Diaphragm type gas meter

A membrane gas meter and membrane technology, applied in instruments, measuring devices, measuring flow/mass flow, etc., can solve the problems of low precision, poor gas meter measurement accuracy, poor operation stability, etc., and achieve good measurement accuracy and structure Simple and reasonable, smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

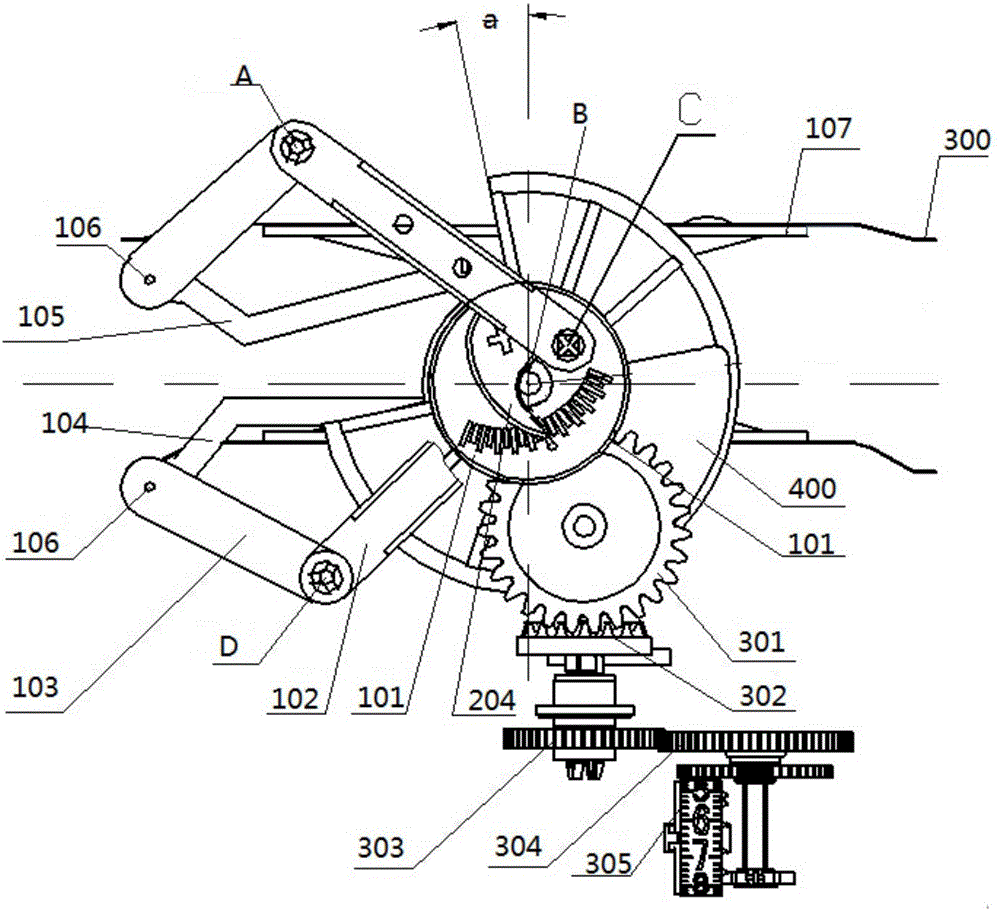

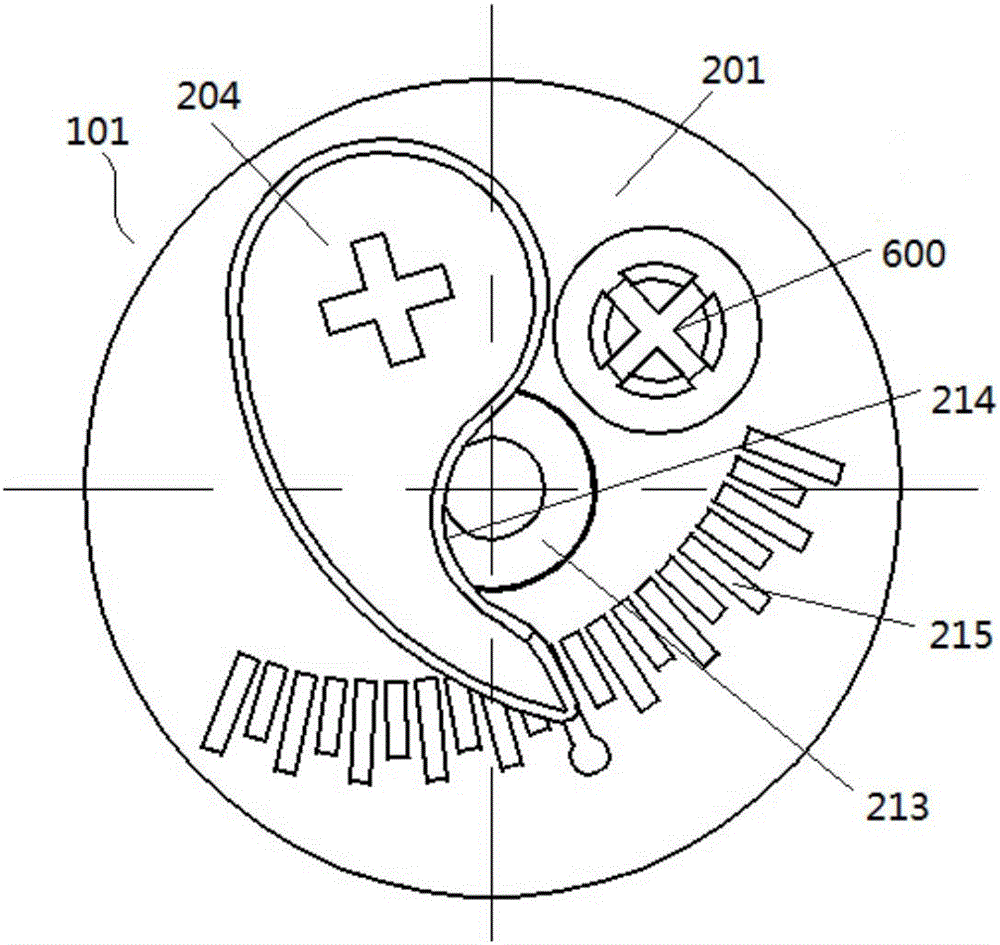

[0034] In the existing membrane gas meter, since the membrane is a flexible rubber part and the transmission mechanism is composed of plastic parts, it is difficult to guarantee the accuracy in the manufacturing process. By changing the gear sleeve that drives the counter, adjust the number of teeth and