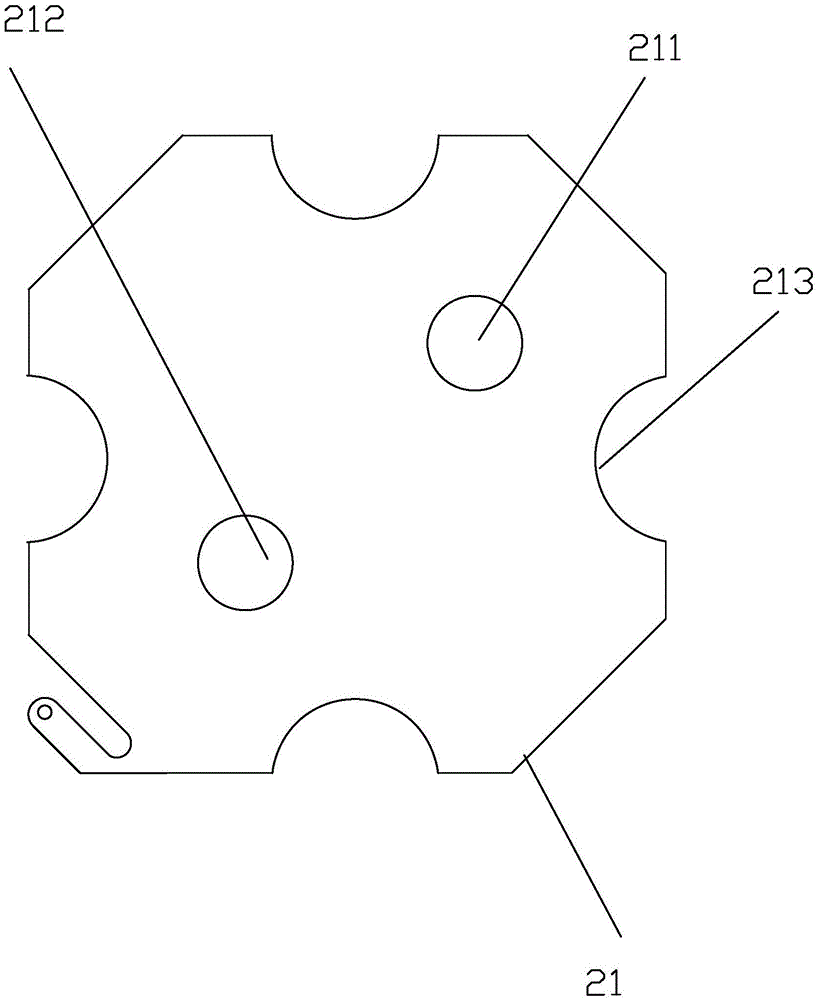

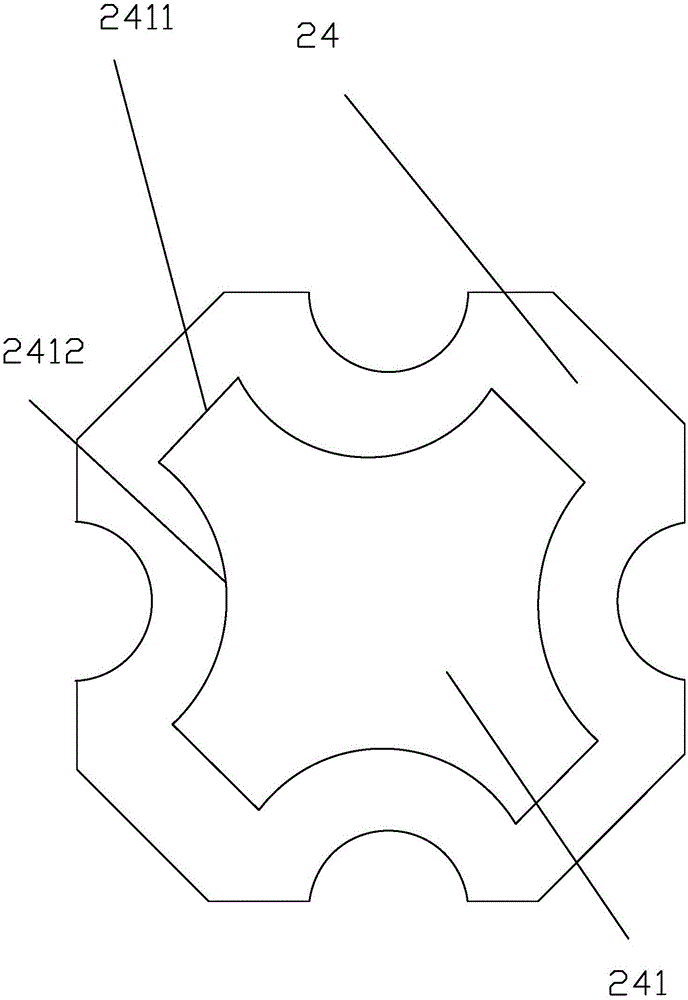

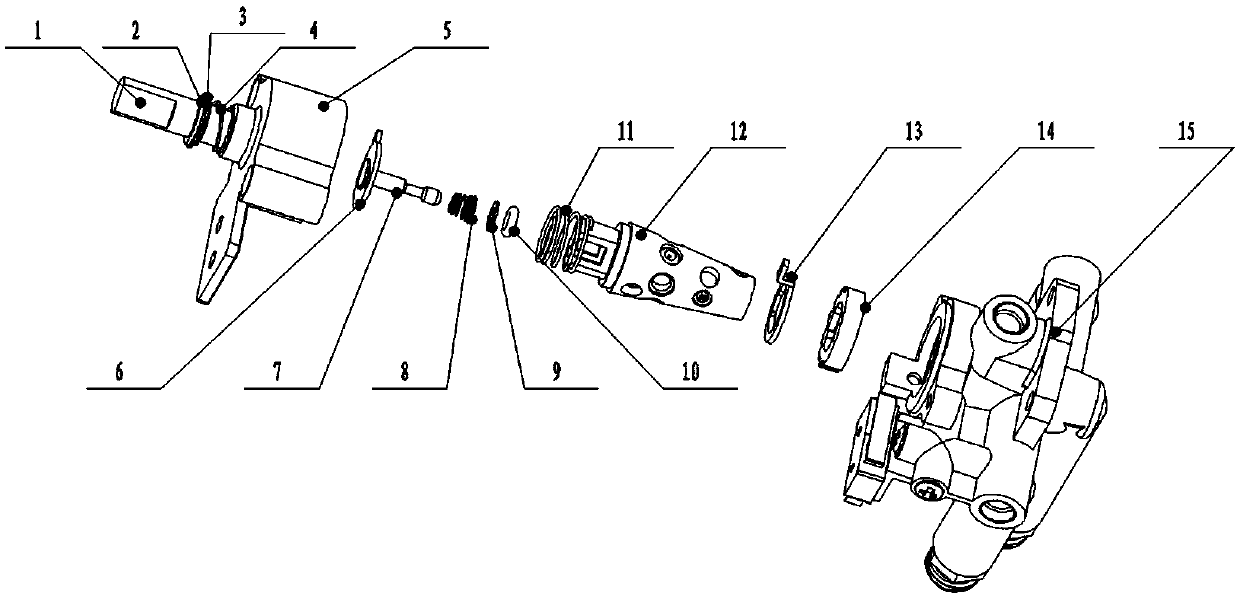

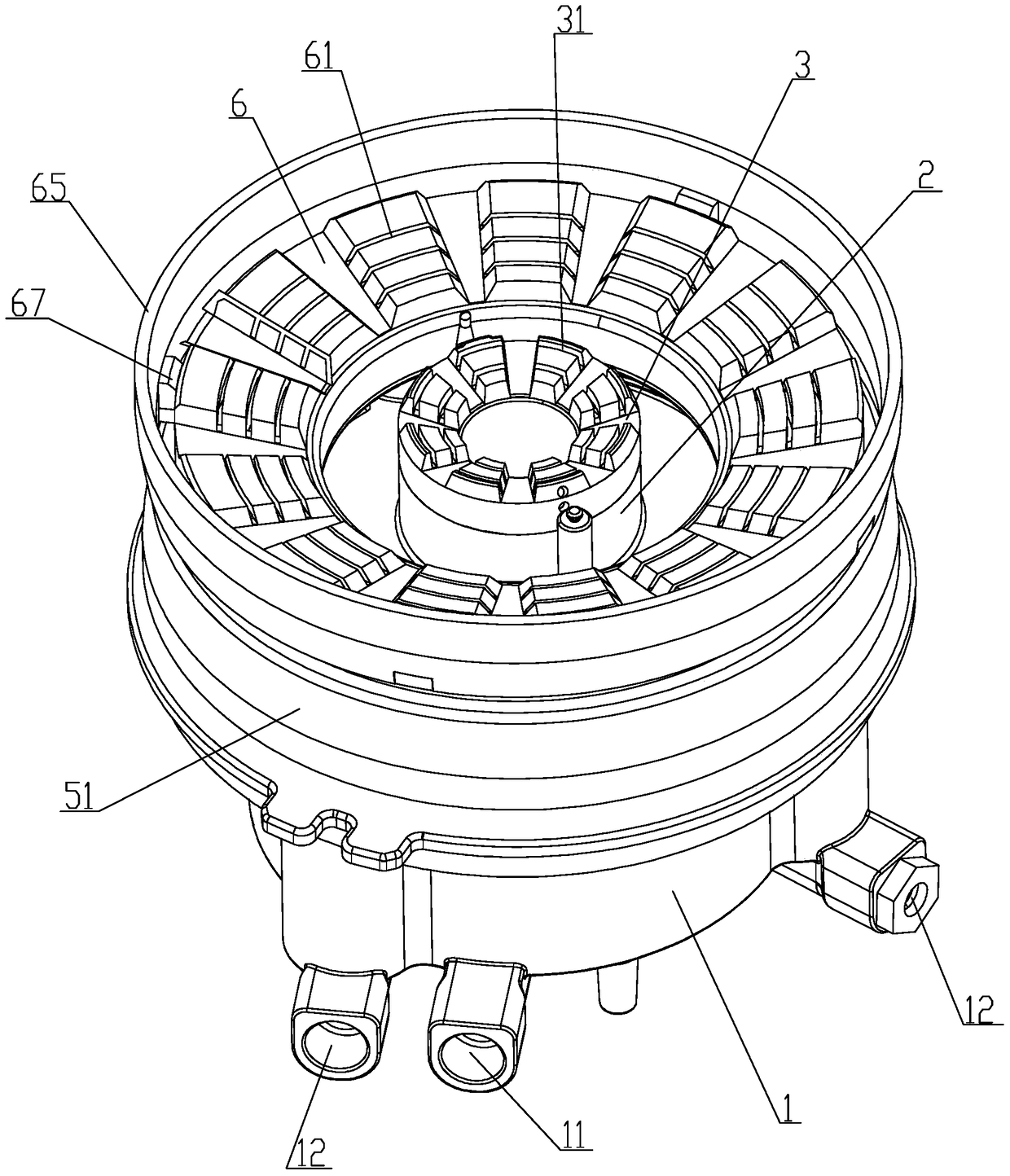

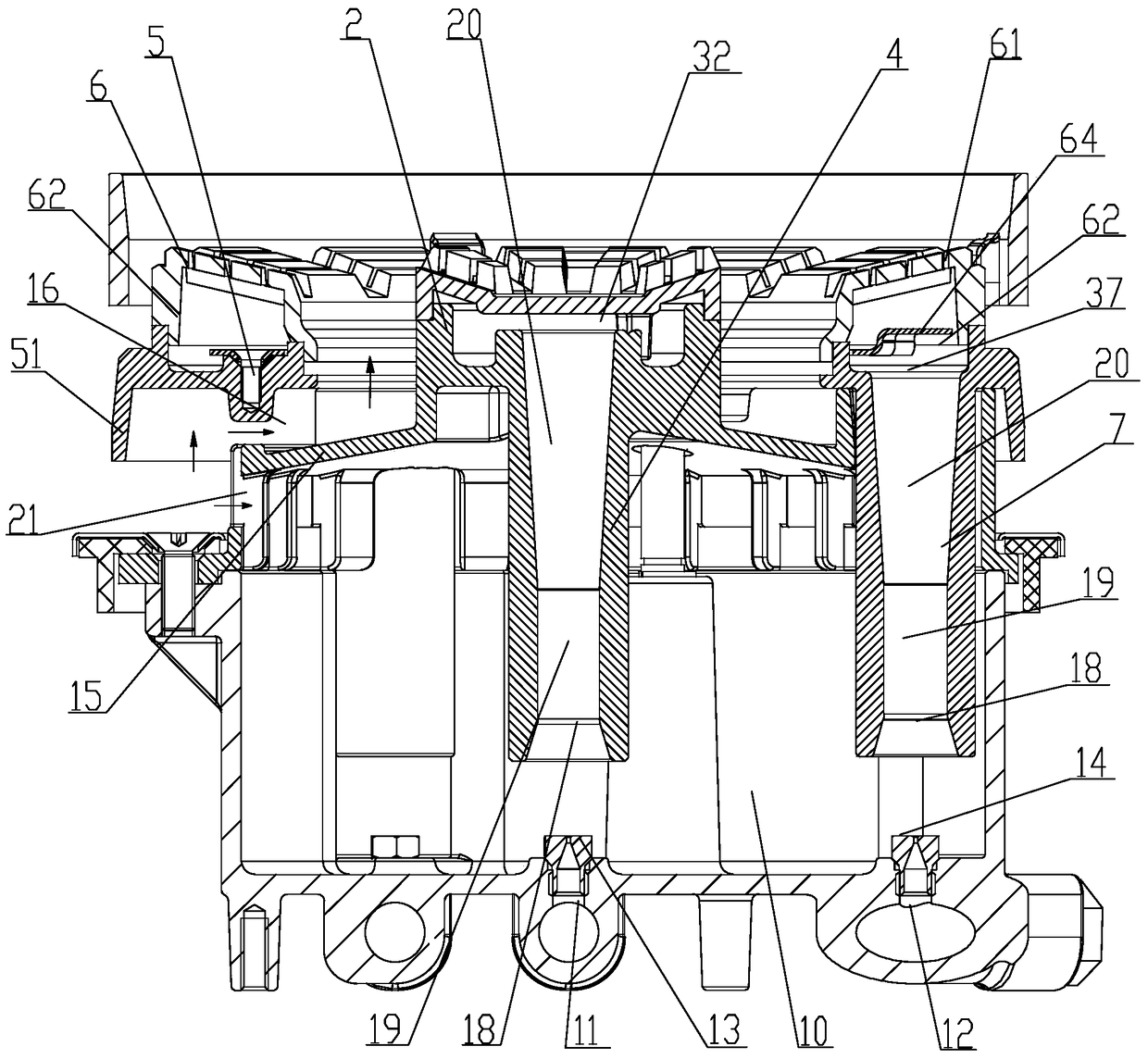

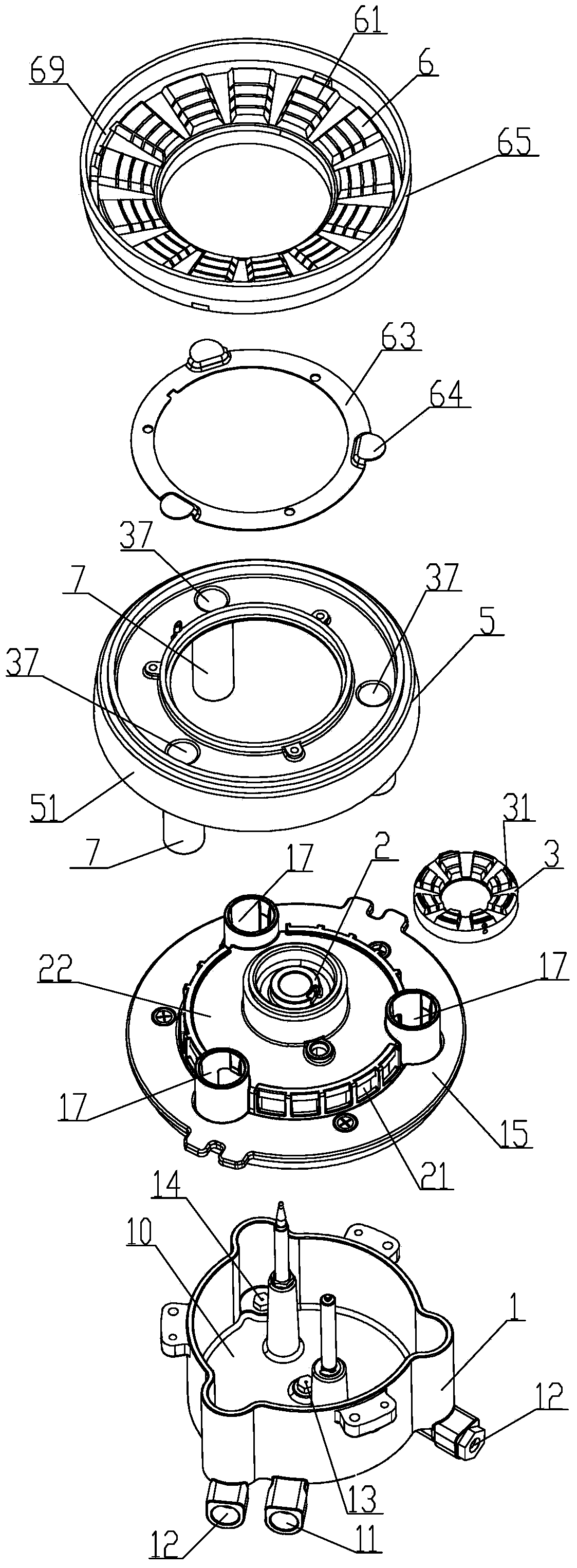

Upper air feeding burner

The invention relates to an upper air feeding burner. The upper air feeding burner is characterized by comprising a burner base, an upper base cover, an inner burner cap seat, an inner burner cap, an inner injection pipe, an outer burner cap seat, an outer burner cap and an outer injection pipe; a base cavity is formed in the burner base, an inner ring air inflow channel and an outer ring air inflow channel are arranged in the burner base, the inner ring air inflow channel is provided with an inner ring nozzle, and the outer ring air inflow channel is provided with an outer ring nozzle; an air supplementing inlet is formed in the upper base cover; the inner burner cap seat is arranged on the upper base cover; an inner burner cap hole is formed in the inner burner cap and an inner ring gas channel is defined by the inner burner cap and the inner burner cap seat; one end of the inner injection pipe is opposite to the inner ring nozzle and the other end of the inner injection pipe is communicated with the inner ring gas channel; the outer burner cap seat is arranged on the upper base cover; an outer burner cap hole is formed in the outer burner cap, an outer ring gas channel is defined by the outer burner cap and the outer burner cap seat, and an air supplementing inflow channel is defined between the upper base cover and the outer burner cap seat; and one end of the outer injection pipe is opposite to the outer ring nozzle and the other end of the outer injection pipe is communicated with the outer ring gas channel. The upper air feeding burner is simple in structure and high in burning efficiency.

