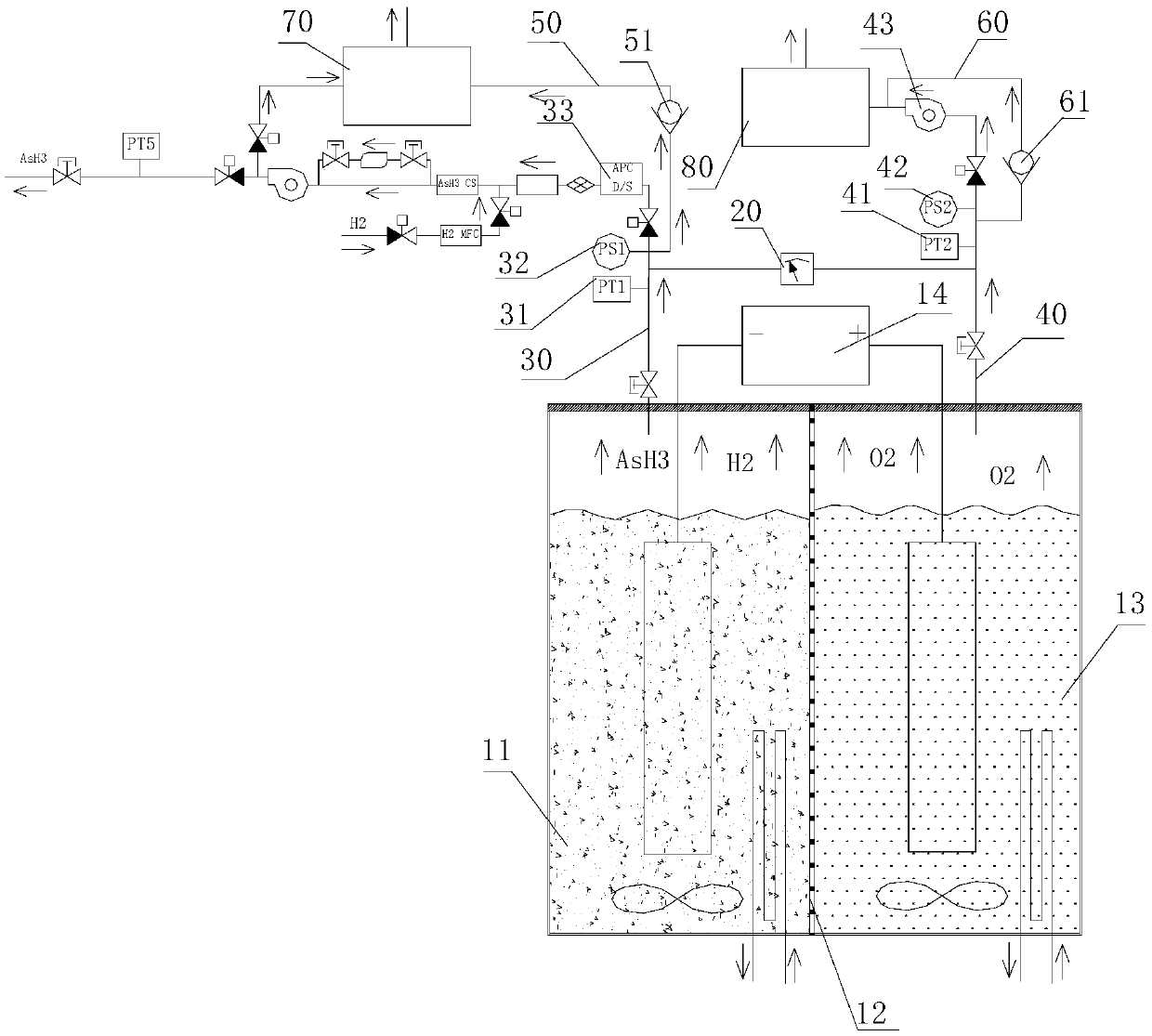

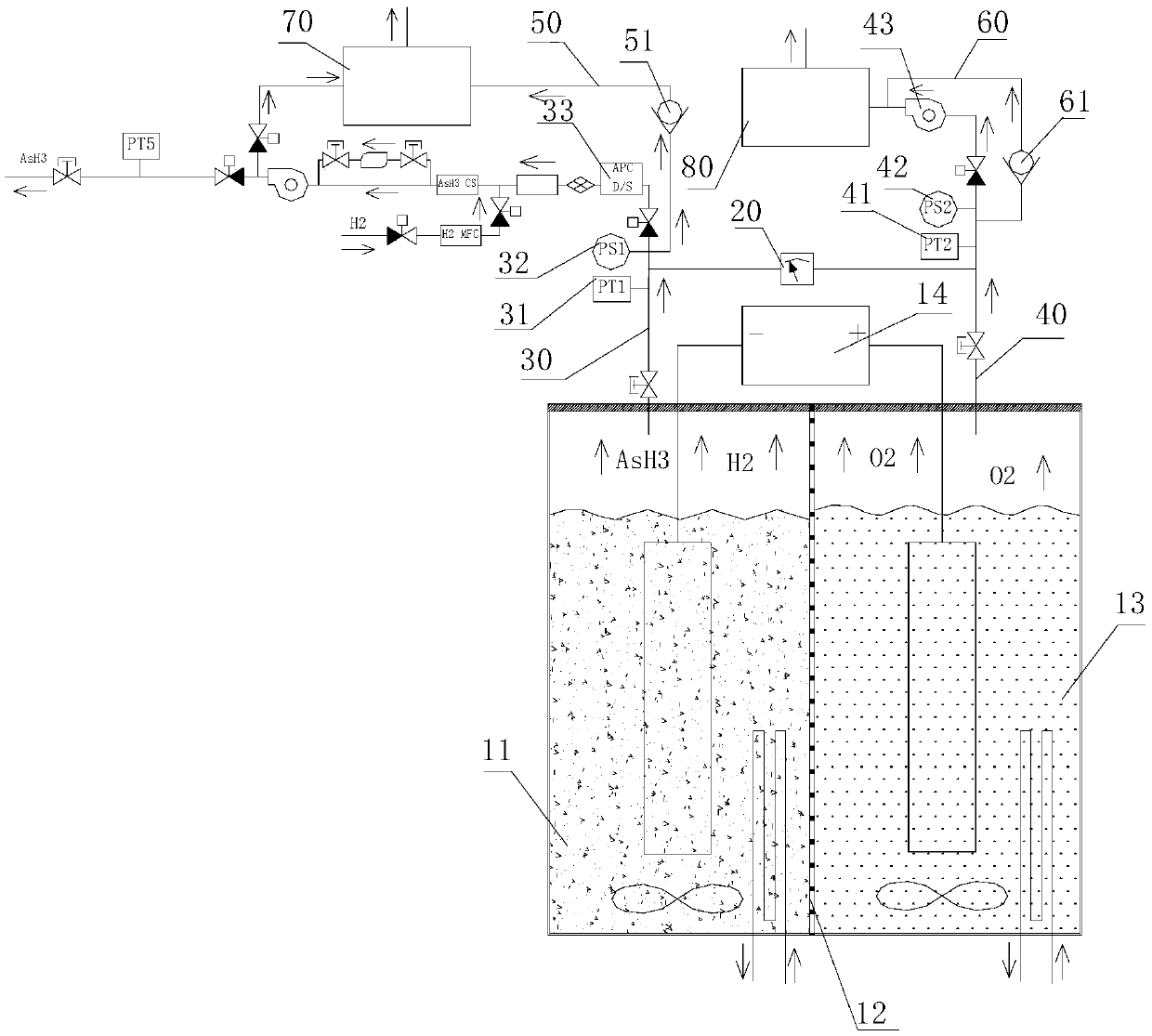

Electrolysis system for preparing arsine by electrolysis method

An electrolysis system and electrolysis technology, which is applied in the field of electronic gas preparation, can solve problems such as unstable arsine gas flow, and achieve the effects of ensuring safe and stable operation, stable gas flow, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0032] As analyzed in the background technology of this application, the pressure difference between the anode chamber and the cathode chamber in the prior art is unstable, and when the pressure between the cathode chamber and the anode chamber is too high, the ion semipermeable membrane can be blown directly, or the ion semipermeable membrane can be blown in a small range. The fluctuation of the pressure difference in the interior will also cause the repeated expansion and contraction of the ion semi-permeable membrane between the cathode chamber and the anode chamber, which is easily ruptured due to fatigue, resulting in the gas mixing of the cathode chamber and the anode chamber, which in tur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com