Method for preparing graphene film through combination of carbon dioxide and low-pressure chemical vapor deposition

A low-pressure chemical vapor and chemical vapor deposition technology, applied in chemical instruments and methods, graphene, single-layer graphene, etc., can solve the problems of potholes, protrusions and pores, hindering the industrial production of graphene, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

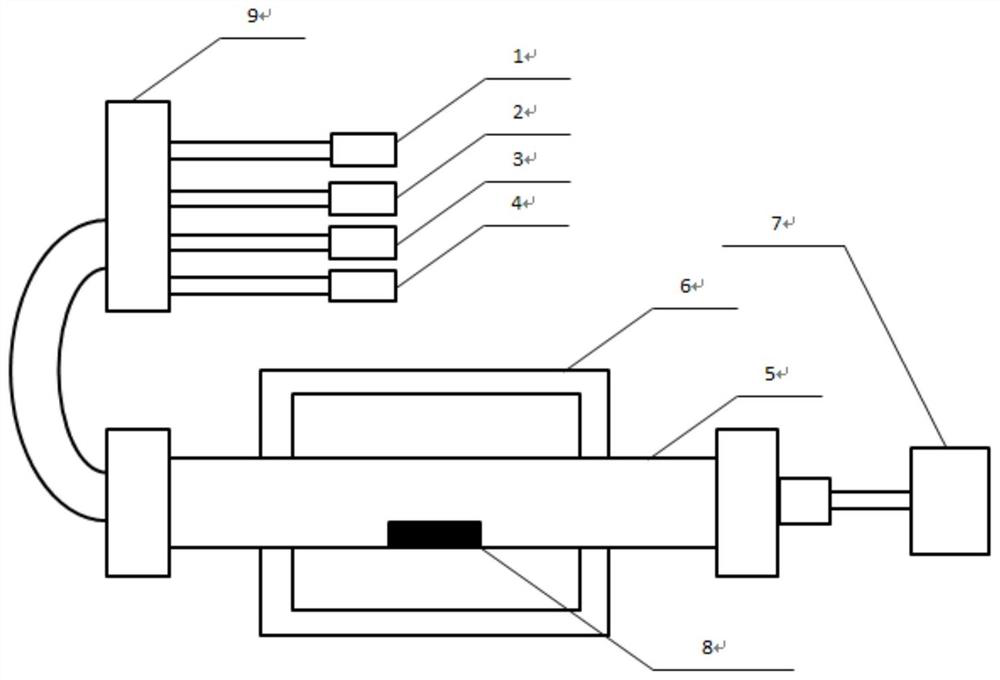

Method used

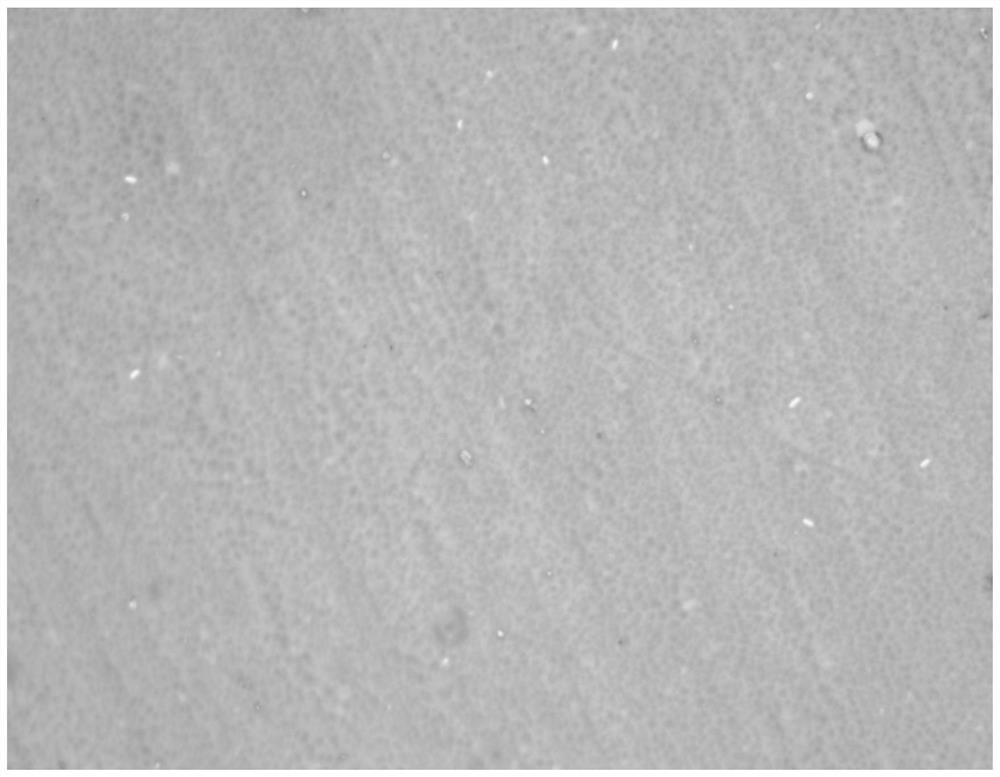

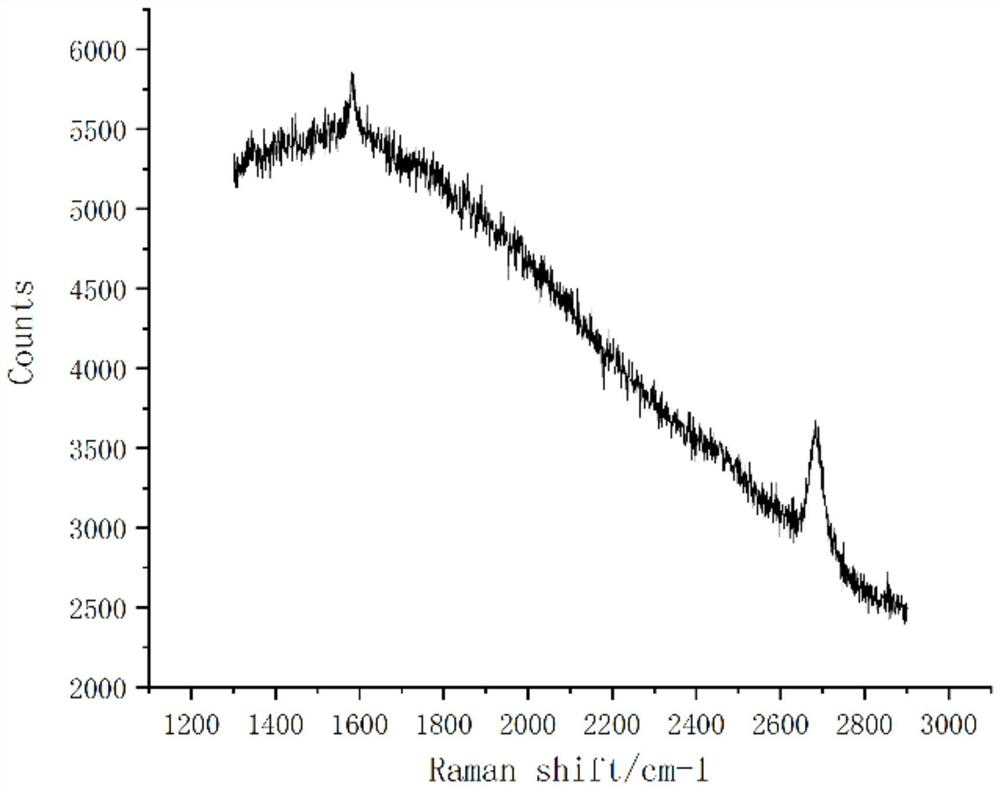

Image

Examples

Embodiment 1

[0041] In this embodiment, a graphene film is prepared by chemical vapor deposition under carbon dioxide combined with low pressure, including the following steps:

[0042] (1) Clean the copper foil ultrasonically with acetone, isopropyl ketone, hydrochloric acid and deionized water for 5~10 minutes, then remove the moisture on the surface of the copper foil, then put the copper foil into the quartz tube, and place the copper foil in the tube furnace In the middle, evacuate to below 5 torr, adjust the flow rate of carbon dioxide to 10 sccm, heat the copper foil to 500°C in this atmosphere, and pretreat the gas for 15 minutes. The hydrogen flow rate is 20sccm, and the copper foil is heated to 1000°C in this atmosphere, and annealed for 40 minutes;

[0043] (2) The annealed copper foil in step (1) was fed into methane and hydrogen to grow graphene, wherein the flow rate of carbon dioxide was 8 sccm, the flow rate of methane was 20 sccm and the flow rate of hydrogen was 240 sccm,...

Embodiment 2

[0049]The present embodiment utilizes chemical vapor deposition method to prepare graphene film under low pressure, comprises the following steps:

[0050] (1) Ultrasonic clean the copper foil with acetone, ethanol, ammonium persulfate and deionized water for 5-10 minutes, then remove the moisture on the surface of the copper foil, then put the copper foil into the quartz tube, and make the copper foil in the tube type In the middle of the furnace, evacuate to below 5torr, adjust the flow rate of carbon dioxide to 90sccm, and helium to 10sccm. In this atmosphere, heat the copper foil to 265°C and pretreat the gas for 55 minutes. After the gas pretreatment is completed, cool down to room temperature and adjust the argon The gas flow rate is 100 sccm, the hydrogen gas flow rate is 20 sccm, and the copper foil is heated to 1000°C in this atmosphere environment, and annealed for 40 minutes;

[0051] (2) The annealed copper foil in step (1) was passed through methane and hydrogen t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com