Owner:CHINABEST HOME APPLIANCE

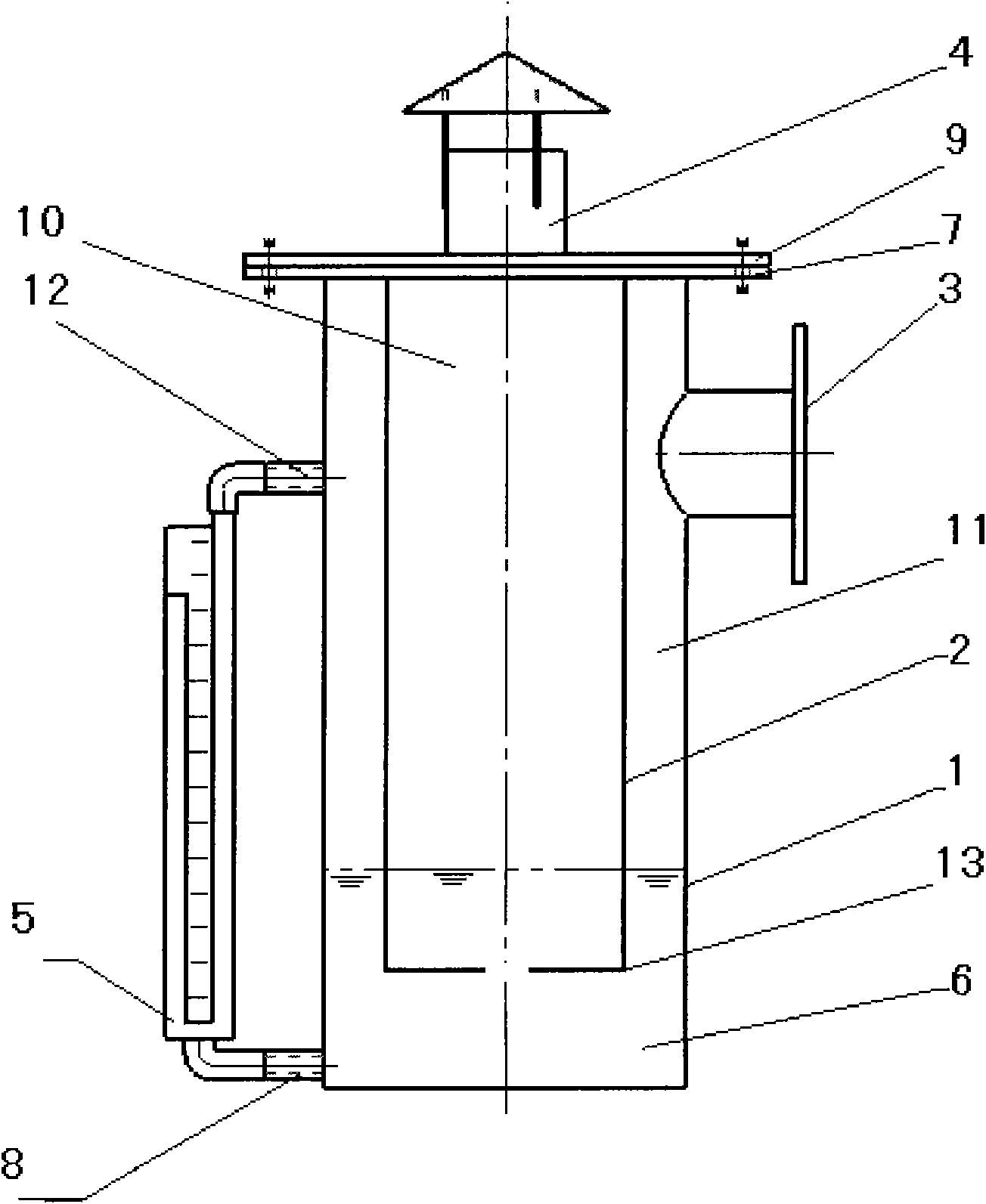

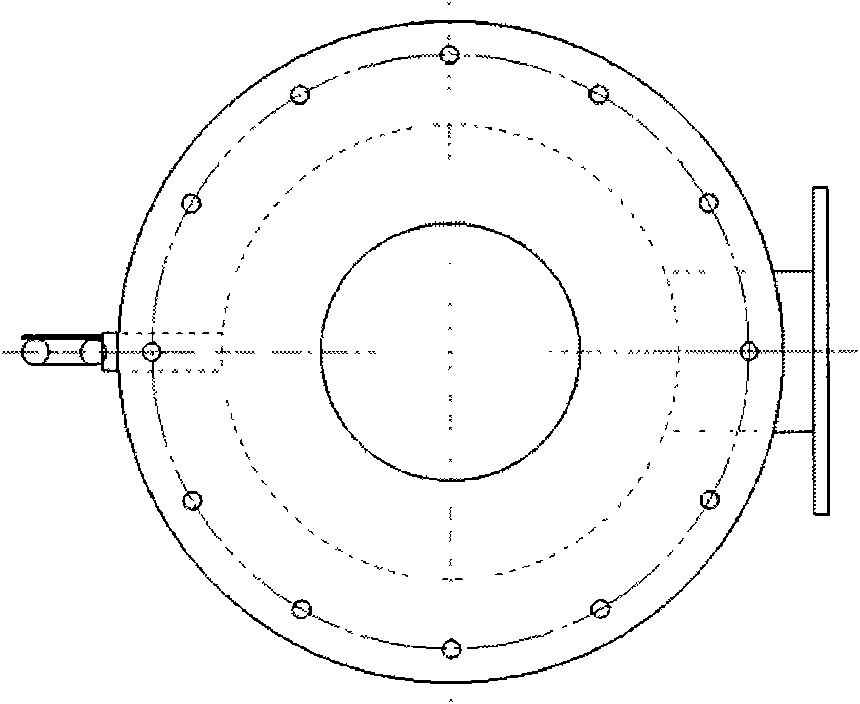

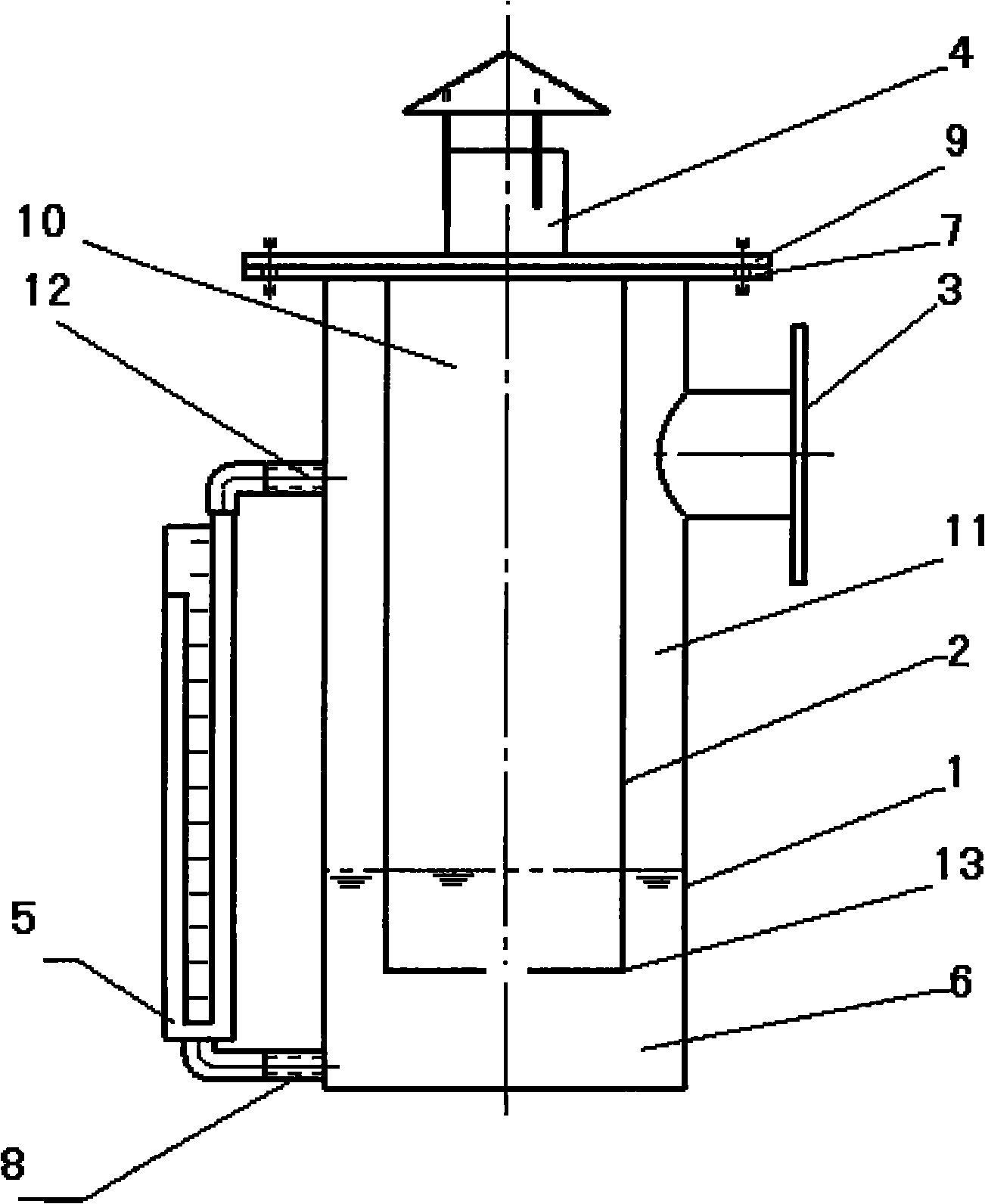

Integral positive/negative pressure protector

InactiveCN102399682AEasy to adjust the ratioLiquidGas production bioreactorsBoiling pointEngineering

The invention discloses an integral positive / negative pressure protector composed of an outer cylinder, an inner cylinder, a pressure balancing pipe, an evacuating pipe, a liquidometer, and sealed liquid. The outer cylinder and the inner cylinder are connected through a flange. The evacuating pipe communicates with the inner cylinder. The pressure balancing pipe communicates with the outer cylinder. The sealed liquid is non-compressible. The sealed liquid is Newton fluid with a boiling point no lower than 80 DEG C and a melting point no higher than -40 DEG C. According to the invention, positive and negative pressure protecting functions are integrated, such that defects of traditional technologies of increased investment, tedious management and large land occupation caused by independent positive and negative pressure protectors are avoided. The protector provided by the invention is advantaged in stable operation. The protector can provide effective and reliable protections for containers.

Owner:LIAONING BEIFANG ENVIRONMENTAL PROTECTION

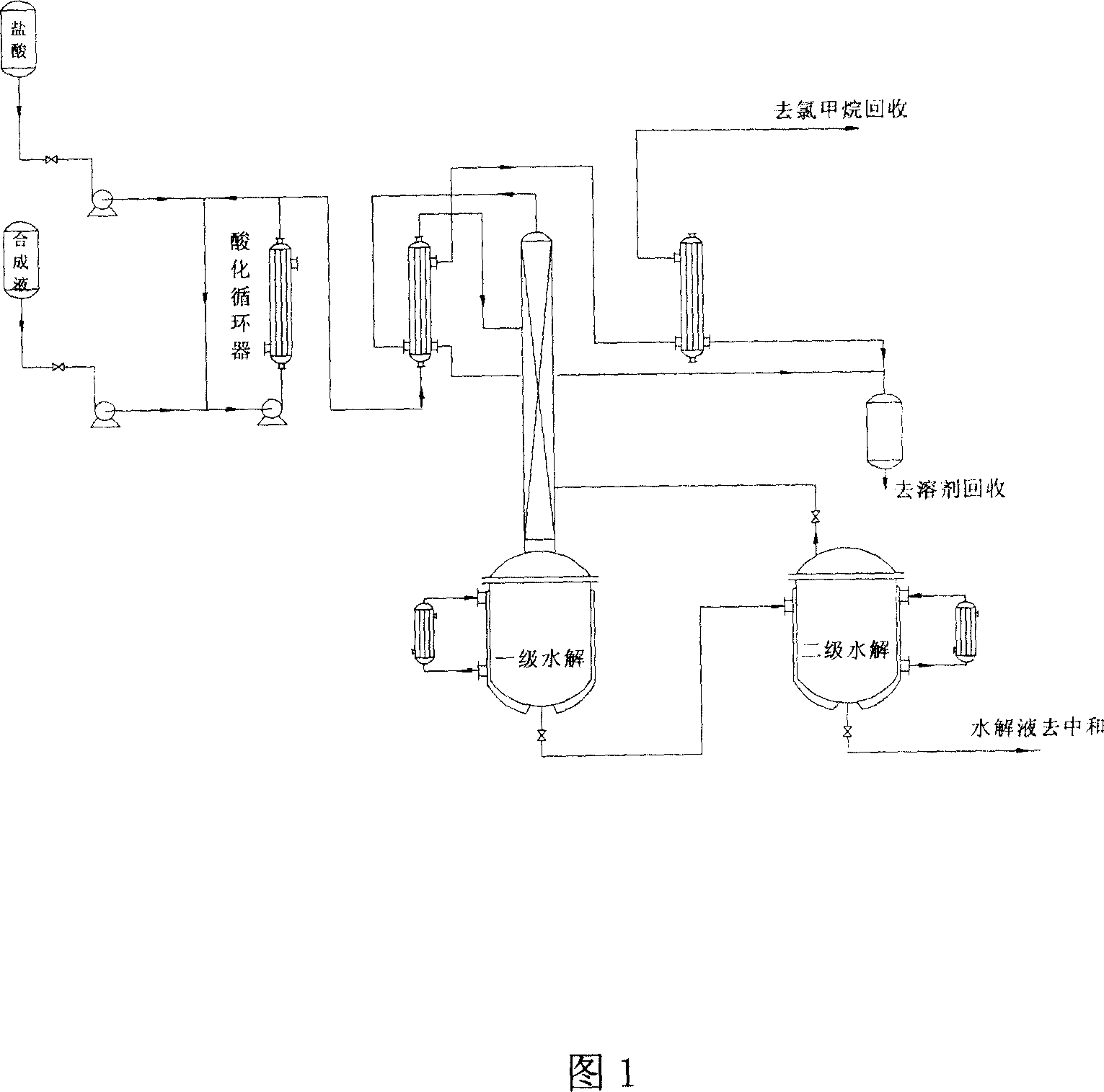

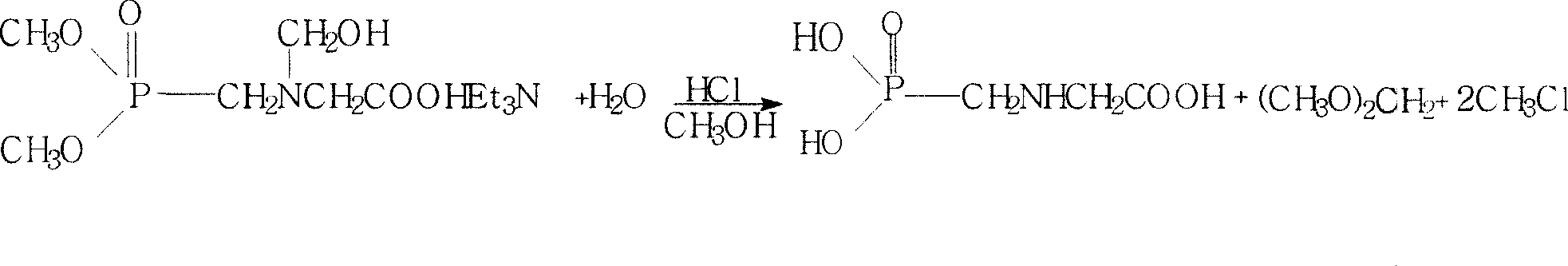

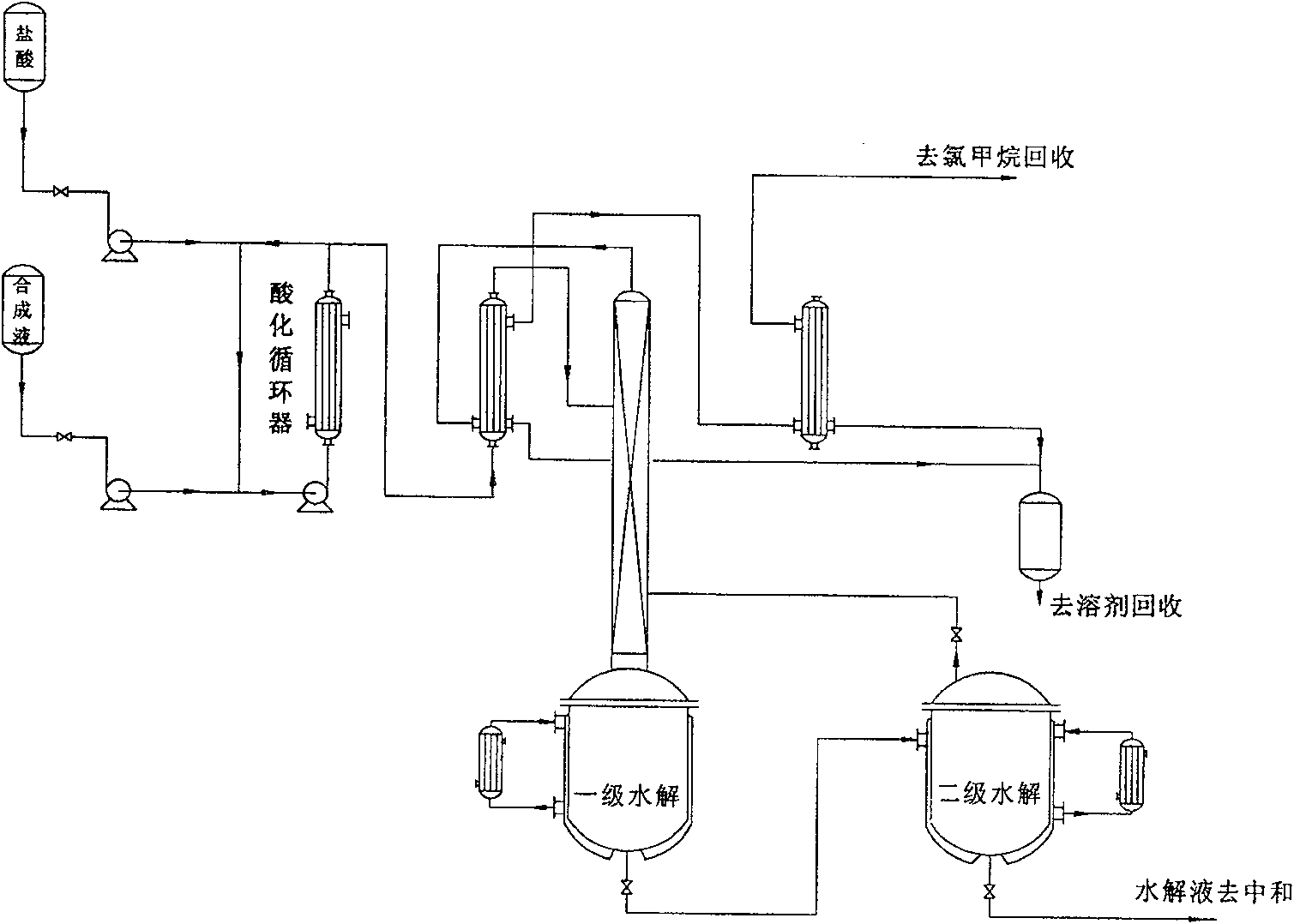

Continuous synthesis of glyphosate by dimethyl ester

Continuous synthesis of glyphosate by dimethyl ester is carried out by taking paraformaldehyde, amino acetic acid and dimethyl ester as raw materials to obtain synthetic liquid, acidizing it with hydrochloric acid, mixing, entering into hydrolytic reactive zone, reacting in hydrolytic reactor continuously, acidizing synthetic liquid, hydrolyzing in hydrolytic reactive zone continuously, forming into glyphosate salt, batching continuously and neutralization crystallizing to obtain the final product. It realizes continuous hydrolysis and simplifies process and can be used in large-scale production.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Diaphragm type gas meter

ActiveCN105784048ASimple structureReasonable structureContracting/expanding measuring chambersVolume/mass flow by differential pressureEngineeringExtreme position

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

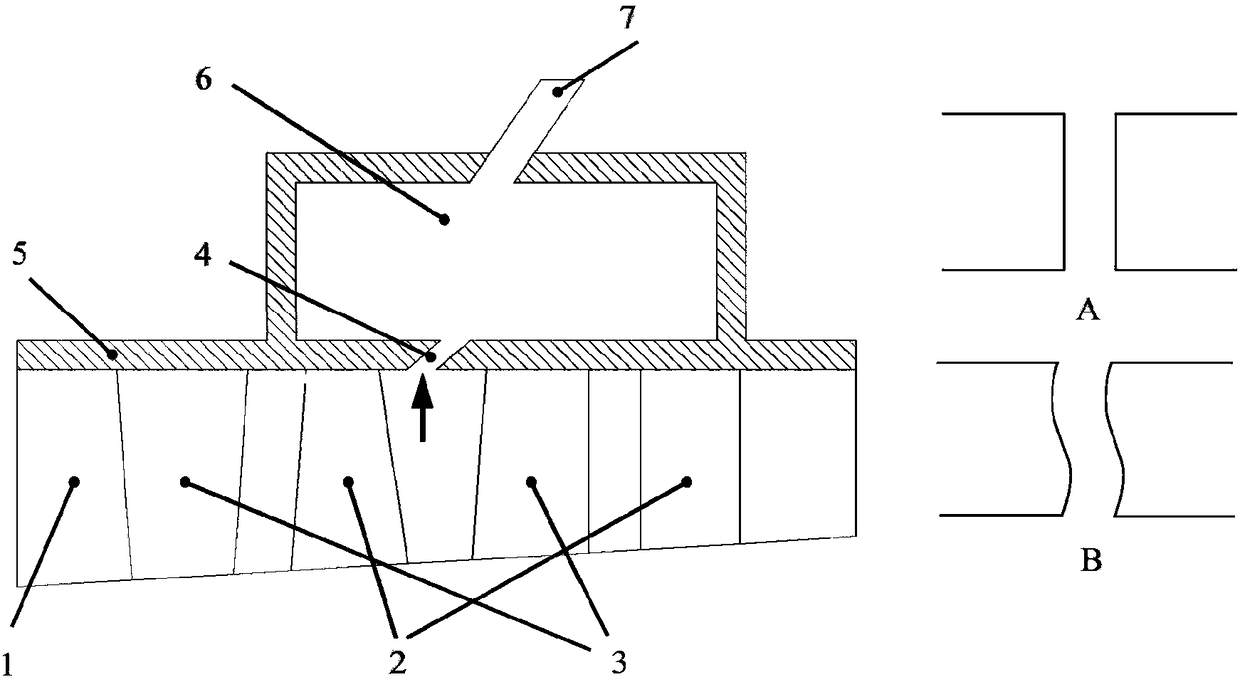

Electrolytic hydrogen fuel bi-motor and use method thereof

InactiveCN105065144AAvoid voltage changesAutomatic width adjustmentNon-fuel substance addition to fuelInternal combustion piston enginesElectrolysisGasoline

The invention discloses an electrolytic hydrogen fuel bi-motor. The electrolytic hydrogen fuel bi-motor comprises a water tank, an HHO generator, a motor and a constant-current pulse width regulator which is used for controlling current flowing into the HHO generator, wherein a liquid outlet I, a liquid inlet I and a gas vent are formed in the water tank; the HHO generator comprises multiple white steel sheets arranged in a sealed shell and an upper cover and a lower cover which press the multiple white steel sheets tightly; the multiple white steel sheets are arranged in a stacked manner; each white steel sheet is provided with a through hole I and a through hole II; a high temperature-resistant insulation pad is arranged between every two adjacent white steel sheets; and a cross-shaped through hole is formed in each high temperature-resistant insulation pad. The invention further discloses a use method of the electrolytic hydrogen fuel bi-motor. According to the electrolytic hydrogen fuel bi-motor, hydrogen generated through electrolysis of electrolyte is used as fuel of the motor in an electrolysis manner; the fuel saving rate can reach 20%-35%; the electrolytic hydrogen fuel bi-motor is applicable to various large, medium and small automobiles, steamships, small fishing vessels, fixed diesel engines, unmanned aerial vehicles and the like; and the electrolytic hydrogen fuel bi-motor is not limited by various automobiles or gasoline and diesel vehicles.

Owner:张建超

Modified compressor air pumping casing

ActiveCN108518355AIncrease resistanceMigration DifficultyTurbine/propulsion engine ignitionTurbine/propulsion engine startersAir pumpEngineering

The invention provides a modified compressor air pumping casing. The modified compressor air pumping casing comprises a compressor casing body and an air pumping casing body; the air pumping casing body sleeves the compressor casing body; a casing channel is formed in the circumferential direction of the side wall of the compressor casing body and penetrates through the side wall of the compressorcasing body; the compressor casing body communicates with the air pumping casing body through the casing channel; and the casing channel is shaped like a complex linear periodic repeatedly-composed circumferential curve. According to the modified compressor air pumping casing, the shape of a traditional circumferential symmetric air pumping casing body is changed into the complex linear periodicrepeatedly-composed circumferential curve from a circumferential straight line surrounding the outer wall of the compressor casing body, so that the on-way resistance of migration of air mass in the circumferential direction of an air pumping channel can be increased, the obstruction effect on the low-pressure separated air mass pumped away from a compressor passage due to the migration of the high-pressure airflow in the circumferential direction of an air pumping channel seam can be weakened, the flow separation can be relieved more easily, the surge phenomenon caused by the intensified rotating stall of gas in the compressor casing body can be effectively avoided, and a gas turbine can be started more stably and safely.

