Plasma film-forming device

A film-forming device and plasma technology, applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of difficult plasma jet area, reduce production efficiency, reduce product quality, etc., and achieve high deposition efficiency, gaseous The effect of stable flow and less sparking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The plasma film forming device provided in the embodiments of the present invention will be further described in detail below with reference to specific embodiments and drawings.

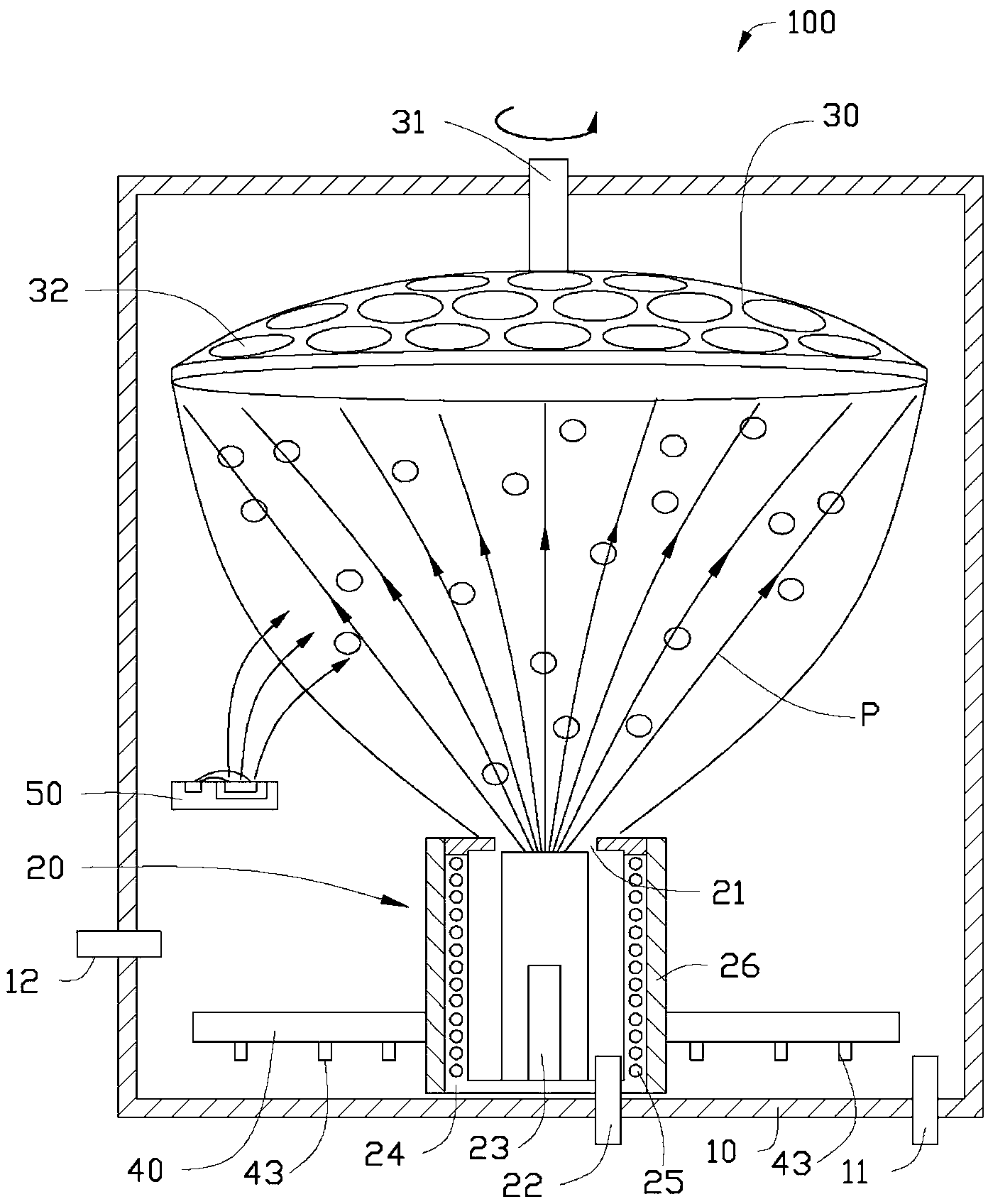

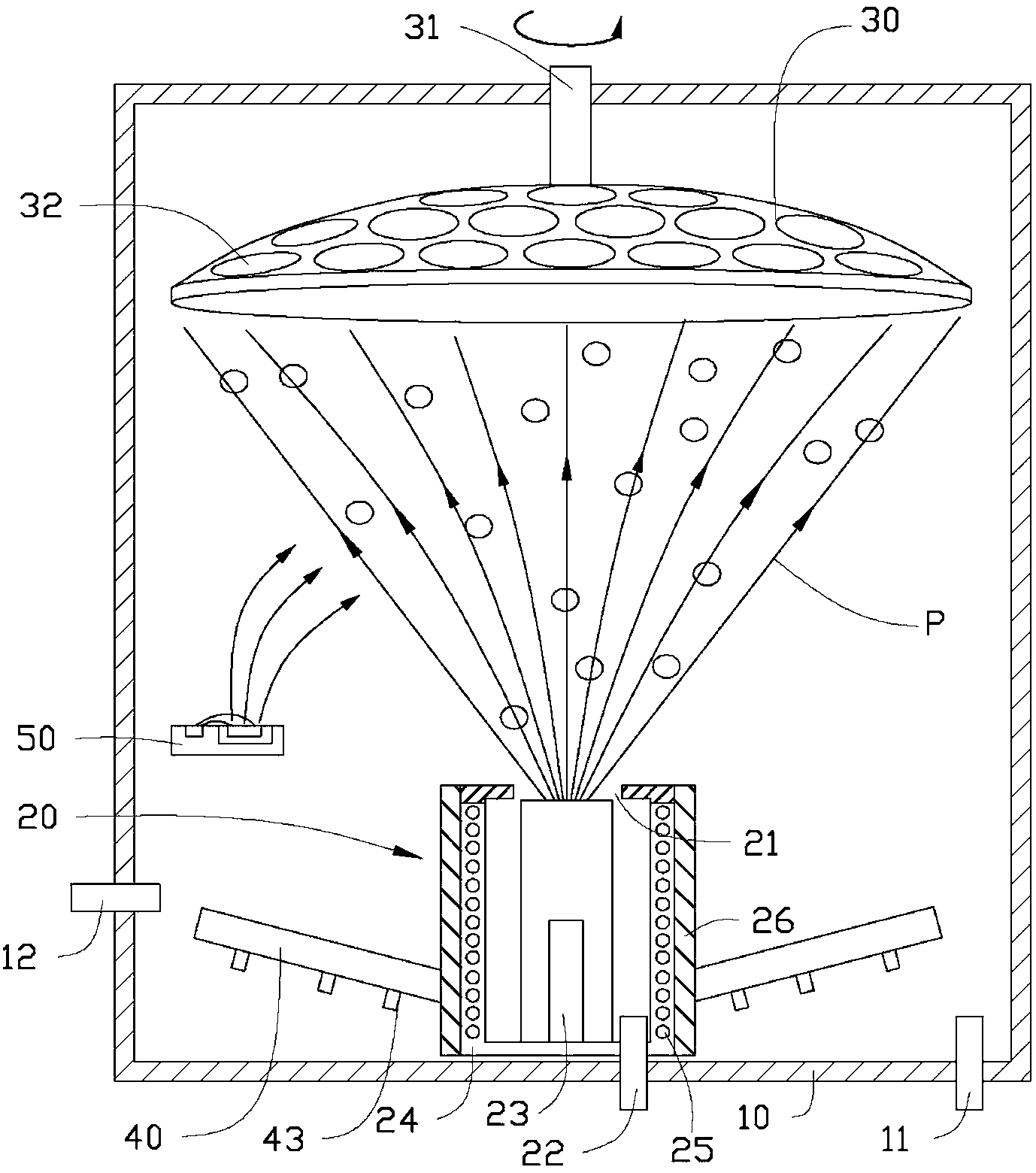

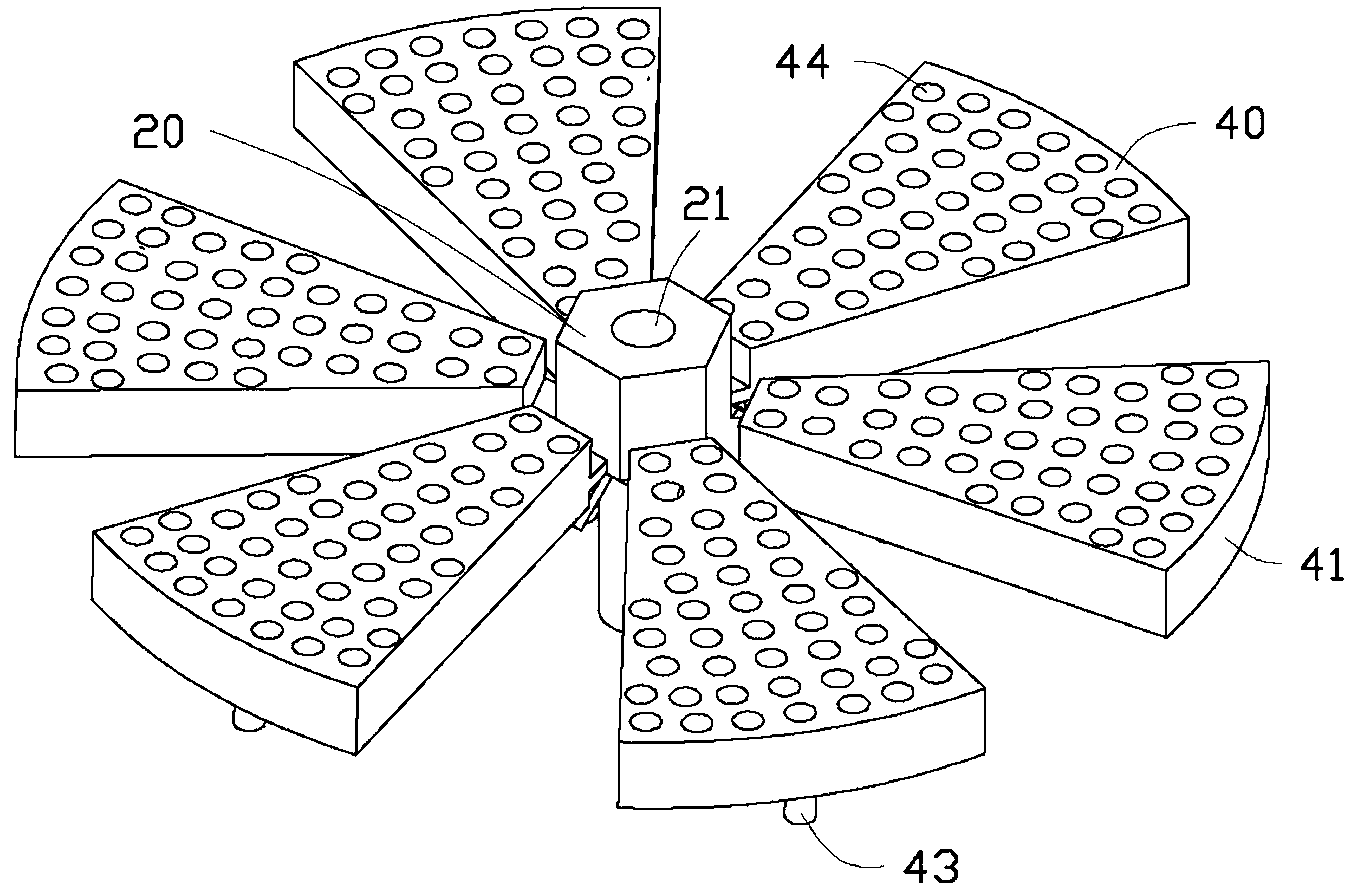

[0016] Please refer to figure 1 and figure 2 , The plasma film forming apparatus 100 of the embodiment of the present invention includes a film forming chamber 10 , a plasma generator 20 , a rotating support frame 30 , a plurality of gas carrier plates 40 and a film material supply module 50 .

[0017] The bottom wall of the film forming chamber 10 is provided with a plasma generator 20 , and the opposite top wall is provided with a rotating support frame 30 . The film forming chamber 10 also includes a gas inlet 11 opened on the bottom wall thereof, and the gas inlet 11 can be connected to an external gas supply system (not shown in the figure) to provide the film forming chamber 10 with protective gas. A vacuum port 12 connected to an external vacuum device (not shown) is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com