Material system intermittent extracting and rectifying method reaching solvent boiling point higher than that of material by single tower and double-still

A technology for extractive distillation and extractive distillation column, which is applied to extractive distillation and other directions, can solve the problems of increasing operation complexity and energy consumption, difficult to meet the solvent accumulation amount, and small equipment operation flexibility, so as to achieve good equipment operation flexibility and increase The effect of stable steam volume and stable gas flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

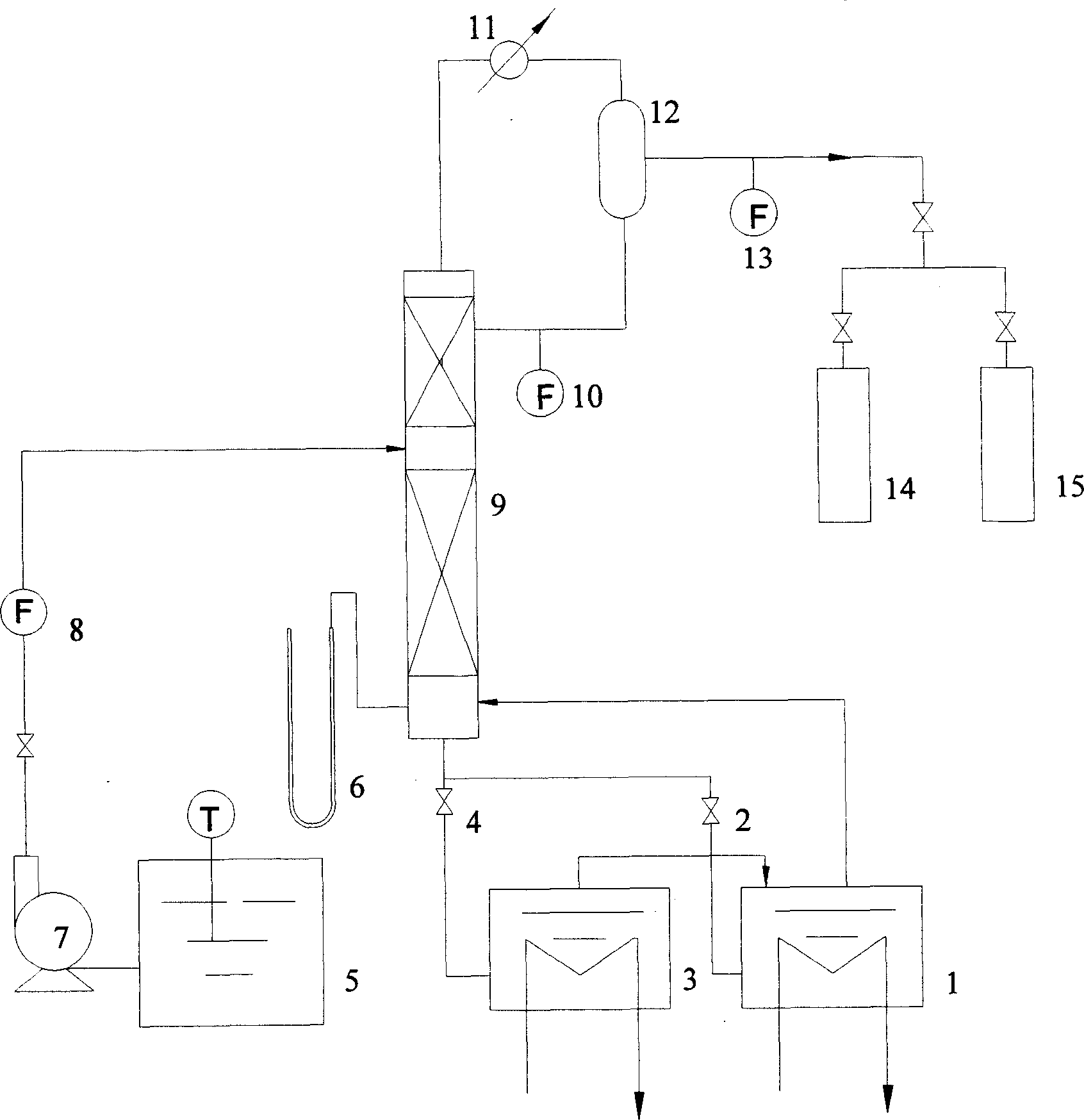

[0012] use as figure 1 The shown one-tower and two-tank extractive distillation device realizes the process of intermittent extraction, rectification and separation of industrial ethanol with a mass percentage of 95% as follows: the inner diameter of the extractive distillation tower is φ30mm, and a φ3×3 θ mesh ring stainless steel packing is installed inside. The height of the packing in the recovery section is 200mm, the packing in the extraction and rectification section is 1000mm, the heat source is heat transfer oil, the cooling medium is circulating cooling water, and the operating pressure is normal pressure. 95% industrial ethanol is put into the material kettle at one time by mass percentage. Now close the valve between the solvent tank and the extractive distillation tower to cut off the communication between the two, keep the connection between the extractive distillation tower and the material tank, heat the material tank to 79°C-81°C, and perform total reflux oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com