Owner:TSINGHUA UNIV

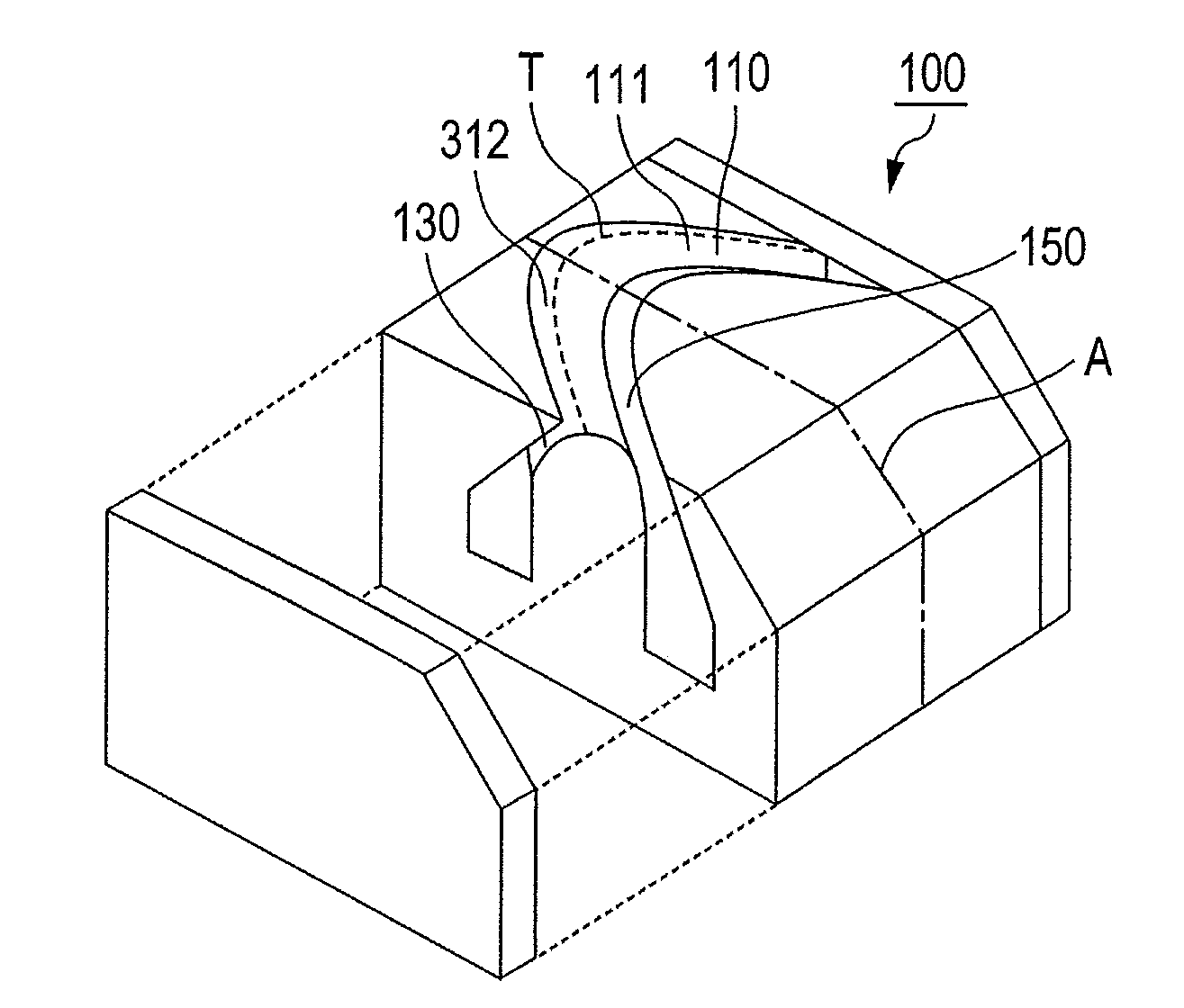

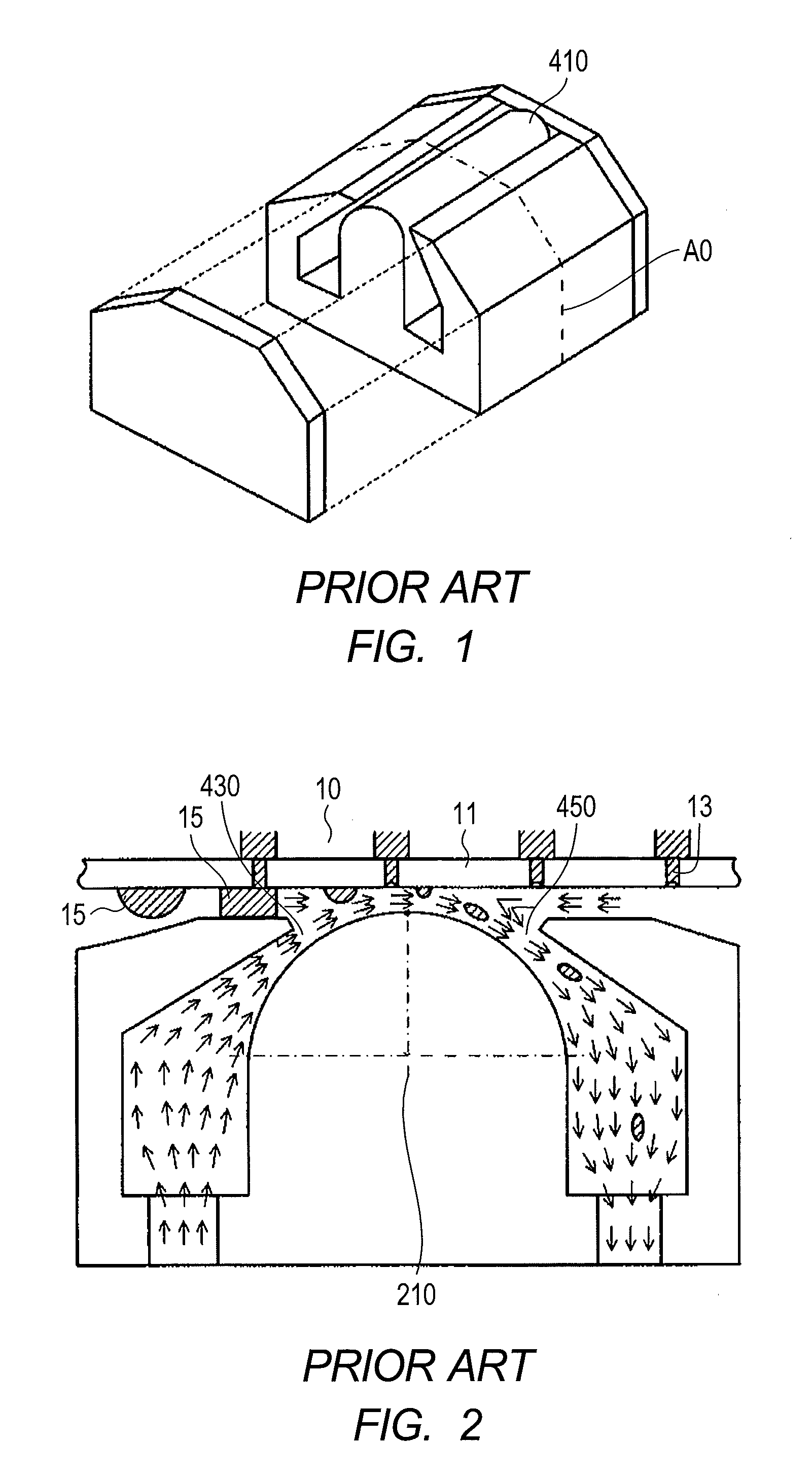

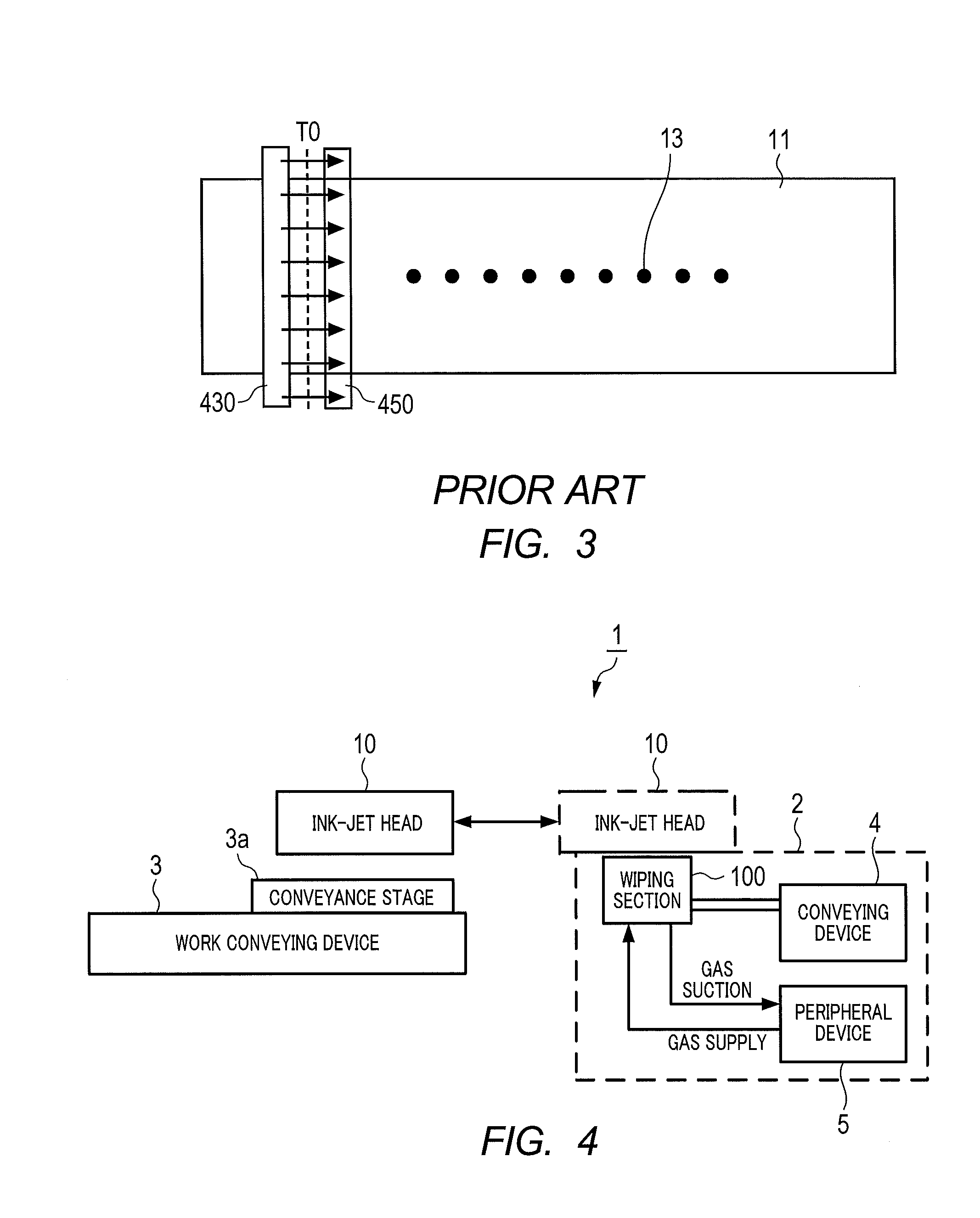

Wiping device, ink-jet device, and wiping method

A wiping device has a wiping section that relatively moves along the nozzle surface, and the wiping section has: a curved surface in which a bulge is continuously formed along the identification line; a guiding section disposed such that the bulge faces the nozzle surface; a gas jetting port that applies gas to the curved surface; and a gas suction port that sucks the gas ejected from the gas jetting port and guided along the curved surface, wherein, as viewed from the direction perpendicular to the nozzle surface, the identification line which is the set of upper end points on the bulge on the curved surface intersects with the edges of the nozzle surface at an oblique angle.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

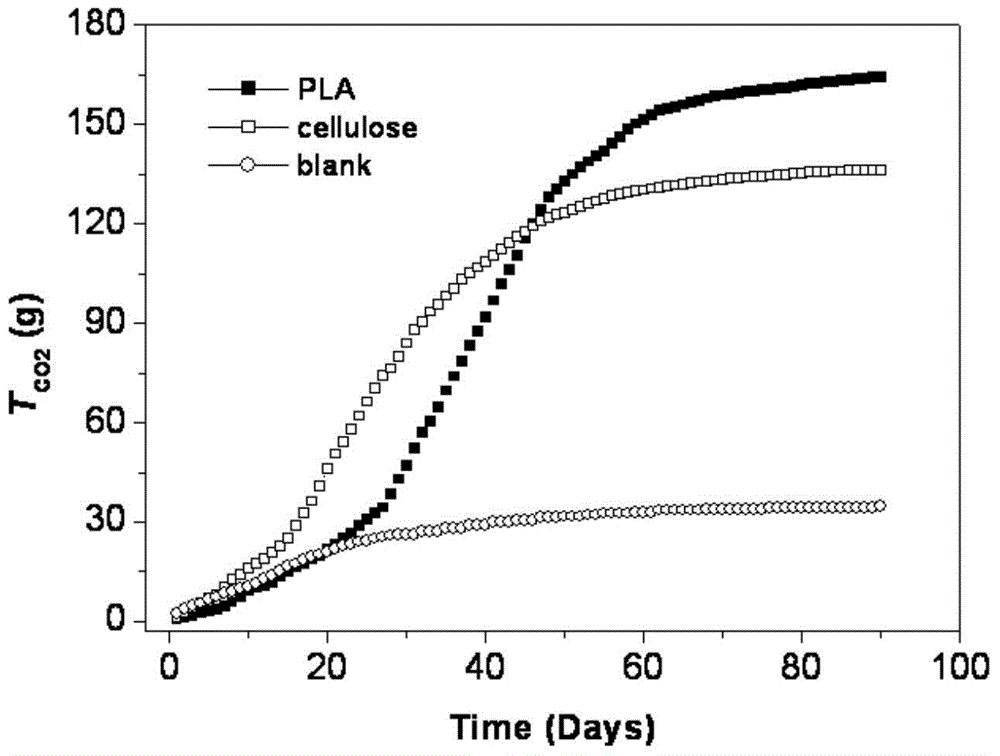

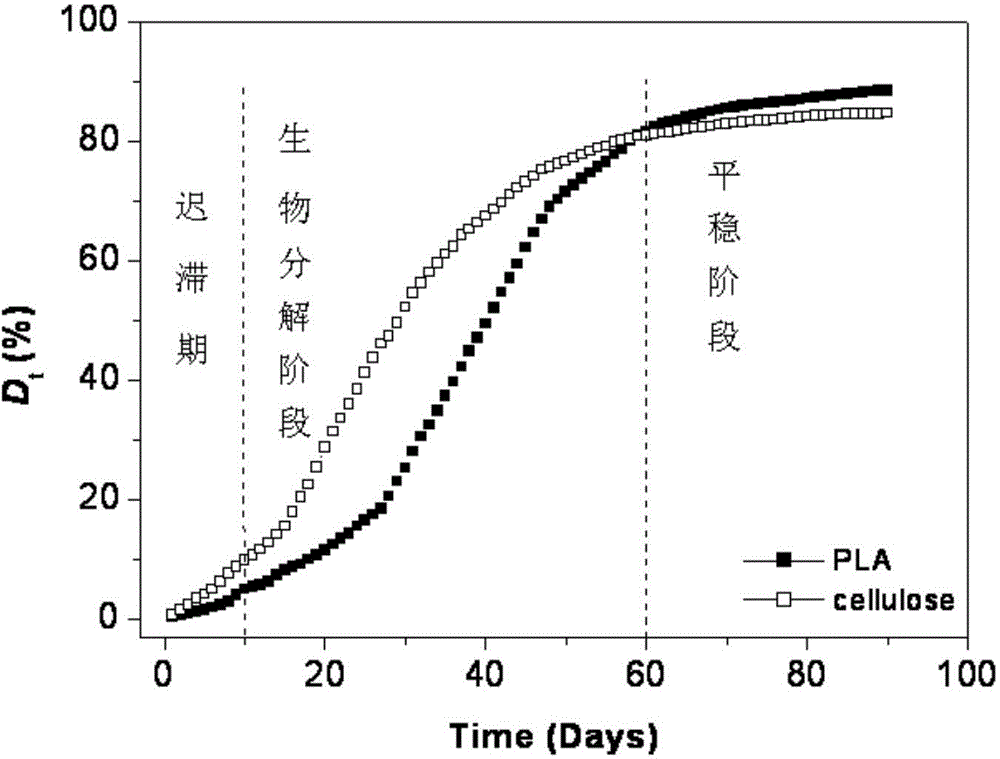

Material biological degradability detection evaluation equipment and method

InactiveCN104949911AAvoid enteringMaintain humidityWeather/light/corrosion resistanceCo2 absorptionProviding material

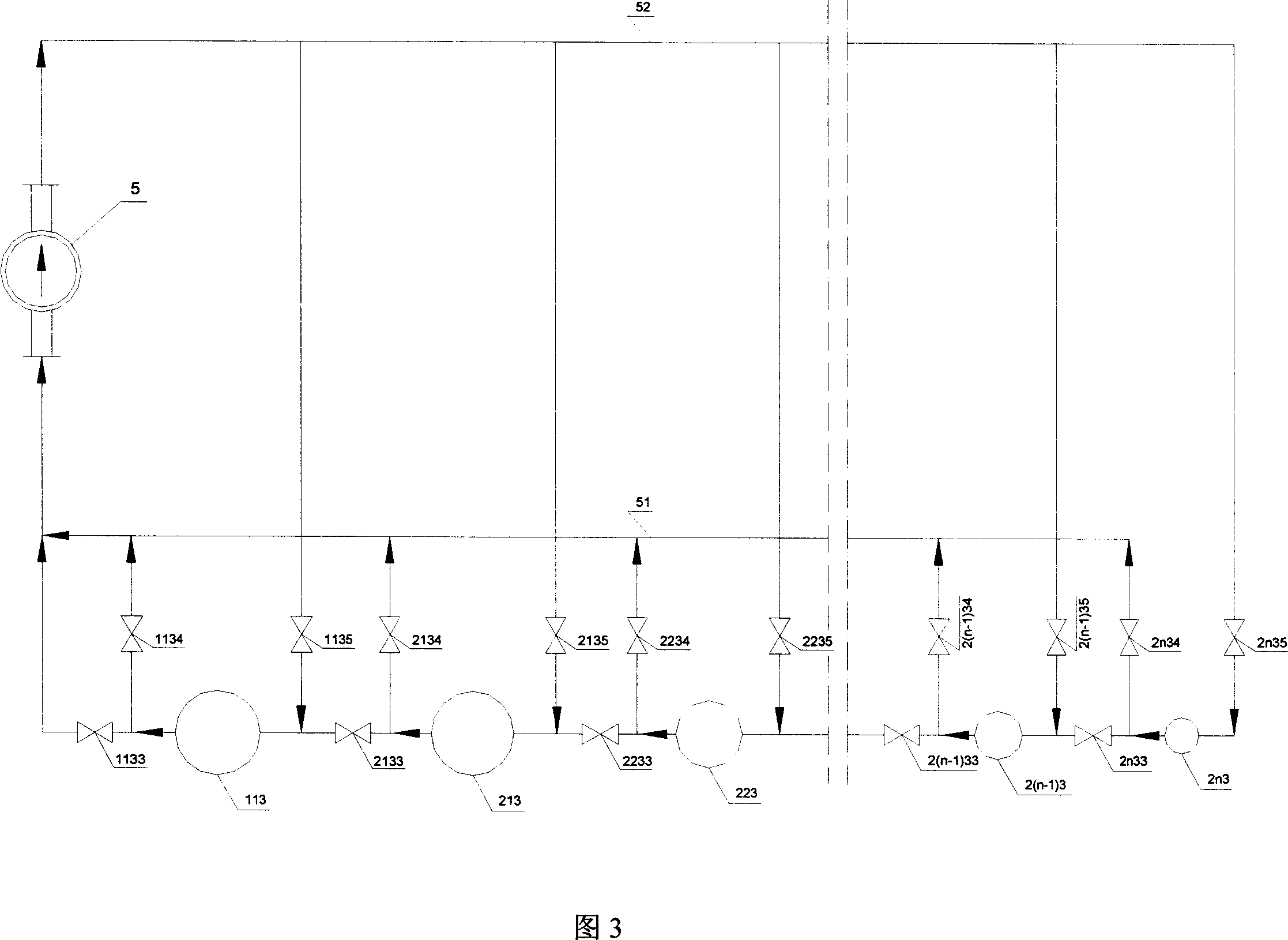

The invention provides material biological compost degradability detection evaluation equipment and a material biological compost degradability detection evaluation method. The equipment comprises an air supply and purification system, an air flow control system, a compost reaction system, a temperature control system and a CO2 absorption system which are arranged in sequence, wherein the air supply and purification system comprises an air compressor, a suck-back preventing bottle, an air purification bottle, a pressure maintaining valve, a pressure regulating valve and an electromagnetic valve, connected in sequence; the air flow control system comprises a flow control device; the compost reaction system comprises a humidification bottle and a compost reaction bottle; the CO2 absorption system comprises a condensation bottle and a CO2 absorption bottle. The equipment and the method have the benefits that inorganic carbon dissolved in the CO2 absorption bottle can be detected periodically through a potentiometric titration method to be taken as the accumulated CO2 emission capacity generated by the compost reaction bottle, and the method is simple and accurate.

Owner:SHENZHEN ACAD OF METROLOGY & QUALITY INSPECTION

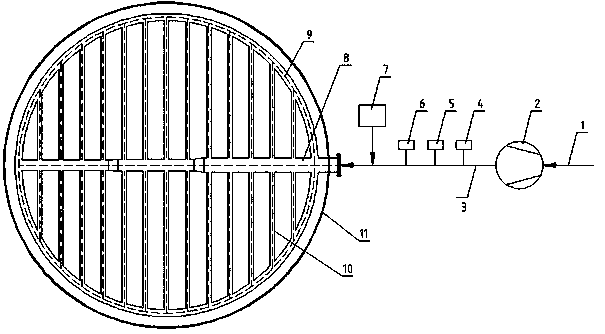

Oxidation air uniform-distribution device for calcium desulphurization

InactiveCN103588238AEvenly distributedImprove oxidation efficiencyCalcium/strontium/barium sulfatesAtmospheric pressureCalcium sulfite

The invention provides an oxidation air uniform-distribution device for calcium desulphurization. The device comprises an air feed main pipe, a plurality of air feed branch pipes and a connecting pipe, wherein each of the air feed main pipe and the air feed branch pipes is a straight pipe with two open ends, the vertical axis of each air feed branch pipe is perpendicular to the vertical axis of the air feed charge, the connecting pipe is an annular pipe, one open end of the air feed main pipe is an air inlet end, the other open end of the air feed main pipe is communicated with the connecting pipe, every two adjacent air feed branch pipes are arranged in parallel at an equal interval, one open end of each air feed branch pipe is communicated with the air feed main pipe, the other open end of each air feed branch pipe is communicated with the connecting pipe, and the sidewall of each air feed branch pipe is uniformly provided with oxidation air jet holes. The uniform-distribution device provided by the invention enables air flow and air pressure of air flowing through each air jet hole to be more uniform and more stable, thereby improving the oxidation effect of calcium sulfite and the utilization rate of oxidation air.

Owner:SICHUAN JUNHE ENVIRONMENTAL PROTECTION

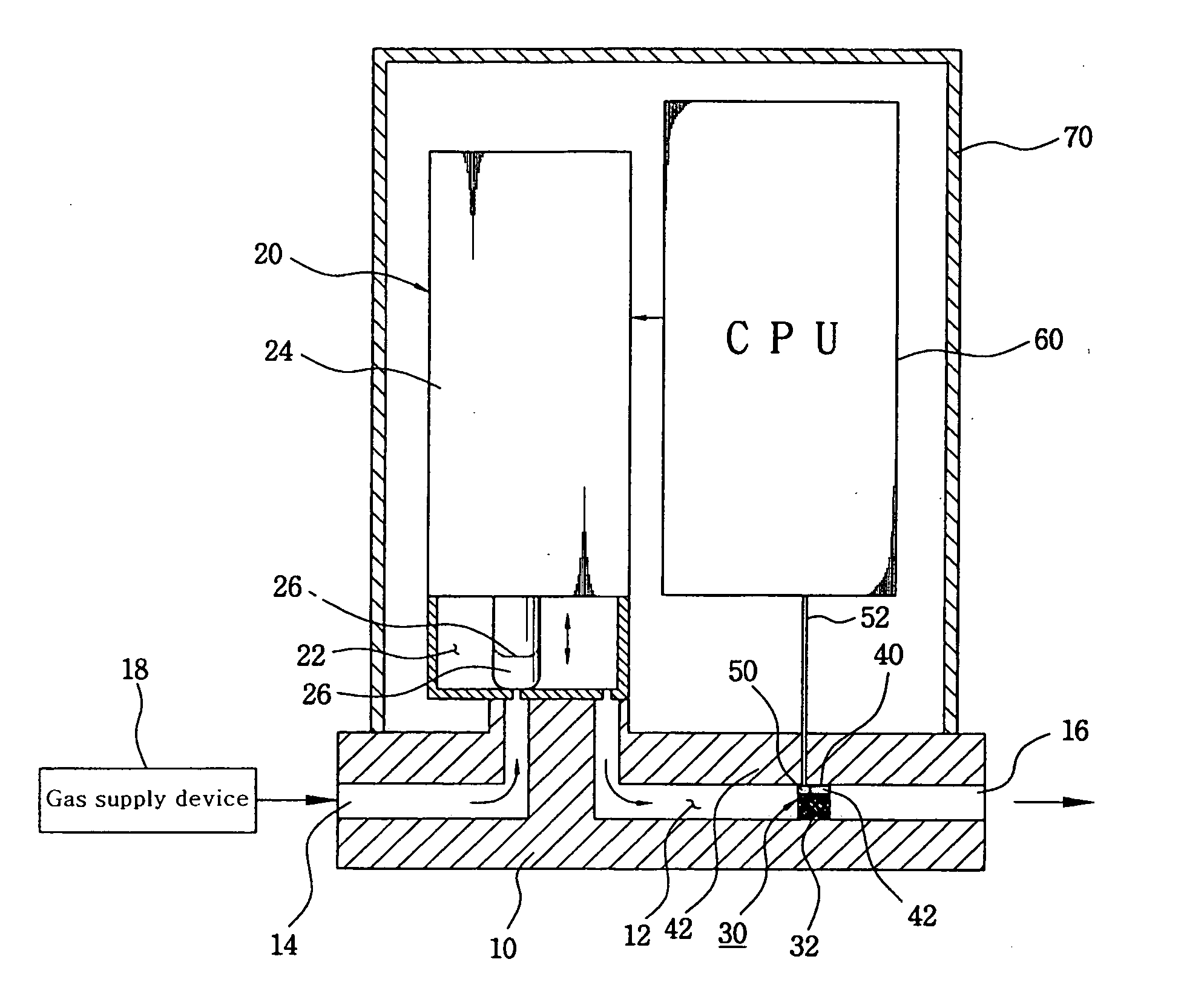

Apparatus for controlling flow rate of gases used in semiconductor deivce by differential pressure

InactiveUS20060151113A1Improve responseImprove reliabilityLiquid surface applicatorsCheck valvesControl flowDevice material

Provided is apparatus for controlling flow rate of gases used in semiconductor device by differential pressure by generating differential pressure in a fluid path. A differential pressure generation element generates pressure difference in the fluid path of gases used in semiconductor device fabrication, a pressure, sensor which is installed at a bypass of the fluid path detects the pressure difference, and a central processing unit (CPU) measures and controls a flow rate of the gases, thereby the present invention is capable of controlling the flow rate precisely and rapidly, and enhancing the degree of purity of the gases by the filtering function of the differential pressure generation element itself.

