Fermented tail gas purification treatment method

A treatment method and purification treatment technology, which are applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve problems that cannot fully meet the requirements of clean production, safe discharge, large consumption of oxidant and alkali absorption liquid, and fermentation tail gas emissions. Large problems such as reducing cleaning and maintenance costs, convenient cleaning and replacement of filter materials, and large dust holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

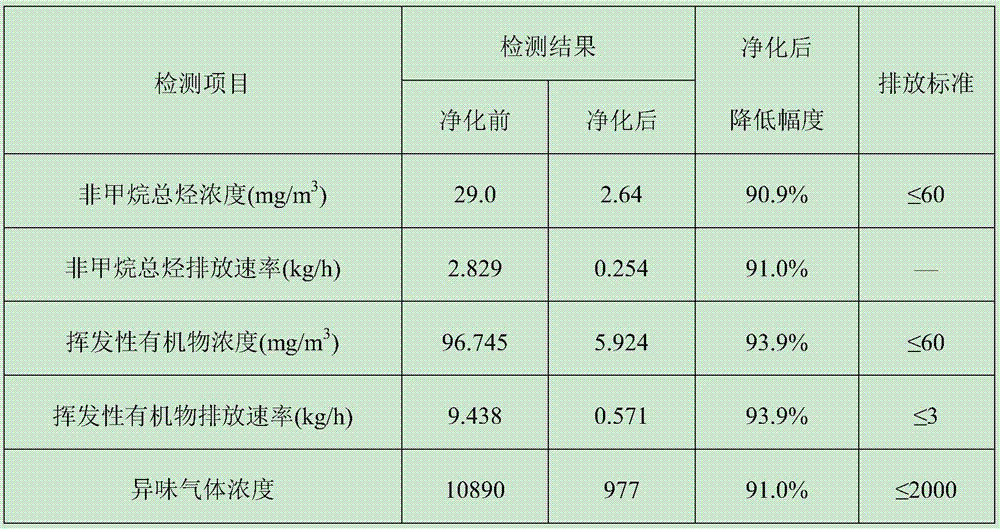

Embodiment 1

[0047] The specific implementation steps are as follows:

[0048] a. Pretreatment: The fermentation tail gas is firstly separated from the gas and liquid by the cyclone, then dedusted and buffered by the plate primary filter, and then dehumidified by the condenser, so that the relative humidity of the gas reaches 35%, and finally the gas is passed through the heater. The temperature reaches 20°C to ensure that the water is no longer condensed;

[0049] b. Molecular sieve treatment: use honeycomb disc rotary molecular sieve, composite high silicon as adsorbent material, runner diameter is 245mm, thickness is 40mm, divided into treatment area, regeneration area and cooling area, according to treatment area - regeneration Zone - Rotation in the direction of the cooling zone at 5 rpm. Molecular sieve filters the gas treated in step a in the treatment zone, desorbs the adsorbed harmful substances with a high temperature gas at a temperature of 150°C in the regeneration zone, and c...

Embodiment 2

[0058] The specific implementation steps are as follows:

[0059] a. Pretreatment: The fermentation tail gas is firstly separated from the gas and liquid by the cyclone, then dedusted and buffered by the plate primary filter, and then dehumidified by the condenser, so that the relative humidity of the gas reaches 50%, and finally the gas is passed through the heater. The temperature reaches 40°C to ensure that the moisture is no longer condensed.

[0060] b. Molecular sieve treatment: use honeycomb disc rotary molecular sieve, composite high silicon as adsorbent material, runner diameter is 245mm, thickness is 40mm, divided into treatment area, regeneration area and cooling area, according to treatment area - regeneration Zone - Directional rotation of the cooling zone at 15 rpm. Molecular sieve filters the gas treated in step a in the treatment zone, desorbs the adsorbed harmful substances with a high temperature gas at a temperature of 250°C in the regeneration zone, and co...

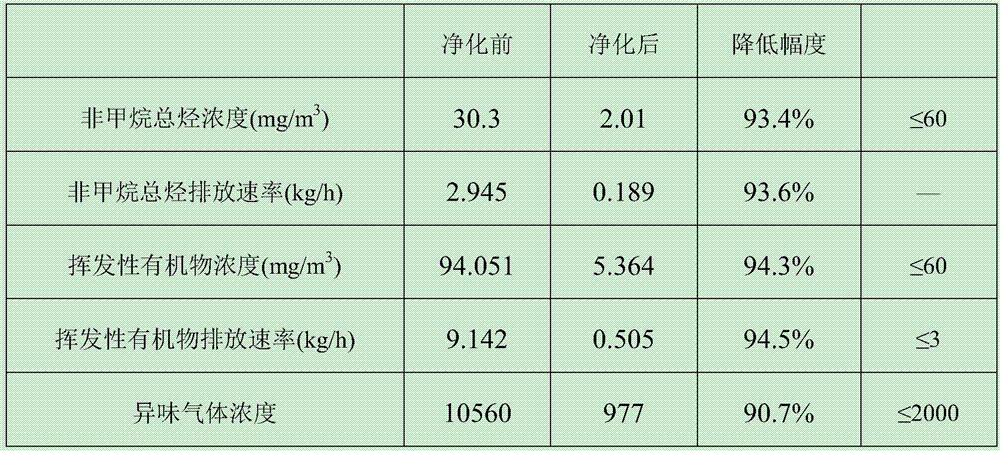

Embodiment 3

[0070] The specific implementation steps are as follows:

[0071] a. Pretreatment: The fermentation tail gas is firstly separated from the gas and liquid by a cyclone, then dedusted and buffered by a plate-type primary filter, and then dehumidified by a condenser to make the relative humidity of the gas reach 40%, and finally the gas is passed through a heater to make the gas The temperature reaches 25°C to ensure that the moisture is no longer condensed.

[0072] b. Molecular sieve treatment: use honeycomb disc rotary molecular sieve, composite high silicon as adsorbent material, runner diameter is 245mm, thickness is 40mm, divided into treatment area, regeneration area and cooling area, according to treatment area - regeneration Zone - Directional rotation of the cooling zone at 8 rpm. Molecular sieve filters the gas treated in step a in the treatment zone, desorbs the adsorbed harmful substances with a high temperature gas at a temperature of 180°C in the regeneration zone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com