Novel coke oven gas regulating device

A regulating device and coke oven gas technology, which are applied in coke ovens, coke oven heating, combustible gas heating coke ovens, etc., can solve problems such as reducing resistance, hidden safety hazards, nozzle blockage, etc., to reduce resistance loss and enhance safety. The effect of stability and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

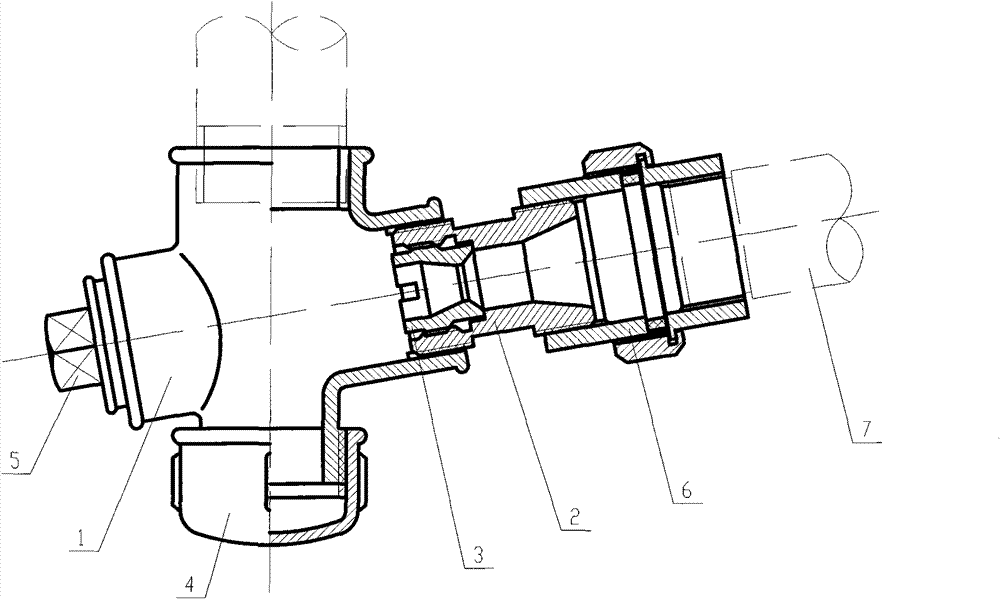

[0019] See figure 1 , a coke oven gas regulating device, comprising a different-diameter cross 1, a special-shaped steel pipe 2, a nozzle 3, an outer pipe cap 4, an outer pipe plug 5, a live joint 6, and the inlet ends of the special-shaped steel pipe 2 and the nozzle 3 are both Features bell mouth.

[0020] The air outlet end of the nozzle 3 is provided with a bell mouth, so that the length of the minimum diameter of the nozzle 3 is 1-3mm.

[0021] The pressure-resistant tight contact form is adopted between the special-shaped steel pipe 2 and the nozzle 3 .

[0022] The outer square pipe cap 4 is replaced by a circular pipe cap.

[0023] When the coke oven gas flows through the coke oven gas regulating device, the gas first enters the special-shaped steel pipe 2 through the pipe 7 and the union 6. Since the air inlet of the special-shaped ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com