Owner:HYUNDAI CALIBRATION & CERTIFICATION TECH CO LTD +1

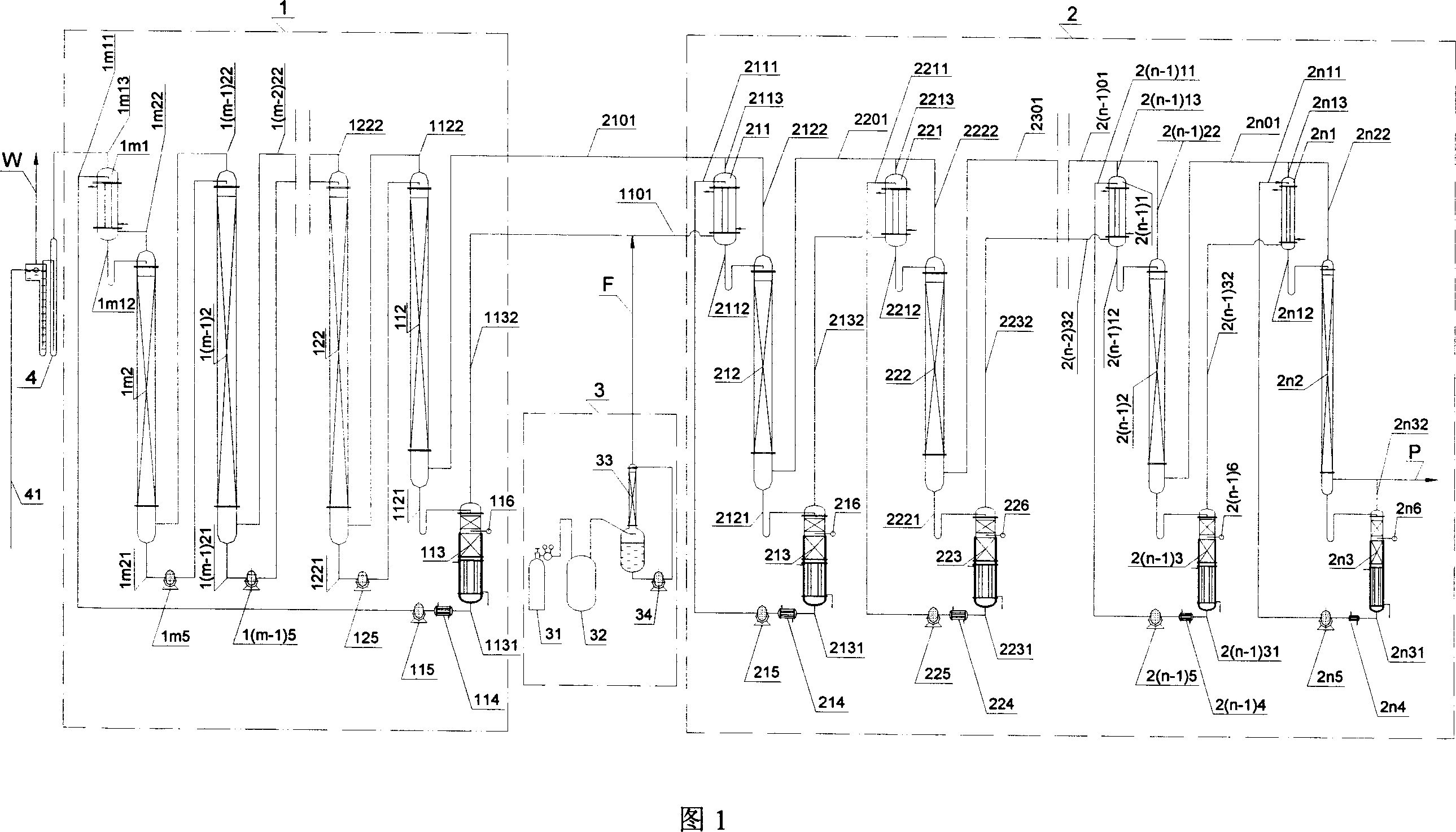

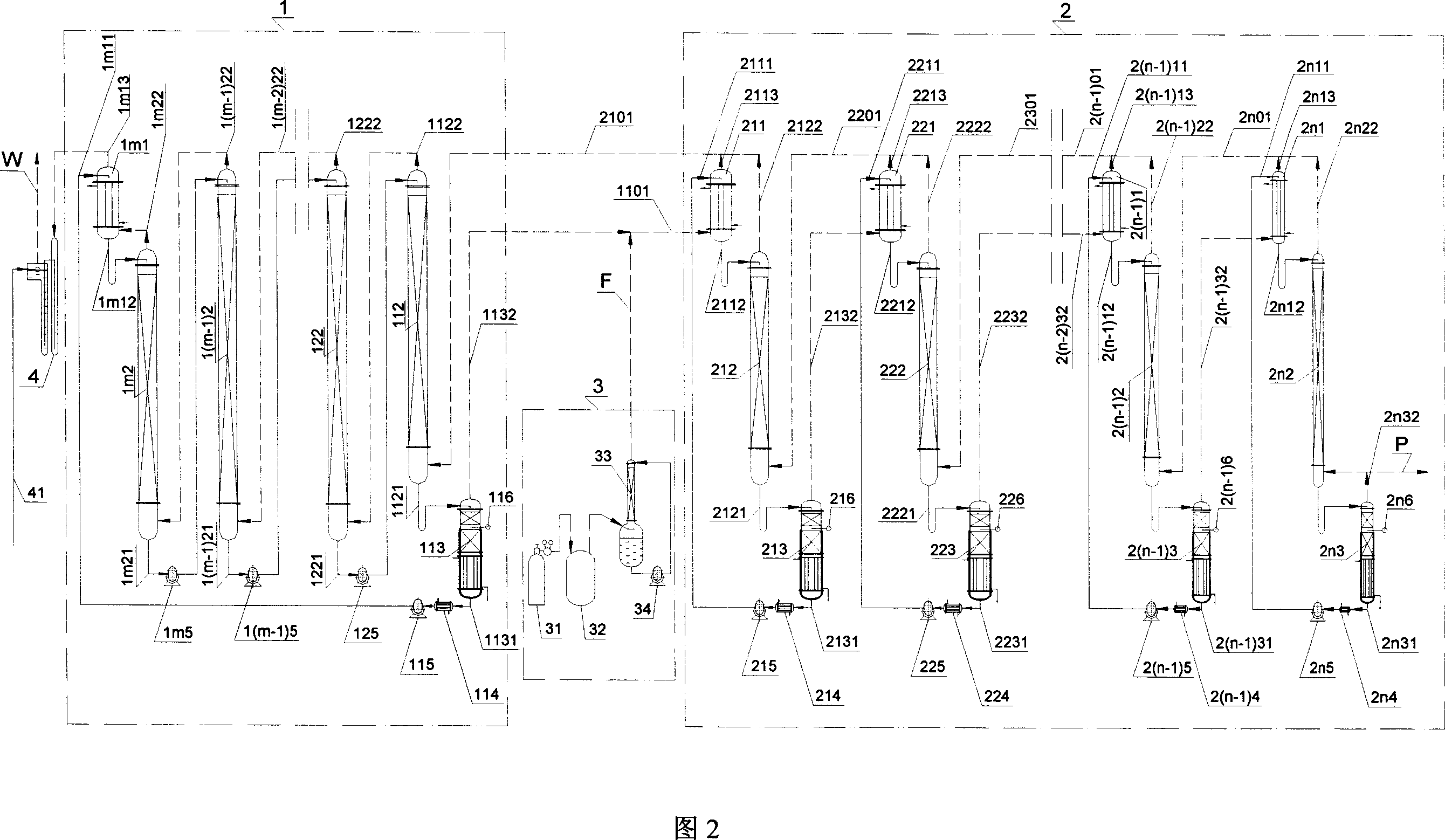

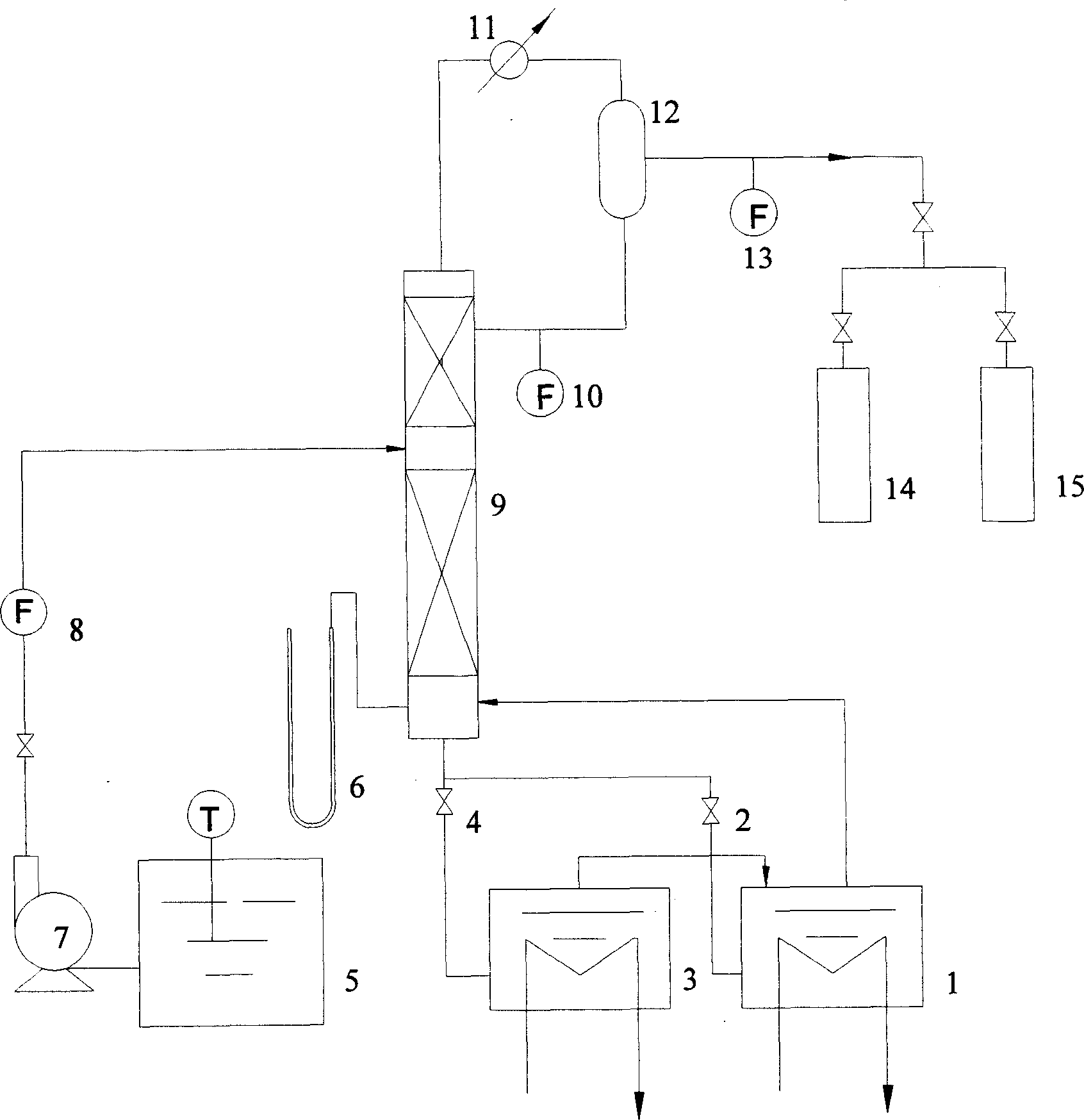

Method and system for producing high concentration carbon dioxide of carbon-13

InactiveCN101054177AReduce manufacturing costAvoid clogging accidentsCarbon compoundsAir quality improvementHigh concentrationSolvent

The present invention relates to a method and a system for preparing C-13 carbon dioxide with a high concentration, belonging to the preparing technical field of stable isotope C-13. The present invention discloses a method and system for the industrialized production of high concentration C-13; wherein the concentration of isotope is more than 99%, the natural carbon dioxide serves as raw material, the carbon dioxide / dinbutylamine / octane serves as the isotope exchange system, and a cold-hot refluxing method is adopted. In the present invention, the technical measures of raw gas presaturation, extractor segment and kettle liquid circulation are adopted, thereby the dosage of raw gas and the solvent consumption are reduced by 99% or so, and the concentration of the working solution of the system is stabilized, so that the concentration effect of the isotope is improved and the production cost is reduced. Furthermore, a hot reflux tower with a direct heat exchange-cool liquid leaching segment is adopted, and the operating temperature and the control requirement are reduced, thereby the crystallizing choking phenomenon is prevented, the operating is convenient and stable, and the energy consumption is saved.

Owner:杨国华

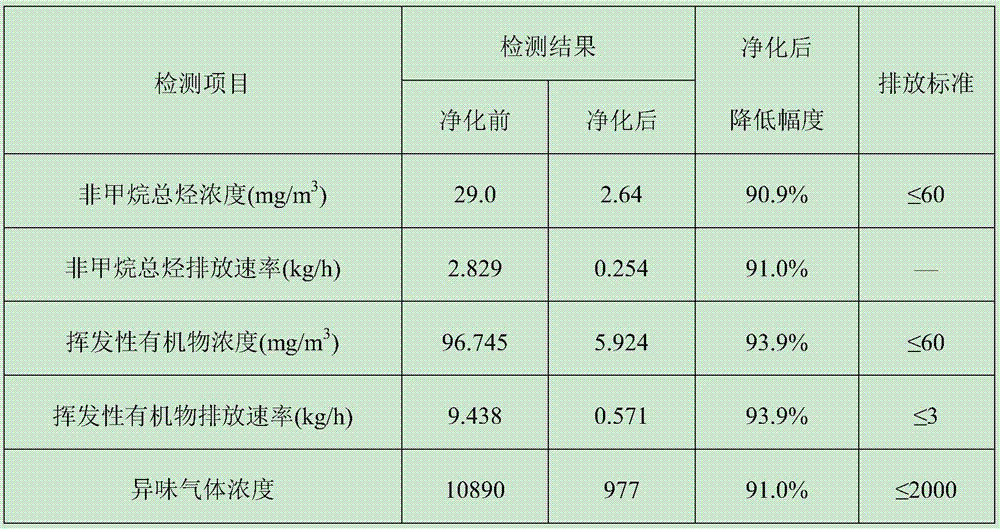

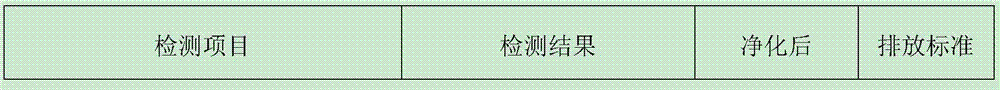

Fermented tail gas purification treatment method

ActiveCN106861393AReduce usageReduce waste gas treatment costsCombination devicesMolecular sieveDecomposition

The invention discloses a fermented tail gas purification treatment method, and belongs to the field of comprehensive treatment of industrial tail gases. The fermented tail gas purification treatment method comprises treatment steps of pretreatment, molecular sieve treatment, catalytic oxidation, alkali washing, secondary oxidation and water washing. According to the fermented tail gas purification treatment method, a cyclone separator, a primary filter, a condenser and a heater are adopted to pretreat a fermentation tail gas firstly, secondly, the fermentation tail gas is concentrated by using a honeycomb disc rotating wheel type molecular sieve, then the fermentation tail gas is subjected to oxidation decomposition in a high-temperature catalytic oxidation device, and finally through absorption of an alkali washing spraying tower, an oxidation spraying tower and a water washing spraying tower in sequence, residual harmful substances in the fermentation tail gas can be completely removed. By adopting the fermented tail gas purification treatment method, use of the spraying towers and absorption liquids can be greatly reduced, the tail gas treatment cost can be lowered, in addition, high treatment efficiency and a good purification effect can be achieved, and the fermentation tail gas can be in safe up-to-stand discharge.

Owner:NORTH CHINA PHARMA COMPANY

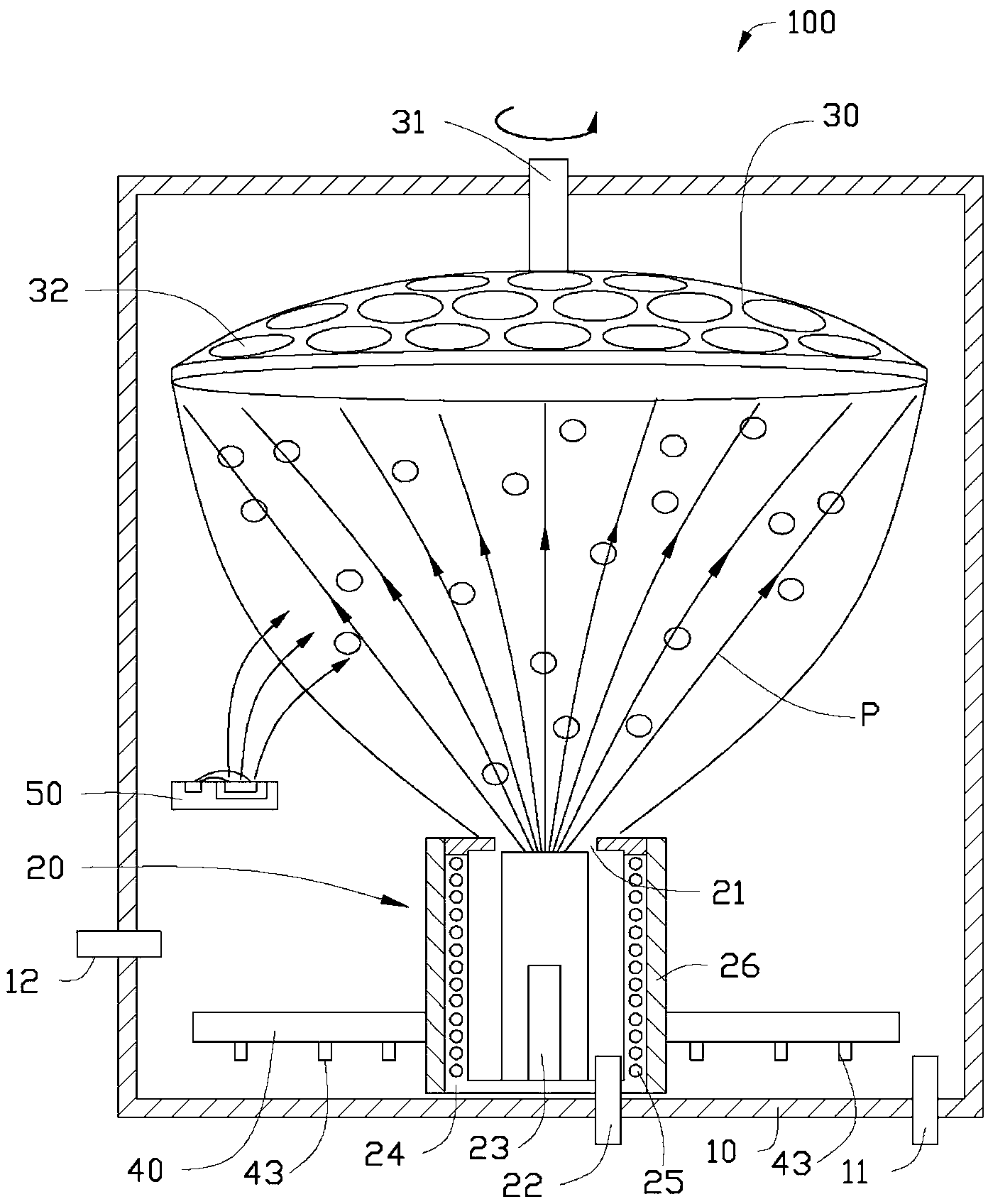

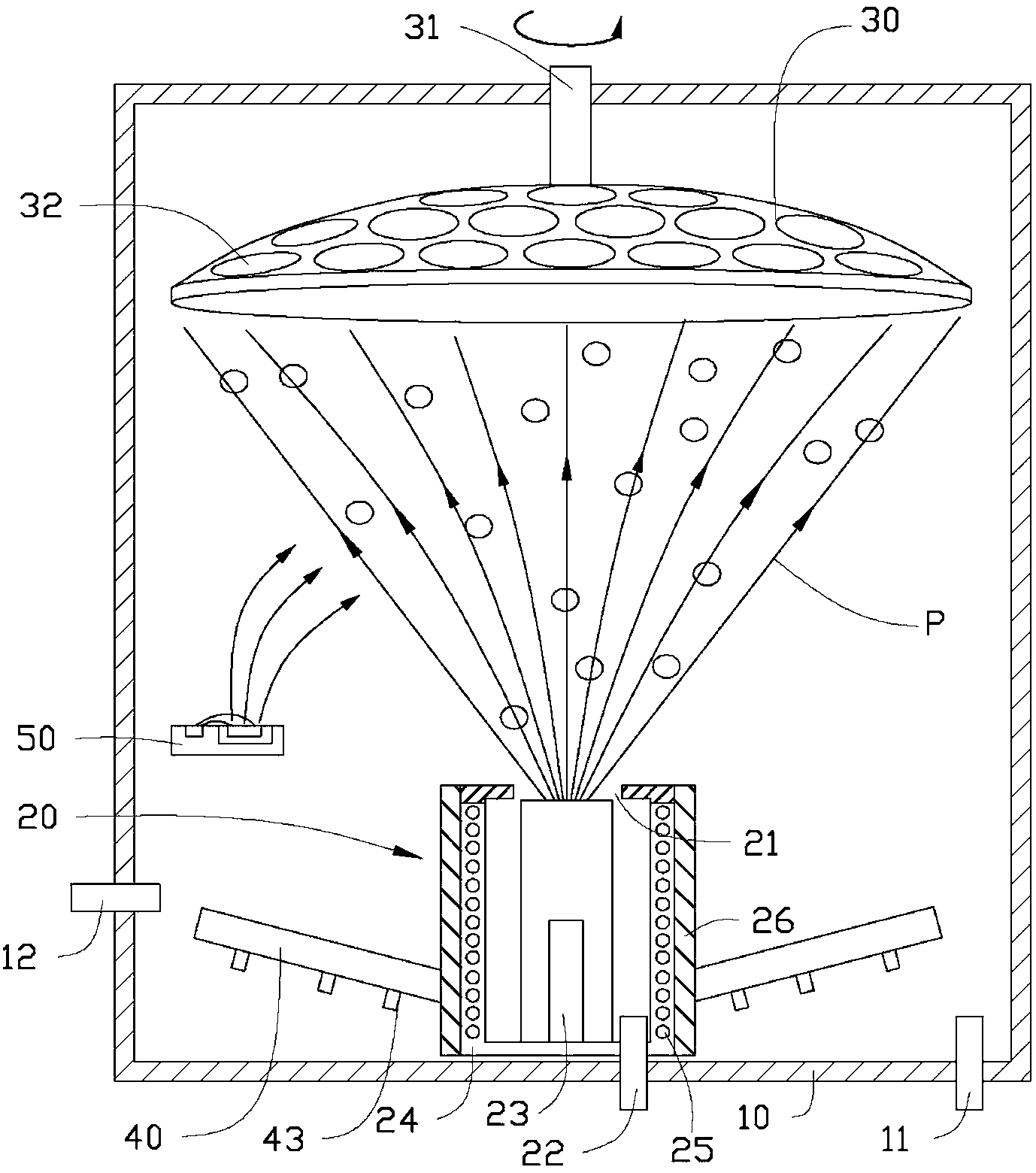

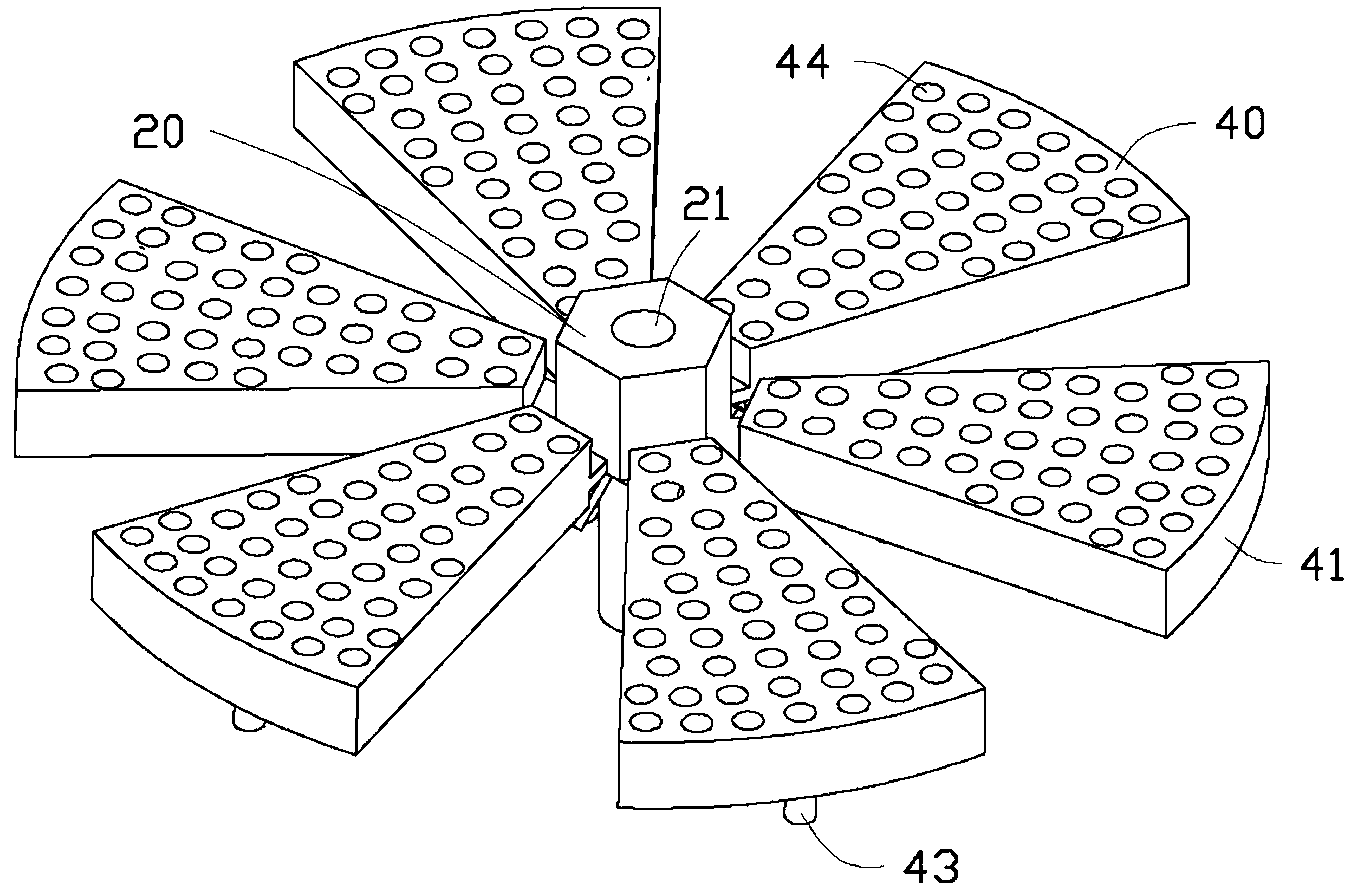

Plasma film-forming device

The invention discloses a plasma film-forming device. The plasma film-forming device comprises a film-forming chamber, a plasma generator arranged in the film-forming chamber, and a gas supply system used for providing a gas for the film-forming chamber, wherein the plasma generator sprays a plasma jet flow and forms a plasma jet flow area. The plasma film-forming device further comprises a plurality of gas flow-carrying plates rotationally arranged around the plasma generator, wherein the gas supply system supplies the gas for the gas flow-carrying plates, and the gas is jetted to the plasma jet flow area via the gas flow-carrying plates; and the shape of the plasma jet flow area can be changed by rotating the gas flow-carrying plates. The film plated by the plasma film-forming device is high in deposition efficiency and few in spark phenomenon while being high in compactness and good in uniformity.