use the gas meter standard calibration equipment to calibrate. The inspection meets the requirements. Due to the wide error distribution and the limited number of gears, there is a certain range and gear for adjusting the accuracy of the gas meter, so the accuracy is not enough

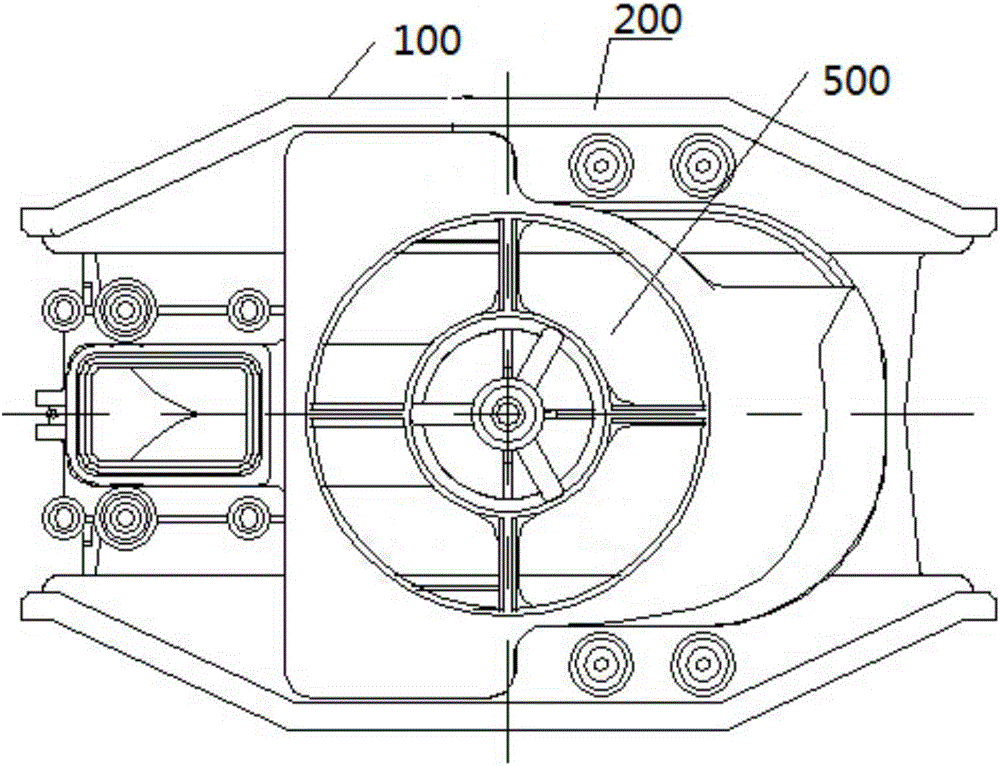

[0035] In view of this, the designer of the present invention has designed a membrane gas meter, which has a simple and reasonable structure and is convenient to manufacture. The change of direction is prior to the flipping of the film, so that before the film reaches the limit position and flips, the pressure on both sides has been balanced, making the movement of the movement more stable and the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com