Owner:FUYU PRECISION COMPONENTKUNSHANCO LTD

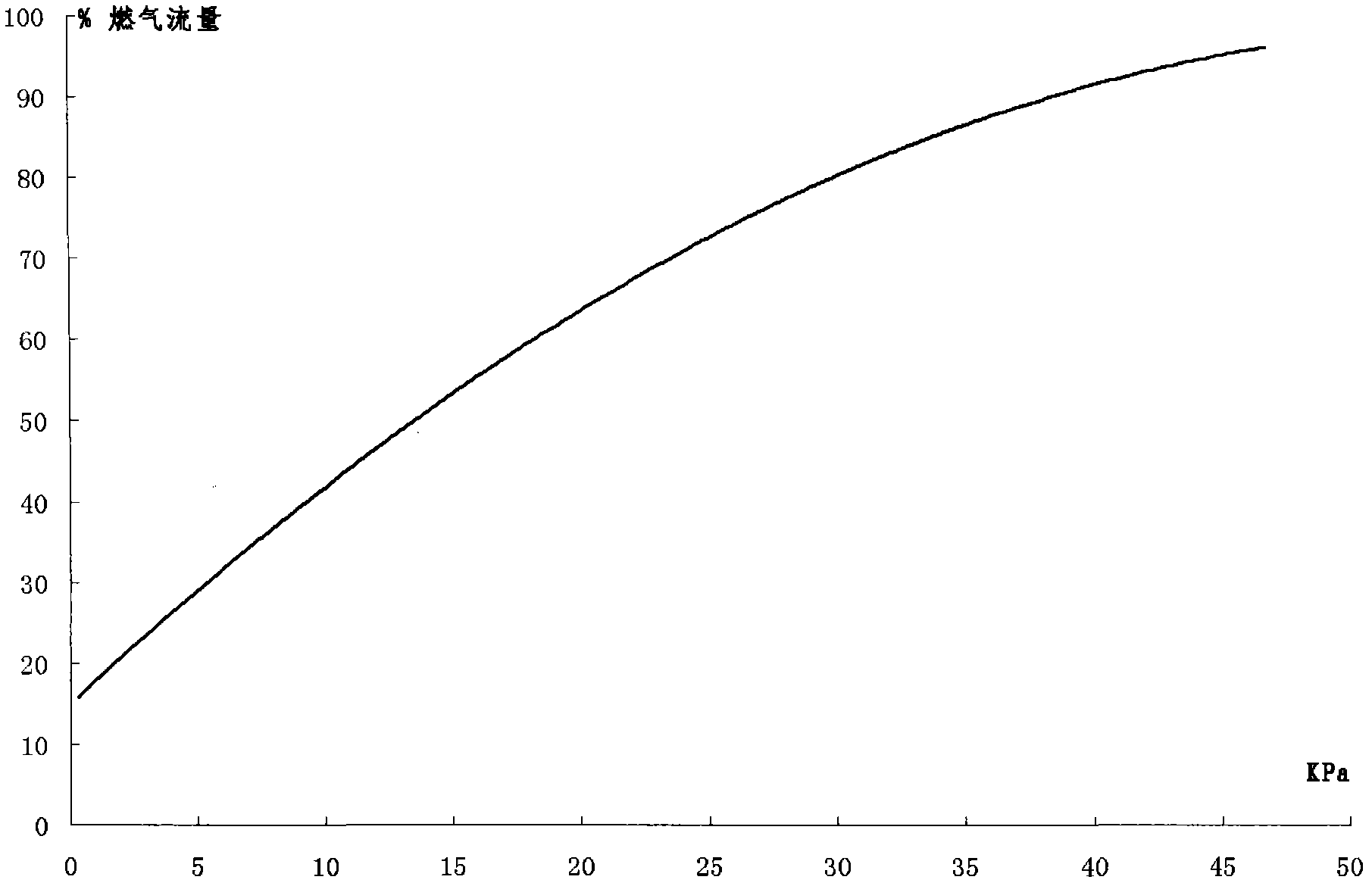

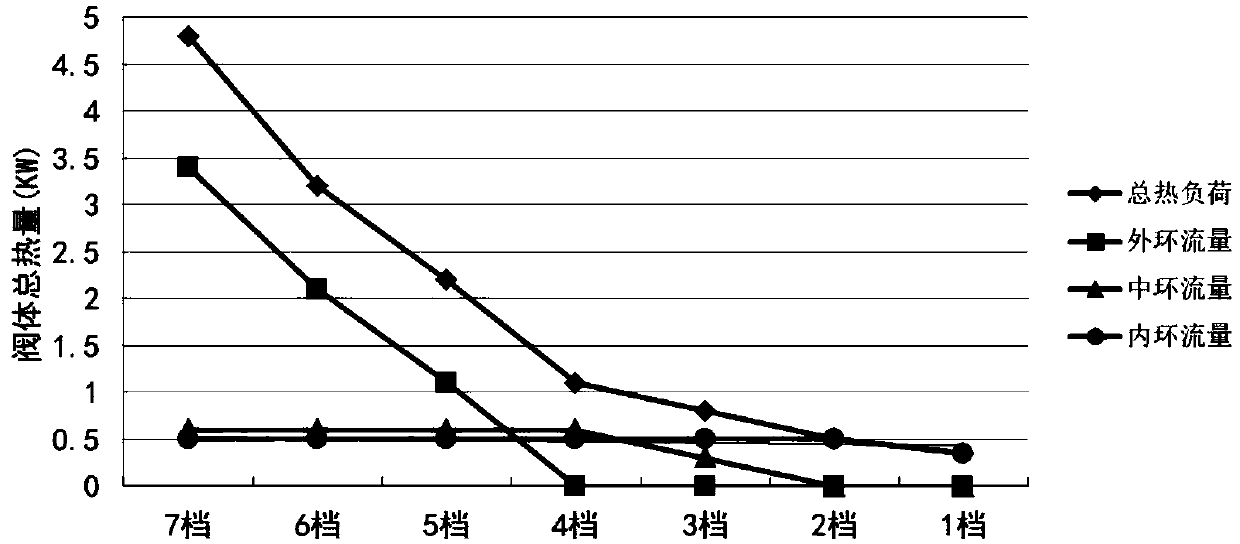

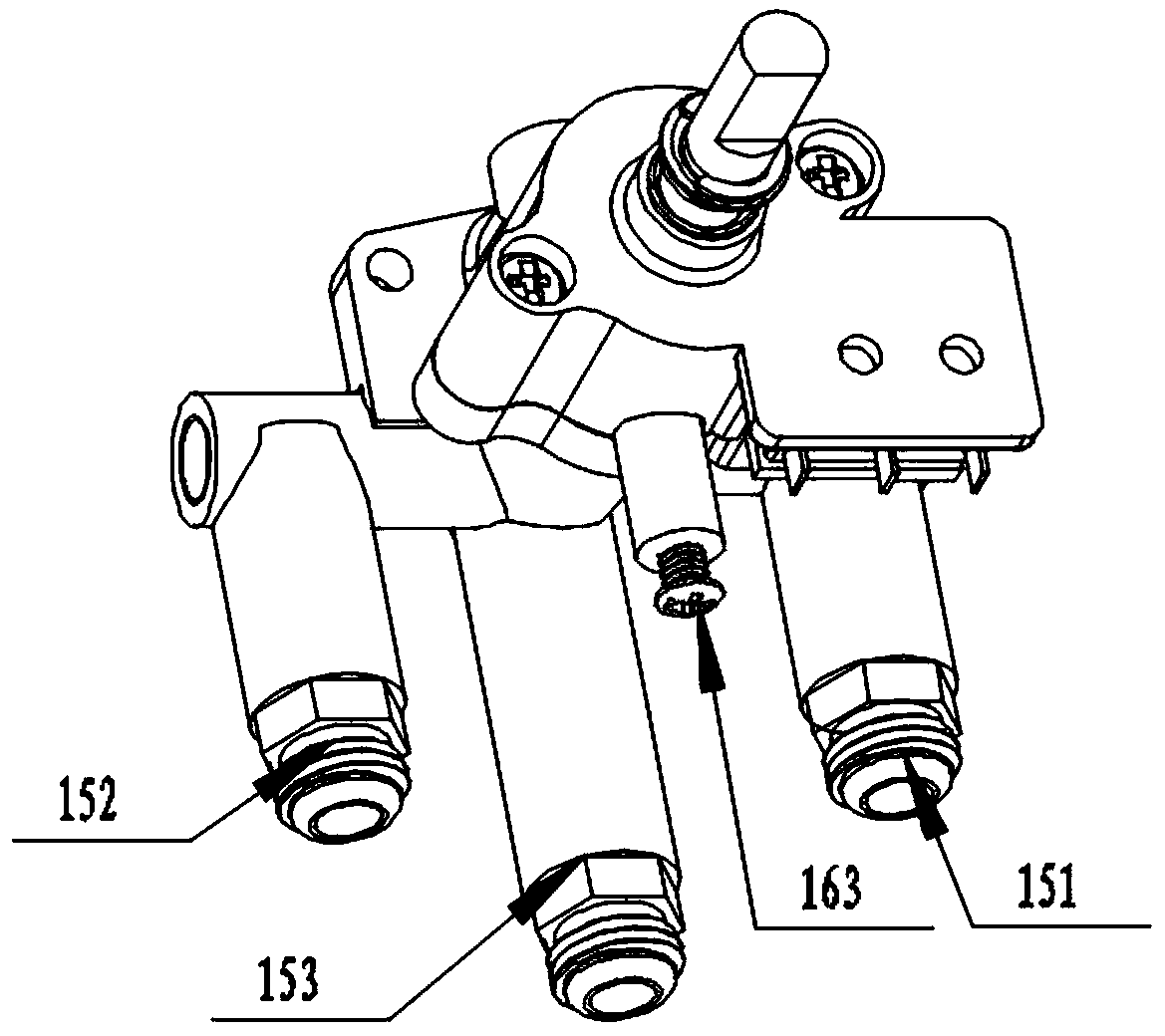

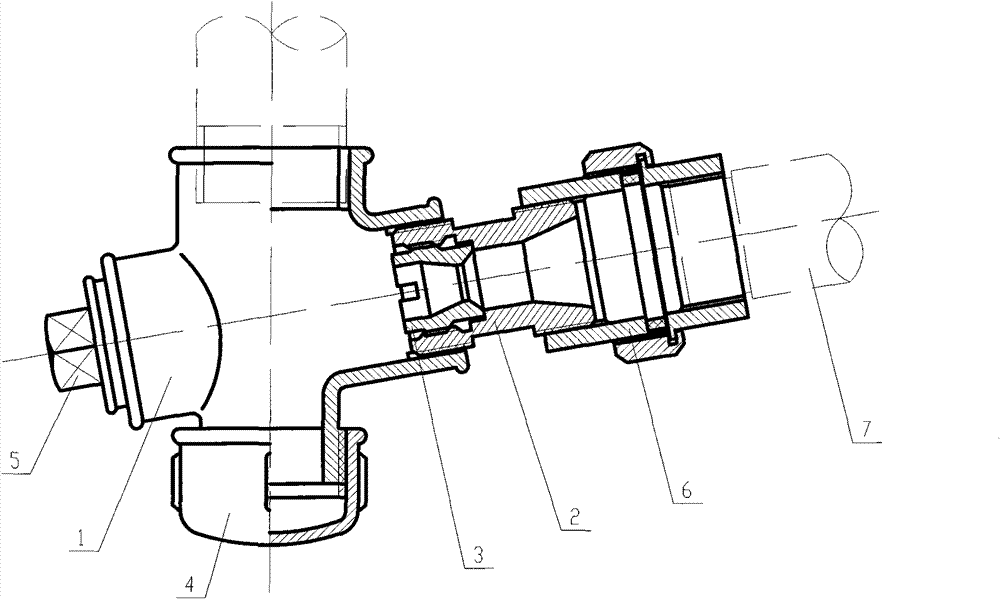

Plug valve capable of assisting in replenishing flow

PendingCN108679255AIncrease gas volumeIncrease heat loadPlug valvesValve housingsEngineeringFuel gas

The invention discloses a plug valve capable of assisting in replenishing flow. The plug valve comprises a valve seat, a valve core and an ejector rod. A groove is formed in the lower end of the ejector rod, the valve core is provided with an auxiliary small hole and a plurality of valve core holes, the valve seat is provided with an auxiliary gas intake passage, and the groove of the ejector rod,the auxiliary small hole and the auxiliary gas intake passage together form an auxiliary passage. The plug valve has at least the following advantages that by designing the gas auxiliary passage on the plug valve, and by setting and adjusting the stroke position, the temporary increase of the gas amount of firepower rings can be realized by driving a rotating shaft, the stable combustion of the transition section can be ensured, and the dangerous situation of tempering is effectively avoided; and at the same time, the gas flow of the firepower rings can be temporarily increased as needed, therefore the cooking firepower is more sufficient so as to meet the needs of instant large firepower of a user.

Owner:VATTI CORP LTD

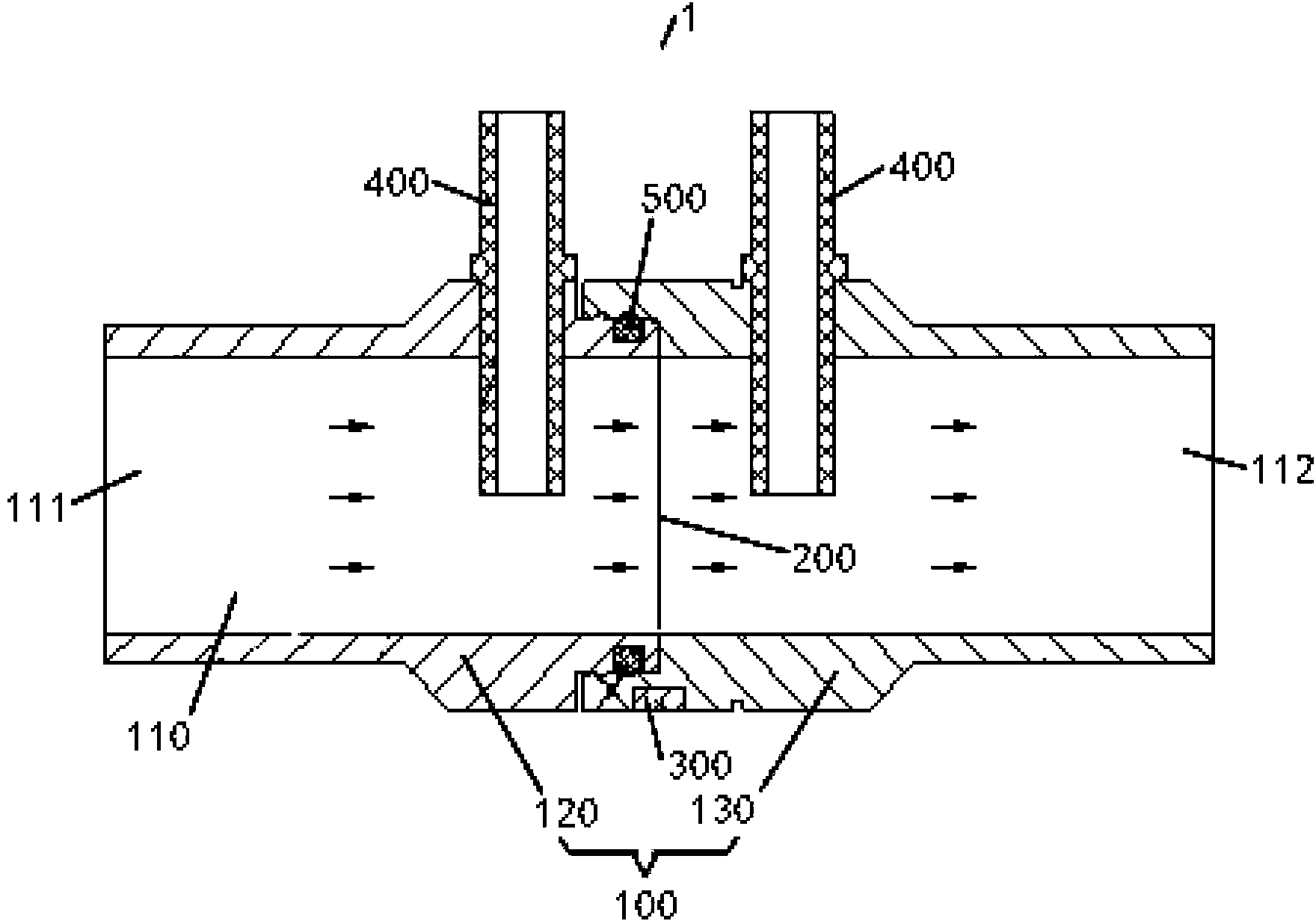

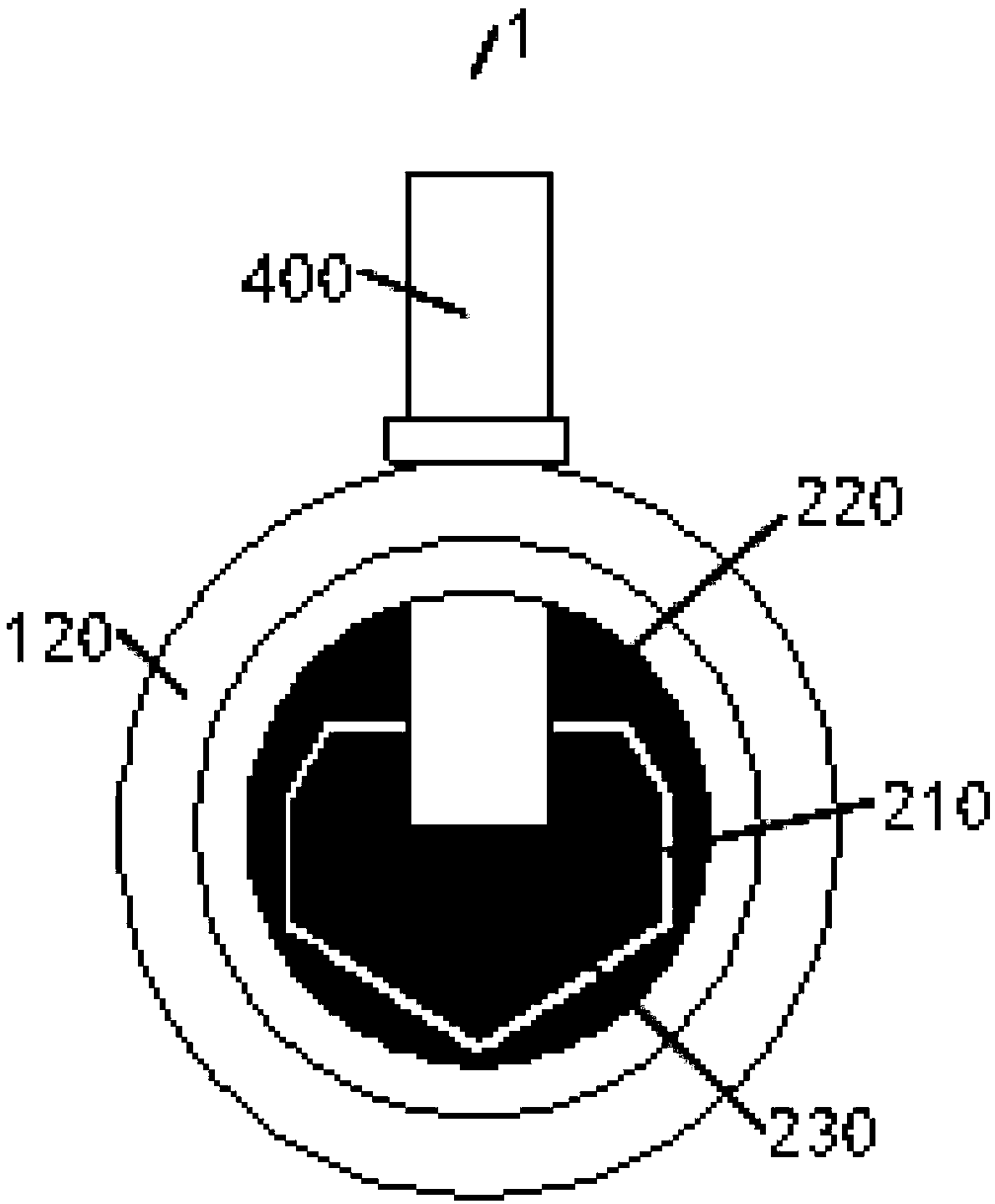

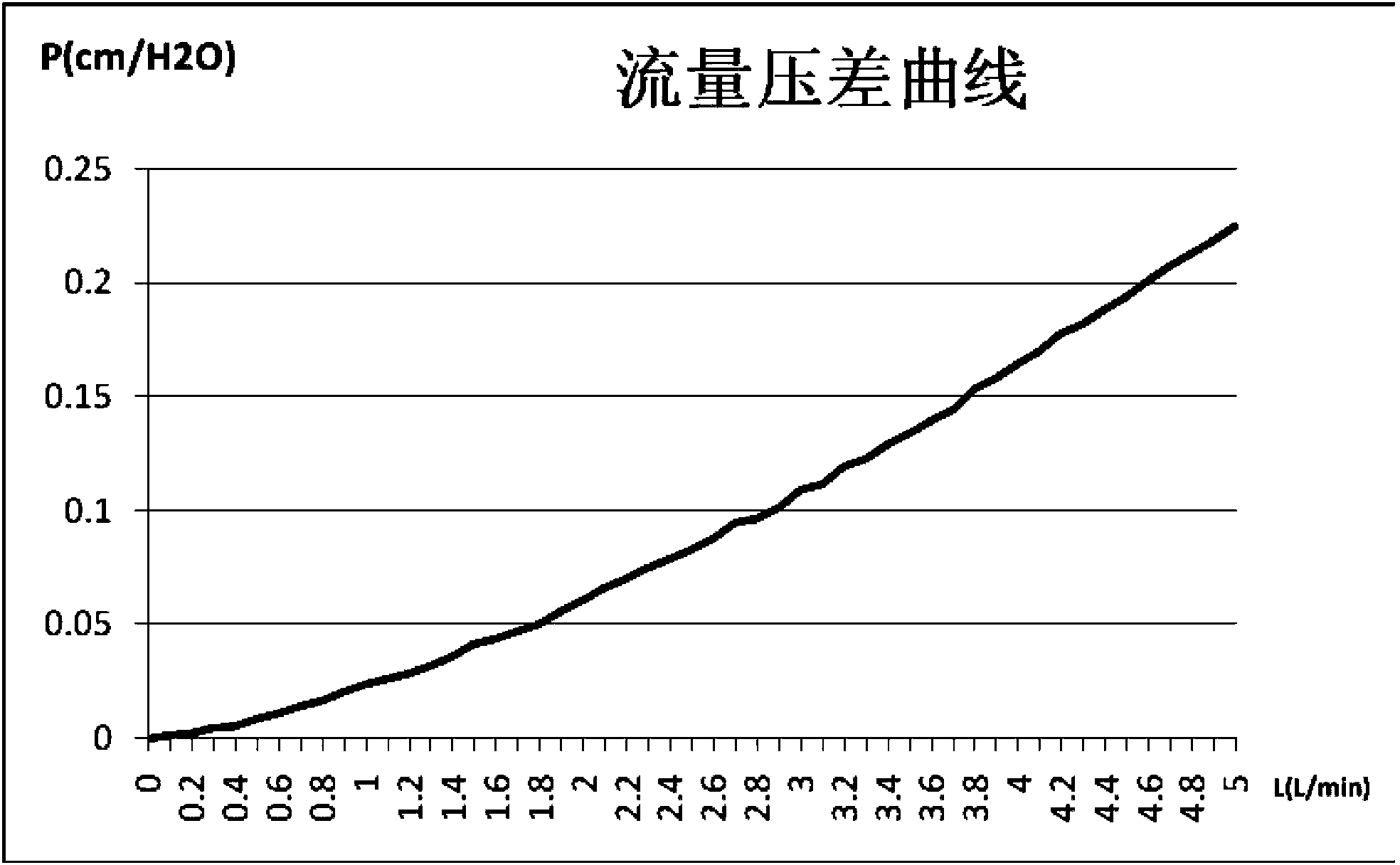

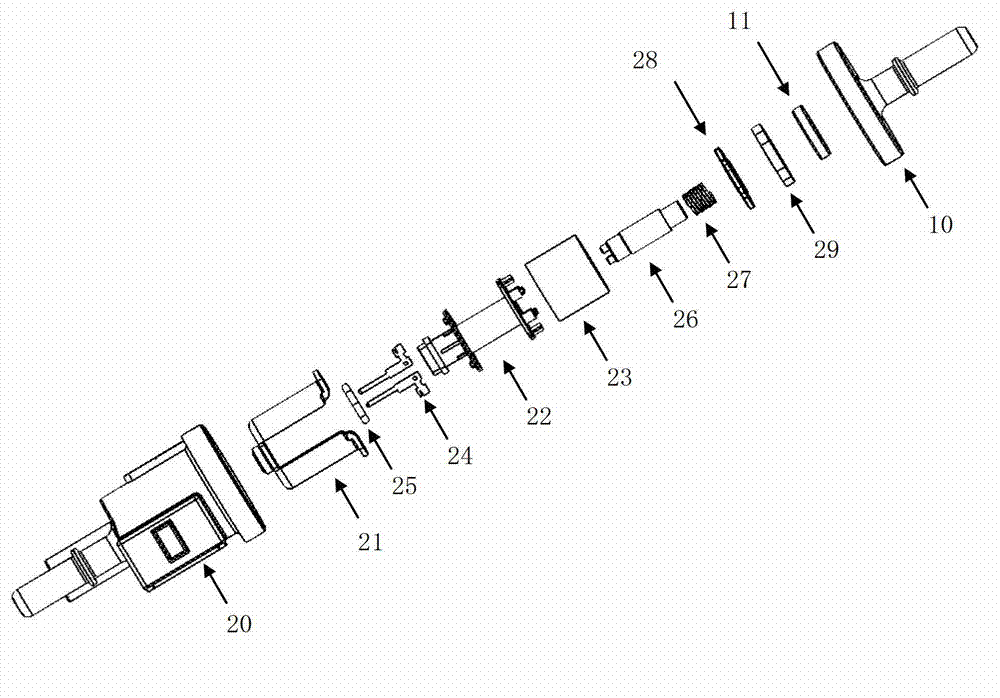

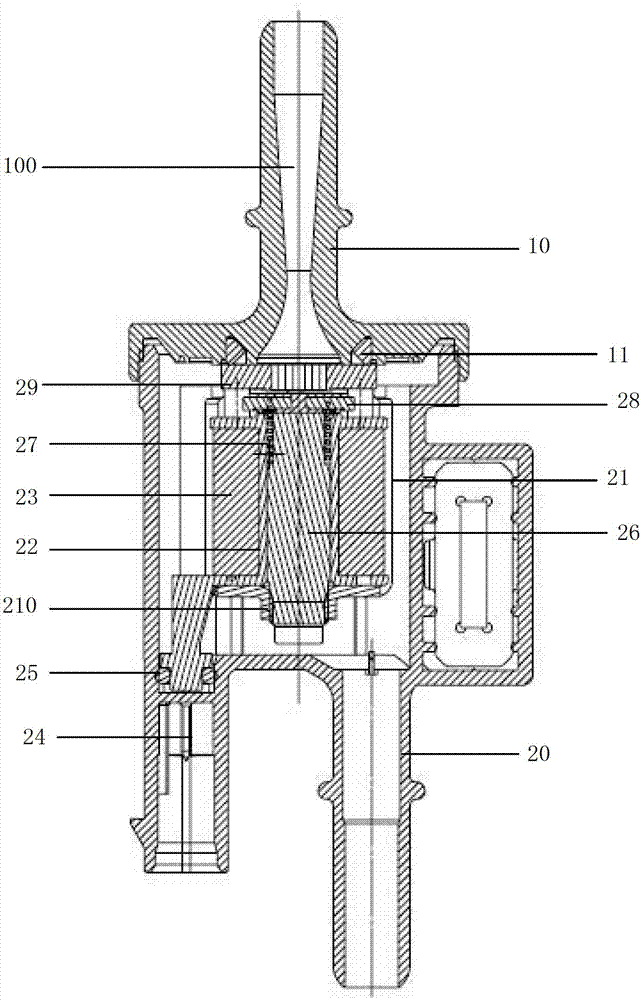

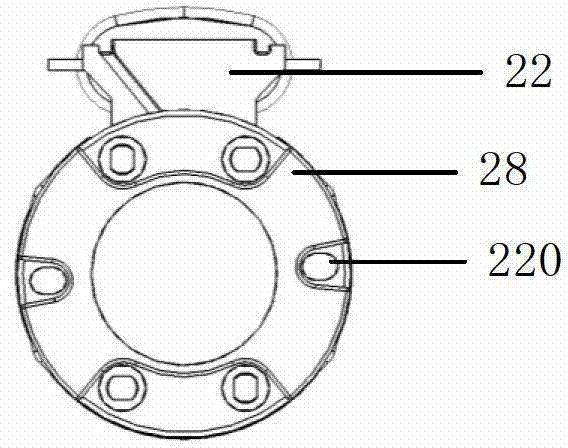

Gas flowmeter and medical device with same

ActiveCN104236643AConstant cross-sectional areaGuaranteed comfortVolume/mass flow by differential pressureDifferential pressureGas passing

The invention discloses a gas flowmeter and a medical device with the same. The gas flowmeter comprises a cavity internally provided with a gas flow chamber, a magnetic throttling member which is arranged in the gas flow chamber and provided with an orifice with a variable cross sectional area, a magnetic member arranged close to the magnetic throttling member on the cavity, and a differential pressure flow sensor used for detecting the pressure difference on both sides of the magnetic throttling member in the gas flow chamber and calculating the flow of the gas passing through the gas flow chamber according to the pressure difference, wherein the cross sectional area of the orifice is unchanged under the action of the magnetic member when the flow of the gas passing through the magnetic throttling member is smaller than or equal to a preset value, and the cross sectional area of the orifice is increased under the action of the gas passing through the magnetic member when the flow of the gas passing through the magnetic throttling member is larger than the preset value. The gas flowmeter has the advantages of being high in measurement accuracy, stable in measurement at small gas flow and capable of providing safe and stable small gas flow and the like.

Owner:BEIJING AEONMED

Control valve of carbon tank

ActiveCN103047470AAvoid pressure differenceMeet tolerance requirementsOperating means/releasing devices for valvesMagnetic coreProduct gas

The invention discloses a control valve of a carbon tank. The carbon tank comprises an upper cover and a shell, wherein the upper cover is provided with a Laval pipe shaped through hole; the shell is internally provided with a magnetic tank, a coil framework, a coil, a contact pin, a magnetic core, armature iron and a valve seat; and the magnetic tank is internally provided with a cavity. The coil framework, the coil and the contact pin are mounted in the cavity; the coil framework is provided with a hollow shaft; the coil is wound at the periphery of the hollow shaft of the coil framework; the contact pin is fixed on the coil framework; a copper line of the coil is electrically connected to one end of the contact pin; the magnetic core is located in the hollow shaft of the coil framework and is fixed with the magnetic tank by screw threads; the armature iron and the valve seat are respectively arranged on the coil framework; a through hole with a radial section is arranged at the center of the valve seat; and a spring is arranged between the magnetic core and the armature iron. By adopting the Laval pipe structure, the control valve of the carbon tank, disclosed by the invention, can overcome a difference of pressures at two ends of the control valve of the carbon tank and realize a relatively steady gas flow.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

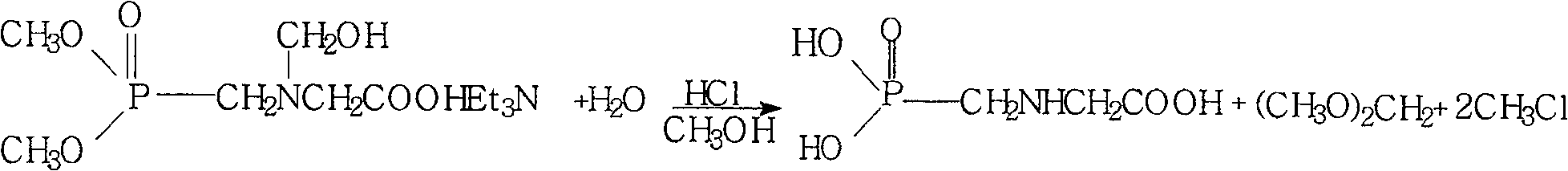

Continuous synthesis of glyphosate by dimethyl ester

ActiveCN100567311CStable gas flowStable flowGroup 5/15 element organic compoundsGlycineReaction zone

The invention provides a method for the continuous synthesis of glyphosate by the dimethyl ester method, which comprises the steps of acidifying and mixing the synthesis solution prepared from paraformaldehyde, glycine and dimethyl ester with hydrochloric acid and then entering the hydrolysis reaction zone. The reactor maintains a continuous state; the acidified synthetic solution is continuously hydrolyzed in the hydrolysis reaction zone to form glyphosate salt, and the raw glyphosate powder is obtained by continuously discharging and neutralizing crystallization. Among them, the preferred embodiments of the hydrolysis reaction zone include "one tower with two tanks" and "three tanks in series". The invention realizes the continuous hydrolysis of glyphosate, simplifies the process and realizes large-scale production.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

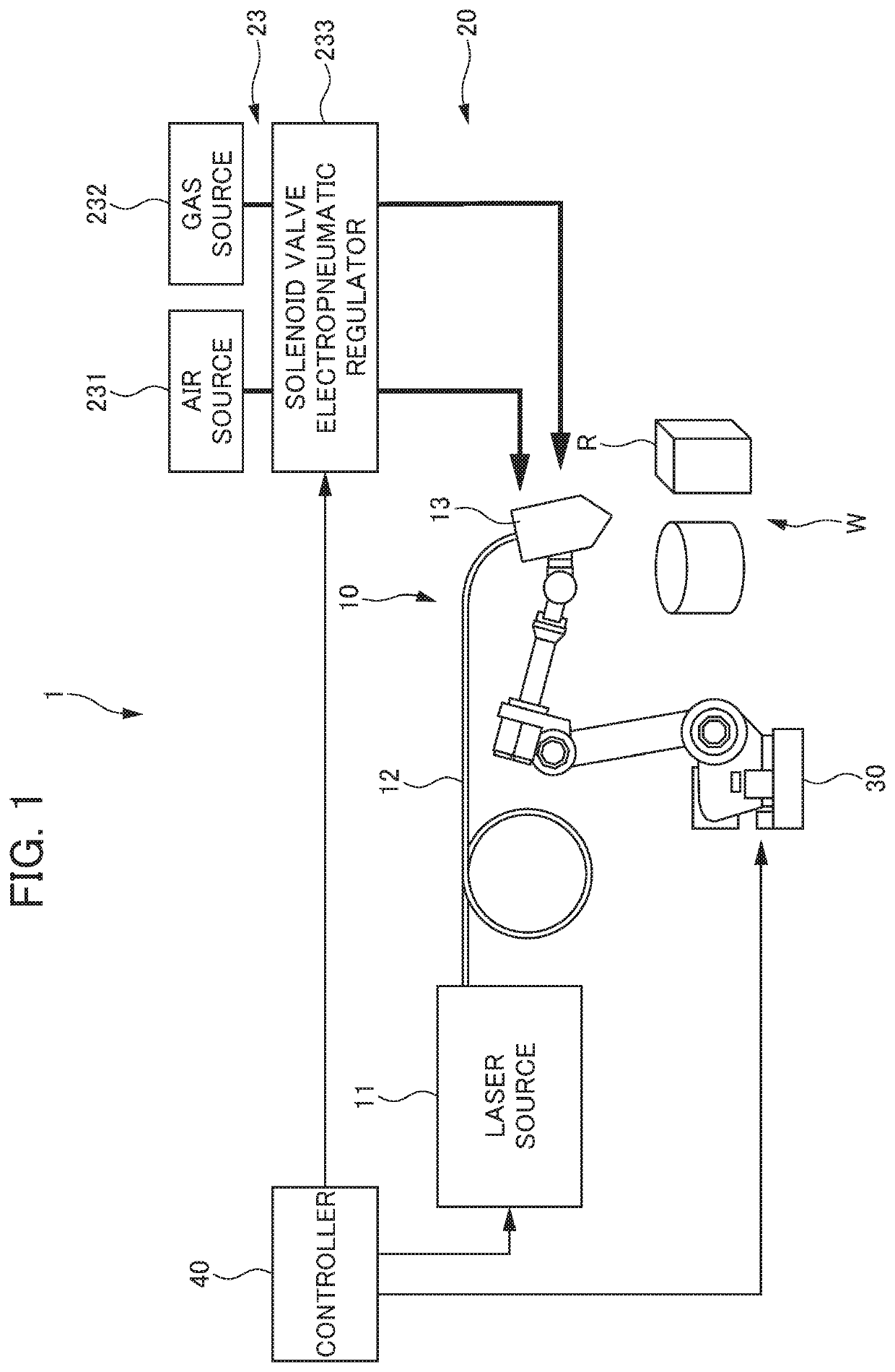

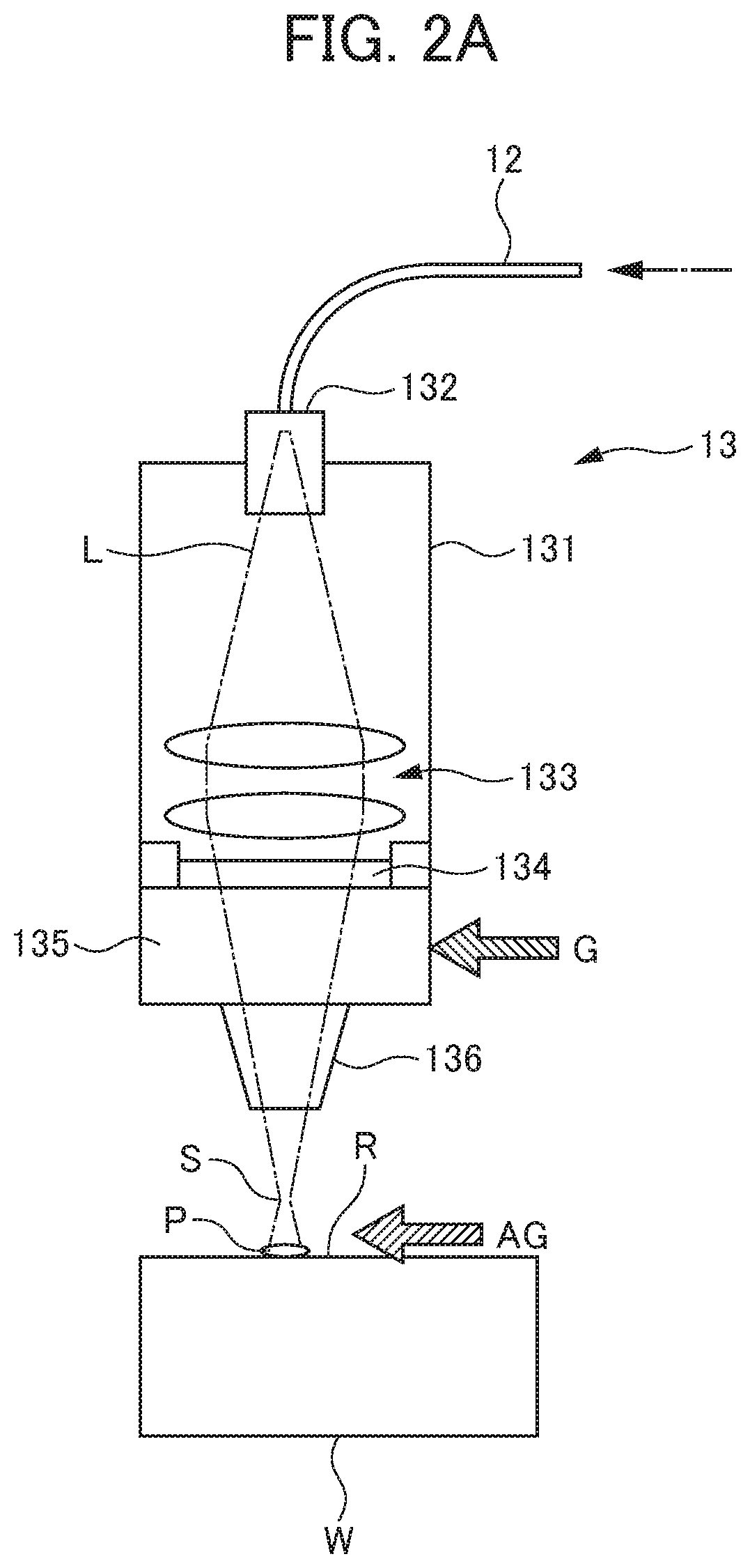

Deburring device

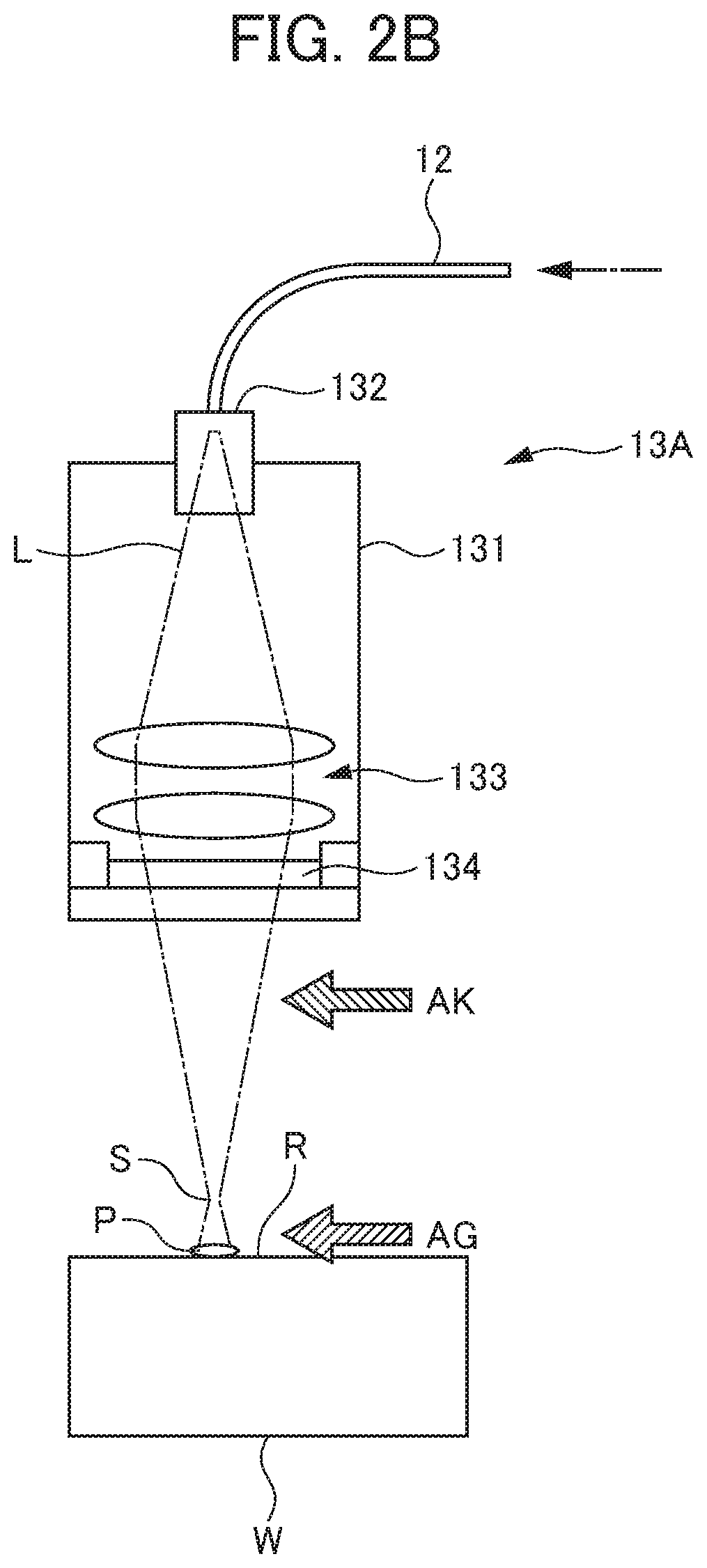

PendingUS20210086305A1Stable gas flowStableWelding/soldering/cutting articlesLaser beam welding apparatusPhysicsLaser light

An object is to provide a technology in which in debarring machining on a three-dimensionally shaped ridge line by laser application, a stable gas flow can be supplied and in which stable deburring machining can be performed. A deburring device for removing a burr which is present on a ridge line of a workpiece after being machined, includes: a laser device which includes a laser machining head that applies laser light to the ridge line; a transport device which transports the laser device and a gas jetting, device; and a controller which controls the laser device, the gas jetting device and the transport device and the controller controls the gas jetting device and the transport device such that a gas jetting nozzle is moved on a plane including the bisector of an apex angle of the ridge line and the ridge line and that in a side view parallel to the ridge line, an angle formed by the ridge line and the central axis line of the gas jetting, nozzle is an acute angle.

Owner:FANUC LTD

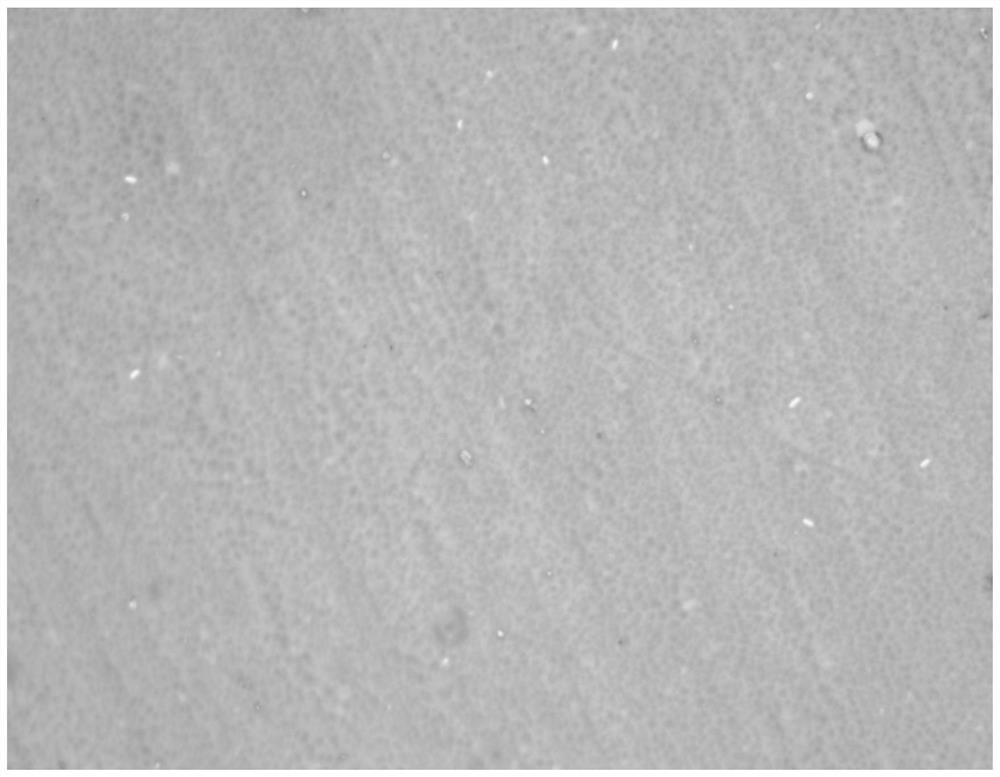

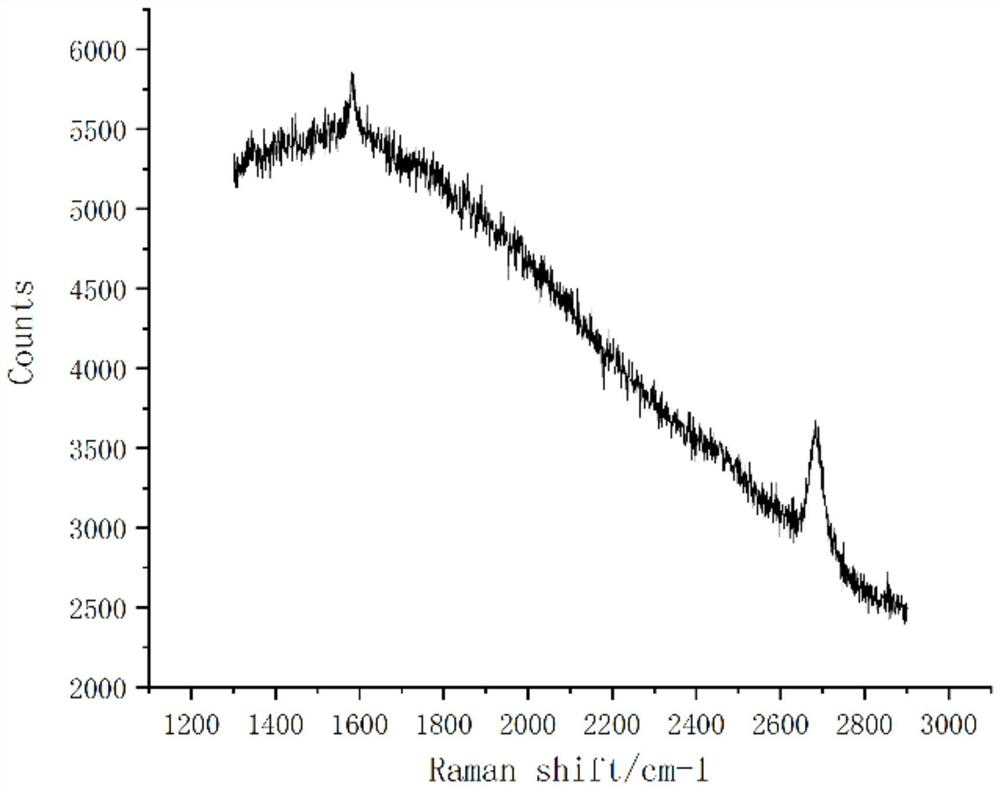

Method for preparing graphene film through combination of carbon dioxide and low-pressure chemical vapor deposition

ActiveCN112919455ARaman scattering is obviousHigh light transmittanceSingle layer grapheneCopper foilGraphite

The invention discloses a method for preparing a graphene film through combination of carbon dioxide and low-pressure chemical vapor deposition. The method comprises the processes of copper foil pretreatment, copper foil annealing, graphene growth and cooling. Carbon dioxide is adopted to pretreat a copper foil, a copper foil is annealed in a mixed atmosphere of hydrogen and argon at 900-1050 DEG C, a deposition reaction is carried out in a mixed atmosphere of carbon dioxide, hydrogen and methane at 900-1050 DEG C during growth, and argon is adopted for cooling after growth is finished. On the basis of overcoming the defects of a normal-pressure graphene preparation method, carbon dioxide is combined with a low-pressure system to prepare the graphene film, so that the phenomena of pits, bulges, air holes and the like on the surface of the graphene film in a normal-pressure experiment are effectively eliminated, the quality of graphene is improved, the carbon source is wide in source, the cost is reduced, and the method is more suitable for industrial production.

Owner:CHIA TAI ENERGY MATERIALS DALIAN

Calibration system and calibration method for aerodynamic particle size spectrometer

PendingCN110441202AImprove Calibration AccuracyImprove accuracyDispersed particle filtrationParticle size analysisAirflowEngineering

Owner:张家港谱析传感科技有限公司

Material system intermittent extracting and rectifying method reaching solvent boiling point higher than that of material by single tower and double-still

InactiveCN1676188AStable gas flowKettle temperature is stableExtractive distillationSolventBoiling point

The present invention discloses a single-tower double-kettle system interrupted extraction rectification method capable of implementing that the boiling point of solvent is higher than that of material. The described single tower is extraction rectification tower whose interior is equipped with filler recovery section and extraction rectification filler section, and the double-kettle comprises solvent kettle and material kettle which are connected with bottom portion of extraction rectification tower. Said invention also provides the concrete steps of said system interrupted extraction rectification method.

Owner:TIANJIN UNIV

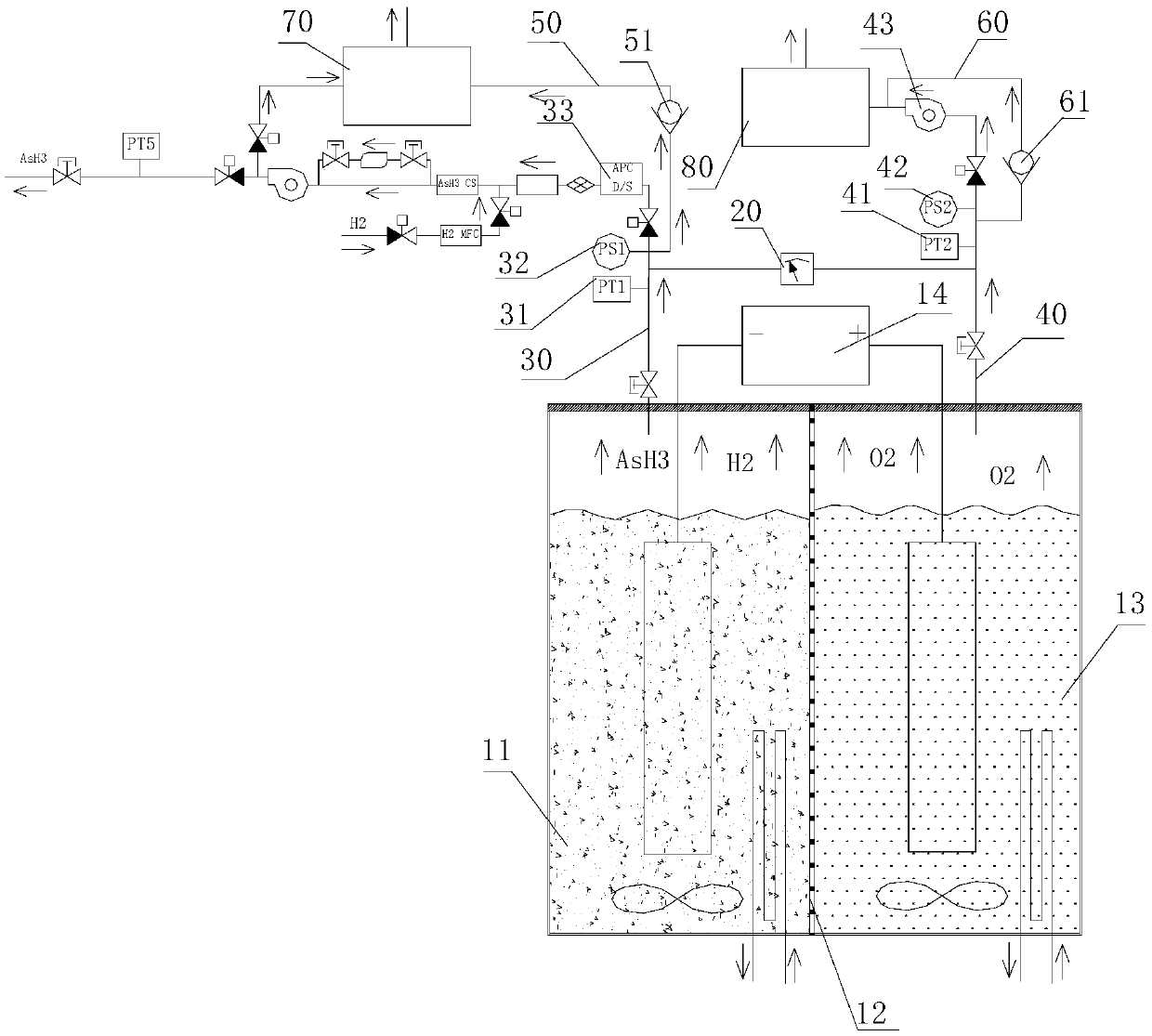

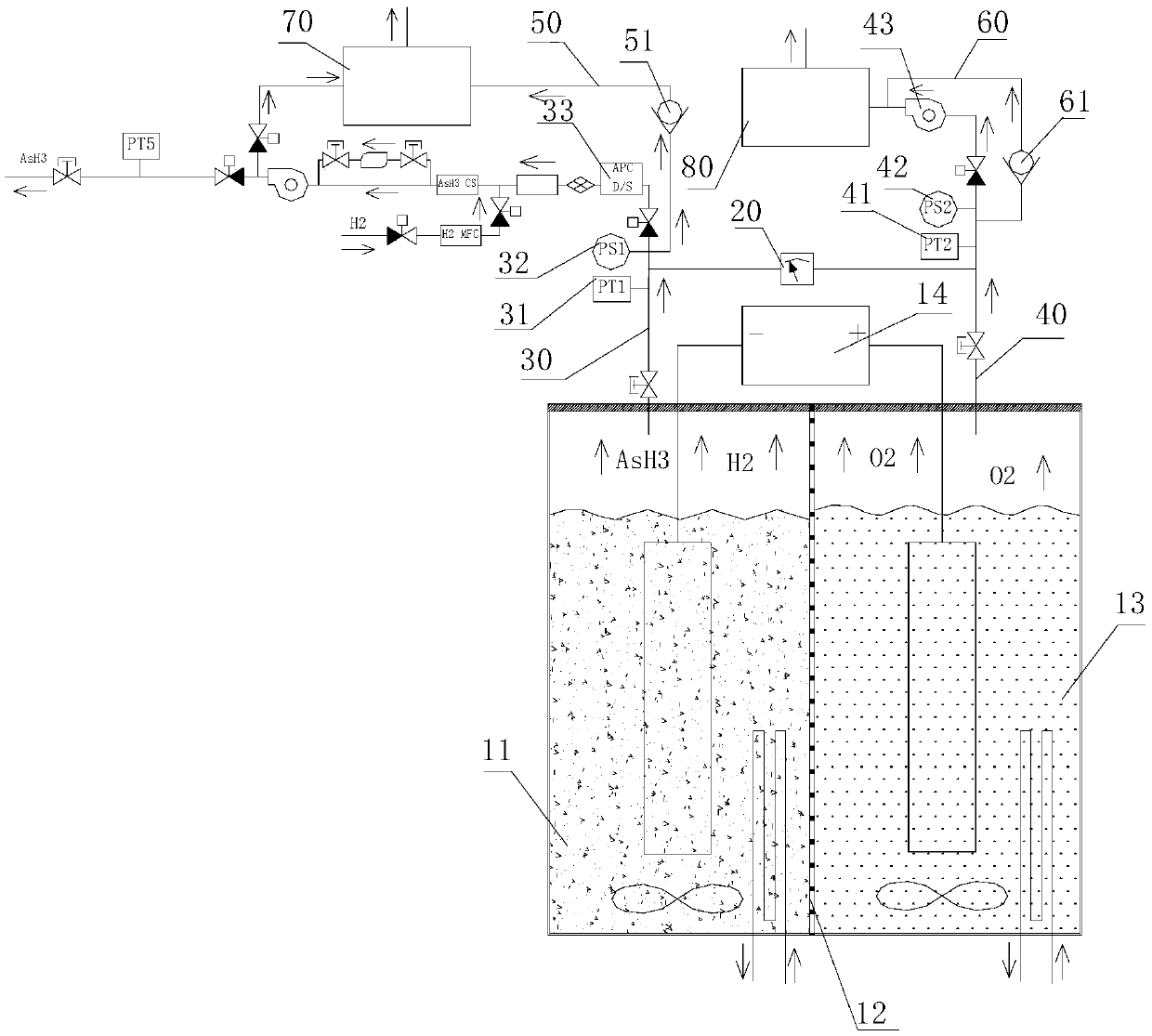

Electrolysis system for preparing arsine by electrolysis method

The invention provides an electrolysis system for preparing arsine by an electrolysis method. The electrolysis system comprises: an electrolytic cell having a cathode chamber and an anode chamber separated by an ion semipermeable membrane, wherein the cathode chamber electrolyzes to generate arsine and hydrogen, and the anode chamber electrolyzes to generate oxygen; a cathode gas conveying pipeline connected with the cathode chamber; an anode gas conveying pipeline connected with the anode chamber; and a first pressure difference sensor arranged between the cathode gas conveying pipeline and the anode gas conveying pipeline and used for monitoring the pressure difference of the anode chamber and the cathode chamber. According to the invention, the pressure difference of the anode chamber and the cathode chamber is monitored by the first pressure difference sensor, and when the pressure difference exceeds the limit, the gas pressure in the anode chamber and / or the cathode chamber is adjusted, wherein the adjusting comprises: adjusting gas flow velocity, voltage and the like to avoid the ion semipermeable membrane from being damaged by excessive pressure difference, so that the stable quality of the gas generated by and flowing out of the cathode chamber is ensured, and the stability of the gas flow in subsequent application is ensured without deep purification so as to ensure the safe and stable operation of the system.

Owner:紫石能源有限公司

Novel coke oven gas regulating device

ActiveCN101709218BLittle resistance lossAvoid depositionCombustible gas coke oven heatingBasementCombustion chamber

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

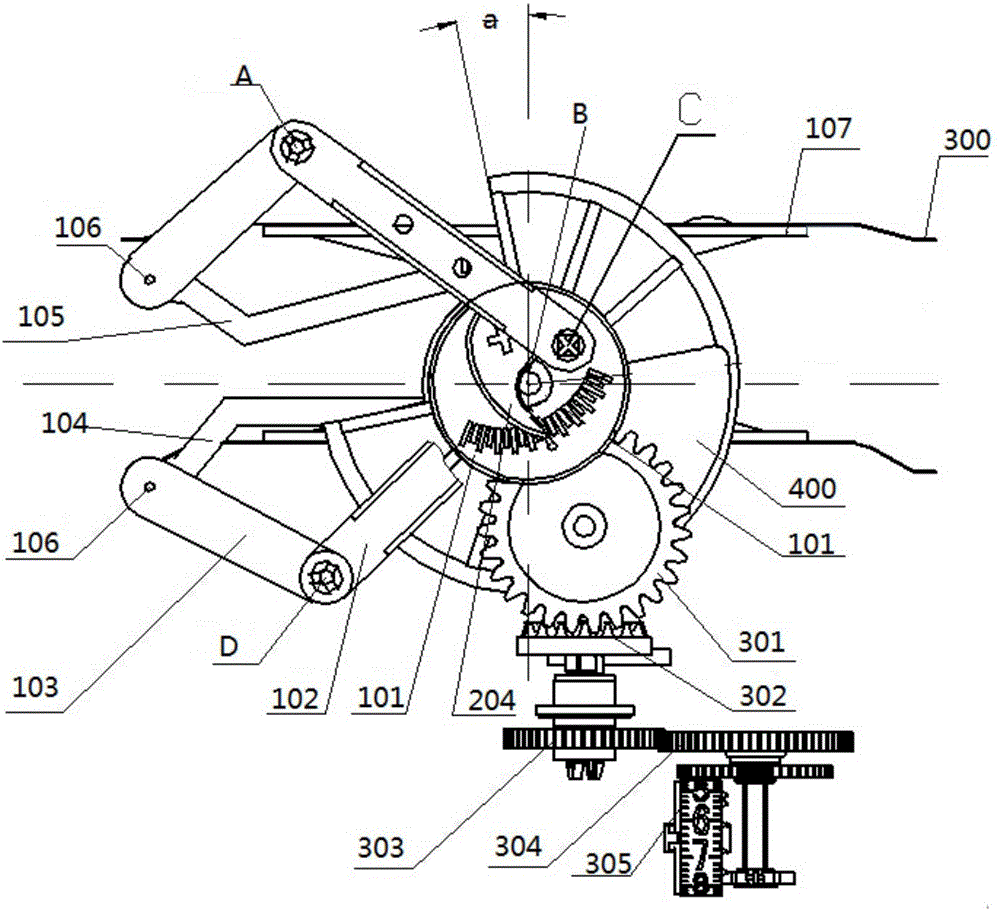

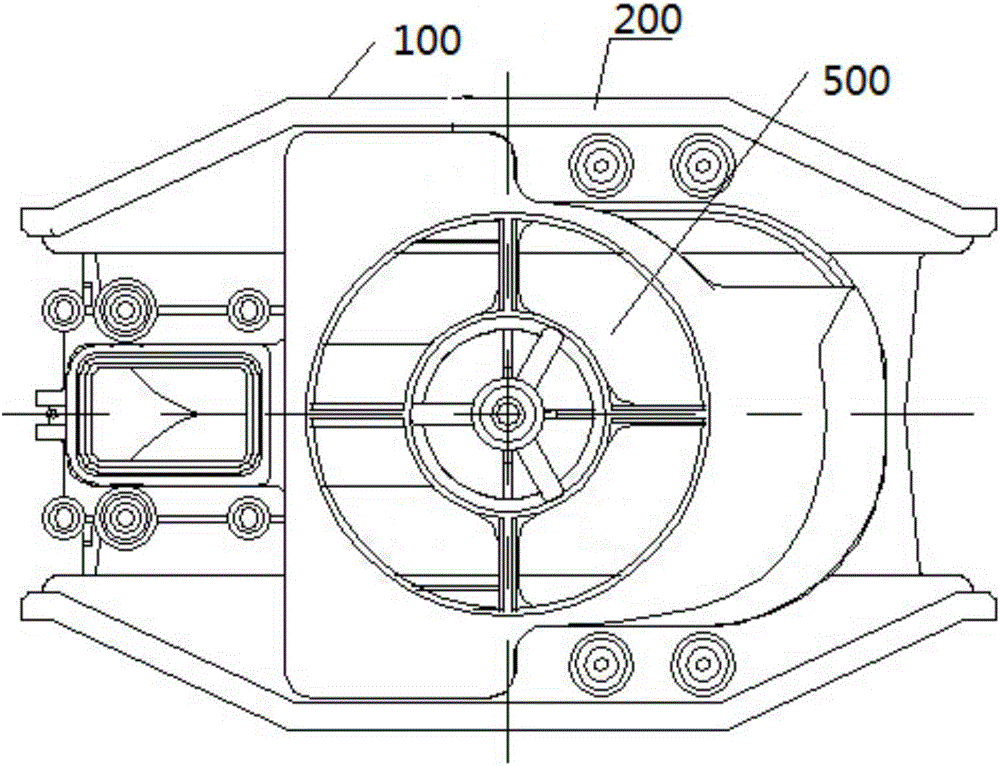

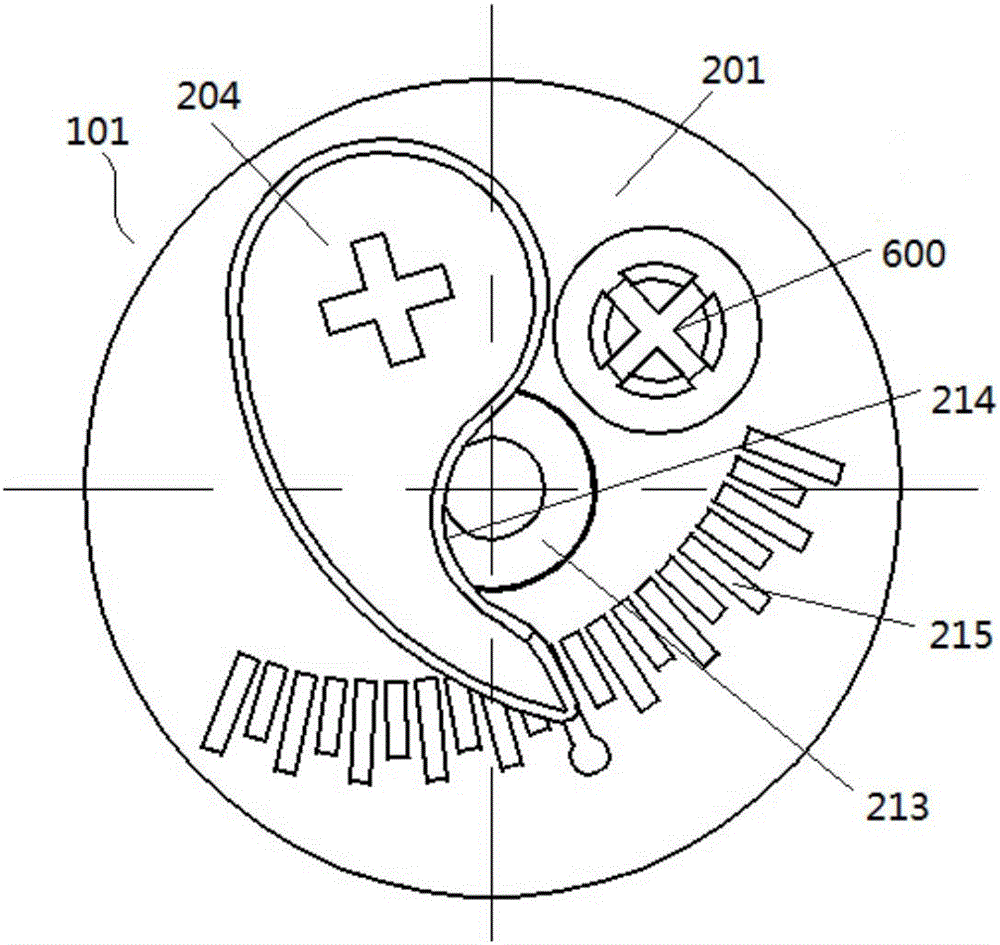

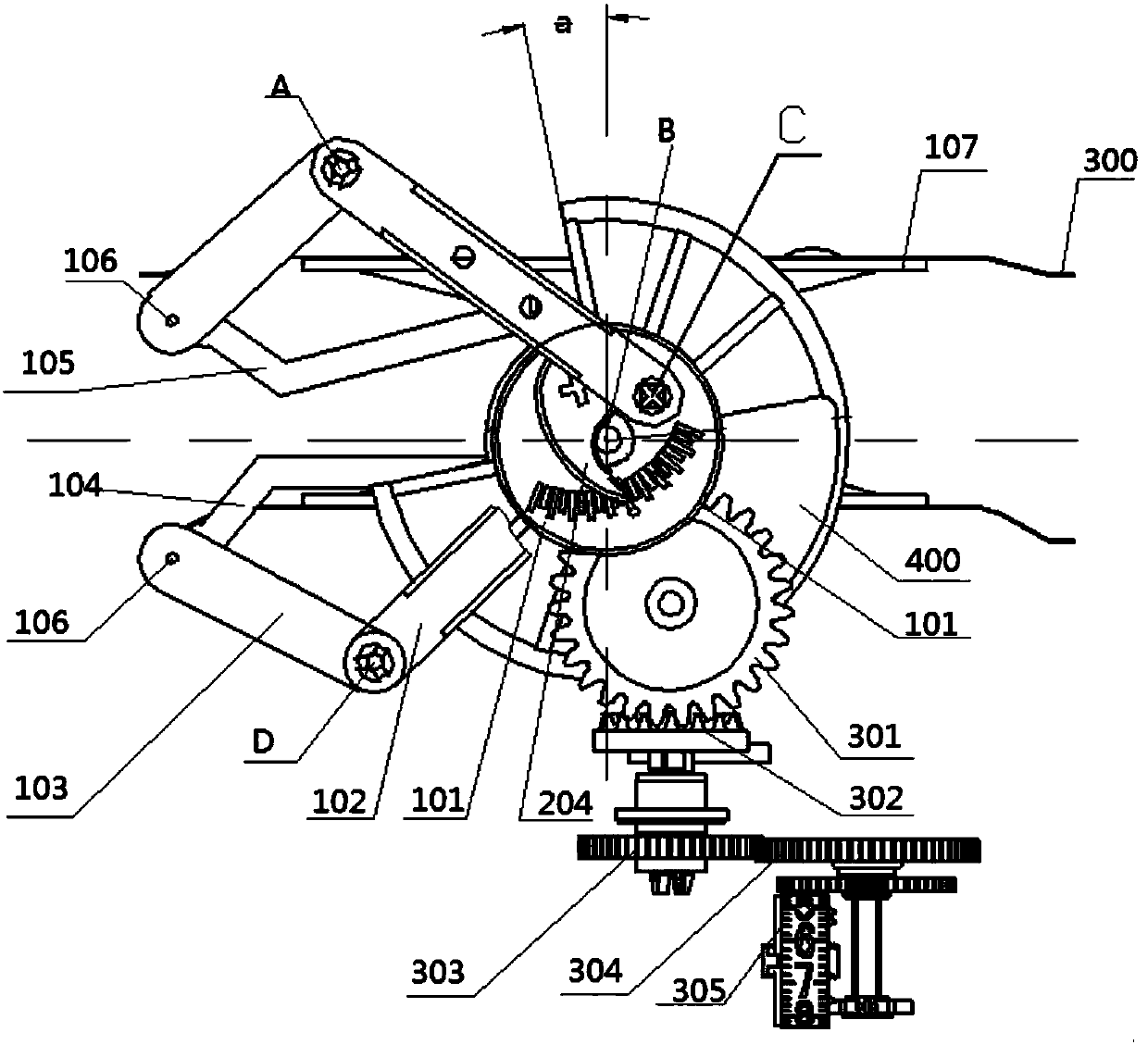

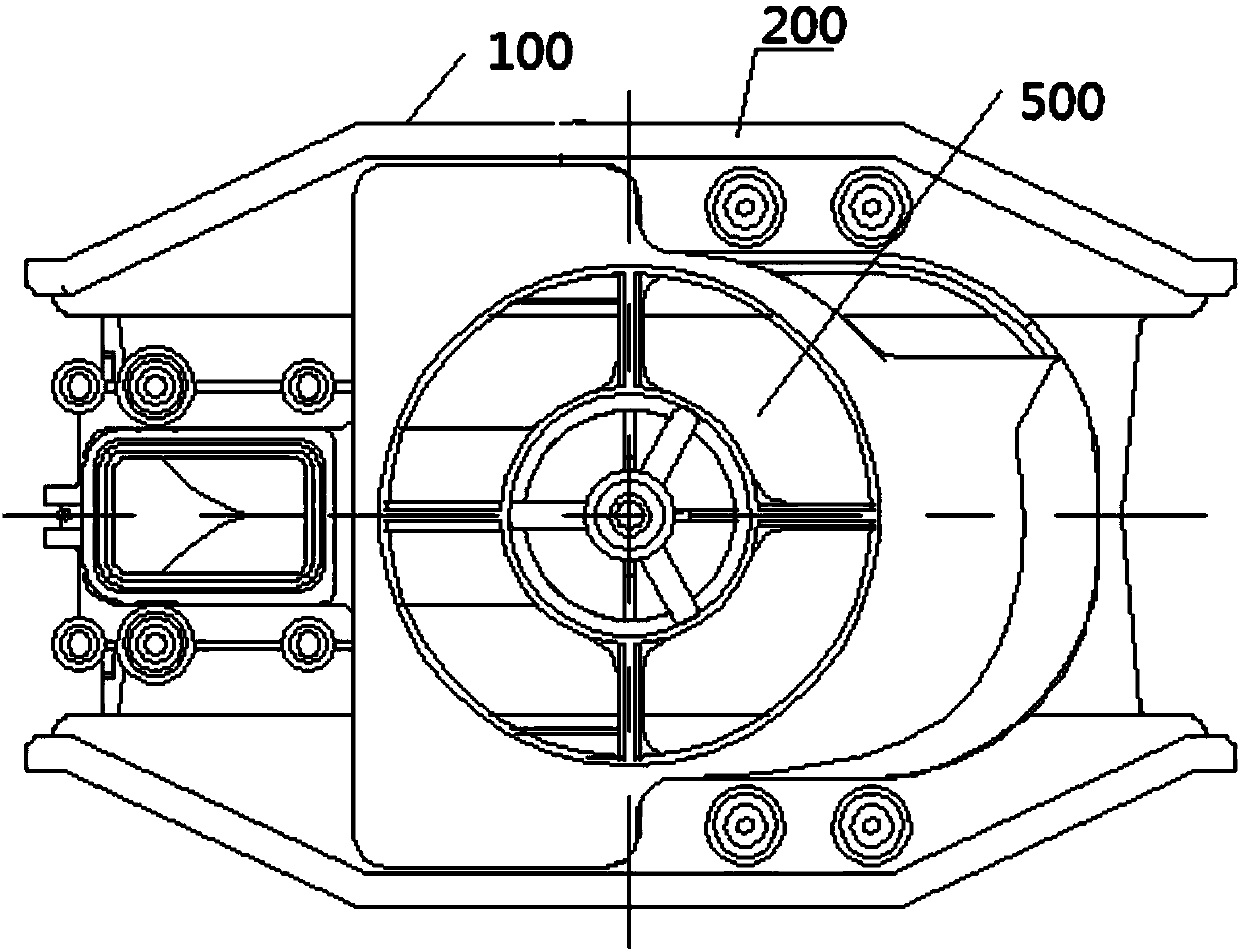

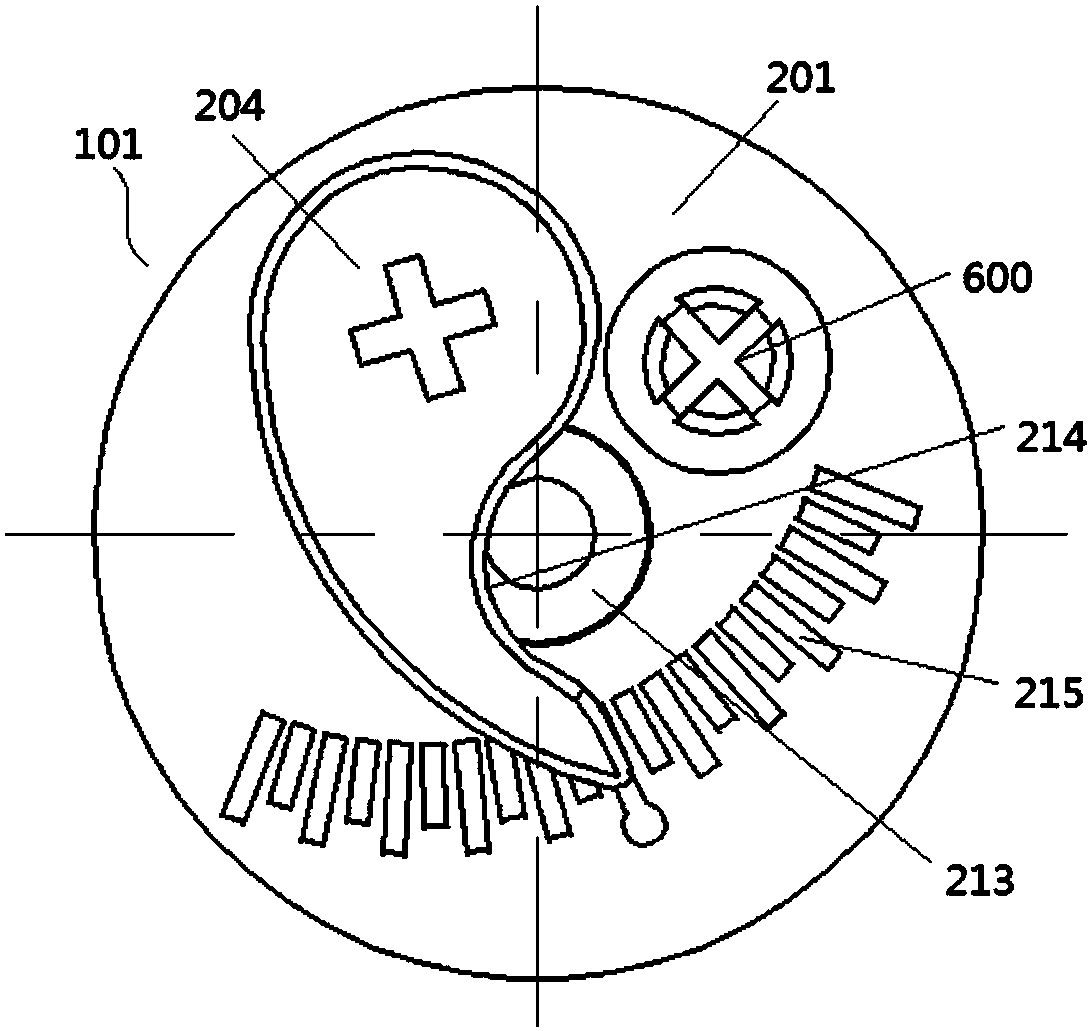

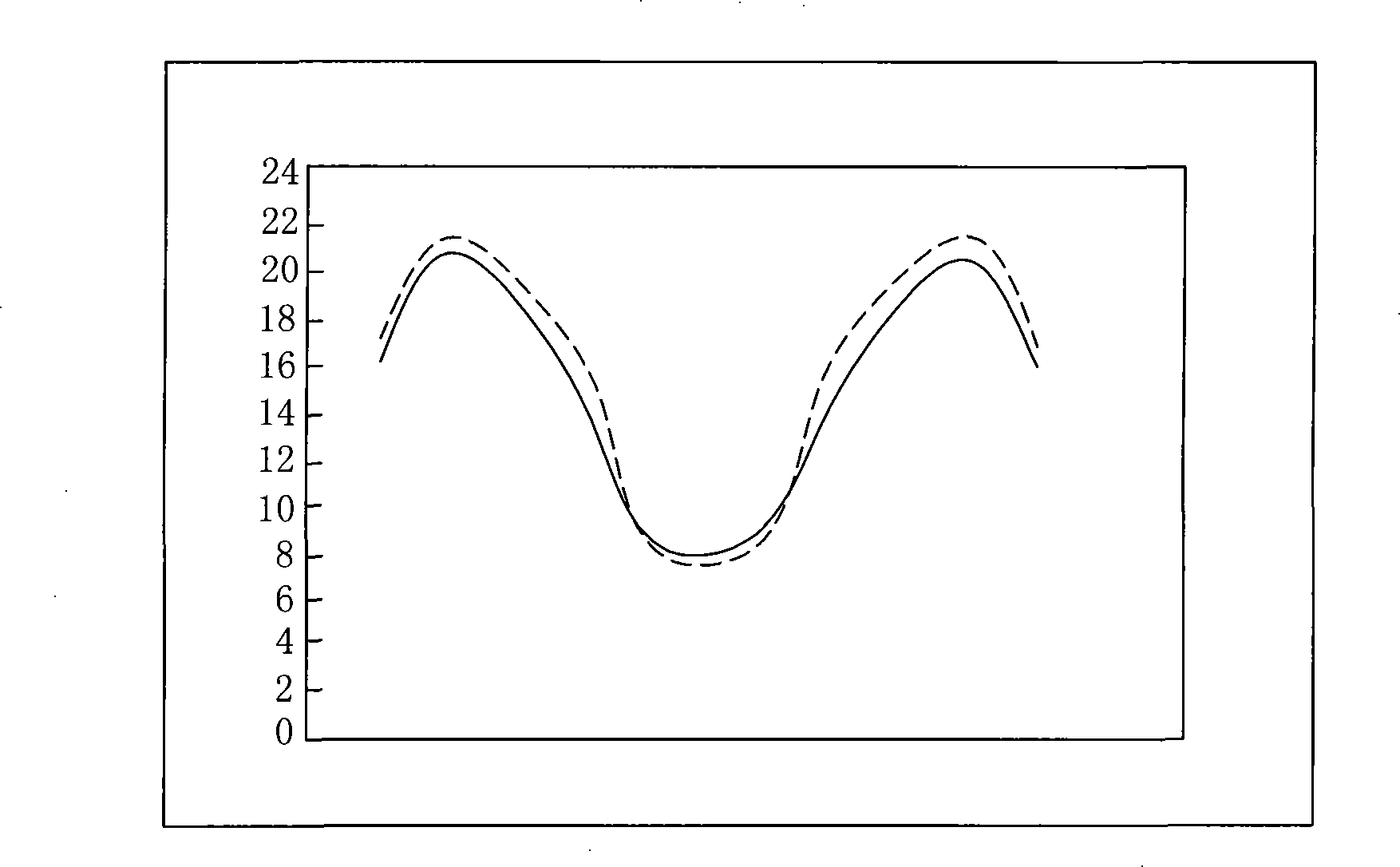

High-precision wide-range diaphragm gas meter

ActiveCN105784048BHigh measurement accuracySimple structureContracting/expanding measuring chambersVolume/mass flow by differential pressureAngular degreesVertical axis

The invention provides a high-precision wide-range diaphragm gas meter, which includes a core, the core includes a bellows, two skins, two bellows, a valve cover and a four-axis joint rotation system, the bellows includes a valve seat and two Two measuring chambers, two membranes are respectively located in the two measuring chambers; each said membrane is connected with the corresponding four-axis joint rotation system, the vertical shaft is fixedly connected with one end of the rocker, and the other end of the rocker is hinged to the connecting rod The other end of the connecting rod is hinged to the crank. The central axis of the crank is the third rotating shaft. The central crank wheel is set on the central axis. The cover rotates synchronously around the central axis, the deviation between the installation limit position of the film and the optimum limit position is within -0.5mm to +0.5mm, the angle error of the rocker is within -0.8° to +0.8°, and the fine-tuning device is installed on the central crank wheel. The gas meter has good measurement accuracy and high measurement precision, which expands the scope of application of the high-precision and wide-range membrane gas meter.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

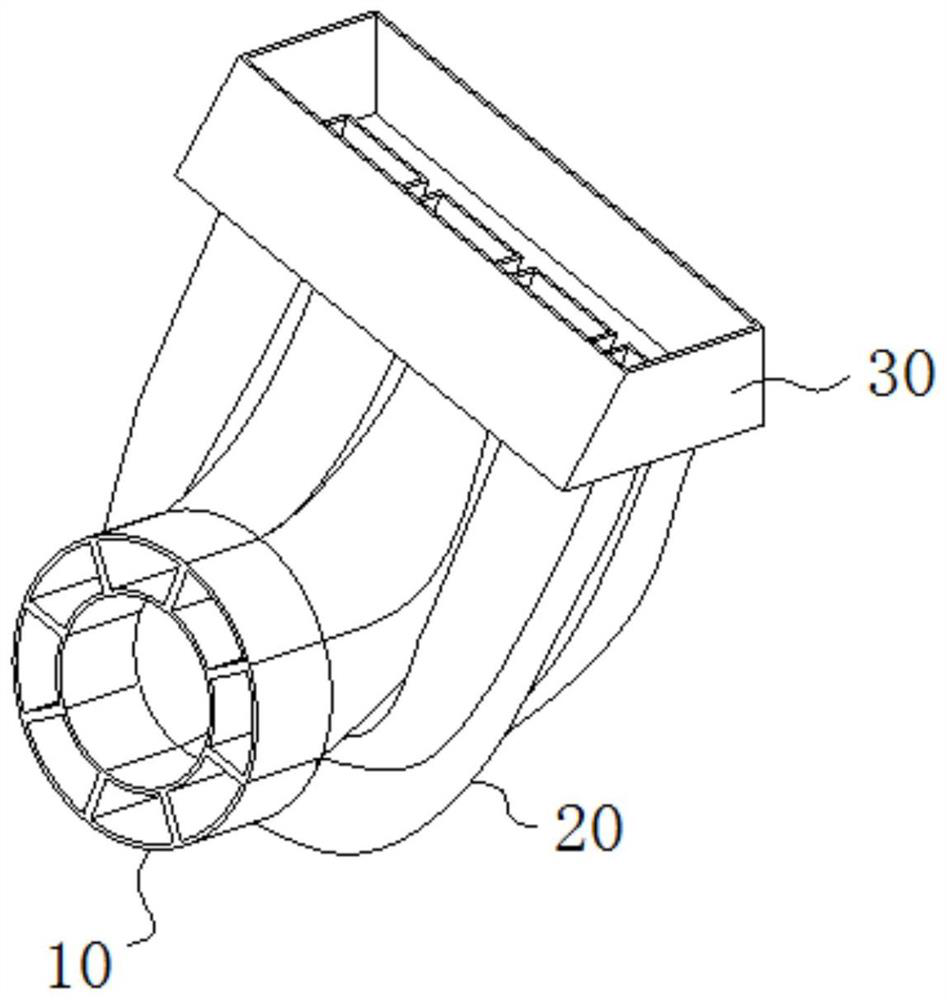

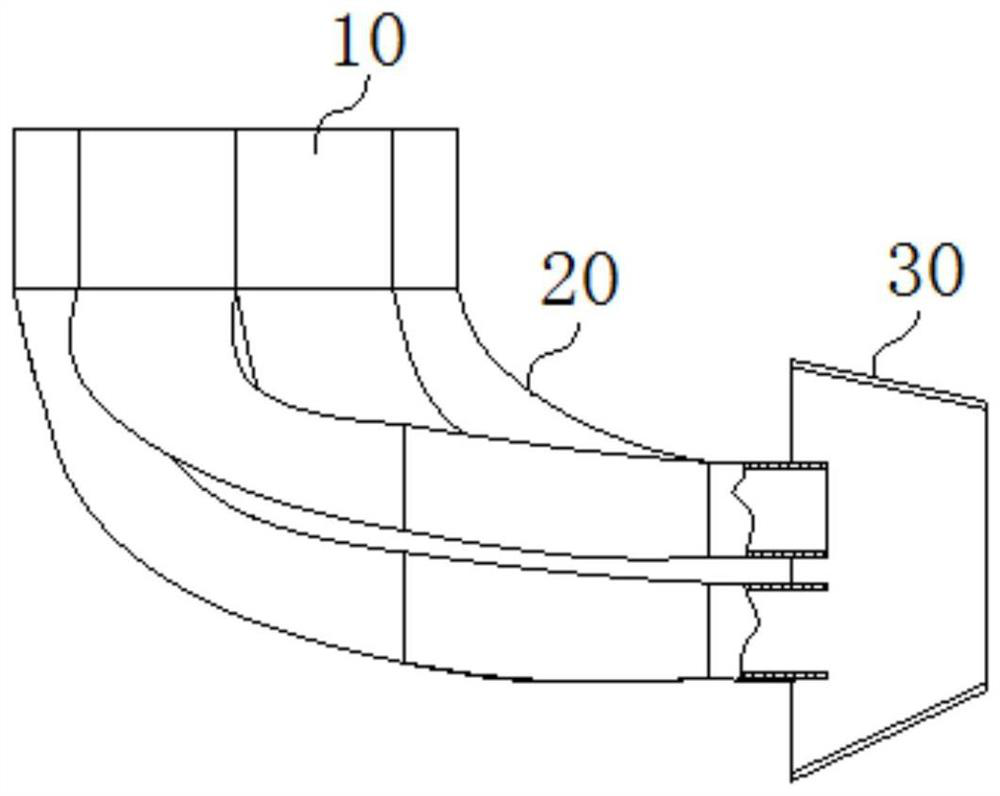

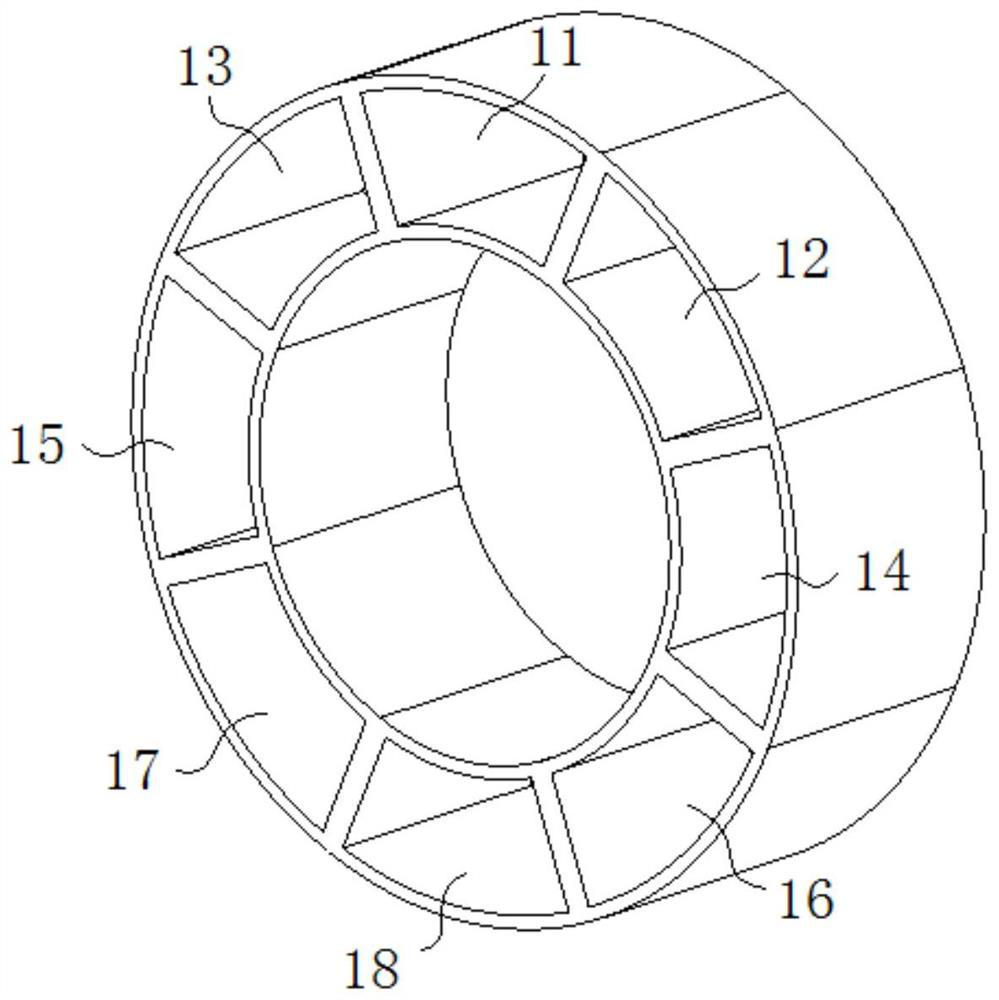

A gas turbine exhaust device

ActiveCN109630219BStable gas flowFlow direction ruleGas turbine plantsEngine componentsMechanicsGas turbines

Owner:AECC SHENYANG ENGINE RES INST

Blast furnace chute polycyclic distributing method

InactiveCN101250602BIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

an upward air burner

The invention relates to an upper air feeding burner. The upper air feeding burner is characterized by comprising a burner base, an upper base cover, an inner burner cap seat, an inner burner cap, an inner injection pipe, an outer burner cap seat, an outer burner cap and an outer injection pipe; a base cavity is formed in the burner base, an inner ring air inflow channel and an outer ring air inflow channel are arranged in the burner base, the inner ring air inflow channel is provided with an inner ring nozzle, and the outer ring air inflow channel is provided with an outer ring nozzle; an air supplementing inlet is formed in the upper base cover; the inner burner cap seat is arranged on the upper base cover; an inner burner cap hole is formed in the inner burner cap and an inner ring gas channel is defined by the inner burner cap and the inner burner cap seat; one end of the inner injection pipe is opposite to the inner ring nozzle and the other end of the inner injection pipe is communicated with the inner ring gas channel; the outer burner cap seat is arranged on the upper base cover; an outer burner cap hole is formed in the outer burner cap, an outer ring gas channel is defined by the outer burner cap and the outer burner cap seat, and an air supplementing inflow channel is defined between the upper base cover and the outer burner cap seat; and one end of the outer injection pipe is opposite to the outer ring nozzle and the other end of the outer injection pipe is communicated with the outer ring gas channel. The upper air feeding burner is simple in structure and high in burning efficiency.

Owner:CHINABEST HOME APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com